The construction of each building begins with the construction of the foundation. This stage is one of the most important, so it is necessary to treat its implementation with full responsibility. Before you start building the foundation, you should make all the necessary calculations. These include such a parameter as the height of the foundation for the bathhouse. This value is selected in accordance with established standards and requirements. This is how we can talk about building a truly reliable and durable structure.

Which foundation is better for a bathhouse, depending on the type of building

This table suggests that wall material is a factor that simply cannot be considered separately from the properties of the soil.

IMPORTANT! To the weight of the structure you also need to add the snow load characteristic of your region.

The heavier the structure, the more thoroughly the foundation has to be made, the more expensive it is, but lightweight structures put little pressure on the ground, so highly heaving soils can push out a structure made of light material.

You can combat frost heaving by either replacing the soil under the bathhouse with drainage soil, or by making a wide blind area (more than 1 meter) around it and discharging precipitation through gutters away from the bathhouse.

Conclusion

A strong foundation is very important for the strength of the entire structure. Therefore, it must be done efficiently. The work is easy to do yourself, which will save you a lot of money.

Also, for greater savings, in some cases you can use the installation of a pile foundation rather than a strip foundation.

Ready-made bathhouse on a columnar foundation

The dimensions depend on the quality and density of the soil, the choice of fill type, and the thickness of the proposed walls: the foundation for the bathhouse is calculated based on these parameters. It is important to remember here that a deeper and wider structure will be more reliable, but more expensive. You should try to find a balance using the recommendations proposed in the article.

It should be noted that the concrete base for the furnace has its own characteristics in laying and must be separate from the general structure. Its width and depth are determined by the material of manufacture: metal or brick.

Source

Do-it-yourself strip foundation for a bathhouse: types and their features

This type of foundation comes in several types. If we consider its types by design, then there are two types: monolithic, prefabricated and monolithic-prefabricated.

The peculiarity of a monolithic foundation is that during its construction a reinforced formwork trench is made into which concrete mortar is poured. A prefabricated base involves assembly from prefabricated reinforced concrete blocks.

A monolithic foundation is more difficult to construct and also takes time, but its reliability is much higher, so this type of foundation is most often chosen. A prefabricated foundation can only be used when building a bathhouse on soil that has good load-bearing characteristics.

Currently, there is also a prefabricated monolithic technology, which includes two types of foundation construction: part of the base is made of reinforced concrete, and the other of blocks.

Depending on the depth, the foundation also comes in several types: non-recessed and recessed.

A shallow strip foundation for a bathhouse is the best option for small and light bathhouses, for example, made of wood. It can be laid on sand and clay. Its advantage is its small depth (about 0.5 m), due to which less building materials are required for its construction, which leads to significant savings.

A recessed strip foundation is a high-quality and reliable foundation, ideal for the construction of large and massive baths, as well as two-story baths combined with a house, etc. But keep in mind that this type of foundation will require large financial expenses, and it is much more difficult to install .

Depending on the material that was chosen for construction, the foundation can be:

- brick;

- rubble;

- sandy;

- soil-cement;

- reinforced concrete.

The foundation made of rubble concrete is recognized as the most reliable. Large stones weigh about 30 kg and are about 0.3 m long. They are quite inexpensive. Such a foundation is easy to make with your own hands. If the soil is sandy and rocky, a rubble foundation will not be suitable, as it can quickly crack.

Brick foundations are also widespread, but their peculiarity is that brick is a hygroscopic material, so the foundation cannot be built to great depths or near groundwater. The brick base is suitable for dry sandy soil. Only red brick is used for the foundation, since it is less susceptible to water.

Sand and soil-cement foundations are suitable only for the construction of light non-residential premises on a solid foundation.

A reinforced concrete foundation is a cheap, but at the same time quite durable type of foundation, which is also suitable for complex-shaped baths. To lift this material you need to use special equipment. You can make a foundation with your own hands using blocks measuring 20x20x40 cm.

More details about the features and types of strip foundations for bathhouses in the video:

Interior work

Before you begin interior work, you need to decide exactly how you want it to look. Some people do it in a certain restrained style, while others prefer a simpler solution, trying to save a little money on it.

We assemble the floor and ceiling from a board that is about forty millimeters wide. One should also take into account the fact that floors must be made independently of the walls of the building.

