- Metal grid

September 2, 2019

1818

In order to significantly increase the strength of monolithic concrete structures, a special reinforcing mesh is used. In order to correctly perform all the necessary installation operations, you will need to know how to calculate the reinforcing mesh. If you do not know the weight of the material, its length and the magnitude of the loads that the structure can withstand, you will never be able to perform the correct reinforcement.

Improper strengthening of reinforced concrete structures can lead to serious consequences. Cracks will appear, the service life will be significantly reduced, sometimes this can lead to the destruction of a building or structure.

In this article we will examine in detail all the issues related to calculations and selection of the necessary material for the construction of various objects.

Conversion tables m2 to kg

Welded mesh TU 14-4-1284-88

| Cell size x wire Ø | Weight 1 sq.m. in kg. |

| 16x24 light | 2.48 |

| 16x48 light | 1.99 |

| 24x48 light | 1.5 |

| 32x48 light | 1.25 |

| 32×24, 16×24 | 2.26 |

| 24x24 light | 1.97 |

| 16x24 galvanized | 2.81 |

| 16x48 galvanized | 2.24 |

| 24x48 galvanized | 1.7 |

| 32x48 zinc | 1.41 |

| 32×24+16×24 | 2.57 |

| 24x24 galvanized | 2.22 |

| TU 127500-245-00187211 | |

| 48x2.0 light | 1.01 |

Welded mesh made of VR-1 wire and B500S reinforcement in cards (sheets) cut to 2000x6000 mm

| Rod diameter, mm | Cell size, mm | Opening, mm | Weight m2, kg. |

| 4 | 100*100 | 2000*6000 | 1.84 |

| 4 | 150*150 | 2000*6000 | 1.22 |

| 4 | 200*200 | 2000*6000 | 0.92 |

| 5 | 100*100 | 2000*6000 | 2.88 |

| 5 | 150*150 | 2000*6000 | 1.92 |

| 5 | 200*200 | 2000*6000 | 1.44 |

| 6 | 100*100 | 2000*6000 | 4.44 |

| 6 | 150*150 | 2000*6000 | 2.96 |

| 6 | 200*200 | 2000*6000 | 2.22 |

| 8 | 100*100 | 2000*6000 | 7.9 |

| 8 | 150*150 | 2000*6000 | 5.26 |

| 8 | 200*200 | 2000*6000 | 3.95 |

| 10 | 100*100 | 2000*6000 | 12.34 |

| 10 | 150*150 | 2000*6000 | 12.38 |

| 10 | 200*200 | 2000*6000 | 6.19 |

| 12 | 100*100 | 2000*6000 | 17.8 |

| 12 | 150*150 | 2000*6000 | 11.84 |

| 12 | 200*200 | 2000*6000 | 8.88 |

If tables are not at hand, then the weight can be calculated this way:

- 1 meter of reinforcement = 1 m x (0.785 x L x D)

- The area of the circle is in parentheses. D - diameter.

- Specific gravity =7850 kg/m³

An example of calculating the required parameters

Let's consider the calculation of reinforcement for a strip foundation using an example.

Let's assume that the height of the tape is 100 cm and the width is 40 cm (a common version of a shallow foundation).

Then the cross-sectional area will be:

40 • 100 = 4000 cm2.

We determine the total cross-sectional area of the reinforcement (minimum):

4000: 1000 = 4 cm2.

Since the width of the tape is 40 cm, 2 rods need to be placed in one grid, and the total quantity is 4 pieces.

Then the minimum cross-sectional area of one rod will be 1 cm2. Using SNiP tables (or from other sources) we find the closest value. In this case, you can use reinforcing bars with a thickness of 12 mm.

Determine the number of longitudinal rods. Let's say the total length of the tape is 30 m (6: 6 m tape with one 6 m jumper).

Then the number of working rods with a length of 6 m will be:

(30 : 6) • 4 = 20 pcs.

Determine the number of vertical rods. Let's say the pitch of the clamps is 50 cm.

Then, with a tape length of 30 m, you will need:

30: 0.5 = 60 pcs.

Determine the length of one clamp.

To do this, subtract 10 cm from the width and height of the section and add up the results:

(40 - 10) + (100 - 10) = 120 cm. The length of one clamp is 120 • 2 = 140 cm = 2.4 m.

Total length of vertical reinforcement:

2.4 • 60 = 144 m. The number of rods with a length of 6 m will be 144: 6 = 24 pcs.

NOTE!

The obtained values should be increased by 10-15% in order to have a margin in case of errors or unexpected material costs.

parameters that should be taken into account when selecting a mesh

Determining the main characteristics will help not only calculate your costs, but also understand which products are best suited in each specific case. The metal mesh is selected depending on the reinforcement scheme and the characteristics of the construction site.

