A traditional strip foundation performs its tasks perfectly when built on fairly dense and stable soils.

In more difficult conditions, other support structures are required that can create a solid foundation on problematic or completely unstable soils.

The optimal option is piles that are able to rest on deep dense layers, passing through unstable surface layers and practically not forming a structural connection with them.

This solution to the problem allows you to get a stationary and reliable foundation, saving money and, often, time.

Let's consider one of the most successful options - the pile-grillage type.

Construction of a pile foundation with a monolithic grillage.

Pile-grillage infill foundation.

To save construction time, budget and at the same time give durability to the building, a variety of construction technologies are used. This applies to all elements of the building, from the foundation to the roof. Let's consider what a monolithic pile foundation is, made using a monolithic grillage. This type of foundation is used for the construction of low-rise buildings. A monolithic pile foundation is not as strong as other types, but this is compensated by the complete absence of excavation work. And one more advantage - you can start building it even in winter. A pile foundation with a monolithic grillage is used mainly on soft soils or with a high freezing depth.

You can build a pile monolithic foundation using the following steps:

- Survey and earthworks.

- Installation of supporting elements (piles).

- Installation of grillage.

- Construction of the basement.

Materials used in the construction of a pile foundation:

Scheme of pile foundation foundations.

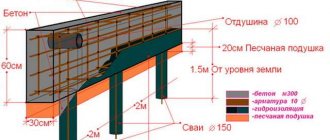

Diagram of a pile-grillage foundation: 1 – bored pile made of monolithic concrete and frame made of reinforcement; 2-grillage made of monolithic concrete and frame made of reinforcement;3 – horizontal waterproofing; 4 – vent.

A monolithic pile foundation is made from various materials. Piles are made from concrete mixture. The structural system itself is made from prefabricated or monolithic reinforced concrete, as well as steel and wood.

In general, the entire process consists of the same stages as in the construction of any other foundation, but still, at each stage you can encounter its own unique installation operations, characteristic specifically for a pile foundation.

Height classification

The grillage, together with the piles that are located under it, can be located in different ways. Taking into account the position relative to the ground level, a monolithic grillage can be of the following types:

- High. In this case, the top of the slab is high above the ground.

- Elevated - the slab is slightly buried in the soil.

- Recessed - a monolithic base is completely immersed in the ground.

Each of these types has its pros and cons. However, the most common is the high base. This is the easiest one to install. Foundations on bored piles with a monolithic grillage do not experience soil pressure.

Highly located slabs also have their disadvantages. Among them is the need to thermally insulate the first floor. When installing such structures, it will not be possible to create a basement. If this utility room is necessary, it is created in conditions of a ruined or elevated base.

The piles under the grillage must also have a certain location. This depends on the expected pressure on the slab. They can be placed as a continuous “forest”, or installed in stripes.

Excavation.

Boer.

Using a hand drill, you can drill holes for piles up to 5 m deep and no more than 30 cm in diameter.

During excavation work, an earth drill is used to construct a pile foundation. It is a device of two rods with a loosening and cutting cup. The drill makes small holes under the piles. You can use a hand drill, which drills holes up to 5 m. It is used when the diameter of the foundation support is no more than 30 cm. A motorized drill is used when it is necessary to drill a hole of a large diameter (from 50 cm). That is, when constructing a small pile foundation with a grillage, you can use manual labor, and if screw piles are used in the structure, then you can simply abandon the excavation work. There are several varieties of this tool: TISE-F, TISE-2F, TISE-3F.

On one side the drill has a soil accumulator, and on the other there is a crossbar with handles. A folding plow is mounted above the soil accumulator. When drilling, the plow cuts off part of the earth. Under the influence of its own weight, the plow cuts the soil, gradually lowering down. The cut soil falls into the storage tank and rises to the top. This drill weighs 11 kg. When drilling, direction should be taken into account.

If, for example, you need to drill a well deeper, then the drill must be rotated clockwise. If anchor extension is required, the tool is rotated counterclockwise.

Sod should be removed before drilling. Depending on the type of soil, drilling can be done either by one person or by two people. A partner is involved if drilling occurs on clay or dense soils.

Materials used

Grillages are divided into light and heavy. Depending on this criterion, source materials are selected. If you need to build a small house, the grillage is made of wood. When a massive building is being erected, the use of a reinforced concrete grillage is justified.

Sometimes the best solution is to use solid metal products. However, this rarely happens as it requires regular treatment. In addition, it is difficult to install.

The technology used to create wooden grillages on a columnar foundation involves protecting the material from water and various pests. The metal structure rusts over time. For this reason, its installation is justified in a small number of cases.

More often, the foundation on piles with a grillage is built from concrete. It is made directly at the site where the house is built. This type of work is more labor-intensive, but it saves money in the long run.

Installation of grillage.

Steel grillage.

A grillage made from I-beams is highly expensive and difficult to install.

A grillage is a part of a pile foundation that combines load-bearing elements into one structure. They are made in the form of a strip or in the form of a slab. If a wooden structure is being erected, then the functions of a grillage are performed by the crown of beams located in the lower part. The steel system is based on I-beams. But such a pile monolithic foundation has several disadvantages. Firstly, a monolithic pile foundation, in which I-beam products are used, is highly expensive. Secondly, the installation process itself is labor-intensive and requires the use of special equipment. It is impossible to mount this part of the foundation manually. Thirdly, even steel treated with a special solution will soon corrode. Therefore, the only method left is using reinforced concrete. In this case, the grillage can be prefabricated.

The types of grillage designs vary, depending on the position in relation to the ground. The first type is tall. This is the most popular type and is located 0.1-0.15 m above ground level. This distance is quite enough to reduce the impact of the soil on the connecting system during heaving. Swelling of the soil due to weather changes is accompanied by raising the grillage and tearing out the pile elements. It is also possible to tear off the structures themselves from the piles. But a height of 0.1-0.15 m allows you to avoid such problems.