Recommended video to watch:

When choosing a stove, give preference to a product made of chrome steel. Such options are considered durable and quickly heat the room. The disadvantages are its rapid cooling. As for brick walls, they will take longer to heat, but they hold steam longer.

Construction of the foundation

You don’t have to build a separate foundation for a metal furnace and limit yourself to fire shutoffs. However, if the weight approaches the maximum value (700 kg), and it consists of the weight of water in a completely filled boiler plus the weight of stones plus the own weight of the stove, it is better to equip a separate foundation for the metal stove. To do this you need:

- Dig a pit (to a freezing depth, but not less than 50 cm), fill it with crushed stone and compact it thoroughly.

- A concrete layer is poured on top, which must completely harden. The composition of the solution is cement with sand 1:4.

- Double layer of waterproofing (roofing felt or similar sheet material),

- Filling the main slab with a solution of cement, sand, fine gravel. While the solution has not hardened, the horizontal line is checked and adjusted if necessary.

The foundation for a brick oven requires a more thorough approach and is made as strong as possible.

- A pit is being dug. Most often, this is done simultaneously with a common foundation pit for the entire building.

- A layer of sand is added to remove the bottom of the pit. Sand is poured in layers of 15 cm, each layer is spilled with water to compact it. Subsequent layers of sand are added only after the water has subsided. This technology makes sand compaction easier and provides a dense layer. After this, a rubble layer is laid - broken brick, concrete, thickness - 20 cm. Again a layer of sand, spilled with water - and so on until a dense cushion is formed that does not settle when compacted.

- A layer of crushed stone 10 cm thick is laid.

- Formwork for the main foundation slab is erected on top.

- A reinforcement frame, welded or knitted, is installed inside the formwork.

- Concrete is poured to a height that does not reach the floor level by 5-15 cm. It is kept until completely dry.

- The surface is generously lubricated with tar, several rows of brickwork are laid on top to the floor level, on which the construction of the furnace itself will begin.

Options

The most common options for building a foundation are considered, proven by frequent use and quite reliable. In some cases, other types of foundations are used, for example, pile-slab. With this method, the monolithic slab rests on piles buried to dense layers of soil.

The good thing about this method is that the possibility of settling of the bedding and the butting layer is excluded, the piles stand firmly and motionless. Driven reinforced concrete piles or screw piles are used as piles, making it possible to independently screw them into the ground. The installed piles are trimmed (extended) to the required length and tied with a channel belt (grillage), which serves as a support for the slab.

Nuances that must be taken into account during construction

Experts advise maintaining reasonable proportionality in the ratio of the weight of the furnace to the power of the foundation. It must be remembered that the foundation itself is also subject to sedimentary processes, which can upset the balance of the foundation, create a distortion or disruption of the plane. The thicker the butt layers, the higher the risk of sedimentary deformations.

Hence the rule: the foundation must correspond to the load. This applies to such types as monolithic, brick, rubble and slab foundations, which are, in fact, variants of the same foundation.

Pile foundations that require the use of equipment must be designed in advance and pile driving work must be carried out simultaneously with general work, otherwise the equipment will not be suitable for the work site. In general, all work on the construction of a bathhouse should be designed and carried out simultaneously, so that one does not precede the other. In this way, errors and inconsistencies in construction stages will be avoided.

Screw piles can be screwed even inside a finished building, if there is room for the gate to move. This option may be needed when constructing a stove in an already completed building or when reconstructing a bathhouse.

In conclusion, it should be noted that the issue of reliable and competent placement of the stove is quite complex and responsible, but it is necessary to understand it, since the safety of the entire building, the comfort and safety of people may depend on the correct actions. Before starting work, it is necessary to thoroughly study all available materials for the chosen construction method, find out the geological conditions of the area, and ensure compliance with building codes and regulations. This will ensure long and reliable service for your bath.

You may also need the following materials from the section on bathhouse foundations:

- Height and depth of the foundation,

- How to do it right and how to do it yourself,

- How to fill correctly

- Which foundation is better?

***

Types of foundation for a two-story house made of brick, timber or blocks:

- Strip base (the strip frame perfectly distributes the load between the walls and nodes, but such a base needs to be calculated correctly);

- Columnar frame (used on moving soil or wetlands);

- Monolithic frame (calculating such a base is not difficult and it is highly resistant to turf movements).

