Converting a brick or metal stove to gas processing is a difficult process that requires a serious analysis of all components. It is imperative to find out which types of gas burners are ideal for furnaces and which ones should not be installed. After all, the result must meet exactly your requirements.

It would seem that the choice of model can be entrusted to gas workers; they can also be entrusted with reworking the burner block and installing the burner itself. But where is the guarantee that the equipment that you will be offered to install will have the necessary operating parameters and desired functionality?

In this article we will tell you how to independently understand the types of gas burners, the basic rules for their installation and operation, so that you can consciously choose which device to install in your heating stove.

Stove gas burner - what is it, principle of operation, features

A gas burner is a special device for burning natural gas and transferring the generated thermal energy to a heating circuit, a container of water or a metal heat sink to heat the room. In this way, the potential energy of the gas substance is converted into heat, which in turn is used in domestic conditions for heating or heating water. Therefore, installations of this type are used in stoves for baths or houses, as well as in heating boilers.

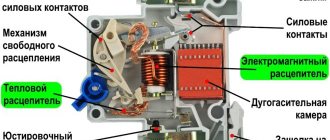

Regardless of the set of technical characteristics and purpose, gas burners consist of the following main components:

- An injector is an element that directly supplies gas to the combustion chamber.

- Ignition device - creates a spark to ignite the fuel.

- Flame sensor – monitors the presence and stability of the flame.

- Automation unit - controls the heating level and other specified characteristics that affect the operation of the equipment.

Gas burner with an automatic control unit Source 33sv.ru

In the classic version, such a burner directly heats the stove body - that is, when gas, rather than wood, is used to produce fire. However, there is often a need to heat water or effectively heat neighboring rooms. Then the device is combined with a tank or thermal circuit.

Operating principle

Using a heating unit as an example, the operating principle of a gas burner comes down to the following algorithm:

- As soon as the temperature of the coolant in the radiators drops below the set value, the temperature sensor detects the situation and sends a signal to a special control unit.

- The gas supply valve opens.

- Simultaneously with the flow of fuel to the injector, the ignition system is activated.

- A flame is formed in the combustion chamber, heating the thermal circuit.

- As the coolant reaches the specified heating level, the temperature sensor responds to the reverse command - shutting off the gas supply and extinguishing the burner.

During the entire period while there is a flame in the chamber, the tracking sensor operates. If the fire suddenly goes out, it immediately informs the automation unit about the event, which in turn sends a command to stop the fuel supply.

Construction of a gas burner for a sauna stove Source stroy-podskazka.ru

Requirements

In addition to compliance with safety standards, the installation of equipment of this type in a domestic environment must meet the following general requirements:

- Silence . This parameter not only affects the level of comfort in using the equipment, but is also an indicator of the efficiency and serviceability of its operation. For example, a gas burner operates with excessive noise with an imperfect design of the combustion chamber, which will indicate its low efficiency. In addition, the occurrence of popping noises during startup indicates that the ignition system is not functioning properly.

- Durability . The more reliable and high-quality the device is made, the longer and more stable the equipment will operate. This set of properties can only be guaranteed by a well-known manufacturer. On the contrary, for models from cheap and unknown companies, burners often fail and have to be replaced periodically, which only increases the final costs.

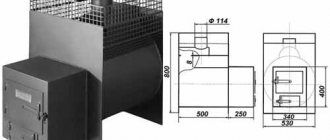

Schematic design of a gas stove for a bath Source pech-center.ru

- High efficiency . This characteristic is influenced not only by the main ones, but also by additional elements, for example, the exhaust system. And the parameter itself sets efficiency, productivity, completeness of fuel combustion, and the degree of purity of exhaust gases, on which the environmental situation of the house and site will depend.

On a note! There are universal models of gas furnaces. In addition to operating from the main burner, they can produce heat by burning solid or liquid fuels, and also use electricity if necessary.

Features of installation in a bathhouse

In order for a gas burner to operate efficiently and safely in a sauna stove, its installation must meet the following set of requirements:

- Quite a strong influx and outflow of air in the room.

- Possibility of traction adjustment.

- The volume of the room is at least 12 m³.

- Compliance with fire safety measures.

- High-quality thermal insulation of the chimney.

An example of using a gas stove in a bath Source pechiexpert.ru

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

To put the equipment into operation, you will definitely need permission from Rostechnadzor. Moreover, if it is powered by liquefied gas, it will require a special storage facility to store the containers. A gas cylinder is not allowed to be placed nearby - in the bathhouse itself or in the dressing room.