Pile foundations come with a low, raised or high grillage.

A monolithic pile foundation with a high grillage has one drawback - the free space between the floor covering and the soil. In this regard, additional thermal insulation is required.

Another type of grillage is an elevated one. The base of the system is located on the soil. Unlike the previous type, here there is no free space between the floor and the soil. To prevent the effect of heaving on the structure, part of the soil is removed from under it - approximately 0.1-0.15 m.

The next type of grillage is recessed. It is made below ground level and some soil is also removed from under the lower part.

The main task of the grillage is to connect all the piles into one system. The structure does not distribute any loads over the ground. It simply applies pressure to the piles. The grillages are not mounted directly on the ground so that sections of the base do not come off due to soil heaving.

Use Cases

There are several options for using grillage material:

- Wood . Either a solid beam 150:200 or 200:200 mm is used, or a pack of edged boards 50:200, assembled in 3 or 4 layers. The resulting beam has high load-bearing capabilities and is easy to process and install. The cost of wood is relatively low, so a grillage of this type is the best option for houses that do not have a lot of weight (wood, aerated concrete, foam concrete).

- Metal . This type of grillage allows you to get a strong base, rigidly connected to the pile heads. The result is a durable structure, the installation time of which is minimal, and the result is very reliable. A channel, I-beam or rail is used as beams; they are attached to the tops of the piles by welding. Most often used in combination with screw piles.

- Reinforced concrete . This type of grillage is built using the conventional technology of casting a monolithic strip (floor tile). The only difference arises from the presence of an air gap between the soil and the bottom of the base. In addition, the reinforcement of the piles must be rigidly connected to the reinforced belt of the tape, forming a monolithic supporting structure . This procedure forms a powerful and rigid base that is resistant to all types of loads. The disadvantage is the long hardening time of concrete, which stops work for a month.

Foundation reinforcement.

Construction of pile foundations.

Foundation reinforcement increases the strength of concrete.

Mandatory reinforcement of the foundation with a monolithic grillage solves a number of useful problems. The resistance of concrete to bending loads increases. Without reinforcing elements, the grillage may crack. All reinforcement work consists of creating two belts. The first chord is located at the top, and the second at the bottom, and each uses at least two reinforcements. The diameter of the reinforced rods should be within 1-1.2 cm. The rods neutralize the deformation effect.

Transverse reinforcement has nothing to do with the load. Its purpose is to knit the entire structure into a single system. Since there is no pressure here, reinforcement with a diameter of 0.6-0.8 cm is used. In addition, smooth reinforcement products can be used.

The reinforcement cage must be completely buried in the concrete mixture. Only the very top section should protrude 2-5 cm. Such belts are a kind of mesh, which consists of ribbed reinforcement. There should be a step of 0.2-0.4 m between the elements. Due to the vertical rods, the upper and lower sections are combined into one structure.

It is important to note that the construction of a foundation with a grillage requires more concrete mixture than for other types of foundations . Before pouring, formwork is installed, into which the reinforcement frame is mounted. To ensure that the steel structure is properly immersed in the concrete mixture, bars are placed under the lowest bars. All elements must be securely fastened.

Reinforcement is also used to reinforce piles. This is necessary to connect to the grillage and strengthen the concrete. To attach the grillage to the piles, surface rods are attached to a frame made of reinforcement. The width of the grillage is made larger than that of the walls, and the cross section is made in the form of a square.

Features of site marking

Draw the base of the house, divide it into rectangles. Mark the position of the supports on the sides and diagonals of the rectangles. The step between supports is 2-2.5 m. Piles are installed at the corners of the house, at the junction of walls and under the living area. Correctly and accurately transfer placement locations from the drawing to the site. The maximum error when marking is 2 cm (according to the collection of rules 70.13330).

Construction of the basement.

After the pile monolithic foundation is built, we proceed to finishing the base. The upper edge of the basement trim is attached to the bottom of the house and is protected from above by a special galvanized canopy (shimmer). From below, the finishing does not reach the ground by several centimeters. This is done so that during soil heaving the base is not subject to deformation. To remove precipitation, drainage is installed, and a concrete blind area about 70 cm wide is made. The best solution for a blind area around the entire perimeter of the house is paving slabs. It is durable, aesthetic and repairable.

Kinds

There are different design options for pile-grillage foundations, differing in relevant characteristics:

- Grillage material. There are wooden, metal and reinforced concrete structures. The choice is usually determined by the weight and size of the building, climate conditions and other external reasons.

- Structure height. There are types submerged in the ground and those located on the surface. From the point of view of durability and safety of materials, external structures that do not have contact with ground moisture are preferable. Submerged in the ground - only reinforced concrete options; wood and metal do not last long in such conditions.

Practice shows that immersing a concrete strip into the ground is impractical. At the same time, the open grillage forms a cold air gap under the ceiling of the first floor, which complicates the supply of communications and requires the construction of special waterproofed trenches.

This increases labor costs and increases material consumption.

Pile-grillage foundation - review of technology.

A pile-grillage foundation is not yet as popular a type of base for a building as a strip, pile or monolithic one. It began to be widely used relatively recently. But, as it turned out in practice, when building houses on loam, highly heaving or peat soils, this type of foundation is the most optimal. It takes into account and compensates for insufficient soil stability, thereby ensuring the stability of the building. An undoubted advantage is the savings of about 30% compared to the price of a traditional foundation.

Construction of grillage foundations.

Features of the foundation structure of the grillage type.

The grillage is essentially beams (slabs) through which piles located on the ground are connected to each other. These concrete lintels play the role of supporting structures for the structures erected on their basis.

Based on the amount of materials used, grillage systems are:

Classification of structures with grillage depending on load distribution:

- a high foundation that takes the weight of the building through the piles and distributes it to the lower layers of the soil;

- low, located below the soil surface and transmitting the load along the base.

Where is a pile foundation with a grillage used?

