Today we will talk about the most important “insides” of building structures. Many will ask: “What “internal organs” are you going to tell us about? Well, I won’t languish for a long time, I’ll answer right away.

One of the vital “organs” of any structure is the foundation grillage. Do you know what this is? Superficial? Okay, then make yourself comfortable. Now we will study it in more detail and discuss in detail the pile-grillage foundation...

Features and basic concepts

Concept

A grillage is a so-called horizontal platform of a pile or column base, which distributes the weight of the structure and evenly transfers its entire weight to the supports. And they, in turn, transfer the load to the ground.

In other words, its purpose is to combine piles or pillars into a solid working structure, which prevents uneven subsidence, cracking of walls, dampness, attack by various microorganisms, insects, rodents, corrosion and destruction of the room.

Thus, a well-made grillage is the key to the durability of the entire structure.

Recognized advantages of grillage

Our hero is known for the following undeniable advantages:

- security;

- versatility;

- multifunctionality;

- practicality;

- reliability;

- strength;

- wear resistance;

- durability;

- efficiency of construction;

- reducing the volume of necessary land work;

- reducing labor costs for installing the device;

- low cost;

- high stability and load-bearing capacity;

- suitability for absolutely any site;

- admissibility of use on almost any soil - sandstone, clay, and quicksand;

- the ability to create curved objects;

- reduced consumption of concrete solution (compared to “ribbon”);

- reduction of heat losses;

- reduction of vibration levels;

- the variety of raw materials intended for its creation;

- the ability to carry out construction at any time of the year, however, if the temperature is not lower than 10°C.

The design, thanks to a well-constructed grillage, will certainly delight you with its impeccable technical characteristics and charming appearance!

Annoying disadvantages

The grillage is known for the following negative “moments”:

- the need to make accurate calculations;

- the impossibility of construction on moving soil - swelling and subsidence;

- inadmissibility of use in the construction of multi-storey buildings;

- impossibility of constructing a basement;

- the need for additional insulating materials.

Attention! Before constructing a particular facility, invite highly qualified specialists to inspect the site, select the type of foundation, grillage for it and make accurate calculations.

Formwork work

Installed grillage formwork

After driving the piles, proceed to installing the grillage formwork. Along the perimeter of the base of the future building, formwork is installed with a height equal to the thickness of the foundation slab. The fencing is made of boards or construction plywood. Plywood is a very durable, reusable building material. Therefore, you can take it from a construction site where the foundation has already been made.

The sides of the formwork are reinforced on the outside with stops made from available material. The supports should not allow the formwork boards to creep away from the pressure of the concrete mixture. Any gaps in the formwork are unacceptable. Cement laitance will leak out through them and the result will be concrete of poor quality. On a previously prepared soil base, with the top layer previously removed, a cushion of crushed stone or gravel-sand mixture is arranged.

Purpose

The grillage is a structure that has a wide range of applications. Let's look at where and under what circumstances it is used.

1.The construction of the facility is carried out on the following soils:

- clayey;

- peat;

- heaving;

- loess-like;

- silty;

- loamy.

2.The construction of the house is carried out on slopes or areas with ornate relief.

3.The creation of the structure is carried out using frame technology. Piles or pillars will support the object from below.

4. The construction of the structure is carried out in an area where the soil freezes to a depth of more than 2 m.

5. The construction of an object with a base width of more than 2 m is being carried out.

As you can see, the grillage is a universal element.

Optimal location

For reliable and long-term service of the grillage foundation, minimizing structural deformations and maximizing its compliance with the state regulations, it is necessary to correctly choose a place for it relative to the soil level. It is better to place the piles vertically (sometimes a small angle of inclination is acceptable on uneven areas). It is most rational to install high or hanging grillages above bored support columns at a height of 0.1 m above ground level. It is believed that this arrangement of the reinforced concrete grillage helps to avoid deformation of the structure and will preserve its solidity for a long time.

The resulting heat loss in the house due to free spaces under the floor can be solved by installing underfloor panels or other additional insulation.

Calculation

To make the calculation, you need to collect all the information about the territory on which the structure is planned to be erected.

For calculations you need information about:

- physical and geographical conditions;

- geological structure;

- hydrological conditions;

- physical properties of the soil.

Based on this information:

- grillage parameters are determined;

- loads are calculated;

- the depth of placement is calculated;

- the required number of supports is determined;

- the diameter of the piles or pillars is calculated.

It is advisable to entrust this work to specialists, since the slightest mistake in calculations leads to disastrous consequences.

Construction of the basement.