The use of such a burner for a bath is justified by the following advantages:

- Fast heating of water and stove body. The steam room is ready for use within 1 hour after startup.

- Compact equipment. Takes up much less space than a classic wood stove.

- Precise control of the heating level set by sensors.

- High system security when using automation.

- Economical consumption of energy resources. It’s a third more profitable than using firewood, and twice as profitable as using electric analogues.

- Environmental Safety. The stove does not become clogged with ash or soot and does not need to be cleaned. In addition, carbon monoxide is not generated.

However, the operation of gas equipment is always associated with the danger of an explosion and the need for strict compliance with norms and requirements, which, perhaps, limits its main disadvantages.

Compactness, safety and fast heating are the main properties of a gas stove Source stovecenter73.rf

Ignition type

All burners can be divided according to the type of ignition:

- Electronic type . They do not have a constantly working igniter. Requires electricity to operate. Electric ignition is one of the most convenient inventions for modern heating units. Thanks to him, the operation of the stoves has become as comfortable as possible. Electric ignition makes it possible to light the burner flame safely, without using available wicks or lighters.

- Burners with piezo ignition . No electricity needed.

Sometimes special working conditions are required, for example, burners are placed in a sauna stove, which must distribute the flame well. These are dividers or ordinary distribution tubes. This is how kitchen gas ovens work.

The fuel consumption passing through the burner can vary widely and depend on its design.

Gas burners for your furnace should be safe and energy efficient. This can be achieved if all technical requirements are met. Self-indulgence in this matter can only do harm. Therefore, the installation of gas burners must be carried out by specialists.

Types of gas burners

Modern types of gas burners are classified according to the following criteria:

- Technical parameters.

Based on power control capabilities, they are divided into:

- Single stage.

- Two-stage.

- Smoothly adjustable.

According to the method of supplying air to the combustion chamber, devices are divided into:

- Atmospheric.

- Supercharged.

- Diffusion-kinetic.

According to the modification of the ignition system, the equipment is divided into:

- Electronic.

- Ignition - ignited manually or by a piezo element.

Even though they have the same technical characteristics, devices may differ in design and area of use.

- Purpose and scope of application.

Depending on the purpose, place of application and installation in a specific type of equipment, burners are divided into 3 main types:

- For sauna stoves.

- For heating boilers.

- Universal.

Let's look at the features of each variety in more detail.

The dimensions and performance of the burner depend on the power of the heating equipment Source strojdvor.ru

Power management

First of all, the devices of this type differ in the ability to control thermal power into 3 main subtypes:

- Single stage . The characteristics of the gas flow do not change. Only the supply is turned on and off at the command of the rheostat.

- Two-stage . As necessary, when not operating heating is required, but only maintaining the already achieved level, the equipment automatically switches to economy mode.

- Smooth adjustment . The burner power can be changed in the range from 10 to 100%.

Reference! The burner power rating is the most important selection factor. The quantity is characterized as a certain amount of fuel burned in a specific unit of time.

Air supply method

Gas burners for heating boilers with automation are also classified according to the air supply mechanism into 3 main modifications:

- Atmospheric.

The device is simple. The air flows in naturally - by force of traction. In essence, it is a piece of pipe with holes through which gas is supplied.

Atmospheric type gas burner Source bani-nsk.ru

General rules for installing a chimney for a stove

Another condition for the normal operation of a gas stove is the installation of a chimney. For gas-fired stoves, smoke channels must be vertical, without ledges. The design of the chimney of a wood-burning stove is often not suitable for the removal of gas combustion products.

The slope of the chimney is allowed, but not more than 30°, and provided that the cross-section of pipes on inclined sections is not less than the cross-section of pipes installed vertically

You can refurbish an old chimney by lining it. Upgrade options:

- Installation of a stainless steel pipe in the chimney duct. In this case, the diameter and height of the pipe should be selected according to the characteristics of the chimney duct. The gap between the walls of the chimney and the pipe is filled with non-flammable heat-insulating material such as expanded clay or foam glass.

- Application of FuranFlex technology. The method involves placing an elastic polymer tube inside the channel, which, under pressure, takes its shape and hardens. The protective layer serves to insulate, seal and internally protect the chimney.

If none of the chimney modification options work, you will have to install a new one. Depending on the location of the stove, two options for installing a chimney are possible: an external attached one or an internal one.

The influence of the characteristics of the chimney on the safety of heating is such that it will necessarily be checked by the Fire Inspection authorities with the subsequent issuance of a written certificate, without which the equipment will not be connected to gas networks.