The use of a building frame made of piles can be used for a relatively light two-story house made of timber, but for a house made of foam blocks or bricks such a foundation is not suitable due to instability. Screw-type piles are used for auxiliary buildings made of brick or blocks.

Why you should choose a strip foundation for a bathhouse

A strip foundation is a continuous strip of concrete located under all load-bearing walls of the building.

It occupies a leading position among alternative methods of building a foundation for a number of reasons:

- First of all, it has a high load-bearing capacity with relatively low consumption of building material. If we consider the comparative need for materials of different types of base, the tape type represents the “golden mean”, optimally combining costs and results.

- The strip base has several options for creation and allows the use of various building materials. During construction, both monolithic concrete casting and ready-made blocks (FBS), brick or stone strips, and other methods are used.

- The depth of immersion in the soil can be either lower or higher than the winter freezing level, which allows you to choose the best option depending on the hydrogeological conditions of the site.

- The properties and features of a strip foundation have been studied better than other types of foundation; the design allows, if necessary, to carry out repair work, waterproofing or other repair and restoration work.

The design of the strip base is simple and understandable to all users. All these features together determine the primacy of the tape over other methods of creating a foundation.

General installation diagram

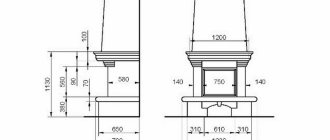

The use of wood is a traditional way of building a Russian bathhouse (6x6 or 6x4). The timber allows you to get strong and warm walls that do not have much weight and do not create excessive loads on the base.

This allows the use of a shallow version of a strip foundation, which requires less excavation and does not require a large amount of building material.

The only external condition for choice remains the hydrogeological situation on the site, soil composition and other conditions.

The configuration of the tape in plan follows the contours of the load-bearing walls of the bathhouse, as well as the internal walls that strengthen the structure and take on most of the loads.

The foundation for the furnace is built separately and is not mechanically connected to the common base.

To create the foundation you will need to perform a number of works:

- Site preparation. The top fertile layer of soil is removed and the site is leveled.

- Marking with pegs.

- Digging a trench.

- Preparatory work before installing the tape (so-called concrete footing).

- Installation of formwork.

- Creation of a reinforcing frame.

- Filling the tape.

- Exposure, removal of formwork.

IMPORTANT! All work is carried out in the specified sequence and requires care and compliance with technological requirements. Any deviation or negligence leads to a decrease in the load-bearing capacity of the tape, fraught with destruction of the building.

Kinds

Based on the instructions described above, you can build a foundation for a bathhouse with your own hands. This option is called shallow-depth tape. It is more suitable for small timber buildings. Monolithic and pile foundations are used for larger premises and for heavy building materials.

Columnar foundations are suitable for buildings made of wood and aerated concrete. In terms of cost, this option is cheaper than others, since there are fewer materials used.

Various building materials can be used for the construction of pillars: brick, aerated blocks, concrete, stone and even wood. The latter option must be additionally treated with waterproofing.

A slab foundation is chosen when a large bathhouse is being built from heavy material and the soil is constantly exposed to various natural movements. It is based on a reinforcement slab filled with concrete. This option is more reliable, but at the same time costly and time-consuming.

In those places where the soil is very mobile, subject to periodic floods, or where groundwater is nearby, which constantly comes out, bathhouses are built on a pile foundation. Its construction is carried out using a pile driver.

Choosing which foundation is best for a bathhouse will not be so difficult, having understood some of the subtleties and why it is important

About the height of the base

The plinth is the part of the foundation protruding above the ground

Its height is an important characteristic

This parameter varies for different structures, and depends on:

- type of foundation;

- nuances of the project;

- soil features;

- the need to organize a basement.

It is important to carefully calculate how high the base of the house will be in order to provide reliable protection to the foundation and extend the life of the house

What does height affect?

The main function of the base part is to prevent the negative effects of moisture on the base.

But you should not be too zealous, since it is irrational from a financial point of view to equip a very large indentation.

In private construction, it is especially important to determine the height so that this part performs all its functions:

- protection of the facade from pollution;

- imparting mechanical strength to the surface;

- elimination of deformations under the influence of shrinkage;

- basement protection;

- ventilation and additional insulation.

The elevation should be calculated carefully, taking into account the dimensions of the main surface of the facade, so that the building is not only well protected, but also looks attractive.

