Mulwatt

8582 0 2

Mullvatt September 2, 2016Specialization: Capital construction work (laying a foundation, erecting walls, constructing a roof, etc.). Internal construction work (laying internal communications, rough and fine finishing). Hobbies: mobile communications, high technology, computer equipment, programming.

It is important to know how to properly install the insulating layer for a sauna.

To fully enjoy bathing procedures at your own dacha, you need to carefully insulate the room. Otherwise, too much effort and firewood will be spent on achieving and maintaining the desired temperature in the steam room.

Today I will tell you how to insulate a sauna from the inside with your own hands. Let's figure out what is the best material to use for this and how to install it on the walls.

Natural insulation for baths

The features of these materials lie, first of all, in their environmental friendliness and ability to “breathe”. In past times, Russian baths were insulated exclusively with the help of natural components. But don’t think too much, this is an easy and quick answer to the question of which insulation is best to insulate a bathhouse. Natural thermal insulation has both positive and negative characteristics.

Advantages

Thermal insulation products of natural origin have the following advantages:

Flaws

Which ones are used to build baths?

Natural materials have long been used as inter-crown insulation for baths. Moss, tow, felt, and hemp were laid between the logs. Red moss, used for internal caulking, is well suited for a timber structure. Among the modern options used for inter-crown insulation, jute fibers can be distinguished, which are also devoid of any “chemicals”.

Scope of use

Thermal insulation of walls

Thermal insulator Rocklight has a wide range of uses. Basalt slabs can be laid on concrete screeds and between joists. The installation technology is to eliminate gaps. A final coating is made on top of the heat insulator. The coating can be absolutely anything (laminate, parquet, etc.).

This insulating material is used for thermal insulation and sound insulation of partitions. The thermal insulator is installed in a frame made of both wood and metal. Sheets of plasterboard are placed on top of the Rocklight, and then the final coating is installed. An additional area of use for this thermal insulation product is ventilated facades.

Rocklight is actively used during the construction of frame houses. The inside of the material is covered with a vapor barrier. This eliminates the possibility of moisture entering from the room. After installing the vapor barrier membrane, the final finishing is done. The wind protection is mounted on the outside of the heat insulator. As a wind barrier, you can install a specially designed film or OSB boards. The choice of wind protection depends on the type of coating. A pitched roof is insulated using a similar method.

"Isover"

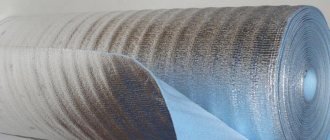

Insulation for baths "Isover". Along with conventional insulation, it also produces a special insulation for baths and saunas - IsoverSauna. Made from mineral wool containing polymerized fiber. One side of the wool is equipped with a foil coating, which is why the material is called foil insulation.

Is it possible to use Isover insulation in a bathhouse?

If we talk about the above product, then this option is a completely acceptable solution for insulating a bathhouse. The foil layer gives the isover vapor barrier properties. The material itself is characterized as suitable for rooms with high humidity. Such qualities fully comply with the requirements determined by the characteristics of the bathhouse.

As for using a regular (non-foil) isover, in this case you will have to lay a layer of foil on top of the material yourself.

Thermal insulation of the house facade

External thermal insulation of a building facade is better than internal. This way you preserve the interior space of the room. The surface of the walls will be protected from sudden temperature changes, which increases the durability of the structure. But it is important to provide an air gap for ventilation after insulation. This is necessary so that the condensate can evaporate freely.

The ease of installation and technical parameters of mineral wool - all this has made this material popular. In addition, the insulating product can withstand fire and high temperatures. Technical characteristics do not get worse even after decades.