After the pile monolithic foundation is built, we proceed to finishing the base. The upper edge of the basement trim is attached to the bottom of the house and is protected from above by a special galvanized canopy (shimmer). From below, the finishing does not reach the ground by several centimeters. This is done so that during soil heaving the base is not subject to deformation. To remove precipitation, drainage is installed, and a concrete blind area about 70 cm wide is made. The best solution for a blind area around the entire perimeter of the house is paving slabs. It is durable, aesthetic and repairable.

Classification

The durability, ergonomics and aesthetics of the structure depend on the type of grillage laid on a pile or columnar foundation. Therefore, his choice should not be taken seriously.

The grillage is classified according to:

- location;

- designs;

- material.

Types of object by location

There are three types of grillage depending on location.

1.High foundation type. It is expedient, as it is located 15–25 cm, or even higher, from the surface of the earth. Due to this, additional floor ventilation is created, which eliminates dampness and mold.

This design also allows you to get under the structure to check the integrity of the foundation of the home and, if necessary, repair it without any problems. In addition, the void under the floor is an additional storage area, for example, for gardening tools or for drying crops.

There is also a drawback: in a house with a high grillage it is impossible to make a basement, so the cellar must be built separately.

2.Low grillage type. Objects of this type are built level with the ground surface. 20 cm of soil is removed from under the formwork so that the slab or beams are above the air “cushion”, but do not touch the soil.

Thanks to this design, there is no space under the home that does not “steal” heat, which allows significant savings on thermal insulation material. True, you will have to spend a little money to insulate the “cushion”, otherwise the grillage will lie on the ground, which will lead to the soil shedding into the open space.

3. Recessed type of base. This option is very popular, as the room turns out to be very warm, comfortable, reliable, durable, and safe. It is carried out as follows: a trench is dug, piles or pillars are mounted, formwork is made and concrete is poured. This type of base is excellent even for houses with several floors.

An object located at ground level is optimal, since it evenly distributes the load on the load-bearing plane.

Types of structures by design

Structurally, there are three types of foundation, but we will consider two.

- Monolithic look. It is a solid slab or closed beam. Monolithic grillage is most often used in low-rise construction.

- Assembled view. It is a “constructor” consisting of parts equipped with a fastening system. It is mainly used for the construction of industrial buildings and multi-storey structures. For private housing construction, the prefabricated category is not suitable, since its production is very labor-intensive and expensive.

An ideal option for private construction is a monolithic option, for example, made of channel or reinforced concrete. We will talk about him further.

Types of base by material

According to the material, there are four types.

- Wood. It is perfect for timber houses and log houses. It is distinguished by reliability, durability, environmental friendliness, and safety. But at the same time, treatment with fireproofing, waterproofing and antiseptic compounds is required.

- Reinforced concrete. It is made of steel reinforcement and concrete, which, when combined, provide durability, wear resistance, strength and reliability to the entire facility.

- Metal. It is durable and reliable. The grillage is perfect for foundations on screw piles. But for a base on bored supports, this is not the best option. In addition, a metal grillage requires lifting equipment (try unfolding and accurately aligning I-beams).

- Concrete. Experts have an extremely negative attitude towards it, since the device works on bending (here is an article for you), and its occurrence leads to cracking of concrete. The grillage is used exclusively for small buildings with many supports.

The best option is reinforced concrete or welded metal (for frame houses).

Types of grillages

Prefabricated grillage

A prefabricated grillage, for example, made from steel beams (channels, I-beams, etc.) is usually welded. Its disadvantage is the difficulty of installing heavy beams on piles, the low strength of the connection of individual beams (the joints are weaker than the beams) and the high corrosion of unprotected metal located in a zone of high humidity (snow, humid ground layer of air) and the seam material. Convenient for short-term construction (country houses, verandas, gazebos) with a planned service life of a maximum of 10-20 years.

Prefabricated grillages can simply be laid on top of waterproofed pile heads and attached to them without grouting. In wooden houses, the role of the grillage is “entrusted” to the lower crown or lower trim.

Types of prefabricated grillages (image belongs to Fundex company)

Prefabricated monolithic grillage

Prefabricated monolithic grillage is more often used in industrial construction and the construction of multi-story buildings. This is a kind of “constructor” from pre-cast parts with “locks” and keyed connections, which are monolithic during (or after) assembly. It is expensive, assembled on site using heavy equipment and requires high precision in piling installation. It is unprofitable for private housing construction.

Monolithic cast grillage

Monolithic-cast (hereinafter referred to as “monolithic”) reinforced concrete grillage is cast in the form of a beam (ribbon, closed perimeter, open contour) or monolithic slab. In any design option, the grillage connects the piles - being attached to them or including them in its thickness. The slab is usually high, the tape can be high, elevated, or recessed. A monolithic grillage is the most convenient option for low-rise construction.

We install the grillage foundation with our own hands

To save money, you can build a grillage on a columnar foundation or pile base with your own hands. This is, in principle, not very problematic. But before moving on to the process of building the object, it is necessary to select supports for the future structure.