There are six main parameters that should be considered when selecting a mesh:

- The diameter of the steel bars from which the product is made;

- Corresponding product class;

- Maximum load values;

- Product weight and length values;

- The specific installation location and shape of the reinforced concrete structure;

- Product price.

The diameter of the rods will be one of the most important indicators that you should pay attention to first. The number of perceived loads, and, consequently, the strength of the structure will depend on this indicator. The thicker the mesh rods are, the more loads it can withstand. The diameter will also affect other indicators. For example, the larger it is, the greater the mass and price.

To strengthen heavily loaded slabs and foundations, products with rod thicknesses from 13 to 30 millimeters are used. Elements of buildings or structures that are not exposed to much external forces can be reinforced with a mesh with a rod diameter of 8 to 12 millimeters. In some cases, combined options are used, when mesh with different thicknesses is used in one reinforced concrete structure.

Reinforcement of warm and other types of floors

Reinforcement of screeds in residential premises

When choosing, preference is given to a mesh with small cells and thick wire. This increases the strength of the floor, but at the same time increases its weight. For interfloor ceilings this may be critical.

Therefore, the choice of material depends on the specific case:

- To strengthen the rough, warm, concrete floor in the apartment, a mesh with a rod diameter of 4 mm is used. and cell sizes 100x100 or 150x250 mm. Reinforcing the floor with such a mesh will provide the same strength as tongue and groove floorboards.

- To strengthen the floor in a garage in which a passenger car is parked (average weight 1.5 tons), a welded reinforcing mesh made of rods with a diameter of 8...16 mm and a cell size of 100x100 mm is used.

In certain cases, it is not technically possible to install a screed of the required thickness (for example, weak interfloor ceilings). In this case, there is a high probability of damage to it as a result of settlement of the house or increased load on the floor. Then, to prevent the appearance of cracks, fiber is used together with the reinforcing mesh. Fiber is polypropylene fiber. It is added to concrete, the strength of which increases by 3 times. Thanks to fiber, the durability of the material is increased and cracks are prevented.

Screed reinforcement gives the floor the following advantages:

- mechanical strength and reliability increases;

- Less concrete solution is consumed, which reduces the cost of repairs and reduces the load on interfloor floors.

Laying technology, consumption and other nuances

Work must be carried out in a room without drafts and with a temperature of at least 20 degrees.

First of all, you should decide on the type of screed, measure the area of work and calculate the required amount of materials.

When laying the screed on the ground, it is necessary to remove the top layer of soil and compact a substrate of expanded clay and sand.

When laying a screed on an old floor, the old coating should be removed, the surface should be cleaned of dirt, treated with anti-mold compounds and primed.

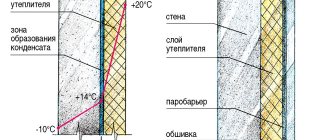

If the screed is floating, then a layer of hydro- or thermal insulation is required. Insulation is carried out using expanded clay, mineral wool or expanded polystyrene, which is protected with a layer of film, membrane or roofing felt.

Fittings for beacons

Using a level, find the highest point of the rough foundation, calculate the height of the screed, the minimum value is 30 mm.

Mark a horizontal marking line on the walls of the room.

The mesh should be laid on pieces of brick, plasterboard or on special clamps so that it is located directly in the screed layer and not on the floor (ground).

Then you need to install the beacons (strictly along the marking line), they are located 1.5 meters from each other and at some distance from the wall.

The mesh is laid with an overlap of 1-2 cells.

Reinforcement mesh

It is recommended to attach damper tape to the walls, which prevents the concrete from cracking when drying.

Then the concrete solution is prepared and poured, distributed evenly over the surface, using the rule the screed is made level.

During the first 1-5 days, the screed is moistened with water.

After 6-7 days, the beacons are removed, the voids are filled with solution. After a month, the screed is ready for further work.

The mesh consumption is calculated in square meters. The consumption rate depends on the installation method and the size of the outlets. But it should be remembered that the norm must be calculated as follows - room area + 10%. In addition, some sites provide the opportunity to perform calculations per 1 sq.m. using an online calculator.

How and why weight is calculated

Determining the weight of the mesh for reinforcement is carried out in order to understand how much the finished construction project will weigh. This parameter will also be very important when choosing methods for delivering products to the construction site.

First you need to find out the diameter of the rods from which the mesh is made and the geometric dimensions of the cells. There are special tables that indicate the weight of the product depending on the above parameters.

If you made an individual order for the production of mesh of non-standard sizes, then you will not be able to calculate the weight of this product using the table, because it takes into account only standard sizes. In this case, it will be necessary to use special formulas for calculation. If you don’t want to do this yourself, you can delegate the task to experienced professionals who will calculate everything in a short time.

