A do-it-yourself door closer is a good option to ensure comfortable operation of the door leaf without spending your budget. There are many ways to make a door closer yourself; this can be done using available materials such as a spring, cable or rubber. A homemade door closer, made in compliance with all the nuances, can serve for a long time, its functionality will not differ at all from a device purchased in a store. On our website you can learn how to make a door closer with your own hands.

Why do you need a closer?

Before installing a door closer, you need to understand its purpose and functions.

Before installing a door closer, you need to understand its purpose and functions. What is the essence of this device? This simple mechanism ensures smooth and silent movement of the door leaf both when opening and closing. In the second case, his role is especially noticeable; he attracts or, in other words, brings the door to the desired position.

Thanks to door closers, you can keep the room warm in winter or cool in summer; it ensures complete adherence of the leaf to the door frame; some models allow you to fully automate the doors. Modern models have many useful functions; with their help, you can set access control, time to ventilate the room, block the door position, etc.

Settings

Setting up a homemade mechanism is as follows:

- the speed of movement of the sash in a homemade product is regulated by changing the length of the elastic element (in spring structures) or the weight of the load (in gravitational ones);

- To change the adjustment to the zero position, change the thickness of the shock-absorbing hose.

When setting up, you can take into account other design flaws, for example, install a shock absorber on the load if it touches the wall, enlarge the hole in the ball if the door is difficult to open, etc.

What can you expect from a door closer?

The functions that factory closers have can significantly simplify the operation of doors. Closers are generally expected to:

- Increasing service life and protecting doors from damage due to the depreciation created by the door closer. If you apply more force than necessary to close it several times, the door leaf and box may be damaged or deformed. If a closer is installed, there is no need to be afraid of this. Drafts will also not be a problem.

- Limiting the speed of opening or closing will reduce the risk of injury to a person who is not expecting the door to move. When she moves slowly, there is more time to react to it and avoid the blow.

- The delayed closing function relieves the human ear from unpleasant pops and knocks. Thanks to it, the door leaf smoothly leans against the frame.

- If necessary, you can lock the door in the open position and not be afraid that it will accidentally close.

- If you don’t have the time or desire to close the door, you can safely not do this, since the pull function will do everything automatically.

All such requirements can be safely put forward to factory door closers. If you make the mechanism yourself, then some functions will not be available. It is impossible to make an analogue of a factory product from scrap materials and using home tools.

Homemade or factory made?

Factory closers have an undeniable number of advantages:

- easy adjustment;

- aesthetics;

- increased reliability.

In fact, their only drawback is the price: it is unwise to spend a lot of money if you need to take care of closing the door leading to the cellar, pantry or garage. In such situations, homemade analogues come in handy. With proper installation and assembly, they regularly perform the functions of a door closer, and at the same time, the cost of creating such an analogue is often limited by the price of the part itself.

Voted over 279 times, average rating 4.2

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Closer, Accessories Features of a closer, and why it is worth purchasing it for a sliding door An open door can cause drafts and cold in ...

Closer, Accessories Which GOST controls the production and installation of door closers? The doors are equipped with special fittings – closers. Purpose…

Closer, Accessories Types of floor-mounted door closers Modern people pay special attention to comfort, safety and ...

Closer, Accessories Characteristics of an electric door closer If you want to achieve a quiet and smooth closing of the door in ...

Closers for entrance doors: types of mechanical devices

Considering the method and place of fastening of door closers for entrance doors, they are divided into the following groups:

- overhead closers;

- bottom (floor) closers;

- hidden (frame) closers.

Overhead closers are fairly common and universal door closers. These types of door closers are mainly used for building entrance doors. They are distinguished by simple installation: the sliding rod and lever are fixed on the lintel of the door frame, and the body is fixed on the inner upper surface of the door leaf.

The design of top-mount door closers offered by different manufacturers may differ in their operating principle. A mechanism with a lever drive and a toothed gear is popular. Another current option is a door closer with a sliding rod and a cam gear.

As for hidden closers for interior doors, they are installed at the production stage of the doors themselves; lower closers are installed in the floor, making them almost invisible.

Classification of closers

The operating principle of any device, regardless of its type, is based on the integrated work of a spring and an oil shock absorber - the main components of the system

Installation of door closers begins with their selection. The operating principle of any device, regardless of its type, is based on the integrated work of a spring and an oil shock absorber - the main components of the system. The viscosity of the shock-absorbing fluid flowing from one chamber through the shock absorber system to another gives smoothness to the processes of closing and opening the door. The type of closer is determined by the mechanism that drives the spring:

- Top closers, the working body of which is mounted above the door or directly on the door leaf;

- Floor closers are an almost invisible system, especially popular in shopping centers;

- Hidden.