Features of choosing a foundation

Choose a foundation taking into account:

- at what depth does groundwater lie;

- soil type;

- the depth of freezing of the earth's surface in winter;

- material used for construction;

- construction area.

After analyzing all the factors, you can decide on the choice of a suitable foundation. Also, when choosing a base for a bath, you need to take into account such an important factor as the natural properties of the soil. Each soil needs a suitable option.

Pile-screw – used in areas with large differences in ground height.

Columnar - suitable for those soils that are not subject to landslides and various shifts. Ideal for a foundation for a log bath.

Pile-grillage - used on those soils that are prone to crumbling, as well as shifts.

Monolithic is the most stable and suitable for all types of soil, but costs more than other options.

Shallow tape - used most often on soils that are not subject to various movements and shrinkage.

How to calculate how much to deepen?

The need for preliminary calculations of the foundation depth is explained by the following reasons:

- The lower the reinforced concrete pad is lowered, the higher the load-bearing capacity of the solid bottom underneath it.

- For areas with a high clay content, trenches are laid below the frost line or measures are taken to minimize the heaving factor.

- The soil at the construction site must be strong enough to support the weight of the building.

- The physical and chemical composition of the earth under the base of the house should not change much due to temperature changes in the environment.

To calculate the underground part of the tape you need to know:

- freezing depth (Dfn);

- a correction factor that takes into account the thermal conditions in the house (K).

As mentioned above, the degree of freezing is determined by the climatic conditions in the region. The value of this indicator can be taken from reference literature.

The freezing depth for some Russian regions is given in the table (the predominant soil types are taken into account):

| City | Freezing line, m | City | Freezing line, m |

| Arkhangelsk | 1,75 | Moscow | 1,30 |

| Vladivostok | 1,80 | Nizhny Novgorod | 1,55 |

| Ekaterinburg | 1,90 | Eagle | 1,30 |

| Kazan | 1,75 | Ryazan | 1,30 |

| Krasnoyarsk | 2,00 | Saint Petersburg | 1,20 |

| Kursk | 1,30 | Chelyabinsk | 2,15 |

Coefficient K is a reference value that reflects the average daily temperature in the room adjacent to the foundation. For clarity, below is a table from which you can take the coefficient for calculations:

| Temperature in the building, oC | Correction factor K | |||

| ground floor | floor on joists | insulated basement floor | basement | |

| 0,90 | 1,00 | 1,00 | 0,80 | |

| 5 | 0,80 | 0,90 | 1,00 | 0,70 |

| 10 | 0,70 | 0,80 | 0,90 | 0,60 |

| 15 | 0,60 | 0,70 | 0,80 | 0,50 |

| 20 and above | 0,50 | 0,60 | 0,70 | 0,4 |

So, how deep should you dig? Using the available data, you can calculate the depth of the sole (Df) using the formula: Df = (Dfn * K).

As a clear example, you can choose a house with an unheated basement in Yekaterinburg, where the temperature in the basement itself is kept at 10 ° C during the day. By substituting the tabular data into the formula, you can easily obtain the estimated foundation depth: Df = (1.9 * 0.6) = 1.14 m.

Let us assume that in the selected area the groundwater passes above the freezing line. Then you need to add 15 - 20 cm to the obtained value for the stability of the base. At what depth should the foundation be laid? The calculation shows that the reinforced concrete strip must be laid to a depth of at least 1.29 m.

Made from concrete

Today, the most durable structure is still considered to be a strip foundation made below the depth of soil freezing. True, this does not negate the fact that pile foundations are preferable on soft soils, but still this design is optimal for most cases.

Concrete is generally universal. As you can see, it is even used inside metal piles. But as the main material it is used in strip and slab foundations. Tape, in turn, can be prefabricated or solid. Prefabricated ones are made from ready-made blocks, but their strength is less due to the presence of seams.

For those readers who are interested in the rules for pouring liquid concrete into any of the existing foundation structures, we recommend this material.

Tape

The video below will be useful not only for those who are planning to install a bathhouse on a strip foundation. It clearly explains what a foundation is in general, why it is needed, and what the consequences of incorrect calculations are. And the specifics of the calculation apply to the strip foundation buried below the freezing level of the soil.

A strip foundation has an advantage over a slab foundation - it does not require as much concrete. However, this circumstance may be a disadvantage on soils characterized by severe heaving.

Slab

We often mentioned slabs, but didn’t talk much. This is another type of expensive foundation, which has increased strength, but is also quite expensive.

