Choosing wooden doors for a bathhouse does not seem to be such a serious problem; it would seem that it makes no difference what material the doors are made of. As long as the bathhouse is cold and dry, there is no difference. You need to heat the bathhouse a dozen times before it becomes clear how real wooden doors to a bathhouse photo differ from a homemade door leaf made from the first board you come across.

Double-chamber entrance door to the bathhouse

The presence of a vestibule prevents cold air from penetrating into the dressing room, but a very humid environment is created between the doors, which damages the structures, so the entrance door to the dressing room should be insulated as much as possible.

The most optimal option for arranging the entrance is to install a two-chamber door. The design should include 2 hollow chambers isolated from each other; inside each chamber there should be a certain volume that must be filled with insulation.

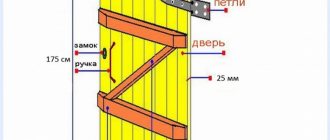

The manufacturing process consists of:

preparation of materials: wooden blocks 20 x 20 mm, 3 fiberboard panels, two of which will act as the outer and inner surfaces, and the third will act as a partition between the chambers and insulation. It is not necessary to use purchased insulation; outerwear that has gone out of use (natural fur coats, batting from coats, padding polyester, etc.) will do just fine.

manufacturing two identical frames from bars according to the size of the door leaf; making the door and installing it in place.

The sequence of work is as follows: first, a sheet of fiberboard is laid on a hard surface, face down, and a prepared frame of bars is nailed to it around the perimeter. Fill the resulting trough with insulation and cover it with a middle shield (it can be made from two components with careful adjustment of the parts).

Next, a second frame is attached to the resulting structure; it is also advisable to fill the second trough with light insulation and cover it with a third shield with the front surface facing outward.

Nails with heads or self-tapping screws must be chosen of such length that they go halfway into the cavity of the part to be joined. The end surfaces must be cleaned with medium-coarse sandpaper. It is advisable to prime the entire door and cover it with varnish or paint.

Insulation of the entrance door to the bathhouse

If the door was made for the entrance to the bathhouse, it must be insulated.

Step 1. Insulation is attached between the stiffening ribs (transverse slats made of timber)

It is important that the material does not protrude beyond the wooden blanks. You can use mineral wool, thin isolon, glass wool

It is important that the material is not heavy and does not create additional stress on the door.

Insulation of the entrance door to the bathhouse

Step 2. Leatherette can be used to finish the door. This material does not allow air to pass through, does not get wet, and looks good. Leatherette is cut to the required size (2000 mm by 800 mm + 60 mm margin on each side).

Step 3. Using nails with wide heads, the leatherette is nailed to the canvas. You can attach the material to the stiffeners, which are located around the entire perimeter of the door. To make the surface of the door look more voluminous, you can place a layer of batting on top of the insulation.

Step 4. Rollers are formed along the perimeter of the door frame, which cover the gap between the leaf and the frame.

Insulate a bathhouse door with your own hands

Step 5. To decorate the door, you can use a “carriage tie” - stretch fishing line or wire between the nails.

Thus, with a minimum set of tools you can make a reliable and durable bathhouse door with your own hands.

Insulate a bathhouse door with your own handsInsulate a bathhouse door with your own hands

Video - Making a wooden door to a bathhouse

How to properly insulate?

A simple way to insulate a bath door is to take bars and make a frame out of them, nailing it to the door with a 15 mm indent from the edges of the door leaf. And to fill the empty space inside the frame, a sheet of hardboard is placed, increasing the heat resistance of the door structure. When the door is closed, the insulation bends, blocking the flow of cold air. Other options are also possible. For example, to insulate a bath door from the cold with energyflex, this material is secured along the edge of the panel with a construction stapler. Metal slats are attached on top of everything for secure fixation. The whole job takes no more than 10 minutes.

It is possible to create a thermal curtain:

- First, let's prepare the sealing frame. Using the example of a door leaf measuring 80×180 cm, it is necessary to make 2 strips of 10×100 cm and two 10×220 cm from the seal. Then the strips are nailed along the edge of the leaf at a distance of 2 cm from the door frame.

- Next, we will make two pairs of bars, one with a size of 184x2x2 cm, the other - 80x2x2 cm. The bars are nailed on top of the insulation on the door frame. After this, the bars are wrapped in insulation, and the remains are removed. Then we make a leatherette or canvas screen 120x200 cm. We attach the fabric to the canvas, turning it on the left side to place a 2x2x200 cm block.