Installation of metal reinforcing mesh for floor screed

If the thickness of the screed does not exceed 6 cm, it must be reinforced. Reinforcement can be excluded only in screeds with a thickness of more than 8 cm. For reinforcing concrete screeds for floors, the most suitable masonry meshes with cells of 10*10 and 15*15 cm, made of wire with a diameter of 3-4 mm. In cases where a large load on the floor is planned, it is recommended to use a mesh made of thicker wire, and increase the thickness of the concrete pour to 15 cm. It is worth remembering that the reinforcing mesh should be located in the center of the concrete pour, so it is not laid on the subfloor, but on substrates. Before work, the subfloor must be cleaned of dirt, treated with waterproofing and adhesive agents, and reinforced with heat and sound insulation materials. To ensure that the future floor is impeccably smooth, the concrete screed is made along special guides made of metal profiles - beacons. The quality of the screed surface depends on the correct installation.

- Using a level, we determine the highest point of the existing rough coating. At this point the screed should be at least 4 cm.

- Using a level (laser, mounting or hydraulic level), we mark a verified marking line on the walls.

- We set parallel guide beacons (profiles). It is better not to use wooden blocks and pipes; industrial guide strips with stiffeners are much more convenient. They are produced three meters long and 2.5 cm wide.

Before work, we remove the existing baseboards, dismantle the old floor covering, and lay down heat-insulating materials with a layer of about 15 cm (expanded clay, etc.). Inside the expanded clay cushion (in the middle of the layer) we lay the first layer of reinforcing mesh. We compact the insulation and lay plastic film.

Laying polyethylene film on expanded clay

We lay a reinforcing mesh with cells measuring 10x10 cm. Under no circumstances should the mesh lie on the thermal insulation layer. Be sure to place either special plastic stands or small pieces of drywall under it.

We lay the reinforcing mesh on the stands

We will place the beacons parallel to the longest wall of the room. For ease of work and maintaining horizontality, nylon threads should be stretched between the walls, which will serve as guides when installing the planks. When the threads are tensioned, each profile is raised to the position of the tensioned threads and secured with a solution of building plaster or alabaster.

Laying beacons for floor screed - photo

Next, you should wait about half an hour until the construction plaster dries completely. We mix a cement solution that is not too liquid (it should be borne in mind that the solution becomes unusable two hours after mixing, so it is not advisable to prepare it in large quantities at once) and pour it between the beacons.

Fill the solution between the beacons

We move the rule along the beacons, leveling the cement.

Leveling the floor using the rule - photo

For 3-5 days, be sure to fill the screed with water, maintain high humidity in the room and ensure there are no drafts. This is necessary to prevent the cement from cracking during drying. Complete drying occurs within four weeks. For perfect smoothness, it is advisable to pour a small layer of self-leveling mixture on top of the dried screed.

Construction of a slab foundation with your own hands.

First you need to prepare the site; this is perhaps the most labor-intensive operation in the construction of a slab foundation. To do this, the top layer of soil is completely removed to a depth determined by calculation. It is recommended to remove and level the last layer manually; this is done in order to avoid unevenness and holes. The pit itself must exceed the dimensions of the foundation by 1-2 m on all sides for ease of work.

Preparing a cushion for a slab foundation made of sand and gravel. Such a cushion is necessary to compensate for the forces of soil deformation, as well as to drain groundwater and prevent its capillary rise to the base of the foundation. The thickness of the cushion depends on the type of soil: on sandy soils it can be 15 centimeters, on saturated clay soils or prone to severe heaving - at least 30 centimeters. Sand is poured into the pit, evenly and distributed over the entire area of the foundation, after which it is thoroughly compacted. For swampy or wet types of soil, part of the cushion will consist of crushed stone, this improves the waterproofing of concrete.

Construction of formwork for a slab foundation. The formwork for a slab foundation must consist of planed boards with a thickness of at least 20 mm, which are connected at the corners using self-tapping screws. From the outside, the formwork is strengthened with struts. Sometimes permanent formwork made of fiberboard is used for slab foundations. It is attached to metal corners and ties, and then struts are also arranged. After the work described above, it is necessary to construct penetrations for communications, and at the same time install formwork around them. Pipes can also be laid and routed through penetrations before the foundation is poured.

Waterproofing of a slab foundation is carried out using a thick polyethylene film, geotextile or roofing felt; it is laid overlapping on the bottom of the pit with an approach to the formwork.