The main advantage of the slab is that it seems to “float” on the surface of the ground “sea”. Seasonal uplifts of the soil do not break, but only lift and slightly tilt the concrete slab.

Foundation – slab for a bathhouse

However, this only happens if the slab is not buried and lies on the surface of the soil.

If it is buried, then the main thing is that no mistakes are made in the calculations - if you watch the video above, you will see in it the scale of destruction of a 35-centimeter concrete slab by the forces of frost heaving.

The main purpose of a slab foundation is to evenly distribute the increased load that, say, is created by brick walls and a heavy roof.

*** As for the optimal choice of the type of foundation for different walls, here are articles that talk about foundations for a log house, for a foam block bathhouse (first and second).

For those who rely only on themselves, the material from this article will be useful, where we consider creating a foundation for a bathhouse with your own hands.

Adviсe

Unfortunately, many developers neglect the above calculations due to time and financial costs, and, as a result, make the wrong choice. Before installing the foundation, it would be a good idea to consult with people who have already gone through this process. But remember that installing a large building is a long-term matter, and many problems (which may arise precisely because of non-compliance with the rules) often become noticeable after more than a dozen years. In any case, it is worth protecting yourself and your property now, so as not to deal with unpleasant consequences in the future.

To see what mistakes can happen when laying a foundation, watch the following video.

Depth of strip foundation for bathhouse

The classic depth of a strip foundation consists of a twenty-centimeter, well-compacted sand cushion. Above is a foundation 60 cm high: 40 cm lies in the ground, and the remaining 20 cm extends to the surface. Since the strip foundation has become the most popular, universal option for bathhouse foundations, the correct calculation of its depth needs to be studied in more detail.

First of all, they start from the properties of the soil. Frequently encountered problems related to the structure of the soil when designing a foundation affect the depth of its construction. The risk of cracks arises when erected on rocky soil. In this case, a shallow or non-buried foundation is used. Soil prone to swelling requires the foundation to be sunk deeply below the freezing level. The possibility of foundation failure is characteristic of fine sandy soils. When building a foundation on such soil, a deep foundation is designed to increase compression resistance.

Let's look at some "travelling" soils

Clayey (or loam)

It has a poor ability to swell and push out the foundation (when it freezes). This is critical when the soil water level is high. Therefore, the depth of laying the tape should be below the underlying water level. The same applies to loamy soils (where the % clay content is from 10 to 30). Here, the pile-tape option will be more reliable.

Sandy (or sandy loam)

Better than clay. Through coarse and medium-grained, water seeps through even at a high level of occurrence. However, if the sand is fine-grained or generally dusty, then water still lingers in it. In this case, the filling depth increases to the freezing mark. You need to know that building on sandy soil leads to deeper shrinkage. Therefore, a high base is quite appropriate. The same applies to clay-sandy soils containing < 10% clay.

Cartilaginous

Consists of gravel, large stones, cartilage

Here it is important to take into account the load on the foundation and the depth of soil water, but the level of freezing is not important

Rocky

This type of soil is ideal in terms of reliability against heaving and shrinkage. It is enough to remove a shallow layer of soil. If it is not possible to go deep, a strip foundation can be installed directly on the surface.

Building size and thickness of monolithic structure

A monolithic foundation is the most expensive type of foundation, which explains the desire of developers to determine the minimum permissible slab thickness that would withstand design loads with a margin.

Factors influencing the indicator:

- reinforcement frame height;

- thickness of the concrete layer above and below the mesh;

- reinforcement thickness.

For baths made of light material - frame-panel or wooden, it is enough to add these three values to find out the thickness of the monolith. The optimal slab size is considered to be 0.2–0.3 m.

In this case, it is necessary to take into account the height of the cushion made of non-metallic materials, which in most cases will be equal to 0.5 m: 0.3 m of sand and 0.2 m of crushed stone. In regions with sharp temperature changes, experts advise placing a layer of insulation 0.1 m high under the slab.

If large-scale construction is underway, for example, a bathhouse with an area of 6 x 6 m, then the weight of the building must also be taken into account, since there is a possible risk of slab foundation subsidence, especially on unstable soils. In this case, the thickness of the slab is increased to 35–40 cm

For economic feasibility purposes, the monolith can be replaced with a foundation using ready-made factory-type reinforced concrete slabs or a foundation with stiffeners can be built.

