Izospan is an insulating film coating. The main purpose of the film is to ensure that the original thermal insulation characteristics are maintained throughout its entire service life. It is difficult to imagine a modern construction project without the use of various types of thermal insulation. Mineral wool, Penoplex, Izolon, Izover, various polystyrene foams and simply polystyrene foam - all these materials require their own protection.

Thermal insulation materials practically envelop our house, retain heat on frosty and rainy days, create comfort in the hot summer, preventing the penetration of heat flows. But how to protect the thermal insulation belt from negative atmospheric phenomena? Reliable protection from moisture, rain, damaging winds is designed to be provided by 100% polypropylene, with the proud name - Izospan .

To create a barrier at the stages of the construction process, to perform the function of protective insulation for thermal insulation, this is the true purpose that isospan vapor barrier successfully fulfills. Despite its apparent simplicity, the material differs by type.

We bring to your attention – Izospan instructions for use. Figure it out: which side to lay the isospan on. Consider the isospan technical characteristics, and the installation method.

Worthy competitors of isospan:

- Tyvek vapor barrier;

- Vapor barrier TechnoNIKOL;

- Vapor barrier Nanoizol;

- Vapor barrier Ondutis;

- Vapor barrier Yutafol.

Before moving on to a detailed review, it should be clarified that the films are presented by the manufacturer in a wide variety and have different purposes. Vapor barrier films and membranes are divided into absolutely vapor- and water-tight and partially permeable to moisture only in one direction. Some of the materials successfully complement thermal insulation, enhancing its characteristics.

Vapor barrier isospan technical characteristics

- The material is waterproof;

- Elasticity is beyond praise; it is not difficult to get around the most difficult areas and bends;

- Resistance to ultraviolet radiation;

- Resistance to negative atmospheric phenomena;

- Does not emit harmful substances. Safe for human health. Does not harm the environment.

- Withstands temperature changes in the range from – 60 °C to + 80 °C

- Fireproof elements added in production determine the fire hazard group G4, which is confirmed by relevant certificates.

Izospan has various applications, taking into account the field of construction use. Isospan, a type of insulation unique in its structure, has individual technical characteristics and its own labeling.

Manufacturers classify their products by letter indices A, B, C, D, F, R. The combination of letter indices adds numerous variety, applications and installation of isospan. Each new designation assumes its own isospan application. This fact must be taken into account when building your home.

roof vapor barrier isospan

Advantages and disadvantages

Izospan insulation belongs to the category of building materials, therefore it has advantages and disadvantages. This feature is typical for any product, however, in the case of the vapor barrier of this brand, there are noticeably more advantages than disadvantages. Let's look at the strengths of the material.

The undeniable advantages include the following characteristics:

- High water repellency.

- Resistant to any external factors and mechanical damage.

- Absolute inertness to the development of pathogenic microflora (wall mold, fungus).

- Environmental Safety.

- Ease of installation.

- Long-term operation – at least 50 years .

Disadvantages include the high cost of some model groups and the lack of fire resistance.

Izospan A

The membrane, like a check valve, freely allows water vapor to pass through from the thermal insulation side. Does not interfere with the natural ventilation of the insulation. On the other hand, it reliably blocks the penetration of moisture from the external atmosphere, prevents the formation of condensation, and prevents the wind from destroying the structure of the insulation.

Due to the water resistance of the material on the outside, membranes are widely used in roofing structures and are widely used as protection for walls and ventilated facades of buildings and structures for any purpose.

The waterproofing property that the isospan membrane has long extends the service life of the thermal insulation. Even the best insulation is destroyed over time under the influence of wind; the use of Izospan A will be the ideal solution to protect the outside of the house.

In a nutshell, we will clarify which side to lay Izospan A . The question of which side of Izospan A should be laid is far from idle. As we noted, its operation is carried out on the principle of a check valve. Or, if you want: – let everyone out, don’t let anyone through. The membrane must be laid on the outside, on top of the insulation.

The smooth side, which is easily identified by touch, should “look” towards the street. The roll is cut into wide strips of suitable size, after which it is carefully spread over the area, overlapping with the next layer.