The construction of a grillage-type foundation base is carried out on soft soils. These include:

- highly heaving;

- peat and silt;

- loess-like;

- clayey mobile;

- loams;

- quicksand

This type is also used if:

- a house is being built on a mountainside or on a site with complex terrain;

- construction is carried out using frame technology;

- the depth of soil freezing exceeds 1.5 m.

The grillage type is also ideal in the situation where the calculations show that the strip foundation for a brick house should have a width of more than 1.5 m.

Pile foundations with a monolithic grillage are used for the construction of small country houses, light brick buildings, houses made of central fiber board, laminated veneer lumber, foam concrete and other similar building materials. The grillage for the above buildings can be monolithic or precast reinforced concrete.

Foundation layout diagram.

What are the advantages

A strip foundation with piles has a number of advantages:

- the ability to install on any soil composition and areas with difficult terrain;

- the supports are driven into dense layers of earth, and the upper structure is located on loose soil;

- minimal use of construction equipment and raw materials (a device for screwing in supports and a concrete mixer is required);

- the design can withstand small shocks and soil movements;

- cast-in-place piles can be made independently from available material;

- for bored supports it is recommended to make square or round formwork;

- the technology is designed for elevated groundwater locations;

- the base is erected in a few days; after the concrete has hardened, you can begin installing the walls.

Installation stages.

The construction of a pile foundation with a grillage begins with driving the piles into the ground. A prerequisite when working is to accurately determine the level of soil freezing. The supports must be buried below this mark. Next, the piles are connected with grillages. By their nature, grillage joints can be made from the following materials:

Grillages protect against soil displacement. They counteract structural instability during freeze-thaw and provide rigid coupling of the building's structural elements. Piles are mounted at points where the heaviest load is expected; their length depends on the depth of soil freezing.

In practice, for the construction of low-rise buildings, supports from 1.5 to 3 m are used. The distance between adjacent elements is 1-1.5 m. The holes for the supports must be lined with roofing felt or similar material. It is possible to casing with asbestos-cement pipes.

4 reinforcing rods are vertically fixed and securely tied in the hole. The top of the pile must be above ground level. The reinforcing thread coming out of the pile support is tied to the grillage reinforcement. The holes are filled with concrete mixture.

Over the course of a week, the concrete will gain strength. After 7 days the indicator will reach 60%. After this, you can begin work on reinforcing the grillage. The process begins with formwork. Sand is poured into it or polystyrene foam is laid. Thus, the grillage will be raised above the ground (hanging on stilts).

Scheme of a pile-grillage foundation.

An important point before reinforcement is waterproofing the upper part of the pile pillars. This stage should not be skipped under any circumstances. Reinforcement is carried out according to the general scheme developed for a specific construction. This is due to the fact that the position of the supports and the distribution of loads on the grillage differs in different places of the structure. The backfill from under the grillage structure is removed after the concrete reaches half of its brand strength (no earlier than 7 days).

Taking into account the fact that for each specific case the position of the supports and the distribution of the load in the grillage is different, reinforcement is carried out on an individual basis. The reinforcement that comes out of the piles is connected to the grillage reinforcement. When the grillage reaches more than half of its brand strength, the bedding from under it is removed. The grillage structure hangs on stilts. The grillage is not allowed to rest on the ground between the piles.

A truly working legal way to save money. Everyone needs to know this!

Pros and cons of a pile-grillage foundation

Like every other building structure, the pile-grillage structure has its own advantages, disadvantages and limitations in application.

It involves minimal time spent on creating a foundation, provided that the work is carried out by experienced craftsmen with their own special equipment. A pile foundation for a brick house (or other type of structure) is installed in the shortest possible time. The customer receives a ready-made turnkey project.

It involves the use of a small amount of concrete due to the fact that there is no need to build a cushion in the ground.

In the cold season, when the soil freezes, the area of interaction between the elements of the pile-grillage foundation and the frozen ground is minimal. Thus, the heat loss of the building is also small.

- The presence of vibration-isolating properties in the structure.

The peculiarities of connecting piles with a grillage provide reliable protection of the structure from vibration associated with the close location of the building relative to large highways, railways or subways. A pile foundation without a grillage is less effective in such cases.

It should be noted that the construction of a pile-grillage structure can be carried out at almost any time of the year. Restriction – work cannot be carried out at temperatures below -10 °C. Another advantage of such a foundation is the affordability of the materials used.

Bored piles.

Disadvantages and disadvantages:

- Use of special equipment.

It is impossible to build this type of foundation yourself. The technology requires the mandatory use of special equipment.

It is almost impossible to build this type of foundation with your own hands.

- The difficulty of constructing basement floors.

Features and layouts of supports complicate the arrangement of basements and basements. Often the space between piles has to be filled, which significantly increases the final cost.

- Low resistance to rollover.

Pile-grillage foundations on subsiding and swelling soils require special precision in adherence to technology.

Installation of driven supports.

The stages of work occur in this order:

first you need to draw up drawings on which you need to plan the project of the future foundation in section, indicate all the dimensions. An example of how the calculation is made is provided for review in the photo below;

then you need to drill holes for reinforced concrete piles;

formwork made of wooden blocks is installed;

for a monolithic grillage you need to dig a trench for filling;

Next, the grillage and piles will be filled with concrete mortar;

the finished structure is left to stand for a month to completely dry and harden.

If you are planning to build a brick house on clay, marshy or heaving soil, then the most reliable option would be to install a pile foundation with a grillage.

Advantages of using cast-in-place piles:

no noise is created during operation, which can ensure round-the-clock operation near residential buildings;

when inserting piles into the soil, vibrations are not created that could damage nearby buildings;

the pile foundation allows it to be mounted at different depths during construction on stable soil;

significant reduction in construction time for a brick house;

low cost of materials.

Minuses:

metal structures are susceptible to the formation of rust spots;

This type of foundation is not suitable for installation on rocky soil.

To build a basement, additional financially costly work must be carried out.