Reinforcement of a slab foundation is a very important stage; the strength of not only the foundation itself, but also the building as a whole will depend on it. For small structures, reinforcement can be done using reinforcing mesh with a mesh size of 10-15 centimeters, and the places where load-bearing walls will be installed must be reinforced with metal rods. If the structure of the structure is more massive, for reinforcement it is necessary to use a rod with a diameter of 10-12 mm, laid in the form of a mesh. The transverse rods are knitted together using wire. Welding of reinforcement is rarely used, since excessive stresses arise at the welding points when the structure moves. The reinforcing mesh must be completely immersed in concrete; for this it is installed on special guides. If the thickness of the foundation is large, then several layers of reinforcement are installed.

Pouring concrete for a slab foundation is done simultaneously, so you will either have to order concrete or mix it very quickly with your own hands. Therefore, pouring must be done by a team of 4-5 people. Concrete is poured into prepared formwork with laid reinforcement, after which it is compacted first using an internal vibrator, and then using a vibrating lath. After punching the concrete and removing voids and air from it, it is smoothed and the surface is leveled.

Drying of the slab foundation occurs within 4-5 weeks. During this time, the concrete gains the necessary strength, after which it is ready for further use. During drying, you need to carefully monitor that the top layer of the foundation does not dry out and is not exposed to excessive moisture; for this, you can use a material with which the concrete can be covered. After the concrete has dried, to improve the thermal insulation properties, the slab foundation can be insulated using polystyrene slabs.

Marking of welded mesh

When choosing the required type of mesh, you need to be guided by the designations printed on the products; several letters and numbers contain all the basic information about this mesh, allowing you to make the right choice.

The first digit indicates the following product type:

- 1 - heavy, reinforced with longitudinal working rods of large sections;

- 2 - heavy, in which the working rods are located mutually perpendicular along and across the card;

- 3 - heavy, working rods of larger cross-section are located across the web;

- 4 - light type with reinforcement across the canvas along its entire width;

- 5 - light types, with a mixed arrangement of transverse reinforcing bars.

Welded structures are designated with a capital letter “C”. When supplied in rolls, the product is designated “Sr”. The diameters of the longitudinal rods are designated by the letter “d”, and the diameters of the transverse rods by “d1”. Additionally, the class of steel used in manufacturing, the pitch and size (a) of the release of transverse rods and (a1, a2) longitudinal ones are indicated. The Latin letters “b” and “l” indicate the dimensions of the width and length of the canvas in cm.

So the following marking of the product 2C - 30 A-III / 25 A-III - 205 × 665 indicates that we have a welded mesh of the 2nd type with working reinforcement A-III with diameters of 30 mm in the longitudinal direction and 25 in the transverse direction , the width of the product is 205, and the length is 665 cm.

In the marking of metal woven netting, the chain-link first indicates a number indicating the accuracy group of the mesh sizes. If square letter designations are not used for the cells, the letter “P” is indicated for a diamond shape. Next, indicate the size of the sides of the cell in mm and the wire diameter used.

For example, the marking 2-P-25-1.6 means that the presented grouse is made of reinforcing wire with a cross-section of 1.6 mm with diamond-shaped cells measuring 25 mm according to the 2nd accuracy class.

Description

The metal sheet is made of steel reinforcement with periodic corrugation of the surface. Resistance spot welding is used to connect the rods into a single structure. The mesh is supplied in flat cards and rolls. The form of implementation depends on the diameter of the reinforcement and the cell size. According to GOST requirements, reinforcing steel with a diameter of 3 to 40 mm is used for the production of welded reinforcing mesh. The cell size varies from 100x100 mm to 500x500 mm. According to the agreed specification, it is possible to order mesh of non-standard sizes.

Table 1. Parameters of welded reinforcement mesh.

| Grid category | Type | Width, mm | Length, mm | Wire diameter, mm |

| Heavy | 1 | 650 – 3050 | 850 – 9000 | from 6 to 40 |

| 2 | 850 – 5950 | from 6 to 25 | ||

| 3 | 850 – 5950 | 850 – 6250 | from 6 to 25 | |

| Lightweight | 4 | 850 – 9000 | 850 – 9000 | from 3 to 10 |

| 5 | 3950 – 9000 | 3950 – 9000 | from 3 to 10 |

This is interesting: A500C reinforcement assortment table

Application of the formula for calculating wall area

To calculate the total number of brick products, it is rational to use a method that is based on calculating the area of the walls. This value is found by multiplying by the number of bricks needed to build a brick wall measuring 1x1 m.

It is also important to take into account the fact that the thickness of the wall can be different, then the correct calculation will be where it will not be the area of the walls that will be calculated, but its volume directly. There is a formula we all know from school to help us:. V = a*b*c

V = a*b*c

The letter a denotes the height of the wall, b is the width of the masonry itself, c is the thickness.