- We attach the 10 cm block remaining after cashing to the wall with the right side. The edge of the bar is covered with a decorative strip and rings (6-8 pieces) are attached on top.

- We screw a 60 mm self-tapping screw on top of the decorative strip. The distance should be equal to the diameter of the rings. Leave 20 mm outside. A 1 m long wire is attached to the screw and pulled through the rings. The end of the wire is secured to another screw. After this, you need to secure two springs in two places (on the left side of the canvas). Then you need to sew the rings to the screen (opposite the springs), which can now be moved in different directions.

TOP 5 main types of wood for lumber

| Photo | Name | Rating | Price |

| #1 | Larch | 100 / 100 | |

| #2 | Cedar | 99 / 100 | |

| #3 | Pine | 98 / 100 | |

| #4 | Fir | 97 / 100 | |

| #5 | Spruce | 96 / 100 |

Larch

Larch is a special type of softwood often used for lumber. In strength, it is second only to yew and oak, and its ease of cultivation and processing ensures a low price compared to elite types of wood. It is slightly susceptible to environmental influences and is resistant to moisture and sun. This is a good material that is used for floorboards, floor beams and creating walls.

Larch Pros

- high strength and moisture resistance;

- durability;

- low susceptibility to warping.

Minuses

- high thermal conductivity;

- There is a possibility of internal cracks appearing due to improper drying technology.

Cedar

Cedar is an expensive wood used for finishing buildings and creating load-bearing structural elements. In fact, products made from real cedar are almost impossible to find on the CIS market, because it grows only on a few islands in the Mediterranean. The alternative used is Korean pine, often named after this rare tree.

Cedar Pros

- resistance to rot and wormhole;

- high strength;

- minimum defects (radial cracks or ring delaminations).

Minuses

- has a specific woody aroma;

- Cedar wood is very expensive.

Pine

Pine wood is considered universal in woodworking because of its qualities. It has a lower density than larch, but processing costs are lower. Pine contains a high proportion of resins, so its durability is high. This material is used for beams, boards, logs and beams, as well as facing material. It is pine that is most often used to produce lining.

Pine Pros

- environmental friendliness;

- strength;

- long period of operation;

- easy repair.

Minuses

- pine wood is soft, easily scratched and damaged;

- Resin stains may form on the walls.

Fir

Fir is rarely used for lumber, because it requires lengthy processing. This wood has high natural humidity and low moisture yield, which is why it needs to be dried long and hard using special ovens. Therefore, this material is used only for cladding.

Fir Pros

- wood is practically odorless;

- does not contain resin.

Minuses

quickly rots and is destroyed by wood-boring insects.

Spruce

Spruce lumber has a low price and is widely available. It is a simple wood often used for cladding. Spruce timber is almost never produced; more often it is used to make saw logs or lining.

Spruce Pros

- spruce wood is practically not subject to warping;

- sticks well.

Minuses

- high humidity;

- large deformation during drying;

- a large number of branch bases.

What are the entrance doors to the bathhouse made of?

Of course, a special material for making the front door has not yet been invented; the entrance to the bathhouse vestibule is made according to samples and diagrams of conventional door systems.

The entrance door for the bathhouse is made using the most traditional materials:

- Completely wooden, or with internal metal inserts;

- Metal, often with wood lining inside and metal on the outer lining of the door leaf;

- Plastic, with or without a metal frame.

The wooden entrance door to the bathhouse is considered the most common; it is made of wood in 70% of cases. The metal structure is installed in bathhouses and dachas, in country houses located far outside the city. Plastic doors are used for bath buildings attached to the house, and they are very beautiful, and there are no problems with steam and excess moisture.

Selection of materials for bath doors

Modern bath door designs are made from practical and durable materials: wood, metal, glass, plastic, combined materials (MDF, chipboard and plywood). Each of them has exceptional performance characteristics.

Made from wood

A classic version of door designs for a private bath. Wood has a number of significant advantages: safety, environmental friendliness, high thermal insulation, ease of processing and maintenance, and attractive appearance.

Since wood is prone to moisture absorption and is partially susceptible to temperature changes, certain tree species are used to make the structure:

- Oak. Durable and practical, but prone to cracking when overheated.

- Larch. It has antiseptic properties, is resistant to rotting and insect damage.

- Linden. It has a mild tonic effect, has a pleasant odor, but is prone to darkening and rotting when exposed to moisture for a long time.