The company's specialists will select and install door closers that are optimally suited for each specific case. In addition, we offer high-quality installation of magnetic locks on the doors of public and residential buildings and premises.

Thus, a lightweight office door can be equipped with a magnetic lock that holds 70-150 kg of weight. Outdoor doors weighing over 100 kg. They need more powerful protection - for them our experts recommend magnetic locks with a holding force of up to 500 kg. The most serious objects require the highest security. In this case, it would be optimal to install a magnetic lock with a holding force of over 1000 kg.

Design and principle of operation of a door closer

The door closer device includes a lever rod and the housing itself with a mechanism that allows the door to take a closed position. The mechanism consists of a fairly powerful spring, compressed due to the force of the piston drive. The spring, usually made of steel, is enclosed in a special capsule. The capsule contains oil, which, when the spring returns to its original position, moves through hydraulic channels into the working container. This technology ensures smooth and soft closing of the door.

The door closer is adjusted using specially designed screws located at the end of the housing. As the screws rotate, they change the cross-section of the channels, which affects the speed of oil movement and, accordingly, the rate at which the door closes.

Improved models of door closers have an additional closer valve that allows you to hold the movement of the door leaf. This happens when the door opens already at 70 degrees before closing, and just before closing (when up to 15 degrees remains), the movement accelerates, which helps to press the door tightly. Thanks to this design, the closer copes with the force of the latches on the doors and overcomes the air resistance formed when closing.

There are door closer models equipped with the additional function of blocking door movement. This system regulates the spontaneous closing of the door. It is very convenient when large items (furniture, household appliances, etc.) need to be brought into the room. The door opens 90 degrees or more and is fixed until it is pushed to close, after which the closer mechanism will ensure its smooth and silent closing.

Door closers can perform a number of additional functions, including a door delay for 30 seconds, a door closing coordinator for door models with more than one leaf, and a sudden swing shock absorber (damper).

Rear doorman

For ease of use of the trunk, we came up with a hands-free access system

. We have already discussed the principle of its operation. And here is how the power drive of the luggage compartment lid works.

An electric motor with a gear reducer that turns the lid by its hinges.

An electric motor with a gear reducer that turns the lid by its hinges.

Moreover, such devices are used both on heavy fifth doors of station wagons and on the lids of sedans.

There are also cars with a hydraulically driven trunk lid.

, but

the drive in the form of a sliding rod with a built-in electric drive

.

Hydraulic drive of the trunk lid of the Volkswagen Phaeton sedan: 1 - hydraulic cylinder; 2 - hydraulic unit; 3 - electric motor; 4 — trunk loop.

Hydraulic drive of the trunk lid of the Volkswagen Phaeton sedan: 1 - hydraulic cylinder; 2 - hydraulic unit; 3 - electric motor; 4 — trunk loop.

A simple do-it-yourself closer option

Not many materials are required for manufacturing. Before you start making your own door closer, you definitely need to pay attention to its weight. To make the simplest design you will need a load.

The more massive and heavier the door is in size, the greater the weight of the closer should be. Those who are making a much-needed household item for doors for the first time with their own hands are usually advised to try to determine the weight of the load experimentally. There is no specific formula for how to calculate the mass of a load.

For the simplest version of the closer, you will need a cable or rope. In order for it to move up and down, the door needs one more element - a wheel. The weight is attached to the end of a rope or cable. It is he who will pull the canvas. But another question arises: what should be done so that the door leaf and the wall are not damaged, because the load will hit them and this action will not have a positive effect on their appearance?

To prevent this from happening, take a piece of plastic pipe, place a load in it and attach it to a cable or rope, attach the structure to the canvas - and the closer is ready.

Do-it-yourself spring-based door closer

Another version of a door closer for a light wooden panel can be made independently. The main structure will be a spring; when closing and opening, it will gently return the canvas to the position where it was. A door closer designed according to this principle is completed quickly. But it is not suitable for massive, heavy canvases, since the spring tends to become unusable quite quickly with constant use.

The spring design of the closure, if complicated, will become many times more reliable and durable. But first you need to figure out what other elements are needed to install the entire structure on the door. The spring is its basis. But we also need a shock absorber to slow down the movement of the door.

The main design will be a spring; when closing and opening, it will gently return the canvas to the position where it was

The shock absorber of the closer is designed on the principle of an ordinary piston. It consists of two chambers, inside of which there is oil. The door opens and one of them is filled with oil. When it is closed using this design, the oil is poured into another. There is nothing fundamentally new in the design of such a mechanism that a person would not learn from a school physics course.