Cost calculation

The cost of any foundation is calculated as the sum of the cost of concrete and reinforcement. When the volume of the foundation is calculated, it is laid out according to its components according to the principle - to produce one m3 of concrete it is required:

- cement - 0.22 m3 or about 0.35 tons (costs 5,600 rubles/t);

- sand - 0.31 m3 or about 0.45 tons (costs about 100 rubles/t);

- crushed stone - 0.70 m3 or one ton exactly (costs 600 rubles/t).

The cost of fittings at metal depots is usually calculated in rubles per ton. Knowing the length, the mass can be calculated by knowing how many meters of reinforcement are in one ton:

Reinforcement Ø 6 mm – 4,500 meters:

- 8 mm – 2,530 meters;

- 10 mm – 1,600 meters;

- 12 mm – 1,120 meters;

- 14 mm – 820 meters;

- 16 mm – 630 meters;

- 18 mm – 500 meters;

- 20 mm – 400 meters.

Manufacturing process

First of all, it is necessary to mark the site, determine the number and location of pile installation points - install pegs in these places

Before installing the supports, it is important to check the diagonals and angles. The distance between supports is also carefully controlled

At the initial stage, screw piles are screwed into the ground. In the places where they will be installed, holes should be made in advance with a depth of 10-15 centimeters.

The supports are screwed into the soil using a rod, and it is important to control the verticality of the entry of the element into the soil. The deepening is carried out until the support reaches a level at which the soil does not freeze in winter.

After the elements are screwed into the ground, the upper ends of the supports must be leveled. A grinding machine is used for this; it can be used to easily trim off excess pipes. After this, a concrete mixture should be poured inside the products, this will increase the strength characteristics of the pipes and significantly reduce the rate of metal corrosion.

At the final stage of installation, it is necessary to take metal plates. It is best to use products whose thickness is 10 mm. They are welded to each support so that they extend beyond the rack on each side, protruding a few centimeters. The foundation for a frame bath on screw piles (with your own hands or by a contractor) is done in exactly the same way.

The supporting elements can be connected to each other using a special structure, it is called a grillage.

Most often it is made of concrete, but rolled metal and reinforced concrete can be used. The structures are made prefabricated and monolithic.

In addition, a foundation on piles for a bathhouse can be made from a ready-made set of supporting elements; they are available for sale in hardware stores.

If there are available funds, installation can be entrusted to specialists.

Bathhouse made of timber

The number of buildings of this type being erected has increased significantly recently. The work can be done with your own hands; the speed of erecting a foundation for a bathhouse on screw piles is very high.

Important! All supports, if they were made of metal, must be treated with an anti-corrosion agent before being immersed in the ground. This will significantly increase their service life

The process of screwing the pile into the soil will be simplified due to the presence of special blades at the sharp end of the pile. Products need to be screwed into the soil.

When calculating the foundation for a bathhouse, it is necessary to take into account SP 24.13330.2011, in addition, the edition of SNiP 2.02.03-85 can be used. If it is difficult to do the calculations yourself, then you should contact a designer. Foundation elements must be purchased taking into account the recommendations of a specialist.

How to drain?

When constructing a foundation for a bathhouse, it is important to drain. Since the bathhouse will be installed on screw piles, a regular drain with a water seal will not work - in winter the water in it will freeze

The drain must be planned so that water cannot accumulate anywhere in it. To do this, you can use an ordinary sewer plastic pipe with a diameter of 40 or 50 mm, securing it, for example, to a metal tape for mounting drywall or to other fasteners every 50-70 cm of the pipe, to the bottom piping of the bathhouse or to the subfloor.

Attention! The minimum acceptable slope for water drainage is 1:30, that is, approximately 3-3.5 cm per 1 meter of pipe. To prevent cold air from flowing through the drain under the bathhouse on screw piles, there is a very simple, proven and cheap way - place a rubber ball with a diameter of 40-60mm on the drain hole

When water enters there, the ball will float up and release it. And when water is not used, it will prevent cold air from entering the room

To prevent cold air from flowing through the drain under the bathhouse on screw piles, there is a very simple, proven and cheap way - to place a rubber ball with a diameter of 40-60mm on the drain hole. When water enters there, the ball will float up and release it. And when water is not used, it will prevent cold air from entering the room.