Video description

Video demonstration of how a stove gas burner works:

- For boiler.

Industrially manufactured heating units are equipped with burners of a given power, and therefore the consumer does not have to make any adjustments. It’s another matter when the boiler has to be assembled from separately purchased components.

In this case, it is necessary to take into account the type of combustion chamber of the unit - closed or open. The type of gas burner suitable for the appropriate operating conditions will depend on this indicator. Power, serviced area, need for automation and other important factors are also taken into account.

- Universal models.

Removable burners designed for installation in any suitable equipment. For example, they can be equipped with boilers and furnaces operating on solid or liquid fuels. At the same time, for maximum efficiency and productivity, such installations are equipped with a powerful air supply system, filters, gearbox and automation.

Principle of operation

Water circuits are rarely connected to gas stoves. The room is heated directly by heated air from the stove. The only difference with a solid fuel stove is that natural gas is used, not wood.

Advice. It is very easy to install a water circuit with a heat exchanger or a water tank in gas furnaces; sometimes a system is connected that allows warm air masses to be discharged into adjacent rooms.

There are options for gas stoves combined with a solid fuel unit or powered by electricity. There are universal burners that run on diesel fuel if the need arises.

Important. All installation and repair work related to gas fuel must be carried out exclusively by representatives of a specialized organization that has the appropriate permit.

Power calculation rules

When choosing a household gas burner for a stove or heating boiler for a home, it is necessary to take into account the required power - sufficient for the equipment to cope with its task. Typically, for every 1 m³ of steam room space, 1 kW of device is required. For example, if the volume of the bath is 5 cubic meters. m, then for high-quality heating you will need a 5 kW model.

The calculation should take into account corrections for heat loss, architectural features of the structure and deficiencies in thermal insulation. So, to compensate for heat loss through a window with an area of 1 m², you need to add 3 kW. Also, if the bathhouse is made of timber or logs, but does not have special insulation, the calculated value must be increased by 1.5 times. Similar, but more complex rules apply to determine the optimal boiler or heating furnace power for a home.

Important! Currently, home-made or home-made gas equipment has become widespread. According to regulatory requirements, the installation and operation of such products in a home or bathhouse is prohibited. In addition, they may be unsafe and ineffective.

Which one is better to choose?

Any buyer thinking about converting their wood stove to gas fuel must carefully weigh the many parameters and factors that will ultimately influence the choice of a specific solution. Atmospheric burners are cheaper - they can be purchased for as little as $100 and do not rely on electricity - but you will likely need some modifications to the fuel chamber. Blast (pressurized) burners are more advanced, easy to use, but expensive - their average price is about 250-300 dollars. The operation of such burners will require a minimum of attention and personal participation from the bathhouse owner.

However, in any case - if you are just planning to build your own bathhouse and are thinking about purchasing a heater stove - it is better to buy a ready-made gas stove with a built-in burner. The design of such a stove and the configuration of its fuel chamber will be adapted to the type of burner you have chosen, and it will be equipped with all the necessary automation and safety systems. And believe me, after you try a gas oven, you will not regret your choice.

Briefly about the main thing

A gas burner is a special device for burning natural gas to generate heat and use it to heat water or a room. It is used in house and sauna stoves and heating boilers. The design includes such basic elements as a nozzle, an ignition system, a flame control sensor and automation. The principle of operation is based on supplying gas to the nozzle and igniting it in response to a command from the control unit - depending on the temperature of the heated area.

The resulting flame heats the surface of the furnace body or the heat exchange circuit with the coolant. A modern gas burner must have high efficiency, noiselessness and durability. The main advantages of using it for a stove in a bathhouse are its smaller size, faster heating, efficiency and the ability to accurately control the temperature. Disadvantages manifest themselves in the need for strict compliance with special requirements and safety rules.

Existing types of gas burners installed in the stove of a bathhouse or at home, as well as in heating units, are classified according to the following parameters:

- Power settings options.

- Air supply mechanism.

- Type of ignition.

- Scope of application.

Each variety has its own number of advantages and disadvantages. When choosing equipment for specific application conditions, it is important to correctly calculate the power.

Ratings 0

Criterias of choice

When choosing a gas injector, take into account the following points:

- Model specifics - power, efficiency level, efficiency, economy, safety,

- Features of operation. When arranging a small bathhouse, preference is most often given to atmospheric models. Powerful automatic burners for blow-type sauna stoves are recommended for use in large rooms.

- Type of heating equipment.