A pile foundation for a brick house is excellent if, for example, the soil cannot bear a high load.

The piles equally distribute the mass of the future structure over the most dense layers of soil lying deeper.

From above, the piles are connected into a single structure by means of a grillage, which takes on the primary load of the building walls.

The construction of this type of foundation greatly reduces the consumption of building materials, which reduces the cost and physical costs of the work.

But you can’t do it without a special construction drilling rig. For a brick house, a reinforced concrete bored foundation is considered the best.

It is recommended to make a concrete strip under the load-bearing walls of the structure, under which vertical pillars should be evenly distributed.

In this design, the weight will be distributed evenly: first on the grillage, and then on the pile pillars.

If you make the right fundamental structure for a brick house, then it will be able to withstand additional load in the form of possible superstructures.

Turnkey foundation cost.

Due to the difficulties of independently implementing the idea of arranging a foundation with a grillage, an important point is the price for the work of the team and the rental of special equipment. Another nuance that affects the final estimate is soil testing and design calculations. In both cases, a balanced approach is required from the customer. On the one hand, he cannot hire non-specialists, since the durability and reliability of the structure is at stake. But there is no need to pay an inflated price either. The optimal solution is to consult friends who have already gone through a similar stage of construction.

The construction price in the Moscow region averages 4,400 – 6,000 rubles per 1 linear meter. The total amount is affected by the number of piles, their quality and size, the total amount of materials, and installation technology.

Construction cost per linear meter.

Advantages of a grillage made from a monolithic slab

Before constructing a foundation with a slab grillage, it is important to become familiar with certain intricacies of the work. For example, a certain type of grillage is chosen taking into account the type of soil. You should find out how friable or hard it is, and determine the degree of its saturation with moisture.

Among the positive aspects of installing a foundation with a grillage made of a monolithic slab are:

- Wide range of applications. Such foundations are erected on any soil, even unstable ones.

- High reliability.

- Long service life. If you use high-quality materials, the operation guarantee of this design is 70 years.

- There is no need to take into account the terrain of the site.

A foundation with a grillage made of a monolithic slab can be constructed using simple technology. This allows you to make a reliable foundation for your home with your own hands.

What is a pile-grillage foundation?

Everyone probably imagines a pile foundation: it is a number of piles buried in the ground to the level of the load-bearing layer or below the freezing level. In its pure form, this type of foundation is rarely used. This is due to the peculiar design, which does not allow the load from the house to be redistributed between the piles. Therefore, pile foundations are mainly made for log buildings made of logs or timber, and sometimes for frame buildings. These types of building materials, due to their characteristics, themselves redistribute the load. They are not compatible with houses made of other materials.

But their improved form - a pile foundation with a grillage - is free of many disadvantages and can be used for both brick and block buildings. In them, all the supports are tied using a tape made of metal or reinforced concrete (concrete) into a single structure. This tape is called a grillage.

Pile grillage foundation.

This is what a pile-grillage foundation looks like when taken out of the ground.

A grillage is a part of the foundation that connects the pile heads and serves as a support for the walls. It is the grillage that receives and, due to the closed structure, redistributes the load, transferring it to the piles. It can be metal, wood, concrete or reinforced concrete. According to the type of execution, concrete (reinforced concrete) grillages are low and high.

Foundation grillage.

There are pile foundations with high and low grillages.

The high grillage is above ground level. Most often it is made of metal - large-section channels or square metal pipes. They also make such a grillage out of concrete, but its design is more complicated: you have to figure out how to fill the tape at a distance from the ground.

How does a grillage work and what does it provide?

Any house in different parts will have different loads: decoration, furniture, sanitaryware, other things are placed unevenly. Consequently, the load from its different parts will be different. The grillage takes on these uneven loads and redistributes them. The “leveled” load is already transferred to the piles.

Pile grillage foundation.

What is the difference between pile and pile-grillage foundations?

Why is this good? The fact is that with the same load on the piles, there is less chance that they will settle unevenly. And uneven shrinkage leads, as is known, to cracks in the foundation and walls. Therefore, the pile-grillage foundation is more stable. Although the main disadvantage of pile foundations remains: we cannot know what kind of soil is under each of the piles. Therefore, it is unrealistic to predict their behavior. That is why architects are not very fond of them: it is impossible to guarantee long-term operation of the house.

Strip foundation on piles.

Low grillages are more predictable in this regard. They usually start below ground level and are cast from reinforced (or not - depending on the project) concrete. Moreover, the reinforcement of the piles is connected to the reinforcement of the grillage.

In this case, the grillage is a shallowly buried strip foundation and it is made using the same technology. It differs in that it has a rigid connection with the piles, which significantly increases the reliability and stability of the structure. Such foundations are also called strip foundations on piles or pile-strip foundations. This design is almost ideal: it combines the advantages of pile and strip foundations, largely compensating for their disadvantages.

Pile grillage foundation.

Construction of a pile-strip foundation.

How does he work? The load from the house is transferred to the belt. Thanks to the presence of longitudinal reinforcement, it is redistributed over the entire area. Since the tape also rests on the ground, part of the load is transferred to it, the rest falls on the piles. In this case, the load and shrinkage are uniform: they are “evened out” by the tape.

In winter, when heaving forces begin to affect the foundation, all the advantages of a pile-strip foundation appear. If the house is located on heaving soils, their depth is below the freezing level, it is very difficult to imagine conditions under which the house will warp or it will shrink unevenly.

When heaving forces act on the tape, the “heels” of the piles, and they themselves, do not allow the soil to move the foundation. Therefore, strip-pile foundations are an excellent choice on highly heaving soils. The costs are much higher than when constructing a conventional pile foundation, but much lower than when constructing a strip below the freezing depth.

Types of pile foundation depending on the driving method

Piles can be made in different ways, which determines the method of immersion in the ground:

- Driven piles are driven into the ground only using special equipment or a vibratory driver.