Thermal protection measures

Laying insulation on the side surface of heaving soil to reduce soil freezing.

Styrofoam, Teploizoplit, Primap1ex, Penoplex and others are used as insulation materials.

Perhaps the most promising, economical and reliable way to reduce soil heaving is a shallow reinforced concrete foundation, which is placed on an anti-heaving cushion. A low-rise building rests on soil close to the surface.

Shallow foundations should be placed to the required depth. The reliability of such a foundation ensures:

- Calculation of the supporting area taking into account soil resistance and loads from the house;

- Calculation of the required width of pits and trenches, the cavities of which are filled with non-heaving soil to create the required stability;

- Calculation of the thickness of the anti-heaving load based on permissible deformations.

In heaving soils, SNiP 2.02.01-83 regulates the laying of foundations. The implementation of these measures will allow you to create a strong and reliable foundation on heaving soil that will serve you for decades.

Concrete preparation technology

Cross section of a strip foundation.

The main indicator is high-quality concrete. To prepare it, you should follow some recommendations:

Purified dry sand and cement are taken in the required proportions. Mix in a clean container until smooth.

Add clean, free gravel or crushed stone to the homogeneous mass. Mix thoroughly again.

Water is added. There are some tricks when connecting with water. In the cold season, it is better to take water heated to a temperature of 40-50°C, this temperature gives the finished solution viscosity. When working in hot weather, on the contrary, it is better to use cold water to prevent the solution from drying out too quickly.

It is better to pour in small batches so that the poured layers do not exceed a layer of 15 cm. After each pour, the mixture is compacted; water should come out over the entire surface of the poured foundation under the bathhouse.

When carrying out work during hot weather, the surface of the solution should be sprinkled with a layer of sawdust or covered with thick burlap. To prevent the poured layer of concrete from cracking, it is periodically watered with water (every 3-4 hours for a week). It is necessary to keep the concrete moist for 3-4 weeks; to do this, it is periodically watered with water and covered with plastic film.

Tape depth

This type of foundation, as mentioned above, is also very popular. Usually it is built for relatively small buildings, including a bathhouse. The depth and width to which the concrete strip will be laid can be different, because it all depends on the type of base:

- Shallow;

- Recessed.

The first type is usually used for the construction of stone buildings, which are small in size. It is also confidently used for log structures. The second option is used for large objects, including those characterized by two floors and basements.

When deciding how deep to dig, you should carefully think through everything and understand which foundation is best to make. The fact is that the second option is characterized by high material costs, so you should choose it only when there is really a need for it.

Information. The depth of the shallow tape ranges from 0.5m to 1m. It is necessary to examine the foundation more deeply only if you plan to build a two-story bathhouse or attic

To decide how deep to dig, it is important to consider:

- Size of the structure;

- Weight.

The fact is that with relatively small building sizes (up to 18-20 m2 of area), you can make a minimum depth (50 centimeters), but if you plan to build a bathhouse of a larger area, you should think about increasing it to one meter.

The depth of the buried foundation depends on the depth of freezing of the soil layers, as a result of which it is necessary to make it a little deeper than this mark. In most cases, with a margin of safety, this type of foundation is buried 1.5 meters. Looking ahead, let's say that the width of the bathhouse strip should be 10-15cm wider than the main walls.

Construction order

After marking the surface, a trench is dug. Its depth is defined as the freezing point of the soil plus 20 centimeters, to a dense layer. The calculated width is taken: the wall plus 10-15 centimeters, usually up to 35-45 cm. Moistened, compacted sand and crushed stone are poured into the trench in layers. The layers alternate, each height is 12-15 cm. The resulting pillow is filled with a liquid cement solution, which will pass through all the layers. To raise the foundation above ground level, formwork is placed, which is filled with reinforcement and filled with mortar. The resulting concrete strip is thoroughly moistened during the entire hardening period (to avoid cracks), after which the formwork is removed. To reduce the threat of erosion, you can immediately make a blind area, the width of which depends on the type of soil. This technology is used for the construction of deeply buried strip foundations. For soil that is resistant to swelling, a finely compacted base can be used. The process of its manufacture occurs in a similar way, the depth of the concrete strip changes - 50-70 cm is enough.

Base reinforcement

Installation of the reinforcing frame is a very important point. The reinforcement is made of longitudinal and transverse rods approximately 10-12 mm thick. The rods are laid out with an overlap of 25-30 cm and tied together with wire.