Sources

- https://ZnatokTepla.ru/utepliteli/roklajt.html

- https://mr-build.ru/newteplo/roklajt-tehnonikol-tehniceskie-harakteristiki.html

- https://bouw.ru/article/uteplitely-roklayt-harakteristiki

- https://stroy-podskazka.ru/dom/uteplenie/roklajt-ot-kompanii-tehnonikol/

- https://ckfi.store/info/teplozvukoizolyatsionnye-materialy/kharakteristiki-uteplitelya-tekhnonikol-roklayt-/

- https://ZnatokTepla.ru/utepliteli/tehnicheskie-harakteristiki-roklajt-tehnonikol.html

[collapse]

Penoplex

Due to its characteristics, extruded polystyrene foam or penoplex as insulation for a bathhouse is a completely suitable material for use. Most often used as thermal insulation for frame and brick buildings. With the help of penoplex, you can insulate the strip foundation under the steam room, as well as perform thermal insulation of the roof, floor and walls.

The properties of the product that allow it to be positively characterized as a thermal insulator for a bath include:

Application

Rocklight insulation, reviews of which may help you understand which thermal insulation to choose, has found wide distribution. It is an ideal material for private construction. Stone wool is used for inclined, horizontal and vertical surfaces, as well as insulation of corner elements, floor slabs, pitched roofs, foundations and basements. You can purchase this insulation in cases where there is a need to insulate an attic or frame house. Due to the fact that the density of the material is not so high that it can be used as a load-bearing structure, it is best to use additional stronger building elements for this.

"TechnoNIKOL"

Insulation for baths "TechnoNIKOL". Russian mineral wool goes on sale in a wide range. In private construction, three lines are used: “Rocklight”, “Technoblock”, “Technoacoustic”. All three types are suitable for both internal insulation, performed by specialists or with your own hands (using a vapor barrier), and for external work under siding.

Of all the types of fire-resistant wool produced by this manufacturer, TechnoNIKOL stitched mats (basalt insulation for baths), which do not contain phenols, are best suited for . In the manufacture of other types of products (TECHNO 03B, 03D, 03M boards), a low-phenolic binder is used.

Technical qualities of Rocklight thermal insulation

Rocklight mineral wool is made from special rocks and is a non-flammable material. The rock is melted and stretched to form fine fibers. These fibers are collected into slabs using a binder.

Rocklight slabs come in two sizes - 50, 100 and 150 mm thick. Insulation is used to preserve heat in outbuildings, as well as in industrial and residential premises. Insulation can be used on both vertical and horizontal structures. It is perfect for insulating partitions in apartments and houses.

It will help protect the room from excess noise and cold, retaining heat.

The ease of installation of Rocklight insulation and its excellent qualities have long been rightfully valued by construction companies and private developers. It is most often used for the following works:

- insulation of external or internal walls of buildings;

- insulation of walls that are planned to be topped with siding;

- insulation of interior partitions;

- thermal insulation of floors;

- thermal insulation of ceilings;

- insulation of attic walls;

- thermal insulation of attics from which living rooms are equipped.

When fastening sheets of thermal insulation with a construction stapler, the characteristics of the material do not deteriorate. But Rocklight can also be fixed using metal profiles and wooden slats.

The technical properties of the Rocklight sealant are as follows:

- Thermal conductivity: 0.039–0.041 W/m2.

- Density: from 30 to 40 kg/m3.

- Flammability level – NG.

- The level of compressibility is not higher than 10%.

- Vapor permeability – 0.3.

- The length of the slab is 1.2 m, width 0.6 m, and thickness from 5 to 15 cm.

If the thickness of each sheet is 15 cm, 4 pieces fit in the package, with a thickness of 10 cm - from 4 to 6 pieces, 7.5 cm - 8 pieces, and 5 cm - up to 12 pieces.

Rocklight mineral wool is not only high-quality sound and thermal insulation, it does not cause problems during installation, because the slabs are very dense and light in weight.

Conclusion: what insulation should I use for a bath?

In conclusion, we can say that the procedure for insulating a bathhouse is purely individual for each individual case. A positive result is influenced by taking into account many factors: wall materials (wood, brick or blocks), floors and ceilings, features of a particular room, design and number of floors of the building. And climate conditions also play a certain role in this matter. Therefore, the above information serves only as a guide to the question “which insulation for a bath is better”, for independent choice of thermal insulation.