What to use: pillars or piles?

Both piles and pillars are used in construction. The former are used to create houses intended for year-round use, and the latter - for the construction of small objects without constant load, for example, bathhouses, small country houses, gazebos, etc.

In general, piles are the best solution for the construction of a particular structure. But we will consider the installation of grillages for both pile foundations and columnar foundations.

Types of grillage and what types it has

The ergonomics, durability and aesthetics of the building depend on the type of grillage that is laid on a columnar or pile foundation. It can be slab, strip and glass.

Pile driven foundation: one of the most economical and reliable types of foundation (read more)

Depending on the location of the grillage relative to the subgrade, the following types of structures are distinguished:

- increased;

- high;

- recessed

A grillage with piles can become the basis for a building made of any material.

The jumper design can be:

- monolithic;

- prefabricated monolithic;

- national team.

Depending on the material of manufacture, grillages are distinguished:

- metal;

- wooden;

- concrete;

- reinforced concrete.

Installation of a grillage for a pile foundation

So, how to make a grillage for a pile base? Let's figure it out now. The ideal time of year to erect a grillage is late spring, early summer or early autumn.

Tools and materials

We arm ourselves with the following materials and tools:

- shovels: “bayonet” and “picking”;

- crowbar;

- stakes;

- rope;

- plywood;

- a set of steel screw piles;

- reinforcement frame;

- metal pipes;

- plumb line;

- level or hydraulic level;

- tape measure;

- concrete mortar;

- special chemicals;

- foam boards;

- sand;

- crushed stone;

- rubber bitumen mastic;

- roofing felt or its analogue.

Work process

We perform the following manipulations:

- we clear the area of vegetation (grass, bushes, trees, etc.);

- we water the cleaned area with chemicals to prevent further growth of vegetation in the area for the future house or bathhouse;

- Using stakes and rope, we mark and level the area;

- we mark the places where the supports for the future foundation will be located;

- for piles we select soil 5-10 cm;

- we screw them in using a crowbar or a pipe that is inserted into the head of the support (in some cases it is reasonable to use special equipment);

- make sure that the piles are perpendicular to the ground;

- we check the tops of the piles for compliance with the horizon and one plane, if necessary, we trim them with a grinder;

- we carry out reinforcement of piles;

- fill the piles with concrete;

- take a technical break;

- we install the formwork using supports and plywood or ready-made panels that already have supporting elements;

- pour sand and crushed stone into the resulting boxes;

- we fix the foam boards along the walls of the boxes;

- we carry out reinforcement - we lay the prepared reinforcement cage;

- pour concrete;

- we take a technical break so that the concrete hardens;

- We produce waterproofing - we treat the concrete with mastic.

Attention! We pour slowly, do not forget to pierce the solution, expelling air from the concrete solution.

What material is best to make it from?

For round or rectangular piles, the following are used: reinforced concrete, simple concrete mixture, different grades of steel, coniferous trees (especially larch).

Concrete grillages are easiest to construct when the cap ties the support piles to a height of 0.1 m. This option cannot be called a strong and durable structure, so concrete grillages are applicable in the construction of only one-story structures.

Heads made of reinforced concrete have a high margin of safety, reliability and rigidity and a long service life. Such structures are given greater strength by reinforcing the concrete grillage with a steel frame or individual rods.

Reference! Professionals know that with such a grillage foundation, this reinforcement must be provided with a protective layer.

The production of heads is also possible from rolled metal - I-beams and channels. Such grillages are rigid and durable, however, like all metal products, they are susceptible to rusting (especially at the joints).

Wood is used for the construction of grillages only in wooden structures. A waterproofing layer of roofing felt or roofing felt must be placed on the tops of the piles, and the connecting beams themselves must be treated with anti-parasitic and anti-mold compounds.

Making a base when using pillars

We've sorted out the installation of the grillage for the pile foundation, and now let's start creating a bearing plane for the columnar base.

Materials and tools

We stock up on the following set:

- “bayonet” and “selection”;

- drill;

- pickaxe;

- tape measure;

- stakes;

- chemicals to prevent the growth of vegetation;

- OSB board, plywood or edged board for making formwork;

- reinforcement frame;

- concrete mortar;

- geotextiles;

- sand;

- crushed stone;

- polyethylene;

- bitumen mastic.

Construction technology.

So, you have a project ready, or you yourself have decided on the location of the piles, their parameters, the type and height of the grillage. Construction can begin.

First, the entire fertile layer of soil is removed, taken out to the garden or stored in one of the corners of the site. The area for the foundation is leveled. Then, using pegs and cords, the boundaries of the house are marked. Moreover, two cords are pulled, marking the outer and inner surfaces of the walls. Be sure to check the geometry by re-measuring and comparing all the diagonals in pairs.

