If a project to build a house or renovate a city apartment involves wooden floors, then the contractor will be faced with the issue of choosing lumber. Not every novice craftsman knows which timber to use for floor joists. After all, logs are the support of the floor structure, which will be affected by all loads, from the floor covering to furniture and people. Therefore, the most important condition for constructing a floor is to ensure its long-term operation, based on the high strength characteristics of the materials used. As for the logs, first of all they are selected according to the cross-section on which the strength of the beam depends, and according to the laying step between them.

If you choose the right parameters of the timber, you can save a lot of money on construction activities related to the construction of the floor structure. And although today manufacturers offer logs made of plastic, reinforced concrete and metal, wood remains a popular material, which is cheaper than all the others.

Advantages of wooden logs

In addition to the low price, wooden logs have other advantages.

- Installation is carried out manually without the use of special equipment and complex mechanisms. This again affects cost savings during the construction or renovation process.

- Utility lines can be installed in the space between the lags.

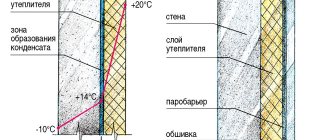

- The insulation is also installed here. Depending on the thickness of the thermal insulation layer, the logs are selected according to their width.

- Wooden beams are a lightweight material, so they do not exert significant loads on the load-bearing structures of the building.

Calculation of logs from LVL timber for the floor

LVL (Laminated Veneer Lumber) is a very durable composite material consisting of wooden lamellas glued together.

It resembles very thick plywood and has a similar manufacturing process.

Using this structural material, you can build very interesting and beautiful wooden buildings, both externally and from the point of view of engineering solutions.

But, in this article we are talking only about the floor joists of a frame house. And my opinion is that in a frame house it is advisable to use LVL beams in single copies as a support beam for the floor.

Use where it is necessary to cover very long openings. And no other way. By the way, the solution in the photo above seems to me unreasonably expensive and unnecessary.

Due to the fact that LVL timber is an exclusive solution, there will be no tables on it. LVL timber is almost always made individually for each opening and each ceiling.

Criteria for choosing wooden blocks for joists

Much will depend on where the joist structure will be assembled. There are several options here, these include floors on the ground, on a concrete base, and on the foundation, when the logs are installed in a canopy. Based on this, the section of the beam is selected, of course, taking into account the distance between the installed elements.

For example, if floors are constructed in a city apartment on a concrete screed, then there are no strict requirements for the size of the bars. The main thing here is to comply with the parameters of the ceiling height, and if necessary, then the parameters of the insulation. If a wooden floor is installed on the ground floor, then the minimum width of the bars used should be 70 mm, because this is the thickness of the insulation that will ensure good thermal insulation of the apartment. In this case, the bars are laid on the edge, that is, on the smaller side of the section, which means that the width of the lumber will be the height of the joist structure.

As for the thickness of the timber, the optimal ratio to its width is 1:2. Since in the example the width parameter of 70 mm was chosen, the thickness of the bar will be either 35 or 40 mm. In this case, the thickness determines the stability of the installation. And the larger it is, the stronger the lag will stay on the surface. But this increases the cost of the product. Therefore, it is necessary to choose the optimal option for the aspect ratio of the beam section.

When constructing a floor in an apartment that is not on the first floor, you do not need to use the standard section aspect ratio. Here you can choose any timber, because the logs are laid on the same concrete floor only without a heat-insulating layer, the dimensions of which are no longer taken into account. These can be bars with a cross section of 40x40, 40x50, 50x50 mm. In this case, the smaller the size of the log height, the higher the ceiling after the construction of the wooden floor.

What does incorrect calculation of floor joists for a frame house lead to?

The Internet is full of reviews about how floors in frame houses sag, creak and spring. There are a lot of tearful texts and videos on this topic.

Thanks to this profanity and populism, a widespread opinion has already formed that a frame house is bad.

Despite the fact that there are a lot of negative reviews, they do not contain one important detail - a true story that in fact these frames were built either by defectors from advertised companies, or by the hands of crooks from crews found in unclear places.

Just as there is no clear explanation of what to pay attention to when installing the floor of a frame house as a whole and what parameters of the lag for the floor of a frame house are important in particular. Many people try to do the right thing, but...

...for example, I don’t like everything in these videos. To put it mildly…

Actually, this article will show the simplest way to calculate floor joists and talk about the main parameter that affects the quality and reliability of the floors of a frame house.