Attention: when performing calculations, it is necessary to take into account openings for windows and doors, which must be subtracted, since they will not be included in the formula

Useful tips

Before you begin to calculate the amount of materials and the foundation itself, you need to study all the features of the soil. Heaving soil can rise and fall several centimeters throughout the year. If this is not taken into account, then over time the foundation will begin to burst under loads, and cracks will spread throughout the house.

The reinforcement is connected to each other with wire, which makes it movable and because of this, the hardened concrete, under the influence of soil deformations, will also be movable, which will preserve its structure and guarantee the absence of cracks.

Video on the topic:

Types of reinforcing mesh

Reinforcing mesh can be classified according to several parameters. First of all, reinforcing mesh can be divided into types based on the thickness of the starting material used:

- If the reinforcing mesh is made of relatively thin metal wire, then it is conventionally called “thin”,

- If the reinforcing mesh is made of a thick metal rod, then it can be conventionally called “thick”.

In addition, the reinforcing mesh can be manufactured with varying degrees of accuracy.

Ordinary welding precision, quite suitable for carrying out external construction work, and reinforcement mesh with increased precision may stand out. The accuracy of welding of reinforcement mesh elements is indicated by numbers after the letter “P” in the marking.

Reinforcement mesh sample

Separately, it is worth mentioning the form in which the reinforcing mesh is supplied from industrial enterprises. Depending on the thickness of the elements used, the mesh can be supplied from the factory in the form of flat plates or in the form of rolls.

In addition, depending on the purpose, the reinforcing mesh can be manufactured with different cell configurations. They can be rectangular or square.

Reinforcement mesh sheets

Why do calculations need to be done?

First, you need to understand why the procedure for reinforcing reinforced concrete structures for various purposes is performed at all. First of all, this is necessary in order to make the construction project more durable and monolithic. The mesh will tighten the concrete, thereby increasing rigidity. This will allow it to withstand heavy loads and also increase its service life.

The reinforcement procedure is quite complex and requires high precision. Therefore, before you begin strengthening concrete structures, you will need to perform all the necessary calculations of the main indicators and characteristics. This will help not only choose the right material, but also save a lot. You will know exactly how much of the relevant products to purchase.

Various building structures (floors, floors, walls, supports, slabs, etc.) require strengthening. Depending on this, a specific reinforcement scheme is selected. This diagram includes a number of rules and basic provisions in accordance with which the installation and assembly of the metal mesh will be carried out. Accordingly, calculations of the main parameters will be performed in different ways.

How to make the right choice

The choice of reinforcing bars is based on design data and builder preferences.

Typically, metal rods are chosen, although composite reinforcement is increasingly used every year in the construction of strip foundations. Preference is given to metal rods due to the ability to give them the necessary bend, which is impossible to do with fiberglass rods.

This is especially important when constructing belts with curved sections or when there are fracture angles other than 90°. In addition, metal reinforcement is more economical, as it allows you to make clamps from a single rod, without the need to create several connection points

In addition, metal reinforcement is more economical, as it allows you to make clamps from a single rod, without the need to create several connection points.

The diameters of the rods have long been worked out in practice; they are often chosen without preliminary calculation - for a tape width of about 30 cm, a 10 mm rod is used, for tapes 40 cm wide, 12 mm rods are chosen, and for a width of more than 50 cm, 14 mm. The thickness of the vertical reinforcement is determined by the height of the tape; up to 70 cm, 6 mm is chosen, and for heights above 70 cm, 8 mm or more.

Correspondence table for reinforcement weights for different diameters

The standard weight of reinforcement of a particular diameter is regulated by GOST 5781-82 standards. The standard calculation table looks like this:

Table of correspondence of reinforcement weight depending on the diameter of the rods

This table is absolutely easy to use. In the first column we select the diameter of the rod in mm that will be used, in the second column we immediately see the weight of one linear meter of a rod of this type.

The third column shows us the number of linear meters of reinforcement in one ton.

1.1 Calculation of reinforcement weight

There are several ways to calculate the mass of reinforcing bars required for construction.

The first and easiest way to find out how much a meter of reinforcement weighs is to use an electronic calculator for similar calculations.

To work with it, you only need to know the diameter of the rod with which we will work. All other calculation parameters are already included in the program.

The other two ways to find out how heavy a reinforcement meter is are somewhat more complicated. Let's look at them in order of increasing complexity.

Since in private construction reinforcement with a diameter of 12 mm and 14 mm is most often used, we will take these rods as the basis for the calculations.

1.2 Example of calculating the weight of reinforcement (video)

Why do you need foundation reinforcement?