After the marking is completed, you can mark the installation locations of the piles. We have them drawn on the plan and calculated, the distances between them are determined.

Pile grillage foundation.

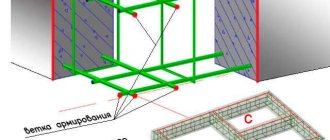

Schematic representation of the work procedure during the construction of a pile-grillage foundation with your own hands.

Excavation and pouring of piles.

How exactly the work will take place depends on the type of piles used. Most often, screw or bored piles are used when building a house.

Screws can be screwed in by hand. When twisting, their heads are aligned at the same level. It is more convenient to mark it with cords.

For drilling, you will need either special equipment or a hand drill of a suitable diameter. These devices drill holes in the right places. The selected formwork is lowered into the finished wells, and reinforcement is installed (four bars of ribbed reinforcement connected to each other). If the foundation is pile-strip, then the reinforcement must have an outlet of at least 60-70 cm. It will then be connected to the grillage. The last step in this stage is pouring the concrete.

Construction of foundations for pile grillage.

The pile foundation is ready for installation of formwork for the grillage. In this case, formwork made of roofing felt or roofing felt, rolled several times, is used.

Grillage arrangement.

If a metal grillage is selected, it is welded to the pile heads. When working, it is important to maintain strict horizontality: then the load will be transferred evenly.

To install a recessed reinforced concrete grillage (low), you will need to add crushed stone of a fraction of 20-60 mm and compact it with a vibrating platform. The minimum layer of crushed stone is 15 cm. To improve the bearing capacity of the soil under the belt, it is necessary to pour crushed stone in small layers (5 cm each) and thoroughly compact it with a vibrating platform. It will not be possible to compact well around the piles, but this is not so important.

Formwork is installed on this bedding. The width of the tape is slightly larger than the width of the walls, the height of the panels is made taking into account the required height of the base. Assembling the panels and installing stops exactly repeats the technology for installing formwork for strip foundations.

Pile strip foundation.

Scheme of reinforcement of a pile-grillage foundation with a reinforced concrete grillage (pile-strip).

Reinforcement is carried out in most cases in the same way as during the construction of a belt: two belts at the top and bottom made of ribbed reinforcement, transverse and vertical posts made of a smooth rod of smaller diameter. All reinforcement rules are preserved. Only the dressing with piles is added. The outlets of the reinforcement from the piles are bent: one row is tied to the lower belt, the second - to the top (do not forget to make the outlets of different lengths). They must be at least 50 bar diameters (if 12 mm reinforcement is used, you need to bend 600 mm (50 * 12 mm)). The reinforcement diagram for the pile abutment is shown in the figure.

Installation of embedded parts.

At this stage, it is necessary to leave ventilation ducts and lay pipes and ducts through which utilities will be supplied (plumbing, heating, electricity, sewerage).

Pile grillage foundation.

Don’t forget about laying pipes for vents and connecting engineering systems.

If this is not done, you will have to subsequently chisel the concrete. And this is a great evil for the foundation, because the integrity of the monolith is violated. So think through everything carefully: there will be no opportunity to redo it.

Pouring concrete.

Concrete is not just poured. It is also vibrated. Without this process, it is very difficult to achieve uniformity and high strength. Therefore, processing foundation concrete with a vibrator can be considered a mandatory process.

If the air temperature after pouring concrete is around +20°C, then the formwork can be removed after four days. During this time, the concrete will gain approximately 50% of its design strength, which is enough to carry out the following work. If the temperature was around +10°, you will have to wait 10-14 days. At lower temperatures, conditions are considered wintry and the poured concrete requires insulation or heating.

Pile grillage foundation.

Everything is ready for pouring concrete: the reinforced belt is tied, the formwork is set and secured (to enlarge the size of the picture, right-click on it).

For all their attractiveness, pile foundations have disadvantages:

- As already mentioned, due to the fact that it is impossible to determine what kind of soil is located under each of the piles, its behavior is almost impossible to predict.

- In such buildings it is impossible to install basements.

- With high grillages, it is necessary to somehow close the gap: animals and insects like to live there.

Recommendation: A good review article, from it you can learn about the construction of a pile foundation with a grillage. Indeed, a pile-grillage foundation is not expensive. If it suits your building in all respects, then you can safely use it, but be careful when calculating the loads, you won’t be mistaken. This is an important point!

Curing

The process of dismantling the formwork

Concrete hardens and gains full strength within a few weeks. All this time, you need to protect the grillage from excessive exposure to the external environment. To protect the concrete surface from precipitation, make a cover from a polymer film. In hot weather, cover the surface of the grillage with a wet rag. After the foundation is ready, the formwork is dismantled.