- Cast-in-place piles are driven into the well using a drill and filled with concrete. Made from concrete or reinforced concrete.

- Drilled piles are reinforced concrete products immersed in a pre-drilled hole.

- Screw piles are metal posts with a screw-shaped tip. Immersion is carried out by directly screwing the pile into the ground.

When can it be used?

It is recommended to install pile-grillage foundations in the following cases:

- When unstable and weak-bearing soils go to a sufficiently large depth. These are karst, forest, peat soils, quicksand, plant and fertile soils of great thickness (more than 1.4-1.5 meters). In this case, the load must be transferred to the dense soils located below with normal bearing capacity. It is not always possible to get to them, and even if it is possible, the foundation turns out to be too expensive. Therefore, transferring the load using piles is the best choice.

- In areas with large elevation differences. In this case, it is often much cheaper to use piles of different heights than to carry out work on leveling the ground or pouring a deep tape that can compensate for height differences.

Pile grillage foundation.

- At high groundwater levels. Pile foundations are the only ones for which the groundwater level does not matter. It is important that there is soil with load-bearing capacity under the heel. The level of water location affects only the type of grillage: if the water is close to the surface, the grillage is made high, if it lies deep, it can be made low.

- During construction in hard soils. In this case, small volumes of earthworks (compared to strip or slab foundations) have a positive effect.

- If you decide to build a house using frame technology. Making a tape for it is a waste of money: you get too much safety margin, which, in this case, is useless. In this case, a pile or pile-grillage foundation is the best choice.

- With a large mass of the building (more than 350 tons). Then it turns out that the tape or plate must be very massive and, therefore, expensive. In this case, a pile-grillage foundation often turns out to be cheaper.

Sometimes it’s even simpler: they start from the lowest cost. But you should always remember that any type of pile foundation is less reliable than slab and strip foundations. And all because we cannot know exactly what kind of soil is under each of the piles. That is why, when calculating parameters, an increased safety margin is included in the design. Not 1.2, as is usually believed, but 1.4. And still, no one can guarantee anything.

Evolution of this foundation

Initially, piles were made from wood, which was additionally treated with natural antiseptics. As a result, this had the best effect on the durability of the structure. These types of piles were driven into the ground using special mechanical pile drivers, according to SNiP. Such a process had multiple disadvantages and disadvantages, was relatively labor-intensive and could continue for a long time. However, the obtained result fully satisfied all technological indicators of SNiP. And the structure, in turn, rose above the ground at such a level that groundwater could not flood it.

Later, with the advent of new technologies and the expansion of SNiP, foundation piles began to be made from more modern and reliable materials. Currently, reinforced concrete pillars are widely used. Their main advantages are that they are quite easy to install, have all the necessary technical characteristics, and also have an acceptable cost.

Also, screw piles made from metal pipes taking into account SNiP receive good reviews. They have increased durability and reliability. For “problem” soils, where the distance to groundwater is minimal, bored types of piles are used. They are an ideal option from the point of view of SNiP, but their construction is more labor-intensive.

What piles to use.

Any piles can be used in pile-grillage foundations. They are selected based on the soil and the planned load of the house. Piles are made of metal, concrete, and sometimes wood. They can have a round or square cross-section. They also differ in the installation method:

- Hammers. They are installed without drilling or excavation. Usually they get clogged, that’s why they are called that. They are rarely used in private construction: special equipment is required.

Pile grillage foundation.

Driven reinforced concrete piles are used more often in the construction of multi-storey buildings.

- Bored. First, a well is made in the ground, then formwork is installed and secured into it. It contains reinforcement that increases strength characteristics. Then the entire structure is filled with concrete.

- Reinforced concrete drilling rigs. In this case, wells are also drilled, but ready-made reinforced concrete piles are installed in them (driven, but with less effort).

- Screw. These are metal piles, pointed at the end and having screw blades that cut the soil. At greater depths, special equipment is required; small ones, up to 2-3 meters long, can be installed manually.

Pile grillage foundation.

One type of piles is screw piles. They can be used with grillages made of different materials for different houses.

In private construction, bored piles are most often used. They are especially popular in the construction of summer houses or baths. They can also be used in the construction of small houses. But if dachas and bathhouses can be built without calculations, then when building a house it is very advisable to order a project.

Different piles come in different shapes: square or triangular, round filled and round hollow, sometimes complex shapes are developed specifically for the project. Based on how piles transfer load to the ground, they are:

Pile grillage foundation.

How do piles differ by type of work?

Hanging piles have a large lateral surface and a significant part of the load (up to 60-70%) is transferred with its help. They are used if the bearing capacity of the soil at the achieved level is not enough to withstand the entire load, and further deepening is impractical. In this case, the presence of a “heel” changes almost nothing: the main load is transmitted by the surface, and not by the tip of the pile.

Rack piles, on the contrary, transfer most of the load through the tip. In this case, the side walls are undeveloped and smooth, and it makes sense to expand at the end of the pile. One type of this type is TISE piles. They have a cylindrical extension at the bottom, which is why they transfer the load to a larger area. Also, the heel prevents heaving forces from lifting the foundation.

Floors on the ground

Floors on the ground are used to create a grillage structure immersed in the ground. If there is an air gap, creating a ground floor becomes too difficult, ineffective and impractical.

The inside of the tape is covered with a layer of sand cushion . Then a layer of geotextile is laid on it and crushed stone is poured, onto which a layer of crushed stone is poured through an additional layer of geotextile.

The entire backfill is compacted sequentially, achieving the best possible result. Then a layer of screed is poured on which the heat insulator is laid.

A screed is again poured on top of it, inside which a heated floor system is installed.

A finishing coating can be applied to this screed . The floor cake is quite multi-layered, but it provides high-quality heating and prevents heat loss due to contact with the ground.

Location of piles in the grillage.

In most cases, supports in the ground are placed vertically. Sometimes an inclined installation may be required, and several pieces in one place. This method is used if horizontally directed forces may arise. For example, during construction on sloping areas.