Important

It should be noted that logs (beams) are just one of the components of the floor structure of a frame house. In a high-quality ceiling, all structural elements must be used and all of them must be matched to each other in terms of parameters.

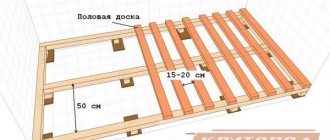

Lag structure on load-bearing beams

The construction of floors using load-bearing beams is common in private housing construction. It is also used to construct building floors and, if necessary, to form floors with a ventilated underground. In this case, the logs are attached to the installed beams only at their ends. The same design is used when constructing the floor of small rooms on the ground floor, when the logs are installed with their ends on the foundation.

In this case, the choice of bars, or rather the choice of their cross-section, depends on the length of the lumber. The longer the beam, the larger its cross-section should be. Here are the recommended values for this ratio.

- The length of the log is 3 m - the section of the timber is 150x80 mm.

- Length 3-4 m – section 180x100 mm.

- 4-5 m – 200x150 mm.

- More than 5 m – 220x180 mm.

If the structure is installed on the ground floor with the installation of logs along the foundations, then the indicated dimensions can be reduced by constructing intermediate racks made of brick, pipes or concrete. But with this arrangement, the distance from the lower edges of the joists to the ground is taken into account. It should not exceed half a meter. If this indicator is greater, then the beams are installed without support posts. This means you will have to purchase lumber in sizes from the list described above.

Linear dimensions of beams

Length and width are the main parameters that must be taken into account when choosing beams for arranging a wooden frame. How to make a competent parametric calculation?

The cost of installing a dry floor screed

- Definition of width. As already noted, logs with a rectangular cross-section are chosen for the subfloor. During installation, they are laid on edge to give the structure greater rigidity. In this case, the formal width of the beam should be 2 times less than the height;

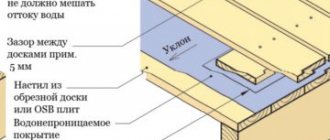

- Determination of length. The length depends on the area of the base itself. However, it is advisable to select the size of the logs taking into account the technological gaps - the distance from the beam to the wall should be approximately 3 cm. The gaps are made in order to avoid significant deformations of the wooden frame during thermal expansion of the material.

Distance between joist elements

Logs are a support for the flooring, plus everything that will be placed on the floor: furniture, household appliances, musical instruments, etc. These are static loads. There are dynamic ones, which include the movement of people and pets. Both loads must be taken into account when choosing the distance between the lags. It is difficult to do this at the construction stage, because it is not yet known what furniture and in what quantity will be installed in the room.

Therefore, it is recommended to use the thickness of the flooring as a basis for calculating the lag spacing. For example, if it is plywood or OSB boards, then their small thickness (16-22 mm) determines the minimum step - 30 cm. As for floorboards, everything will depend on their thickness.

- If the thickness of the board is 20-25 mm, then the distance between the logs is set within 30 cm.

- If boards with a thickness of 30-35 mm are selected, then the installation step will be within 50-60 cm.

- Accordingly, 40-45 mm – 70-80 cm.

- 50 mm – distance within 1 m or more.

It should be noted that the pitch of laying the logs is the distance between the middles of the bars along the longitudinal axis, and not between the edges of the elements. From the calculation of this parameter, the number of required beams for the logs is also calculated. In this case, one technological point is also taken into account - the distance from the walls to the outer elements of the floor structure is 25 cm.

Calculation of logs from boards for the floor of a frame house

The most common and affordable material used to install floor joists in a frame house are boards. Standard sizes of boards that you can buy at any retail outlet in our vast country:

- 200x50 (195x45)

- 150x50 (145x45)

Several important notes on the procedure for selecting lag parameters for the floor of a frame house using tables:

- due to the fact that it is extremely difficult to find real dry planed calibrated boards on the Russian construction market, when purchasing materials, special attention should be paid to the quality of boards for floor joists (beams),

- I certainly hope that you will not place tanks, cars and other important multi-ton household utensils on the floors of your frame houses, but just in case, the table shows the log parameters for a fairly high load - 300-400 kg/m2.

| Board size | Distance between joists (center) | Maximum span length |

| 150x50 mm | 400 mm | 3480 mm |

| 600 mm | 2850 mm | |

| 200x50 mm | 400 mm | 4240 mm |

| 600 mm | 3460 mm |

As you have already noticed, the main parameter that we select is the span length. In other words, the distance between the supports - the load-bearing walls of a frame house.