- Pine. Strong and durable, with a light pine aroma, resistant to temperature changes and overheating.

- Aspen. Cheap and easy to process. Resistant to cracking and deformation when dry.

- Spruce. Capable of quickly absorbing excess moisture, so it needs frequent drying.

Increased demands are placed on a wooden structure: it must withstand temperature changes and high humidity, but at the same time retain heat indoors. All this can lead to condensation accumulation and rotting of the wooden surface.

The best solution to the problem is to treat the wood with moisture-proofing compounds or install a frame structure with internal thermal insulation.

From glass

Glass doors are often installed in hammams and saunas. They are distinguished by aesthetics, convenience, resistance to high temperatures, humidity, rotting, and ease of use.

The steam room and washing room can be equipped with glass doors.

Among the design disadvantages are the following: the high cost of raw materials and components, the difficulty of manufacturing the product on our own. In addition, the glass sheet requires a technical gap of 3 cm from the floor level, which can lead to constant drafts.

Made of metal

Entrance doors are often made of metal due to its high strength, wear resistance and durability.

In addition, the metal structure is easy to use, resistant to deformation, mechanical damage, rotting, changes in temperature conditions, and high-quality thermal protection reduces the likelihood of corrosion and heat loss.

Insufficient insulation can lead to the formation of condensation, so for a private bath it is better to use a door made of a metal frame with a heat-insulating layer. It is a metal base, the interior of which is filled with insulation, and the outer surface is sheathed with plywood, board or chipboard.

Thermoplastic

The thermoplastic product is highly resistant to temperature changes, high humidity, hot steam, practicality and durability. The door leaf can have a classic design or be an imitation of wood, glass and metal surfaces.

Plastic doors can be installed for any room - washing area, steam room, relaxation room and dressing room.

Made from chipboard, MDF and plywood

Bathhouse doors can be made of artificial materials - chipboard, MDF and plywood. They are characterized by low cost, resistance to humidity and overheating, and are less susceptible to deformation and rotting in contrast to natural materials.

The service life of such products is much shorter, and the parameters of environmental friendliness and safety are questionable, despite the assurances of the manufacturers. The quick and easy production of doors from artificial materials is their indisputable advantage.

We insulate the door in the dressing room

In cold weather, going to the bathhouse is a special pleasure; after warming up in the steam room, the body is in a comfortable, healthy state for a long time, so you want to stay in the bathhouse longer. In order not to overheat, you need to periodically enter the dressing room, and then continue the thermal procedures.

It’s good when the dressing room is built taking into account the lowest temperatures and is comfortable in it, because if the cold comes from the floor, then you won’t sit in such a dressing room for a long time, you can easily catch a cold and the impression of such a trip to the bathhouse will remain negative. Most often, the cause of discomfort in the form of a cold draft is the loss of sealing of the entrance door to the bathhouse.

Hanging blankets on the door or installing a second block do not solve this problem, but, perhaps, aggravate it by the fact that frost forms on the inside of the door and in some places the canvas freezes to the jamb. Then it becomes impossible to open the bathhouse without an ax; mechanical impact can lead not only to the formation of even larger cracks, but even to breakage of the block.

Features of Akma door production

Glass doors for baths and saunas have been produced by the Akma plant since 1998. The company offers 220 models of door structures for steam rooms, washing rooms and other premises.

Production is fully automated. The plant's equipment allows us to produce products of high optical purity and hardening strength, with a ground surface and a Euro-edge. For production, we use materials that meet European standards and GOST requirements. Each product undergoes quality control for strength and ability to spontaneously explode. At the same time, the price of the finished product is affordable.

The Akma sauna door has a number of advantages:

- Environmental friendliness of materials.

- Durability. The plant provides a five-year warranty on its products, provided they are used correctly. Glass and anodized aluminum are non-corrosive and non-toxic when heated.

- Safety.

- Hygienic: resistant to mold, easy to clean.

- Tightness. All Akma glass blocks have a closed perimeter of the door leaf, and the frame joints are adjusted on an automated German production line.

- High temperature resistance.

- Multifunctional design. They can be right- or left-handed and are suitable for steam rooms, washrooms, bathrooms and other rooms.

- Possibility of installing a magnetic closing mechanism.

- Original design. Akma products are decorated with fusing, diamond engraving, deep sandblasting, silk-screen printing, ceramic printing, photo printing, and colored varnish. You can choose transparent, tinted or colored door leaf.