Pile grillage foundation.

Location of piles on the house plan.

Piles can be located pointwise - under supports (columns, racks). This arrangement is typical when constructing canopies or installing roofs over open areas. Then the supports are placed exactly under the columns holding the roof.

For private houses with a small number of floors, the piles are placed in the form of a strip. They are placed in one row, sometimes in two or three, shifting them relative to each other. Sometimes in the most loaded parts, for example, in corners, under areas with a large planned load, they are placed in bushes: several pieces at a short distance from each other.

How to place a house on a plan yourself.

When designing a pile foundation on your own, you usually proceed as follows. On a building plan drawn to scale, piles must be laid in the corners and at the intersections with the walls. If they are more than 3 meters apart from each other, intermediate supports are placed between them. It is advisable that the piles be located one from another at a distance of 2 to 3 meters.

Pile grillage foundation.

First, the piles are placed in the corners, then under the junctions of the load-bearing walls.

The principle is simple, but you still need to determine the required area of the piles. And it needs to be calculated (or rather, selected).

Creating a pile field

At this stage, you will also have to follow a certain order of actions. First, mark the area for the pile field. At the points where the piles will be driven, reinforcement bars are immersed in the ground. A string is pulled between them and the accuracy of the base geometry is checked.

Then do the following:

- Unloading the piling rig. Bored piles and a machine for driving them into the ground are brought to the site. The installation is small in size and equipped with a swamp chassis. This allows you to keep the coverage of the area intact.

- Transportation of piles around the territory. Reinforced concrete elements are unloaded in one place, and a pile driving machine delivers them to the installation point. Often the piles are moved around the site on a trolley.

- Preparing for installation. First, the piles are lowered and fixed to the ground, and then the boom is raised. The piles are lifted with a winch.

- Driving piles. Piles are placed into the ground using the impact method. One element is immersed to the required depth in a few minutes. The installation of reinforced concrete structures is monitored using a level.

- Cutting off the ends of piles. The piles are partially trimmed until the reinforcing bars are exposed. The work is performed with a hammer drill.

During operational work, a pile field is created in a few hours.

Calculation of a pile-grillage foundation.

In order to be at least partially confident in the reliability of the foundation, it is advisable to at least approximately calculate it. To do this, you will need to do several not very complex calculations.

- The weight of the house is calculated (all materials and the approximate weight of the “filling” are taken into account).

- Based on the weight and safety factor, the required supporting area is determined.

- Since the piles have already been placed, we can count their number.

- Next we select the cross-sectional area of the piles. Since we know their number, multiplying by the selected area, we find out the total.

- We compare the obtained result with the reference area calculated earlier (point 4).

- If the area found in step 4 is larger than that calculated in step 2, the selected pile parameters are suitable for us.

- If it is less, we increase the planned cross-section of the piles, multiply again and compare. This is how we find the required area of the pile.

Sometimes it is more profitable not to increase the area of piles, but to install them more often. The calculation method does not change.

Load-bearing capacity of bored piles.

Load-bearing capacity of piles of different diameters in different soils.

The support area required for normal load distribution is calculated by the formula:

Where N is the bearing capacity of the soil (it can be taken from the table). The coefficient of 1.4 was applied due to the fact that pile foundations require a larger margin of safety: we do not know what kind of soil is under all the piles. Therefore, it is better to play it safe.

For more information on calculating the supporting area and calculating the mass of the house, watch the video.

Features of soil analysis

The geological report includes data on heaving, thickness of soil layers, presence of groundwater and its depth. The main characteristic is load-carrying capacity.

Contact a geologist or send a sample of unloosened soil to a construction laboratory. You can find out on your own about the type of soil, its homogeneity and the presence of underground flows. It should be noted that independent observations are subjective.

Determine the type of soil using the comparison table.

| Name | Characteristic |

| Fine sand | Floating, swells greatly and freezes. It is impossible to build a foundation on it. |

| Gerbil | It compacts well and allows water to pass through. Doesn't swell. The foundation on sandy soil does not soak, is durable and can be quickly installed. |

| Clay | The most “inconvenient” soil for construction, as it swells greatly. With such soil, specialists either create an anti-heaving cushion or change the installation location. Dry clay without groundwater is processed without problems. |

| Rock or debris | It is difficult to process, but the foundation on it is the most stable. Does not swell, does not freeze, does not change over time. |

Look at the asphalt road leading to the site. If in the spring it becomes covered with cracks, the soil is heterogeneous. Pits indicate groundwater, therefore, high-quality waterproofing of the pillars is necessary.

Construction technology.

So, you have a project ready, or you yourself have decided on the location of the piles, their parameters, the type and height of the grillage. Construction can begin.

First, the entire fertile layer of soil is removed, taken out to the garden or stored in one of the corners of the site. The area for the foundation is leveled. Then, using pegs and cords, the boundaries of the house are marked. Moreover, two cords are pulled, marking the outer and inner surfaces of the walls. Be sure to check the geometry by re-measuring and comparing all the diagonals in pairs.

After the marking is completed, you can mark the installation locations of the piles. We have them drawn on the plan and calculated, the distances between them are determined.

Pile grillage foundation.

Schematic representation of the work procedure during the construction of a pile-grillage foundation with your own hands.

Excavation and pouring of piles.

How exactly the work will take place depends on the type of piles used. Most often, screw or bored piles are used when building a house.

Screws can be screwed in by hand. When twisting, their heads are aligned at the same level. It is more convenient to mark it with cords.

For drilling, you will need either special equipment or a hand drill of a suitable diameter. These devices drill holes in the right places. The selected formwork is lowered into the finished wells, and reinforcement is installed (four bars of ribbed reinforcement connected to each other). If the foundation is pile-strip, then the reinforcement must have an outlet of at least 60-70 cm. It will then be connected to the grillage. The last step in this stage is pouring the concrete.

Construction of foundations for pile grillage.