Even a novice craftsman can easily make a door closer if the inside of the device is done correctly. In order for the oil to move back, a bypass valve must be installed inside such a structure. But you can go another way: do not install an oil shock absorber on it, but instead install a regular pump.

It is believed that it is quite difficult to adjust it to the operation of the door. This is indeed true, because such a closer, like the one designed in the form of a rope and a primitive load, is adjusted to the functioning of the doors only experimentally.

To make such a design, a rack and pinion gear is also selected. Its size depends on the size of the structure. The load on the spring comes precisely through it. The stronger the rack and pinion gear, the longer the door closer will last and be more reliable in operation.

Those who prefer to solve the problem without resorting to such complex devices even suggest using a piece of old rubber or part of a car inner tube as a closer. It will not look so aesthetically pleasing, but for some time it will be able to work quite reliably until the owner of the house or apartment makes another design with his own hands.

DIY magnetic door closer

A magnetic door closer is very simple to implement. Even a novice craftsman can easily cope with its manufacture. For this you will need:

A magnetic door closer is very simple to implement. Even a novice craftsman can easily cope with its manufacture.magnet;

- metal plate with mounting holes;

- self-tapping screws;

- chisel;

- screwdriver

The parts are installed flush according to pre-applied markings to provide them with maximum adhesion, which, in turn, will facilitate the door to close tightly. Working surfaces (those on which markings are applied) are cleaned using a chisel to the required depth. The magnet is attached to the frame, and the metal plate is attached to the canvas itself, which is done using self-tapping screws. When the door is closed, the magnet and plate must be completely aligned with each other. This guarantees high-quality operation of the mechanism.

Door closer made from rubber elements

Another option for a homemade closer is a mechanism that is assembled from a rubber hose, cable, car camera, expander, or even a rubber bulb, which can be easily purchased at any pharmacy. The appearance of this type of door closer is very unique, so it is best to install it in those rooms where guests do not visit so often, and where the structure itself will be hidden from prying eyes.

This ensures soft shock absorption of the door and absence of noise during its movement. Installation of the elements is very simple. First, markings are applied, according to which the device is located on the box either closer to the hinges or from the outer corner of the canvas. The first installation option will provide a smoother closing of the door.

The rubber bulb is placed with its sharp end towards the frame and fixed on the plane with a screw or nail. When the door is closed, the pear slowly deflates, and when opened, it quickly restores its previous shape.

What functions should the slamming mechanism perform?

Before you make an automatic door closer with your own hands, you need to have an idea of what it should ultimately provide. The main function is shock absorption - preventing the door leaf from hitting the frame. Along with this, the following functionality is highlighted:

- adjustment - the ability to set the closing speed;

- attraction - if the closure is not tight, the mechanism will close the door itself;

- fixation - the ability to fix the closer in one position.

The last point is not mandatory for factory models either, so in the homemade version, any suitable objects are used as a stopper.

Its closing mechanism must attract and smoothly close the door. For these purposes, ready-made parts from cars or improvised means are used.

How to install door closers

How to install a door closer correctly? To do this, it is necessary that high-quality door awnings are embedded and the door itself is installed without distortions. You should avoid installing a powerful door closer on a plastic door that is light in weight or has a narrow design. In this case, this will affect the service life of the door and the use of additional force when opening it. This also applies to the installation of closers for glass doors.

Closers are mounted on the door itself or on the door frame and can be installed internally or externally. All products are supplied with an installation diagram and instructions for adjusting the door closer. The diagram is made in full size, which is very convenient for error-free mounting.

The diagram is fixed with tape directly on the door, and the locations of the holes are marked on it. Following all the instructions in the instructions, the device body is secured.

As soon as the mechanism of the device is secured, the installation of the lever sliding rod begins. It consists of two halves connected to each other by thread. The length of the lever is adjustable taking into account the door opening angle of 90 degrees. If the door closer is installed correctly, the door closes evenly and silently.

If you are not entirely confident in your skills or do not have the necessary tools for installation, you should seek help from specialists.

How to install the simplest spring closer

To install the simplest spring closer you will need to spend a minimum of labor and money

To install the simplest spring closer you will need to spend a minimum of labor and money. It is enough to buy a suitable spring and fasteners and install them. One end is attached to the door frame, and the other to the leaf. This completes the installation work. The main difficulty is that here the spring must also be selected experimentally based on the tightening force, as in the first option.