The finished door for the Akma sauna consists of a glass door leaf 6 or 8 mm thick, a wooden frame, hanging hinges and a handle. All the necessary holes are drilled at the factory, so installation of the structure is simple - just follow the instructions for the product.

Assembling a glass door structure

Such doors are made only from glass, the thickness of which is at least 8 mm. This material is heat resistant, that is, when exposed to high temperatures, it will not burst, and the door will not be deformed. The glass door leaf should not be closed tightly so that the room does not become stuffy. To do this, a space of about 5 cm in height is created between the door and the threshold.

Necessary materials

The choice of material is influenced by what kind of glass door you plan to make. It can be created from a single sheet and complemented with metal loops with a handle. If this option is not to your liking, then the door is made with glass inserts, that is, from lumber or paneled frames. You can create and install a solid glass sheet yourself. It is advisable to purchase a sheet of standard sizes: 1.7 m high and 0.8 m wide.

In order for the glass door between the washing room and the dressing room to look aesthetically pleasing, its leaf should be tinted or decorated with a pattern. You shouldn’t buy completely transparent glass for one more reason: it’s invisible, and therefore everyone will bump into it during their first visits to the bathhouse.

In addition to the glass sheet, to make the door you will need:

- door frame made of durable aluminum or glued profiled aspen;

- fittings (practical handles that will not burn, and canopies that ensure reliable fixation of the glass in the box);

The hinges that can be used to secure the glass sheet are made of metal - silicone seals necessary for a tight fit of the glass to the door frame;

- Magnetic type latching mechanism (3 pairs of magnets are enough);

- 2 loops;

- screws;

- anchors;

- decorative plugs;

- protective film (optional).

Tools

To assemble a door from prepared materials you will need several tools:

- screwdriver;

- a drill with a metal drill (if the door frame is made of metal);

- glass cutter;

- hammer;

- building level.

Guide to creating and installing a glass door

The glass door structure is manufactured in stages:

- A sheet is cut out of a glass sheet to fit the dimensions of the doorway (the height of the workpiece should be 5 cm less).

- Holes for hinges and handles are made in the glass sheet.

- 4 frame elements are attached to the doorway using anchors.

Glass is inserted into a box made of wood or metal - The bolt heads are covered with decorative plugs.

- Hinges are screwed to the door frame, onto which the door leaf is later installed.

- A handle and magnetic latches are attached to the glass.

It is desirable that the handle be wooden - Glue the film onto the cleaned glass sheet, carefully smoothing it out and getting rid of bubbles. The excess around the edges is trimmed off.

Entrance doors to the bathhouse

There are no special features here. You need to keep warm and protect yourself from thieves. Therefore, you can install any doors to the bathhouse from the street, even metal ones. The main thing is good thermal insulation: heat cannot be released. But there are problems with the iron door. They do not lead, they do not swell, they are reliable and retain heat well (if they are well insulated). But in winter, having opened it and jumped out to cool off, you will definitely close it - don’t let the bathhouse dry out. But back, if you accidentally touch the surface, you will freeze instantly. Here is a review of the entrance metal door in the bathhouse:

Metal steel door to the bathhouse - reliable and warm, but you can freeze

This problem is also solved: the outside is sheathed with wooden slats or clapboards and varnished. No problem.

In general, there is nothing better for thermal insulation than a well-made solid wood panel. A thick board (you can use tongue-and-groove flooring) retains heat well, and also suits the style of most country baths. There are some for sale, but if you don’t trust factory-made ones, you can make the outer door to the bathhouse yourself. If you need good insulation, then you can knock down two panels, fill the bars between them, and fill the gap with insulation. Then connect both shields and decorate the perimeter with a thin strip. The result will be warm, economical and reliable.

Entrance door for baths and saunas made of wood

But the wooden entrance door to a bathhouse is not without its drawbacks: it rots and swells. Rotting can be combated with impregnations and antiseptics. There is no way to deal with swelling. This was the case in a bathhouse near Arkhangelsk:

And here is another review about a wooden street door to a bathhouse:

The third option - the entrance door to the bathhouse - is plastic. If there are no security issues, then this is a good option. And the color can be made to order: exactly like wood. The imitation is so good that until you touch it with your hand, you won’t understand that it’s plastic. Their cost is higher than white ones for the door by about 2 thousand rubles.