The pile foundation is ready for installation of formwork for the grillage. In this case, formwork made of roofing felt or roofing felt, rolled several times, is used.

Grillage arrangement.

If a metal grillage is selected, it is welded to the pile heads. When working, it is important to maintain strict horizontality: then the load will be transferred evenly.

To install a recessed reinforced concrete grillage (low), you will need to add crushed stone of a fraction of 20-60 mm and compact it with a vibrating platform. The minimum layer of crushed stone is 15 cm. To improve the bearing capacity of the soil under the belt, it is necessary to pour crushed stone in small layers (5 cm each) and thoroughly compact it with a vibrating platform. It will not be possible to compact well around the piles, but this is not so important.

Formwork is installed on this bedding. The width of the tape is slightly larger than the width of the walls, the height of the panels is made taking into account the required height of the base. Assembling the panels and installing stops exactly repeats the technology for installing formwork for strip foundations.

Pile strip foundation.

Scheme of reinforcement of a pile-grillage foundation with a reinforced concrete grillage (pile-strip).

Reinforcement is carried out in most cases in the same way as during the construction of a belt: two belts at the top and bottom made of ribbed reinforcement, transverse and vertical posts made of a smooth rod of smaller diameter. All reinforcement rules are preserved. Only the dressing with piles is added. The outlets of the reinforcement from the piles are bent: one row is tied to the lower belt, the second - to the top (do not forget to make the outlets of different lengths). They must be at least 50 bar diameters (if 12 mm reinforcement is used, you need to bend 600 mm (50 * 12 mm)). The reinforcement diagram for the pile abutment is shown in the figure.

Installation of embedded parts.

At this stage, it is necessary to leave ventilation ducts and lay pipes and ducts through which utilities will be supplied (plumbing, heating, electricity, sewerage).

Pile grillage foundation.

Don’t forget about laying pipes for vents and connecting engineering systems.

If this is not done, you will have to subsequently chisel the concrete. And this is a great evil for the foundation, because the integrity of the monolith is violated. So think through everything carefully: there will be no opportunity to redo it.

Pouring concrete.

Concrete is not just poured. It is also vibrated. Without this process, it is very difficult to achieve uniformity and high strength. Therefore, processing foundation concrete with a vibrator can be considered a mandatory process.

If the air temperature after pouring concrete is around +20°C, then the formwork can be removed after four days. During this time, the concrete will gain approximately 50% of its design strength, which is enough to carry out the following work. If the temperature was around +10°, you will have to wait 10-14 days. At lower temperatures, conditions are considered wintry and the poured concrete requires insulation or heating.

Pile grillage foundation.

Everything is ready for pouring concrete: the reinforced belt is tied, the formwork is set and secured (to enlarge the size of the picture, right-click on it).

For all their attractiveness, pile foundations have disadvantages:

- As already mentioned, due to the fact that it is impossible to determine what kind of soil is located under each of the piles, its behavior is almost impossible to predict.

- In such buildings it is impossible to install basements.

- With high grillages, it is necessary to somehow close the gap: animals and insects like to live there.

Recommendation: A good review article, from it you can learn about the construction of a pile foundation with a grillage. Indeed, a pile-grillage foundation is not expensive. If it suits your building in all respects, then you can safely use it, but be careful when calculating the loads, you won’t be mistaken. This is an important point!

Step-by-step instructions using the example of a monolithic grillage on bored piles

To build a foundation of this type, an individual developer needs to determine the main dimensions of the elements: cross-section of the grillage (height, width), depth of the well, parameters of the reinforced belt, type of formwork. After which, the amount of building materials is calculated. For convenience, below are step-by-step instructions describing the key points.

Geological surveys, calculation of parameters

Unlike screw piles, for which it is often enough to test screw in a building spot in several places to determine the depth of the bearing layer, this will require full-fledged geological surveys. According to SP 24.1333, this will require a set of operations:

- soil testing with static loads;

- pessiometry, dynamic and static probing;

- laboratory analysis of groundwater, soils from different layers during drilling 3 m below the design level.

Soil samples.

In addition, specialists will take into account the impact of piles on nearby buildings and the environment. The result of the research is a geological section in which the thickness of each layer of the layers of different rocks present in the building area is visible. This allows you to select from the corresponding SP tables the standard values of the bearing capacity of clay, sand, and loam to calculate the bearing capacity of the pile.

For example, for soil conditions of 2 m refractory loam, 1 m hard loam, on top of wet sand, there are several options for drilled piles:

- A – the depth of the piles is more than 3 m (passing through loam with the base resting on the sand), diameter 0.5 m;

- B – depth 3 m, diameter 0.4 m;

- B – depth 2 m, diameter 0.5 m.

In the first option, the load-bearing capacity of the pile will be 15.4 tons, in the second 10.7 tons, in the third 7 tons. With the same prefabricated load from the dwelling, the maximum pitch of the pile field for the first case will decrease in the last two options by 0.8 m, 1. 6 m, respectively. That is, three-meter piles will be needed 2.2 times less than two-meter ones.

The prefabricated load on the pile field is calculated (weight of the roof, floors, wind, snow load, furniture, weight of floors, walls, foundation, internal stairs, equipment). The resulting figure is divided by the load-bearing capacity of the pile, taking into account a safety margin of 15 - 30 percent for possible redevelopments and extensions.

The width of the grillage depends on the parameters:

- pile diameter - for rubble concrete and reinforced concrete structures, the minimum size is 50 and 30 cm, respectively;

- wall thickness - it is allowed to widen the masonry with the lower rows by 10 cm in each direction;

- protective layer - 3 cm from the reinforcement to the outer edge of the grillage.

Thus, the minimum cross-section of the grillage is 40 x 35 cm (width, height, respectively). The depth of the grillage is selected depending on the characteristics of the soil and the construction budget:

- the hanging grillage will have to be protected with a fence at the end of construction;

- under a low grillage after stripping, it is necessary to remove a layer of soil/sand 10 - 15 cm or place one or two layers of foam plastic before pouring into the formwork;

- a high grillage allows you to place communications underground;

- ground grillage allows you to make floors on the ground, which are the most economical option for flooring.