Roof vapor barrier

Water vapor barrier of the roof starts from the bottom. When laying isospan A membranes, contact with the thermal insulation material should be avoided. Touching the membrane significantly reduces its waterproofing properties.

Probably those who went camping with their grandfather’s canvas tent noticed that if during rain you run your finger along the “roof” from the inside, then literally after 10 minutes it will drip in that place. It is for this reason that laying Izospan A is allowed only with double lathing.

Isospan flooring is carried out outside the thermal insulation on a lathing made of slats. The use of a membrane increases the degree of insulation and extends the life of the entire structure.

It is extremely important to monitor the absence of possible swelling or sagging during work. Otherwise, you will become a constant listener to gusts of wind with the characteristic sounds of a membrane beating on the roof. Thin slats are enough to secure isospan A, leaving 2-3 centimeters of free space to the insulation.

Preparation for installation of a water vapor barrier layer

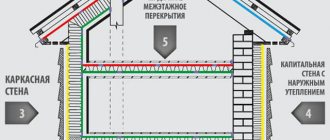

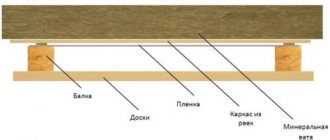

Installation of Izospan V involves a number of preparatory works. In general, the floor pie in a wooden house is the following design:

- rough base;

- wooden logs;

- thermal insulation layer;

- waterproofing;

- finishing floor;

- finishing coating.

You should not violate the technology for installing a wooden floor, because otherwise the structure will turn out to be unreliable. The entire pie should ideally rest on brick or concrete supports, with a small ventilated area between the soil and the wood floor. The vapor barrier should be installed immediately during the construction of the house; there is no need to postpone this stage “for later”.

Vapor barrier will reliably protect against moisture and condensation

Preparations before laying the vapor barrier membrane are as follows. To begin with, all wooden parts of the floor pie are treated with a special protective compound, which will allow the tree to acquire immunity to rot and fungus for the longest possible period. Particular attention should be paid to wooden joists and the rough floor, on which the membrane material will be laid.

On a note! If the vapor barrier layer is planned to be installed in an already finished building, then before doing so it is recommended to replace all the old elements with new ones. This is a replacement of insulation and worn elements of the subfloor.

Connecting tape (adhesive tape) Izospan FL

Izospan B

As we found out, isospan A, firstly, protects from the wind, and secondly, it creates a powerful hydrobarrier for the insulation. There remains a danger in the form of condensation, wetting of the insulation - condensation, which, before passing through the membrane in the form of steam, saturates the thermal insulation with moisture.

Humidification by only 5% will reduce the thermal insulation performance by half. The further prospect is the penetration of condensation onto the metal tiles, with the subsequent transformation of the roof into a colander.

The anti-condensation surface in combination with the steam and waterproof effect will save you from such troubles. When carrying out installation work on arranging the roof, you must clearly understand that even the best insulation for the roof is gradually saturated with water vapor.

By creating a barrier to internal vapors, Izospan B will serve as a kind of vapor barrier. The material consists of two layers, a layer with a smooth structure is adjacent to the insulation during installation, the second fleecy side is designed to absorb condensation.

That is why the installation of the coating is always carried out with the fleecy side down, with a gap to the finishing materials, for ventilation and drying. Type B is laid with an overlap with an overlap of at least 10 centimeters on the insulation side and secured using a construction stapler or another method.

Where is it used?

This group “B” (B) is considered universal, therefore it has a rather multifaceted scope of application. The only installation limitation is internal installation. Izospan B is not suitable for external insulation; there are other groups for this. For internal insulation, the material is used to insulate the following surfaces:

- Wall structures.

- Internal partitions.

- Interfloor ceilings.

- Floors in rooms with high humidity.

- Underlay for parquet or laminate.

- Roof insulation.

This demand is due to the fact that the thermal insulation pie will not cope with its functions without a vapor barrier film.

Which side should I lay towards the insulation?

According to the official instructions:

- For the roof. Smooth side to insulation.

- For walls. Smooth side to insulation.

- Attic floors. The film is laid between the finishing material of the living room ceiling and the rough ceiling (smooth side towards the rough ceiling).

- Basement ceiling. The rough side is towards the insulation.