Plastic entrance doors to the bathhouse - another opportunity

There is also an option: a frame door, but the frame is made of steel, and a sheet of metal is also welded on the outside. There is good insulation inside, both sides are covered with boards or block houses. A great option for those who like to do everything with their own hands. In principle, you can order the production of the entire structure, or just the metal part (and the door frame too).

Choosing a door: what you need to know

When choosing a suitable product, in order not to make a mistake, you should take into account both important characteristics and finances. The best option from both a functional and economic point of view is a blind door structure made of linden.

If your goal is to surprise guests and friends with traditional and impeccable bath interiors, you should think about purchasing luxurious linens made from valuable species. For those who want the interior to be not traditional, but rather modern, it is recommended to opt for elite combined models with tempered glass inserts.

Safety in a bathhouse is very important and wooden bathhouse doors must meet all its requirements. So, for a steam room it is necessary, as already noted, to choose the right fittings. Experts and those who like to take a steam bath in a traditional Russian bath do not recommend fashionable stone products - they become very hot during the process and you can get serious burns from them.

Fire safety for a door to a steam room is also an important requirement. The canvas should be as fire resistant as possible. Today there are many compounds on sale that will give wood these necessary properties. They can also significantly extend the life of the product.

Which model to choose is a personal matter for the person who chooses the door. You just need to remember about resistance to humidity and high temperatures - this is the key to high quality.

Materials

Bathhouse doors can be made from various materials.

Glass

Glass doors are popular in Turkish and other baths for a reason. This material can easily withstand high temperatures, is not afraid of humidity and does not require fastidious care of the panels. The glass used to make the door should be heat-resistant, impact-resistant and tempered. Glass doors are always supplied with silicone seals, which are necessary to ensure tightness when closing.

In addition to the fact that a glass bath door looks completely beautiful and is distinguished by its inherent attractiveness, it has an almost unlimited service life, which is not a characteristic feature of wooden doors. Glass is not inherent in the process of rotting, deforming and releasing harmful substances, however, installing a glass door yourself so that it complies with safety standards is very difficult and prohibitively expensive.

Tree

Another equally popular material used to make bath doors and considered traditional and the most functional is wood. It is best able to withstand any changes in temperature and humidity. The most reliable option when choosing a material for a bathhouse door with your own hands and preferred by experienced craftsmen is tightly knit boards made of aspen and linden. Doors that are particularly massive are usually made of wide and tongue-and-groove boards.

For doors that are installed at the entrance to the steam room, cross beams or, as they are often called, dowels are considered mandatory elements, they are necessary to securely fasten the boards and prevent their deformation. It is advised to choose timber and forcing not from coniferous trees, but from deciduous trees, since otherwise resin will be released when heated

When decorating a door with clapboard, pay attention not only to its quite reasonable cost, the relative lightness of the covering, but also to its low moisture resistance. As a result, periodic treatment with protective varnish coatings is inevitable.

What to make the entrance to the steam room from

The wooden door leaf for the entrance to the steam room is made mainly from hardwood, very rarely from treated cedar, and almost never from young coniferous wood. No one wants to touch with their hands the drops of resin and resin that sweat on the wooden cladding when trying to open the door and leave the steam room. Therefore, internal doors for bathhouses are made from linden or aspen. More expensive ash and chestnut are used for wall cladding and wooden furniture.

Advantages of linden doors

The structure of linden has slight differences from other most common species. Linden has a developed network of surface microcapillaries filled with air. The thermal conductivity of linden is significantly lower than that of pine, ash or oak, therefore, if you touch a wooden door lining heated in a steam room with your hand, it will not seem as hot as in the case of oak or cedar trim.

Linden fibers are quite thin, the material itself is very soft and easily deformed. Therefore, even with strong heating, linden steam room doors will never jam or become deformed. In addition, it is enough to simply insert heat-resistant glass into a linden door leaf; even with severe overheating, the glass insert will not burst.

The main disadvantage of linden is the poor durability of the material. A wooden door lined with linden must be thoroughly dried and conditioned; any puddle under the door can lead to rotting of the finish.

A wooden entrance block for a steam room is never made in the form of a single solid mass or sheet of tongue-and-groove boards. Most often, an oak frame with insulation is sheathed with linden clapboard, this allows you to effectively insulate heat and ventilate moisture from the door leaf.