- Features of fuel supply - from the main line, gas tank or cylinder.

- Purpose of the product.

Models of nozzles of certain categories provide for installation in certain types of heat generators. For example, some proposals from domestic manufacturers are designed for use exclusively in boilers with a long channel for the fuel mixture.

Installation in a bathhouse

If you want to install a gas-powered device in a steam room, you will first have to obtain permission from a specialized gas supply company.

Its employees will check the correct location of the device in the room and compliance with all safety measures.

When choosing a location for a sauna stove, you must follow the following rules:

- the walls around the stove are carefully covered with fire-resistant material ; a non-combustible base must be installed on the floor;

- the height of the fire-resistant base is 10 cm higher than the floor level ;

- the device itself is installed at least half a meter from the walls ;

- the presence of adjustable draft in the combustion chamber;

- the best option would be to position the stove so that its entire front side is in the dressing room, and not in the steam room - this will protect the stove from exposure to a humid atmosphere, facilitate control and increase safety;

- high-quality ventilation must be established in the dressing room ;

- all pipeline joints are checked for perfect tightness to avoid the risk of gas leakage ;

- The pipes connecting the stove to the chimney are insulated especially carefully - when passing through the ceilings and roof.

Important! Compliance with all requirements will allow you to install a gas stove with a ventilated burner without much difficulty. When using an atmospheric burner, the risk of a hazardous situation is significantly higher , and the inspection of the premises will be more thorough and strict.

Other differences

Let's consider the division of gas burners by type of ignition. The simplest option is with a burning igniter (wick). When the automation is triggered, the wick ignites the gas and the boiler begins to heat the coolant. There are two disadvantages here - increased gas consumption and low safety (the igniter may go out). Primary ignition is carried out with matches or using a piezoelectric element that produces a spark.

Natural gas from the mains provides even combustion without forming excessive soot on the walls of the chimney pipe.

Electronic ignition of the burner requires the presence of a high-voltage converter in the gas boiler. Energy is taken from batteries or the electrical network. The first option is used in non-volatile boilers that do not have electronic automation. The second option is relevant for complex units with electronics on board. Along with such ignition, modules for ionization control of the presence of flame are often installed.

There is also a division according to the type of fuel used. Natural gas supplied from the pipeline is cleaner, it is supplied at optimal pressure (we do not consider cases of pressure surges in both directions). The flame in the boiler is clean, without soot. The equipment is connected to the network without modifications. There are burners that can operate on propane - this requires setting up the system and installing a jet. The flame from propane combustion gives off a yellow color, and there is increased soot deposits on the chimney.

Jets allow you to normalize the propane pressure to an acceptable value - they are supplied as a set or purchased separately.

Safety regulations

Frequently encountered dangerous malfunctions and methods of elimination according to safety rules:

- flame failure is a moment during which the flame extinguished, but the gas supply did not stop. The solution is to turn off the gas supply and open the room in which the boiler is located for ventilation. During ventilation, it is strictly forbidden to use open fire, turn on and off electrical appliances, lighters, etc.;

- decrease in the filling of the circulation circuit with water - occurs when there is a water leak. If a leak is detected, turn off the boiler, but under no circumstances start filling the circulation circuit. Wait until it cools down completely, find the leak, and fix it. After which you will have to fill the circulation circuit again;

- the draft in the chimney has disappeared - stop the boiler, clean the chimney. Ventilate the room. When the draft resumes, return the boiler to operation;

- The pilot light goes out - turn off the boiler, carry out the switching procedure according to the passport and the attached instructions.

First start

Before starting the gas water heating boiler for the first time, it is necessary to check the correct installation and installation, in compliance with all instructions. The installed boiler must be inspected by a gas service inspector and sealed. After which you can begin preparing for the first launch. Before starting, the automation is configured with the required parameters set, following the operating instructions supplied with the boiler.

Filling the system with coolant

Step one is to fill the system with water or another coolant. The entire circulation circuit is checked for the presence or absence of “air” plugs in the system.

If present, air pockets must be vented by slowly releasing air through a special valve. Most often this is found on heating elements.

Etching should be carried out with caution, with the readiness to close the valve in time

Checking the supply lines

Step two is to check gas pipes, valves, and shut-off valves for leaks. The inspection is carried out by a gas service employee. But if you smell a specific gas smell, you can check it yourself before a specialist arrives and find the leak. For this, use a regular soap solution.

By applying it to welds, at the joints of pipes and shut-off valves, you can detect gas leaks.