It should be understood that the width of the board is 200 (195) or 150 (145) in the case of using a log of this size in the ceiling of the first floor directly affects the thickness of the insulation. That is, when using boards as joists, the maximum insulation of the first floor floor will be 200 mm, which is not so much in modern times. It is also obvious that this thickness of insulation is completely unsuitable for energy-efficient houses.

These conclusions smoothly lead us to the need to use other, more modern materials in ceilings.

Wood moisture content

Dry wood is the key to high quality and long-term operation of a wooden structure. Therefore, builders recommend using bars with a humidity of no more than 20%, preferably within 12%, for the construction of a joist structure. In construction stores, all lumber is sorted according to this indicator. But there is no guarantee that this is true, because storage conditions in stores are sometimes violated. This means that the actual humidity of the purchased timber may not coincide with the passport value.

You can accurately determine the moisture content of lumber using a special device called an electric moisture meter. This is a device with two pins protruding from the body. They need to be stuck into the wood being tested. The display shows the humidity values. Everything is quite simple if you have this device in stock.

There is another way. To do this, a piece is cut from the block with a saw, which must be weighed. Then it is placed in an oven preheated to +100C and dried for an hour. The dried piece is weighed again. Now we need to do some math:

- The second value is subtracted from the first weight.

- The result obtained must be divided by the final (second) weight.

- The resulting number is multiplied by 100%.

- This results in the moisture content of the lumber.

All this, of course, is accurate, but difficult. Therefore, craftsmen have long used purely visual criteria for determining the moisture content of wood. For example, you can run a chemical pencil along the cut. If the line turns bright purple, then the humidity is high. And vice versa.

Humidity is also determined by chips. In dry wood it is brittle, in wet wood it is elastic, bends well and does not break. You can knock on the beam with a metal object. If the sound is dull, it means the humidity is high. If it is sonorous, then it is low. Coniferous wood releases resin when processed. If you press it with your finger and it crumbles under pressure, then you can talk about dry lumber.

Section and dimensions

There are exact values for spans:

- No more than two meters, the cross-section is 60x110 mm.

- For three meters you need a size of 80x150 mm.

- Four are already 100x180 mm.

- Five meters requires a material of serious strength, so the minimum is 150x200 mm.

- A span of six meters is the maximum, and we naturally select the maximum cross-section of 180x200 mm.

You also need to take into account the distance when working with the floor. And for this there are the following characteristics:

Wood for logs

Since logs must withstand heavy loads, and at the same time not change their qualities and dimensions under the influence of changes in temperature and humidity, timber made from softwood is most often used as them. Deciduous trees have less bending strength. Namely, the logs are subjected to these loads. Although there are no strict restrictions in this regard.

Everything will depend on the budget for construction and repairs or the location of the floor. As a budget option, these are bars made of spruce or pine. But it is better not to use them in damp rooms, where the wood will be exposed to the negative effects of moisture. Under its influence, the lumber will begin to warp and change its parameters, which will lead to the formation of gaps between the floorboards, lifting of part of the flooring and other types of defects.

More durable materials, such as larch, will withstand any load, but such wood is expensive, which will lead to an increase in the construction budget. But such logs, even in a bathhouse, will last for decades, which will cover the initial costs of their purchase. In addition, larch contains a large amount of resin inside. Therefore, bugs and other harmful insects do not touch it.

Today, manufacturers offer various easy-to-install devices that determine the speed and quality of lag installation. And if the traditional installation option is logs secured with wooden bosses to the base floor surface or nails to load-bearing beams (sometimes additional fastening is done using binding wire), then the modern approach is special fasteners.

One of the varieties is metal fasteners in the form of profiles of various shapes. These are perforated parts with which the logs are attached to the load-bearing structures of the building. The photo below shows how the logs are attached to the concrete base with metal corners.

Another type is adjustable supports made of metal or plastic. The supports themselves are attached to the base with anchors or screws, and the beams are installed on their structure. In this case, the logs can be raised or lowered by rotating the threaded connection of the supports.

What are lags?