Izospan S

The structure of the material combines two layers: on one side there is a smooth surface, on the other there is a fleecy surface. The fleecy layer retains condensation followed by weathering. Izospan C creates a vapor barrier for the insulation, preventing the absorption of vapor from water particles formed inside the room.

The material is widely used in the construction of walls, installation of insulated, sloping roofs and interfloor ceilings. Steam-waterproofing using type C is installed in various cement screeds and in flat roof structures.

In a word, in structure and characteristics the material is very similar to type B. At the same time, it has an increased margin of safety and, therefore, the reliability of the super-dense panel is higher. Buying isospan C will cost the consumer about 50-60% more than type B.

Characteristics of isospan Type C:

- 100% polypropylene;

- Applicable temperature range -60 – +80 °C;

- Tensile load: longitudinal // transverse. N//5cm not less than 197/119

- Vapor-tight

- water resistance not less than: 1000 mm water column.

Application of isospan S:

- Sloping roof with an overlap of at least 15 cm

- Attic floor protection. A vapor barrier layer is spread on top of the insulation, smooth side down;

- Concrete floor. spread on a concrete surface, smooth side down;

- Wooden floors of horizontal design.

Laying the canvas on sloping roofs should be done from bottom to top. The material overlaps about 15 centimeters.

To avoid depressurization, overlapped joints are glued together with a special tape that is sticky on both sides, similar to double-sided tape.

The structure is secured with slats 5 cm thick. A gap of at least 5 centimeters is left between the roof tiles and the vapor barrier layer; it is necessary for natural ventilation.

Izospan C is spread on top of the insulation; for ventilation it is necessary to leave a gap of about 50 millimeters from the panel to the heat-insulating material. In the installation of a concrete floor, type C, an overlap is laid on the concrete surface, then a cement screed is laid on the canvas, and only after that the floor covering is installed.

Main functions

The need to use a vapor barrier is obvious, because excess vapor release is one of the most destructive effects, since it can pass through any building material in a structure, even brick or concrete. The main functions are:

- protection of the structure and heat-insulating material from exposure to steam;

- thanks to the water-repellent composition with which the Izospan B vapor barrier is treated, it can also be used as a waterproofing layer;

- Due to its strength, this material can be used as a vapor barrier when finishing a pitched roof.

Izospan D

High-strength, completely moisture-proof waterproofing material. Polypropylene sheet with one-sided laminated polypropylene coating. The versatility of the moisture-vapor-proof material implies widespread use in construction technologies for the construction of any type of structure.

Izospan D successfully withstands moderately strong mechanical loads, is resistant to tearing, withstands strong gusts of wind, and in winter copes with heavy snow loads. In comparison with other similar films, Izospan D has gained fame as the most durable and reliable option.

Izospan D Area of application

In any type of roof, as a barrier preventing the formation of under-roof condensation. Widely used in the installation of hydro- and vapor barriers during the construction of buildings and structures. Protection of wooden structures. The material largely resists negative atmospheric phenomena.

Izospan D is often used on construction sites as a temporary roof covering and installation of a protective wall in objects under construction. Such a roof or wall can last up to four months.

Type D is especially popular when constructing concrete floors that require a waterproofing layer to protect against earth moisture.

Manufacturer company

All categories of Izospan are manufactured by Izospan, which has its own production facility in the Tver region. The company produces various membrane films with vapor barrier, moisture-repellent and energy-saving properties.

Products undergo strict quality control at all stages of production and have international certificates of conformity. Thanks to these features, the products are in consistently high demand in the domestic and European markets.

Useful tips

Izospan is not installed on a plastered ceiling. The reason is that the interior decoration will suffer if the membrane is on top, because moisture will accumulate under it, destroying the coating and stimulating the formation of fungus. There is no need to use foam or polystyrene foam film. The latter do not have vapor permeability, so they act as insulators.

In a room where Izospan is laid on the ceiling, ventilation is important to reduce the percentage of moisture in the air. If the material is torn in the middle during installation, the damage is sealed with construction tape or tape placed between the sheets. This is done in two or three layers so that the cut does not spread when the membrane is pulled. The installation process is clearly shown in the video below.