Minuses

Although in general, TechnoNikol products have proven themselves in the market, as you know, there are no ideal things. This means that Rocklight also has its “dark” sides.

Firstly, users note that mice still eat it. And if they don’t eat, they definitely gnaw. Therefore, like polystyrene foam, insulation requires the construction of a dense frame through which unexpected inhabitants of your home cannot reach it.

Secondly, should this be attributed to the shortcomings of the insulation itself... or rather the approach to choice - flammability. Although TechnoNikol wool itself does not burn or melt, you still should not expect that in the event of a fire the insulation will work a miracle, say, in a wooden house. Walls made of wood, OSB or other flammable materials will burn and mineral wool, although it will not contribute to combustion, will definitely not be able to stop a huge fire.

Thirdly, we have already spoken above about the release of harmful substances (unconfirmed!).

Fourth, consumers complain about poor adhesion or contact with alkaline-based wall finishing materials.

In addition, they report the hydrophobicity of the insulation, the fragility of the sheets, and some say that even when purchased, the sheets in the package are deformed and wrinkled, which makes the installation of the slabs very difficult.

Review of ready-made systems for thermal insulation of baths or saunas

Without high-quality thermal insulation, a bathhouse is a strange and very expensive way to heat the air in your area, and a sauna is a huge radiator in an apartment or house. Up to 70% of the heat can escape outside. If you count the costs of firewood and electricity, it turns out to be a lot of expenses that literally go down the drain.

We offer to stop heat loss using ready-made solutions. They are designed strictly for baths and saunas, that is, for rooms with extremely high temperatures and humidity.

Solution 1. TH-WALL Bathhouse PIR

The system is suitable for both an apartment and a separate building on the site. The basis for the thermal insulation system of a bath or sauna is a wall made of timber, brick, blocks ( 1

) and the ceiling support frame (

2

). Usually this is a frame made of a metal profile or wood.

is laid on them (3)

.

The boards are laminated with foil, so no additional vapor barrier layer is needed when installing them. In addition, the foil serves as a heat reflector - it directs heat flows into the room. The sauna heats up quickly because the insulation layer returns up to 95% of the radiant heat energy from the sauna stove to the room.

Characteristics of LOGICPIR insulation:

In addition to thermal insulation of baths and saunas, the material can be used to insulate rooms where there are high requirements for temperature and humidity parameters: pitched roofs, attics, balconies, floors and swimming pools.

The joints of the plates are glued with self-adhesive aluminum tape LOGICPIR (4)

It will allow you to make a continuous and sealed vapor-proof layer that reliably protects the entire structure from moisture. The tape must be glued overlapping to avoid curling at the edges and work should be carried out at a temperature not lower than +5 ° C.

Sheathing strips 20x40 mm (5)

can be installed in a horizontal or vertical direction depending on the direction of the finishing layer of eurolining.

Internal lining (6)

It is better to choose from hardwood. Install it so that there is a gap of at least 20 mm between it and the insulation.

Solution 2. TH-WALL Bathhouse

It can also be used to create a sauna in an apartment or a bathhouse in a separate building.

On an existing wall made of brick, wood or blocks (1

) a frame made of timber 50x50 mm (

2

) is installed, and on the ceiling 50x100 mm (

3

)

ROCKLITE stone wool slabs (4)

installed in the frame

The slabs are used as heat and sound insulation in horizontal, inclined and vertical structures, such as attics, frame walls, walls with siding, floors and ceilings, partitions.

An alternative to ROCKLITE slabs can be TECHNOLITE mineral wool slabs

They have similar characteristics and are also suitable for thermal insulation of baths or saunas.

The top of the slabs is covered with 50 micron aluminum foil (5

). This is necessary for vapor barrier of the room. The foil layer protects the mineral slabs from waterlogging and additionally reflects thermal energy. We recommend rolling out aluminum foil horizontally along the walls with the bottom sheet overlapping the top sheet.