It is known that stone structures (which include concrete - artificial stone) withstand compressive loads well, but easily break when stretched or bent. The main load experienced by the foundation is central compression. The question may arise: why do you need to reinforce the foundation at all, if concrete copes well with the loads acting on it even without reinforcement? This is exactly what builders reasoned at the beginning of the last century. As a result, many buildings from those times of construction have defects in the form of gaping cracks in the walls and distortions.

Some of these buildings can no longer be restored and must be demolished. And all this in most cases is due to improperly executed foundations. Do not forget that a patent for reinforced concrete was received in France by J. Monnier in 1867, and the use of reinforced concrete structures in construction began at the beginning of the 20th century, and its widest distribution began in the war (for the creation of fortifications) and the post-war period (for accelerated restoration and rebuilding what was destroyed during the war). It turned out that reinforcing foundations can significantly reduce the consumption of materials, make them stronger and more reliable, and withstand bending loads that occur during frost heaving of the soil (when the soil freezes, it increases in volume due to the water contained in it), during a sudden rise in groundwater or emergency leaks in utilities in subsidence soils that tend to sharply lose their bearing capacity when soaked.

Used grades of reinforcing steel

In regulatory construction documentation, all reinforcing steels are divided into 6 classes: from A-I to A-VI. All classes, except A-I with a smooth section, have a periodic (ribbed) profile. Roman numerals indicate the strength levels of steels. The designation of hot-rolled steels with thermal hardening includes the letter “T” (for example, AT V). Reinforcing wire is divided into 2 classes. B-I is used as distribution structural reinforcement, and B-II is used as working reinforcement in light-type meshes. If the wire has a ribbed surface, the letter “r” is added to its designation (for example, VR-1).

In accordance with current state standards, the following types of reinforcing steels are used for the manufacture of building mesh:

- hot-rolled reinforcing steels A-III, with increased strength, sections from 12 to 40 mm, as well as thermally strengthened properties when rolling steel of class At-III-C, for working reinforcement of heavy-type meshes;

- reinforcing bars made of hot-rolled steel AI and A-II as working reinforcement for light meshes and structural distribution for heavy ones;

- wire BP-I and V-I for working reinforcement in light types of meshes and structural reinforcement in heavy ones.

To provide additional protection against corrosion, galvanized reinforcing mesh is used. The zinc layer is applied to products using the following methods:

- electrolysis of rods performed before welding the meshes (about 10 g/m2);

- electrolysis of finished meshes (layer thickness 20 g/m2);

- hot galvanizing (up to 130 g/m2).

The greater the thickness of the protective layer, the higher the protective characteristics. Although galvanized products are more expensive than black ones, their high quality, durability and good appearance fully justify the higher prices.

Classification of meshes for reinforcement

Types of reinforcement products:

a - flat mesh

b, c - flat frames

g - spatial frame

d, f - spatial frames of T- and I-sections, respectively

g - bent mesh

h - spatial frame, bent from meshes

and - embedded parts

Reinforcing mesh is divided into two main subtypes presented below:

1. According to the original location of the working fittings .

- The working reinforcement goes in one direction and is distributed in the other (both longitudinal and transverse strips can be working).

- The working fittings are made in both directions.

2. According to the diameter of vertical and horizontal rods .

- Heavy (12-40mm);

- Lungs. (3-10mm)

Heavy types include meshes with a diameter of over 12 mm . Light include all other meshes that are in diameter from 3 to 10 mm inclusive.

In order to increase service life, this building element can be galvanized or treated with polymers, which have a protective function and prevent the formation of corrosion.

Conventions. How to read the label correctly?

Currently, a single standard marking has been adopted to indicate types of fittings:

- AI (hot rolled smooth, Roman numeral I indicates strength level)

- AII, AIII, AIV. AV, AVII (hot rolled ribbed)

- AT III, AT IV, AT V, AT VI (hot-rolled heat-strengthened)

- B-1 (cold rolled with round section)

- VR-1 (cold rolled with periodic profiling)

Transcript example

“ 100x100x5 ” is a mesh with a cell size of 100 by 100 mm , made of 5 VR-1 corrugated wire .

Types of wire

According to GOST 3282-7, various types of general purpose wire are produced, however, only heat-treated wire is suitable for tying reinforcement. It is marked with the letter O. Annealing is used to return the product to its original ductility, which is lost during drawing.

The production process begins with broaching. At this stage, the product receives its geometric size. Next, it is sent to bell furnaces for firing in a nitrogen environment. Since the wire does not have contact with oxygen during annealing, its surface remains light and is not covered with scale. By this feature, you can distinguish rolled products made in accordance with GOST from lower-quality analogues. If the product was fired in oxygen, it will have a black coating that leaves marks on the hands. In this case, knitting of reinforcement with knitting wire is done while wearing gloves.