The distance between the monolithic grillage and the blind area of 45–50 cm is considered the most convenient for the entrance porch. An odd number of steps (in this case 5 pieces) is more convenient than an even number. In addition, the resulting height of the intake is sufficient for the manufacture of ventilation ducts in the underground. They will not be covered with snow in winter at a height of 35 cm from the blind area.

Marking, excavation, input of communications

Marking the pile foundation

According to existing standards SP 70.13330 regarding geodetic work in construction, the maximum error when marking the foundation is 10 mm. For a pile foundation, the technology for transferring axes from the project to the construction site has the form:

- installation of cast-offs - structures of two pegs with crossbars are placed at the corners, cords are pulled along them along the axes of the future walls, and internal walls are marked in a similar way;

- marks for piles - the centers of corner piles are marked with lime mortar, chalk or paint on the ground, distances equal to the design pitch of bored structures are set off from them with a tape measure, in these places a plumb line is lowered from a stretched cord, similar marks are created.

According to SP standards, the minimum diameter of piles is limited to 30 cm, 40 cm, 50 cm for reinforced concrete, concrete, and rubble concrete structures, respectively. Hand drills with 50 cm equipment are produced by a limited number of manufacturers. Therefore, in most cases, when choosing rubble concrete piles, the developer has to dig pits to the full depth, use support piles, and fill them with non-metallic material after stripping.

If reinforced concrete piles are used, the width of which is 40 cm, there are no problems with the drilling tool. This allows you to avoid a large amount of excavation work without reducing the load-bearing capacity. The depth of the wells depends on the results of geological surveys; it rarely exceeds 3–5 m. To reduce labor costs, a motorized drill can be used, the rental of which is much cheaper than special equipment.

Drilling wells for piles using special equipment.

At the same stage, the supply of engineering systems is carried out. When using a low grillage in combination with insulation of the blind area, a depth of 0.7 - 1 m for water supply and 0.5 - 0.7 m for sewerage under the base of the building is allowed. Communications under a monolithic hanging grillage must be insulated. Thermal insulation technology looks like:

- the pipes are wrapped in mineral wool, with a heating cable in the air;

- placed in polystyrene shells in the ground.

The depth increases to 1.2 - 1.5 m for water supply, 0.7 - 1 m for sewerage.

Formwork and reinforcement

When choosing formwork for drilled piles, the following factors must be taken into account:

- when poured into the ground, the load-bearing capacity of the piles due to friction of the side surfaces fully corresponds to the calculated one;

- if roofing felt rolled into a cylinder is used, the characteristics practically do not change;

- when using an asbestos-cement pipe as permanent formwork, the load-bearing capacity along the side edges is reduced by 10–15%, but the pulling forces during soil swelling are reduced by 30%;

- if a polyethylene pipe is used as permanent formwork, heaving forces have virtually no effect on the piles, however, the load-bearing capacity along the side surfaces is lost by 50 - 70%, all loads are transferred to the sole.

Frame for piles.

Thus, if the height of the drilled pile does not exceed 2 m, the base does not reach the layer with bearing capacity, it is better to abandon polyethylene pipes or reduce the pitch of the pile field by 1.5 - 2 times.

When choosing the height of the formwork, it is necessary to take into account the type of grillage, the depth of the heads into it by 5 - 6 cm. It is at this mark that the lower reinforced belt will be mounted, taking into account 5 cm of the protective layer. The technology for reinforcing reinforced concrete piles is carried out as follows:

- cut - 4 longitudinal rods (this is the minimum value for one pile);

- cutting and bending of clamps;

- ligament – connection of vertical rods with clamps;

- installation - the structure is lowered into the formwork or well, maintaining a 5 cm protective layer.

We recommend: How to properly reinforce bored piles.

Pouring of piles.

For reinforcement, rods of 10–12 mm of periodic section are used. The clamps are bent from 6–8 mm of smooth reinforcement. For tying, it is better to use annealed wire. The pitch of the horizontal clamps is 30 - 60 cm, the rods should protrude 30 - 40 cm above the heads. After stripping, they are bent at right angles parallel to the axes of the walls and connected to the lower belt of the grillage.

Pouring and waterproofing

The formwork for the grillage begins to assemble from below.

Due to the large volumes of concrete work, a pile-grillage foundation is usually poured in stages. First, the mixture is placed in pile formwork and compacted with an in-depth vibrator or reinforcing bars to remove air. The grillage formwork is installed after the piles have gained at least 50% strength (3 – 5 days after pouring). The technology looks like:

- deck installation - only for a hanging grillage, holes are cut in the shield according to the size of the piles, it is put on the heads, supported by H-shaped posts along the entire length;

- installation of side panels - attached to the deck, propped up with bars or pins, the top side should be 5 - 7 cm higher than the design mark;

- reinforcement - two belts of 10-16 mm bars of periodic cross-section reinforcement, fastened with 6-8 mm clamps, bend at the corners, at the junction of the walls.

Grillage reinforcement.

We recommend: Proper grillage reinforcement.

Filling occurs according to standard technology with laying and vibration compaction of the mixture. The entire formwork must be filled in one go. Caring for concrete consists of protecting it from waterlogging (covering it with a film from rain), drying out (sand or sawdust on the top edge of the grillage with periodic moistening in the first three days).

Pouring the grillage.

Waterproofing is carried out after stripping the grillage in several ways:

- impregnation with penetrating compounds (the service life is similar to concrete structures, no repairs are required);

- coating with bitumen mastics (resource 15 – 30 years, budget option);

- gluing with roll materials (lifespan of glass hydroisol is 30 - 50 years, the need to seal joints, use 2 - 3 layers).

Preferable impregnation waterproofing or a set of measures according to the last two options (coating + gluing).