The number of longitudinal rods will depend on the width of the bathhouse base. The overall structure should be approximately 5 cm smaller than the formwork and the base surface. It must be further strengthened in the corners. The top of the reinforced frame can be strengthened with U-shaped brackets for greater strength. To prevent the reinforcement from shifting during the process of pouring concrete, plastic fasteners are inserted between the formwork and the reinforcement. The finished structure is installed on supports.

Another option for installing reinforcement is that rods are driven into the bottom of trenches at regular intervals, the diameter of the rod being about 10 mm. Using wire, horizontal pins are attached to the vertical pins.

The first bottom row is performed at a height of 60-75 mm from the bottom of the trench. The distance between the rods should be about 50 cm.

The top row of rods is hidden with concrete mortar 70 mm from the top point of the foundation.

The rods must be treated with an anti-corrosion coating, because... Concrete, even after pouring, always contains moisture. It is not recommended to weld rods together due to the fragility of such joints in concrete.

Marking

Stages:

- Prepare 8 wooden stakes with ropes.

- Mark the outer boundary of one of the walls of the future foundation.

- Drive two pegs into the corners and stretch a thread between them.

- Calculate the right angle to figure out where the next angle will be. It is easier to do this using the Pythagorean theorem to calculate right angles.

- After calculating the third angle, measure the diagonal between it and the other existing angle.

- Take the same diagonal from a known angle to an unknown one.

- Check the evenness of the sides, check the diagonals.

The last stage is marking the internal boundaries of the belt trenches. The optimal width is 40–50 cm.

Columnar foundation with grillage

When constructing a heavier bathhouse building (for example, made of brick) or if you want to equip a basement, you can mount a columnar foundation with a grillage. This is a monolithic reinforced concrete strip structure that connects the top points of all foundation elements buried in the ground.

To fill the grillage, you will need formwork material: edged board with a thickness of 20 to 40 millimeters, plywood, OSB or other similar building material. As well as reinforcement with a cross-section of 10-12 millimeters and concrete of at least grade 150. Most often, grade 200 concrete is used to fill the grillage, and if you make it yourself, you need to mix M400 cement, coarse sand and medium or fine crushed stone in a ratio of 1:2, 5:4,5.

Let's calculate the amount of lumber for formwork. It must be taken into account that the height of the grillage should be at least 0.3 meters, and its width should be 10 centimeters greater than the width of the manufactured columnar supports.

- We determine the immediate height of the grillage and add another 0.2 meters to it since the height of the formwork must be greater than the level of concrete poured into it.

- We fix the thickness of the formwork material in meters.

- We measure the total length of the future grillage.

- We multiply all the obtained parameters together and get the required amount of material for formwork in cubic meters.

From the prepared lumber we knock down the formwork box. In its lower part, holes should be cut for the previously made pillars, which should rise slightly above the lower part of the formwork.

Formwork assembly

Video - Installation of formwork

From reinforcement rods it is necessary to make frames with transverse square clamps, which can be bent from thinner smooth reinforcement or from wire Ø6-8 mm. They will give the necessary strength and reliability to the structure. Every 30-35 centimeters we connect clamps and reinforcement rods with knitting wire in an amount equal to the entire perimeter of the grillage. We calculate the size of the frame in such a way that there is 5-7 centimeters from it to the walls of the formwork.

If the finished foundation pillars are located at a considerable distance from each other, then for reliability you can strengthen the formwork with wooden supports, which must be installed strictly horizontally.

Before pouring concrete into the formwork box, we will install a reinforcing frame, fixing its lower part to the reinforcement protruding from the columns.

How to calculate the dimensions of the tape?

The dimensions of the LF are the length, height and width of the foundation. They are defined as follows.

Length

The length of the monolithic tape is calculated based on the garage plan. If there is a partition inside the building, then a tape is also placed under it, the length of which is added to the overall size of the LF.

Width

For example, a developer plans to build brick walls 1.5 bricks thick (380 mm), then the optimal foundation width will be 420 mm. That is, on each side of the wall the tape should protrude at least 20 mm.

Height

The height of the strip foundation consists of two parts - the depth of the base and the vertical size of the base (the above-ground part of the LF). Typically the height of the plinth is 150 - 200 mm above ground level. That is, with a laying depth of 300 mm, the height of the tape will be 500 mm.