There is also galvanized binding wire. It is marked with the letter C. However, its use in monolithic works is not advisable, since the concrete solution reliably protects the connecting nodes from exposure to oxygen. It is more suitable for the construction of fences, the manufacture of gabions and other products that will be used in the air.

Which binding wire for reinforcement is better? There is no clear answer. The products are identical in their physical and mechanical properties. The question comes down to price, scope of use, convenience and speed of operation.

Calculation of slab base reinforcement

The reinforcement of the slab is selected taking into account its thickness. If it is less than 15 cm, lay one mesh with a cell of 15-20 cm, with a larger value - two. The frame is welded from rods with a diameter of 12-16 mm, connected to the top layer of reinforcement with vertical clamps with section dimensions up to 10 mm.

Slab foundationSource keysdom.ru

The calculation of the slab is carried out according to the Code of Rules 50-101-2004 and the “Guidelines for the design of slab foundations”. It consists in determining the bearing capacity based on the specific load on the soil and bending forces.

The width of the foundation slab is 10 cm greater than the size of the house. For the reinforcement mesh, determine the number of rods in both directions. If two frames are used, double the number of rods.

To find how much reinforcement is required for connections, determine the number of joints in the mesh. It is multiplied by the length of the clamp, equal to the thickness of the slab minus the protective layer of concrete.

Reinforcement of slab foundationSource stankotec.ru

Now you can calculate the required amount of reinforcement, allowing for a margin of about 5%. Based on the steel grade, its weight is determined.

The quality of this product

The characteristics of welded mesh depend on their purpose:

- masonry and road;

- strengthening thermal insulation and glass.

Use wire with low carbon content. Rods of different lengths are welded using resistance spot welding. Protection against corrosion is carried out by polymer coating or galvanizing, which is carried out in several ways:

- galvanizing of rods before welding;

- electrolytic method;

- hot coating.

Reinforcement without a galvanized layer is called light.

The welded mesh for glass and thermal insulation is corrugated in 1 or 2 layers.

Consumption of reinforcement during reinforcement

Having accurate numbers, you can choose the right reinforcement, slab thickness, grade and amount of concrete. This in turn will save effort and money.

Let us remind you again, no matter how trivial it may be, but you should not save on purchasing high-quality building materials, especially when it comes to the foundation. Otherwise, it may affect the life of the structure, and during repairs you will need to shell out much more money than was saved.

There are generally accepted standards for calculating the consumption of reinforcing material per 1 cubic meter of concrete solution. When laying, the reinforcement is placed close to the surface of the slab, leaving 3-5 cm from the edge.

Calculation using the example of an 8x8 slab

The exact amount of reinforcement is calculated using the example of a slab measuring 8x8 meters.

For soil stability, a ∅ 10 mm reinforcement rod is ideal. As a rule, a mesh of reinforcement is laid out in increments of up to 200 mm. Based on this, it is not difficult to calculate the required number of rods.

To do this, the width of the slab is divided by the step size in meters and 1 rod is added (8/0.2+1=41). To obtain a mesh, the rods are placed in a perpendicular direction. This means that the result obtained must be multiplied by two (41x2 = 82 rods).

Important! When installing a monolithic slab, it is necessary to lay a two-layer mesh of reinforcement on top and bottom. Therefore, we multiply the data by two again (82x2=164 rods)

The length of a standard reinforcing bar is 6 meters. Based on this, the following calculation is obtained: 164x6 = 984 m.

The layers are interconnected by intersection points, the number of which can be easily calculated if the number of rods is multiplied by the same indicator (41x41 = 1681 pieces). Reinforcement in the form of a grid is laid 5 cm from the base of the slab.

The thickness of the monolithic slab is 200 mm. To make the connection, you will need a rod 0.1 meters long.

To make all connections you will need 0.1 x 1681 = 168.1 meters of reinforcing material. In total, 984 + 168.1 = 1152.1 meters of reinforcement will be required for construction work, this can now be calculated in weight if you know how much a meter of reinforcement weighs

The figure will also be important for calculating the loads on the foundations of the building

Almost always, reinforcing bars are sold in construction stores in kilograms. One rod weighs on average 0.66 kg, which means that 0.66x1152.1 = 760 kilograms of reinforcement will be required.

Calculation of reinforcement for a monolithic slab

Calculation of reinforcement for a monolithic slab Monolithic slabs are used when it is planned to deviate from standard parameters during construction and use the special characteristics of buildings.

What is a selection calculator

On the Internet you can find various online calculators that help you determine all the necessary parameters in a few clicks. These are specially programmed algorithms. To calculate, you will need to specify the basic parameters, and the program will give you the result.