Aspen door leaf

Aspen wood has characteristics similar to linden. A light, soft and at the same time well-insulated material is much cheaper than linden, so aspen doors are not inferior in popularity to linden.

Aspen is classified as a soft and low-strength species, so frames or boxes are never made from it. Unlike linden, the structure of aspen has huge pores, so the surface without treatment quickly loses its light background and darkens.

Aspen doors for bathhouses withstand strong moisture and condensation; the lining, even in its untreated form, practically does not rot, warp or deform, so it is ideal for the steam room of a small apartment bathhouse.

Fabrication

The simplest version of a door to a steam room with your own hands is a shield made of solid wood. To make it, you need to select tongue and groove boards and lay them out on a flat surface. At the ends there are curved stripes - traces of the annual rings of the tree. Adjacent parts should be positioned so that the direction of the rings is opposite to each other. This way the door strips will not be damaged by moisture.

The grooves of the boards and their protrusions must be connected so that a minimum gap remains. Cut 2 bars, the length of which is equal to the width of the door leaf. The bars are mounted on a board panel at the top and bottom of the structure. The connection can be made in different ways:

- Place the block on the surface of the boards in the transverse direction. Fasten with self-tapping screws, screwing them in from the side of the block so that there are no traces of fasteners left on the front side. Sometimes they do it differently and drive the fasteners into the front side of the door, recessing the heads into the wood. The recesses are covered with a special composition of glue and small sawdust. For the strength of such a structure, it is advisable to install a jib located diagonally between 2 parallel sections of the bar.

- Connection without fasteners is more difficult. To make a canvas, connect the boards and place a 5x5 cm block on top, cut on both sides. Its profile resembles a trapezoid. The narrowing is 1.5 cm and is performed smoothly along the entire length of the part. Draw lines on the canvas corresponding to the profile of the bar. Cut out a groove, deepening it by ½ the thickness of the block and observing the angle of inclination of the side surfaces. Remove the wood from the groove with a chisel and level the surfaces. Push the bars in from the wide side of the groove. In a room with high humidity, the mount will not dry out.

From lining

To assemble a door from a lining, you need boards at least 2.5 cm thick, with selected quarters on the sides facing the inside of the panel. The length of the vertical bars of the strapping should be equal to the height of the canvas, and the horizontal bars - to its width. Connect the frame parts using the half-timber method, selecting part of the wood at the ends of the planks. Lubricate the recesses with glue, connect the parts and tighten them with clamps. After drying, drill through holes and insert wooden dowels into them using glue.

Cut the lining into equal sections. Their length is equal to the distance between the boards in the selected quarters (vertical or horizontal). Cut off the side with the groove at the outer lining, and place the part in the frame, in the groove of the selected quarter. The remaining elements are joined, pressing the tenons tightly into the grooves. Cut the last board so that it fits tightly into the remaining gap. Attach a wide glazing bead around the perimeter of the frame.

Frame-panel

When making such a sheet, it is worth considering that in order to insulate it, a heat-insulating layer must be placed inside the door. Therefore, you need to prepare an EPS sheet or other material in advance. Make the frame from a 3x3 cm block:

- choose ½ thickness at the ends for a length of 3 cm from the edge;

- connect long and short bars into a frame, placing the selected parts on top of each other so that the joining surfaces form one plane;

- screw the screws into the joints of the planks;

- make 1-2 transverse spacers, choosing a groove in the long planks in the same way as at the ends.

Attach plywood or MDF to the frame on 1 side of the door. Place insulation between the bars and foam the gaps between the EPS and the slats. Cover the top with a sheet of plywood and attach it with self-tapping screws around the perimeter and to the crossbars.

How to make a wooden door for a bathhouse

Stage I. Material

Before making a wooden door, first decide on the material. The most accessible and inexpensive is considered to be an array of coniferous wood (spruce, pine, cedar, pine needles). Pine is considered a durable, stable material, while spruce does not darken for quite a long time, maintaining its original shade. But it is worth considering the ability of coniferous material to “cry” with resin and the rich pine smell when heated.

Solid hardwood (aspen, linden, oak, alder, larch) contains a smaller amount of resins; therefore, resin streaks will not appear on the product, releasing a pronounced aroma upon evaporation. Hardwoods are distinguished by their beautiful texture. Bathroom doors made of solid wood are characterized by increased strength and long service life, but there is a possibility of cracking. Substances inside larch act as a natural antiseptic, so such wooden products are not subject to destruction by bugs and rot. When heated, linden releases phytoncides, which have a healing effect on the respiratory system, but, unfortunately, without regular treatment with special antiseptic compounds, the tree quickly darkens and rots. Of the hardwoods, aspen is considered the cheapest. A self-made aspen door retains its original shade for a long time and does not crack when dry.