Beams located longitudinally and transversely on a rough foundation in a room are called joists. Boards are attached to them to form a wooden floor. To make logs, dry, first-class wood is used, which must be tarred, treated with antiseptic and fire retardants, as well as compounds against damage to the material by rodents and insects.

The logs shown in the photo perform the following functions:

- a flat floor surface is created and the load on the foundation is correctly redistributed;

- an air gap is formed between the rough base and the back side of the floor board;

- the space between them can be filled with sound and heat insulating materials, which leads to a decrease in noise pollution and reduces heat loss;

- Thanks to their installation, it is possible to quickly replace a floor covering element that has become unusable.

If the floor joists are calculated and installed correctly, the wooden floor will last for many years.

Reviews

Oleg, 34 years old, Novosibirsk

When building the bathhouse, I first used pine logs. At the beginning of construction, we had to save every penny; the family budget did not allow us to splurge on quality material. The savings turned out to be imaginary. Firstly, I forgot to treat the logs with an antiseptic, which ultimately led to the formation of mold. Although ventilation was installed in the floor. Secondly, as it turned out, the moisture content of the wood was high. The masters explained this to me later. That's why there were lags. Three years later, a hand fit into the gap. I had to lift the floors completely and throw out both the boards and joists. After which I purchased timber from Siberian larch. It is difficult to work with, it is very durable, nails cannot be driven in, but the structure is durable. So it is not recommended to save on lags. It’s better to invest a little more money, but be sure that the bathhouse will last a long time.

Alexander Surkov, 28 years old, Izhevsk

I got an apartment in a new building and decided to install plank floors in it. This is where I had to suffer, because the construction of the logs is directly related to the selection of the beam according to its cross-section. Due to inexperience, I purchased 100x50 mm bars and installed them at a height of 100. As it turned out, I did it wrong, and the ceiling height decreased sharply. Then I placed them on edge 50. The height became normal, but why did I need such a width of the joists, since the expected loads in the room were small. It turns out I just overpaid. So think first and then buy.

Maria Sergeevna, 52 years old, Nizhny Tagil

During the construction of the dacha, we chose a project where the floors are installed along joists. The project specified floors made of 50 mm boards. We decided to use OSB. And here we miscalculated the distance between the lags. We used a design value of 85 cm, but the slab bent under the weight of a person. Therefore, I had to add lags between those already installed.

Determining the step size for laying joists

Calculation scheme for the distance between logs under OSB panels

Calculating the optimal pitch for wooden beams is quite difficult to determine. If there is a directly proportional relationship between the cross-section of the beam and the size of the span, then with the interval of laying beams the situation is different. A simplified version of the calculation should be as follows: the larger the step between the logs, the thicker the board that is laid on the wooden sheathing. Why is that?

The explanation of this rule is not difficult to understand: the thicker the board, the less it will be subject to deformation. However, it should be taken into account that the interval between the layout of the beams does not depend in any way on the material from which they are made. Indeed, in this case we are talking about the ability of the board to withstand static and dynamic loads.

How to carry out the calculation and determine what the step size should be? To do this, consider a simple formula:

Base length = distance between beams + gap between beams and wall + beam width. For clarity, let’s analyze the expression with numerical substitutions:

10 m = 0.6 m*(T-1) + 0.03 m*2 + 0.07 m*T, where T is the total number of beams. In this case, the expression T-1 is the step between the beams laid at a distance of 60 cm from each other. In the course of simple calculations, we find out that T = 16 (beams). That is, to construct a subfloor from logs, a total of only 16 beams will be required.

In this case, the sum of the intervals between the beams will be equal to: 10 - 0.06 - 16 * 0.07 = 8.82 m. Now the resulting expression must be divided by the total number of intervals: 8.82 / 16 = 0.55 m. In our case, to assemble a wooden sheathing, the logs must be installed in 0.55 m increments.

Protect from rot

A large number of impregnations, stains and other antiseptic agents have been created to protect ordinary wood in conditions of high humidity.

And each unit must be impregnated with such products individually. It is recommended to leave a significant protective layer (from 5 to 15 mm) and use environmentally friendly types of impregnation.

In addition, when purchasing such timber, pay attention to the dryness of the wood. Now there are instruments that show the degree of moisture in any lumber.

Even before installation, you need to think through a plan for ventilation - this is the third important natural condition for protection from rot, mold and rodents. Floors must be ventilated using air cushions.