Putting the boiler into operation

Step three is the direct start of the gas water heating boiler itself. Carry out strictly according to the attached instructions. If you can’t figure it out on your own, then it’s better to contact specialists who have access to this type of work.

Boiler shutdown

At the end of the heating season, if the boiler is not planned for use in the hot water supply system, then it must be turned off for a long period. To do this, follow a few simple steps:

- turn off the gas supply, make sure that the burner in the boiler goes out completely;

- turn off the power supply to automatic ignition and automation;

- shut off the water supply to heating and water supply.

No special additional actions are required. Do not drain the entire coolant circulation system to avoid corrosion.

GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

1.1. An employee who is at least 18 years old, who has undergone a medical examination and has no contraindications for health reasons, who has the necessary theoretical and practical training, who has completed introductory and initial workplace safety briefings and training according to a special program, and who is certified, is allowed to perform work using a gas burner. qualification commission and received permission to work independently. 1.2. An employee who performs work using a gas burner (hereinafter referred to as the employee) must periodically, at least once a year, undergo training and testing of knowledge of labor protection requirements and receive permission to perform high-risk work. 1.3. An employee, regardless of qualifications and work experience, must undergo repeated training on labor protection at least once every three months; If an employee violates labor safety requirements, as well as during a break in work for more than 30 calendar days, he must undergo an unscheduled briefing. 1.4. An employee who has not undergone timely instructions and testing of knowledge of labor protection requirements is not allowed to work independently. 1.5. An employee performing work using a gas burner, who is allowed to work independently, must know: safety measures when using gas cylinders and burners. Rules, regulations and instructions for labor protection and fire safety. Rules for the use of primary fire extinguishing agents. Methods of providing first aid in case of accidents. Internal labor regulations of the organization. 1.6. An employee sent to participate in work unusual for his profession must undergo targeted training on the safe performance of the upcoming work. 1.7. An employee is prohibited from using tools, devices and equipment that he has not been trained in the safe handling of. 1.8. When performing work using a gas burner, an employee may be exposed mainly to the following dangerous and harmful production factors: - the possibility of a fire when using a gas burner; — the possibility of a gas cylinder explosion; — gas burner surfaces heated to high temperatures; - uncomfortable working position. 1.9. An employee performing work using a gas burner must be aware that during work, the most likely cause of injury may be burns from the open flame of a gas burner. 1.10. To protect against the effects of dangerous and harmful production factors, the employee must use special clothing, safety shoes and other personal protective equipment. 1.11. To prevent the possibility of a fire, the employee must comply with fire safety requirements himself and prevent other employees from violating these requirements; Smoking is permitted only in designated areas. 1.12. The employee is obliged to comply with labor and production discipline, internal labor regulations; It should be remembered that drinking alcohol usually leads to accidents. 1.13. If an accident occurs with one of the employees, the victim must be given first aid, report the incident to the manager and maintain the situation of the incident, if this does not create a danger to others. 1.14. The employee, if necessary, must be able to provide first aid and use a first aid kit. 1.15. To prevent the possibility of illness, employees should observe personal hygiene rules, including thoroughly washing their hands with soap before eating. 1.16. It is not allowed to perform work while intoxicated or in a state caused by the consumption of narcotic drugs, psychotropic, toxic or other intoxicating substances, as well as drink alcoholic beverages, use narcotic drugs, psychotropic, toxic or other intoxicating substances at the workplace or during work. time. 1.17. An employee who violates or fails to comply with the requirements of labor safety instructions is considered a violator of industrial discipline and may be subject to disciplinary liability, and, depending on the consequences, to criminal liability; if the violation is associated with causing material damage, then the perpetrator may be held financially liable in the prescribed manner.

Trouble-shooting

Having a boiler at home brings many advantages, but it also has a number of disadvantages, and the user does not always know what to do correctly. Boiler faults are common to many types. It is important to promptly determine the cause of these faults before calling emergency services. List of the most common and most likely faults.

First of all, if the boiler does not start, you need to check the circuit components:

- network voltage;

- faulty boiler fan switch or motor;

- damaged boiler cables;

- false triggering contacts of automation or commissioning equipment;

- availability of water, whether the gas boiler is powered to the minimum required level specified by the equipment manufacturer.

If the boiler failure is not caused by any of these problems, the following procedure:

Pay attention to the noises made by the boiler, because they are often the first witnesses of destruction. They can also be due to hot water trapped inside the firebox or due to the presence of air in the heating system due to clogged air ducts.- Pipe rupture. It usually occurs due to problems with a jammed boiler feed valve, various scale-forming deposits in the boiler, or a malfunction of the condensate drainage systems.