Stage II. Quantity of material

For the door to the steam room you will need the following materials:

- Glued laminated timber 50x50 for the jamb;

- Board 50x30 and strapping beam 35 mm thick for the canvas;

- Box timber of the same wood species as the board for the canvas, of suitable length with dimensions 60x80;

- Canopies, wooden handle, latch or latch.

Stage III. Tool

The wooden door to the bathhouse is assembled using a standard carpenter's kit, which consists of a jigsaw (hacksaw), hammer, chisel, milling cutter, plane, screwdriver or screwdriver, as well as screw-on hardware and dowels.

Stage IV. Manufacturing process

The door to the bathhouse, when made with your own hands, can be made of a board, a board with strapping, or be paneled.

The simplest and fastest way is to make a door from boards of equal size, which are connected to each other in such ways as gluing smooth sides, inserting a tongue and groove or a quarter along the edge. The last two methods are made from a ready-made purchased tongue and groove board or cut out using a router from an ordinary board.

The boards assembled into a single structure are fastened together across and diagonally with bars from the outside. To do this, threaded hardware and a screwdriver are used. The finishing touch is screwing the awnings. In order to make a door with a sauna frame, recesses (grooves) are cut into pre-fitted bars using a milling cutter, into which boards for the canvas and tenons of horizontal bars (in the upper and lower parts of the sash) will then be inserted. The tongue-and-groove connection is fixed with self-tapping screws. Do-it-yourself products are reduced by the width of the strapping beam so that the door fits tightly into the door frame. There should be no gaps between the components of the wooden door structure.

Stage V. Installation

Before installing the doors to the bathhouse, the door frame is screwed onto the pre-blocked opening. Then the hinges are screwed on, the canvas is hung and fittings (handles, latches) are installed. The risk of skewing can be minimized by installing 3 hinges: at the top, in the center and at the bottom of the door.

You can see how to install a door to a bathhouse with your own hands in the video clip above, which shows all the stages of installation step by step.

Installation of sliding glass doors in the steam room

The installation procedure steps are as follows:

- Measure the item to be installed and add fifteen centimeters from the edge to mark the guides

- Apply these marks on both sides of the opening and connect using a level, drawing a line with a pencil or marker

- Check the width of the opening. The gap between the wall and the guide should be no more than 5 cm

- Fasten two guides along the drawn lines

- Fasten with dowels if the floor is concrete. If the flooring is wooden, then use self-tapping screws

- Assemble all the carriages and tighten the bolts. No need to tighten tightly

- Take the glass door and insert it into the top guide carriage. Then insert into the grooves and secure with bolts. Align vertically

- Press the canvas using paranitic gaskets

- Using a level, check the door horizontally and vertically. Give both canvases a ride.

Wait three days and you can use the steam room. Next, we will consider a manual for installing a wooden door.

Glass door to the steam room of a Russian bath: advantages and disadvantages

The conditions of the Russian steam room are very different from the Finnish ones. Humidity is much higher and temperatures are lower. In such an atmosphere, the tree inevitably swells. The exception is linden, which is why wooden doors to the steam room are recommended to be made from its wood.

It is in the Russian bath that the property of glass to preserve its original geometry is in demand.

But here’s the problem: manufacturers of doors made from it are focused on products for saunas, so they make a gap of several centimeters at the bottom. That is, it is usually a door without gaps with a gap to the floor of 2-5 cm. For a sauna, which is based on strong constant convection (air heat exchange), this is a necessary detail. But in a Russian bathhouse, uncontrolled convection is evil.

...usually this is a door without thresholds with a gap to the floor of 2-5 cm...

Therefore, traditional doors are made low and with high thresholds: you need to leave enough space at the top - a “pocket for a steam cake”, and put an obstacle in the form of a threshold at the bottom so that cold air from outside does not penetrate the floor.

Ceiling and threshold in a Russian steam room

Unfortunately, it is unlikely that the glass sheet will be able to be independently adjusted to the requirements of a Russian steam room.

IMPORTANT! There should be no gaps at the bottom if you have a Russian steam room.

But even if we assume that someone managed to make the required size to order, the next problem will be the already mentioned condensate.