There are two types of calculators. The first type helps to determine the loads, and the second helps to calculate the weight and cost of rolled metal. The load calculator gives only a general idea, but not exact data. Therefore, it cannot be used to draw up a project. Exact load values should be calculated only by experienced people and using special formulas and algorithms.

You can use the weight and price calculator to its fullest potential. It gives fairly accurate indicators. The program has several fields to fill out. They indicate the thickness of the rods, the dimensions of the cells and the cost of one ton of specific products. If you have to reinforce structures of a rather complex shape, then the mesh will have to be cut. In this case, an additional percentage must be taken into account. In most cases this is no more than 5 percent.

After you have filled out all the fields, click on the calculation button, and the calculator will give you the weight of the material and the total cost. It is very easy to find such programs on the Internet; you just need to enter the corresponding query in the search bar.

For high-quality strengthening of various reinforced concrete structures (floors, floors, slabs, blocks, supports, bridges, etc.), you need to know how to calculate the reinforcing mesh. This procedure consists of several steps that must be performed sequentially. We discussed each of these stages in detail in the article.

Conversion tables m2 to kg

Welded mesh TU 14-4-1284-88

| Cell size x wire Ø | Weight 1 sq.m. in kg. |

| 16x24 light | 2,48 |

| 16x48 light | 1,99 |

| 24x48 light | 1,5 |

| 32x48 light | 1,25 |

| 32×24, 16×24 | 2,26 |

| 24x24 light | 1,97 |

| 16x24 galvanized | 2,81 |

| 16x48 galvanized | 2,24 |

| 24x48 galvanized | 1,7 |

| 32x48 zinc | 1,41 |

| 32×24+16×24 | 2,57 |

| 24x24 galvanized | 2,22 |

| TU 127500-245-00187211 | |

| 48x2.0 light | 1,01 |

Welded mesh made of VR-1 wire and B500S reinforcement in cards (sheets) cut to 2000x6000 mm

| Rod diameter, mm | Cell size, mm | Opening, mm | Weight m2, kg. |

| 4 | 100*100 | 2000*6000 | 1.84 |

| 4 | 150*150 | 2000*6000 | 1.22 |

| 4 | 200*200 | 2000*6000 | 0.92 |

| 5 | 100*100 | 2000*6000 | 2.88 |

| 5 | 150*150 | 2000*6000 | 1.92 |

| 5 | 200*200 | 2000*6000 | 1.44 |

| 6 | 100*100 | 2000*6000 | 4.44 |

| 6 | 150*150 | 2000*6000 | 2.96 |

| 6 | 200*200 | 2000*6000 | 2.22 |

| 8 | 100*100 | 2000*6000 | 7.9 |

| 8 | 150*150 | 2000*6000 | 5.26 |

| 8 | 200*200 | 2000*6000 | 3.95 |

| 10 | 100*100 | 2000*6000 | 12.34 |

| 10 | 150*150 | 2000*6000 | 12.38 |

| 10 | 200*200 | 2000*6000 | 6.19 |

| 12 | 100*100 | 2000*6000 | 17.8 |

| 12 | 150*150 | 2000*6000 | 11.84 |

| 12 | 200*200 | 2000*6000 | 8,88 |

If tables are not at hand, then the weight can be found out by simple calculations.

- 1 meter of reinforcement = 1 m x (0.785 x L x D)

- The area of the circle is in parentheses. D - diameter.

- Specific gravity =7850 kg/m³

Reinforcement of floor slabs

Floor slabs manufactured at concrete factories have standard dimensions and a load-bearing capacity determined by calculation. Reinforcement of such slabs is carried out with reinforcing mesh and embedded parts according to a project developed by specialized organizations. The parameters of the slabs are indicated by the seller and selected based on the required indicators for a particular building.

Independent production of a monolithic reinforced concrete slab is not possible due to the complexity of carrying out calculations of the structure and formwork itself, and the need to use heavy construction mechanisms and devices in the manufacturing process. A small error in calculations can lead to accidents or destruction of the building, which can endanger human life and health. Therefore, to carry out this type of work, it is imperative to contact specialists.

Scope of application of the reinforcing frame

Reinforcing mesh provides a multiple increase in the strength of any structure that involves its use. The key tasks during construction are considered to be reinforcing the foundation and giving greater strength to the walls - creating a kind of wall frame. which ensures long-term operation of the entire structure.

- Reinforcement of quickly destructible road surfaces.

- For reinforcement during masonry work.

- To strengthen the foundation.

- To improve performance and strengthen thermal insulation.

- For leveling and maximizing the strengthening of the original floor covering.

- For strengthening walls when working with plaster.

- It is also used in the production of partitions in both private houses and apartments.