For better sealing, the joint of the panels must be glued with aluminum tape 50 mm wide (6

)

Next, a 20x30 mm counter-rail is nailed (7

) to create an air gap between the vapor barrier and the sheathing.

The interior trim is nailed to the slats (8

). This can be eurolining made from linden, aspen, or Canadian cedar. The planks are placed in a horizontal or vertical direction.

Source

Storage

Packages with TECHNONICOL LOGICPIR Bath insulation are stored horizontally. They can be stacked. The material is placed in a dry room at a distance of at least 1 m from heat sources.

The material can be stored outdoors in its original packaging for 3 months. The packages can be placed under a canopy so that it is not exposed to sunlight or precipitation.

If these requirements are met, the guaranteed shelf life for TECHNONICOL LOGICPIR Banya thermal insulation is 2 years (from the date of production). If this period has expired, the safety of its basic properties is monitored before installation of the material.

The thickness of the material is selected according to the design of the walls (maximum thickness of the slabs is 50 mm).

Sauna insulation: 3 lines of defense against the cold

It is important to know how to properly install the insulating layer for a sauna.

To fully enjoy bathing procedures at your own dacha, you need to carefully insulate the room. Otherwise, too much effort and firewood will be spent on achieving and maintaining the desired temperature in the steam room.

Today I will tell you how to insulate a sauna from the inside with your own hands. Let's figure out what is the best material to use for this and how to install it on the walls.

Features of insulation of baths and saunas

The method of thermal insulation of a sauna or bathhouse depends on what material and technology the house itself is built from. The instructions presented in this article tell you how to insulate a room whose walls are constructed from profiled timber.

This material itself has a low thermal conductivity coefficient, so it does not require the installation of a thick insulating layer (although everything here depends on the climatic conditions of the area where the building is located).

The insulating layer performs several important tasks.

However, personally, I under no circumstances recommend abandoning insulation, since this event helps solve several additional problems:

Now about the features of the technology relating to the wooden sauna. When choosing insulation material and the procedure itself, you need to consider the following points:

Required materials and tools

Let's start with the choice of thermal insulation. I will not now list exotic methods of insulation, which include sprayed polyurethane foam or ecowool, as well as old-fashioned methods - sawdust, dry leaves, and so on.

The most important thing is to choose insulation.

There are two main options to choose from - expanded polystyrene and mineral wool. Since the first material disrupts air infiltration and, when heated strongly, releases substances hazardous to humans, I will not recommend it for work. Therefore, only mineral wool remains.

I’ll tell you a secret, this is the material I really like to use for sauna insulation. And all because it has many advantages.

| Characteristic | Description |

| Low thermal conductivity | For effective insulation of walls, a layer of wool 50 mm thick is enough, but I would recommend laying thermal insulation 100 mm thick on the ceiling and floor. |

| High vapor permeability | The material does not prevent air infiltration through the walls due to its open structure. |

| Hydrophobicity | The insulation fibers do not absorb water, liquid does not linger inside the heat-insulating layer thanks to the hydrophobic resins used to glue the material. |

| Fire safety | Basalt mats belong to the NG category, so they not only do not burn, but also serve as a barrier to the spread of fire. |

As a material, I personally chose TechnoNIKOL Rocklight basalt mats, 50 mm thick, dimensions 1200 by 600 mm. They are perfect for solving the tasks at hand. The price of this material is 590 rubles per package of 0.432 cubic meters or 68 rubles per square meter.

TechnoNikol Rocklight is an excellent insulation for baths and saunas.

But of course, buying insulation will not end with a trip to the store. You also need to stock up on other materials:

The required part is aluminum foil for the heat-reflecting layer.

Now about the tools. You will need:

Physical and mechanical characteristics

| Indicator name | Unit | LOGICPIR Wall |

| Compressive strength at 10% strain | MPa | 0,12 |

| Thermal conductivity at 25 °C | W/m*K | 0,021 |

| Water absorption by volume for 28 days | % | No more than 1 |

| Operating temperature | °C | -65/+110 |