Glass and tiles are the places where it forms first. Therefore, you should not be surprised if by the end of the procedures a puddle of drained condensate forms under the door. It goes without saying that the transparent glass will become matte, like a bathroom mirror.

Heat loss was discussed above. Nothing changes here: you have to pay for beauty.

CONCLUSION: glass does not swell and does not lead to damage. This is where the advantages end, because a standard door with a gap at the bottom is not suitable for a Russian steam room.

Features of bath doors and requirements

A real Russian bathhouse is built from logs. Not only its exterior, but also its interior decoration, fittings and design elements are made of wood. Bath doors were traditionally also made of wood, but today a large assortment of glass bath doors of various designs and designs has appeared on the market.

Doors made from natural, eco-friendly wood fit perfectly into the interior of a bath room, and they are distinguished not only by their aesthetic appearance, but also by their high functionality and practicality. The wooden canvas can withstand thermal effects with sudden changes, the action of wet steam and biological microorganisms.

The advantages of doors made of natural wood are:

- High quality, operational reliability and long service life of the structure.

- When heated, wood releases essential oils that fill the room with a pleasant healing aroma,

and also create a comfortable and serene atmosphere for rest and relaxation. - Low thermal conductivity of the canvas

(there is no risk of burns upon contact with the doors). - Wood perfectly retains heat in a steam room.

- Affordable cost

(wood is easier to process compared to glass and other materials). - Safe operation, no release of toxic substances when heated.

Note!

A significant disadvantage of wooden doors is the possibility of deformation of their structure as a result of prolonged and intense exposure to steam and maximum temperatures, which leads to drying and swelling of the canvas, deterioration of its closing and opening. To prevent these unpleasant consequences, bathhouse doors must be treated with special impregnations.

Since the bathhouse consists of several rooms, more than one door is installed during its construction. Depending on the installation location and functional purpose, entrance and interior doors are distinguished. Wooden entrance doors protect the interior from the influence of the external environment and prevent the entry of unauthorized persons. Their design should not have gaps through which cold air from the street will enter the vestibule or dressing room.

Interior doors for other bath rooms have a simpler design; they can be made of wood with various inserts or heat-resistant glass.

How to choose

Nobody argues about the reliability of the entrance structure. But we are not talking about a safe option. The presence of a complex mechanism can lead to trapping people inside the room if a fire occurs. Therefore, the outdoor model for the bathhouse should be standard, with hinged doors. If the choice fell on a single-leaf metal or wooden model, then the locking mechanism should be elementary.

Only for a steam room, the design must have certain functionality. Many people prefer to buy glass products. Especially when it comes to indoor small saunas and infrared saunas. Combined or wooden products are chosen for a regular bathhouse. Although glass ones are superior to their wooden counterparts in many respects. Therefore, whether to purchase a wooden or glass model is up to everyone to decide for themselves.

Basic requirements for such structures

The classic Russian bathhouse is a wooden frame, so the internal contents must correspond to the style. Traditions require the installation of wooden elements, which must have such properties as resistance to temperature changes, not heating up, and not being afraid of constant humidity. Among other things, they must have an attractive appearance.

Wooden elements have many advantages:

- Ecological cleanliness.

- Presence of natural aroma.

- Therapeutic effects on the human body.

- Pleasant sensations for visitors to the steam room.

- Low thermal conductivity.

- Attractive design.

There is one serious drawback to such products. Constant exposure to extreme conditions leads to deformation of the structure and shrinkage and, as a result, the need to completely replace the product.

The fabric parameters for the steam room are slightly different from the standard ones. A small threshold (10 - 15 cm) is made at the entrance itself to prevent steam from escaping. If the ceiling height is 220 - 250 cm, then the height of the canvas should be 160 cm.

Doorway

In bathhouses of modern design, special stoves or electric fireplace systems are used. Thanks to this equipment, the room is constantly maintained at comfortable and required temperatures. If cold air enters a room, it will heat up almost immediately. Even more - modern equipment requires a constant small flow of air to operate. The wooden door for the bathhouse at the bottom has a small gap, which solves the problem of ventilation.

The optimal size for a doorway in a steam room is 1.8 x 0.8 m. At the same time, the ceiling height should be approximately 2.2 m. You need to know that in a traditional steam room the distance from the top door strip to the ceiling should be at least 40 cm. All depends on the door design. In the case of a wooden door, there may not be a threshold.