- Failures due to exceeding the pressure and temperature readings, their corresponding sensors can trigger, for example, due to a broken thermometer or, conversely, which is especially dangerous as a result of real overheating of the boiler.

- The heating circuits are not working, possibly due to poor quality of feed water and scale formation in the boiler pipes.

- A problem occurs with the burner (flame breaks, gas accumulation causes detonation and explosion).

For some of these problems, mainly pressure or temperature, the boiler monitor displays an error message, then the system shuts down and automatically restarts. If the problem persists after restarting, it is best to call a professional to troubleshoot the problem. It should be noted, however, that most of these failures can be avoided.

The best prevention is to have your boiler inspected, maintained and cleaned annually, usually by a professional. This will prevent the pipes from clogging and bursting. Prevention is better than restoration, and a simple annual inspection will protect the equipment and the health of users from possible emergency situations.

Equipment setup

Floor-standing gas boilers with an atmospheric burner can be configured independently. Pressurized systems are regulated by an automatic control unit and do not require additional configuration.

Scheme of actions for setting up single-stage equipment:

- Install the device on the boiler.

- Connect to the gas pipe.

- Check for absolute tightness.

- Remove the burner housing.

- Using a pressure gauge, measure the gas pressure at the inlet.

- Connect to electricity. Make sure that the jumpers and phases are connected correctly.

- Place a gas analyzer in the chimney pipe.

- Start the device.

- Using a pressure gauge, take pressure readings at the outlet of the burner block. Pressure readings must correspond to the parameters indicated in the data sheet.

- Adjust the air flow using the air damper.

- The gas analyzer readings must also comply with all gas equipment installation standards.

Setting up gas equipment should be carried out by specialists. The simplest open-type boilers can be configured independently if you have certain skills and knowledge of the design of the burner unit. The efficiency of the boiler, its level of efficiency, and fuel consumption depend on the quality of the burner. It is possible to superficially determine that the equipment is malfunctioning by the changed burner flame.

A heating system where the main element is a gas stove is a common type of heating for private households and cottages. There are many things in favor of natural gas as a heat source: high efficiency, environmental friendliness, and the ability to make the heating process fully automated. The fuel itself is also the most inexpensive at present, unless, of course, you take into account wind energy and solar radiation. But these methods have not yet found wide demand due to the unaffordable price of the equipment.

The quality of gas heating depends on how efficiently the gas burner for the stove works.

Preparing for the manufacturing process

Having understood the structure of the gas burner and decided on the model, you can move on to the next preparatory step. Make a list of the necessary materials and tools.

The following list can be taken as a basis:

- steel tube 100 mm long and with walls 2 mm thick;

- fuel control valve;

- steel cap, piezoelectric element, rubber for handle;

- welding machine, grinder.

Don't forget about little things like connecting elements. For example, for a valve type VK-74 you need to stock up on a cap with a conical thread.

Advantages and disadvantages

Using burner equipment already has the advantage that you no longer have to spend a lot of time igniting the furnace itself. The combustion process will be initiated as quickly as possible and will not require any special effort. You just need to unscrew the valve and put the system into operation. But it is also worth noting that gas fuel is significantly cheaper than heating with wood, coal, electricity or diesel.

Even taking into account the gradual convergence of prices, the opportunity to save space on fuel storage is very attractive.

It is also worth noting that the devices are quite safe in terms of fire. The designers did not stand still, but continuously solved the problems of fire protection with the means available to them. In addition, natural gas burns at a lower temperature than coal or other fuels. Therefore, the chimney will become less hot. However, in just 60-90 minutes the room will be completely heated.

Automatic protection system

Unburned fuel in a sauna stove sometimes causes an explosion of the gas-air mixture. Therefore, monitoring the flame of a working nozzle is necessary for your safety. This can be done visually or using automation with modern photocells sensitive to light.

The burner protection system automatically provides the following functions:

- power regulation;

- fuel and air supply;

- completeness of gas combustion.

It is necessary to take into account the increase in dimensions of the modernized design. Especially with small bathhouse sizes. If device size is an important criterion for you, then all automation can be placed outside for compactness.

You can add automatic schemes for working with simple elements. Compact placement will save usable space in a small bathhouse

To control the combustion process, you can use an automatic factory-made installation such as SABK-8-50S. It provides a high level of security thanks to four levels of protection. The operation of furnace gas equipment with such a device will automatically stop in the event of a dangerous emergency mode.