You can improve the mechanism and thereby expand the functionality of the closer by additionally installing a shock absorber. It will serve to slow down the movement of the door and soften the impact when closing.

The shock absorber consists of two sealed chambers fastened together. There is a bypass valve between them. In one of the chambers, when the mechanism is at rest, there is oil. When the shock absorber stretches and the door opens, oil flows from one chamber to another. After the end of the movement, when the hand releases the door, the spring force comes into play, pressing the shock absorber in the opposite direction. At this time, oil under pressure slowly flows back into the first chamber, and the valve smoothly closes.

If you can’t find a suitable shock absorber, you can take the simplest bicycle pump instead. Using it, the mechanism will work almost the same.

You can make a mechanism with your own hands using other materials, but the two described methods are the simplest and will look good. If all the work is done correctly, the structure can last a long time. And the most important thing is that the costs will be almost invisible.

The secret to securely attaching hinges

There is such an important point when using hinges - this is the reliability of fastening the doors. Without reliable fastening, the smooth fastening system will be unnecessary.

Hinge Cup Attachment

You can secure the hinge cup to the door using self-tapping screws, but there is a more reliable method of fastening using special spacer plugs and screws.

To install the plugs, you need to drill two holes with a diameter of 8 mm. Find out if such a service is provided in the place where you order drilling for awnings.

| Rice. 27-28. Drilling the facade under the hinge cup and spacer plugs |

| Rice. 29. Spacer plugs for attaching the hinge cup |

| Rice. 30. Installation diagram for a hinge with Expando spacer plugs |

Mounting the strike plate

The strike plate can be secured to the side wall using self-tapping screws, Euroscrews, and the most reliable way is with Euroscrews of smaller diameter through spacer plugs.

The structure of the chipboard is loose and a self-tapping screw or Euroscrew may eventually break out of the chipboard and you won’t be able to screw it back in, you’ll have to glue in the chips, re-drill, and then, it won’t last long, you’ll have to change the side wall. Only a bar for spacer plugs will ensure long-lasting and reliable fastening.

Drilling is done with a drill with a diameter of 5 mm, similar to drilling for Euro screws.

If you don’t have the time or extra money to improve your door design, you can make a door closer with your own hands. In this case, you can use the simplest items that you probably have in your pantry. Such a homemade mechanism will allow you to eliminate the problem of door knocking at minimal cost.

How to adjust door closers

As for adjusting the door closer, the device has two screws for different stages of closing. With their help, regulation occurs. The first closing range is the main movement of the door, the second is the finishing of the door to the closed position starting from an angle of 15-20 degrees just before closing (finishing-slam).

Initially, the door opening angle is set. To do this, use a screw to select the desired position of 90 or 180. After this, the speed of movement of the door leaf is set, which is regulated by the second screw. The door is opened to the set angle and released, and by rotating the second screw, the uniformity of the move at the last degrees and the resulting slam are adjusted.

When adjusting the doors yourself, you should remember that you should not rotate the screw with great force. Turning the screw a quarter has a noticeable effect of slowing down the door. During the operation of the mechanism, they adjust the door closer with their own hands. If the installation and operation of the closer is carried out correctly, then adjustment will only be needed when the air temperature changes.

Sources:

- https://remoo.ru/okna-i-dveri/dovodchiki-dlya-vhodnyh-dverej

- https://garpun.by/furnitura/kak-ustanovit-dovodchik-na-dver.html

- https://www.itcentr.net/montazh/dvernyh-dovodchikov/

- https://yaris124.ru/1/kak-sdelat-dovodchik-dveri-svoimi-rukami

- https://dvernojmir.ru/izgotovlenie/dvernoj-dovodchik-svoimi-rukami.html

- https://gruppawlc.ru/delaem-dovodchik-dlia-dveri-svoimi-rykami-iz-podrychnyh-materialov/

Automotive parts

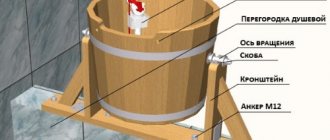

If you don’t know how to make a door closer with your own hands, look for suitable spare parts in a car door. It's great if you have an unnecessary spare part that ensures smooth movement of the trunk in five-door models. In this case, a car door motion limiter can be installed in the opening of an interior or even an entrance door. How to make a door closer from a spare car door with your own hands? To attach the lifter rod and cylinder, you will need to attach a bracket with “fingers” to the parts. Screw one side of it to the wall or frame, and the other to the canvas. With the help of such a device, you can ensure not only smooth movement of the door, but also hold it in the open position if necessary.

You can build a door closer with your own hands using spare parts from a car door closer