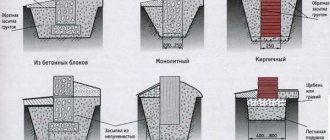

- Corner connections

Reinforcement for the foundation of a private house

Due to the fragility of cellular concrete stone, which works well in compression but weakly in tension, the foundation under the walls built from it should be as static as possible. Only a reinforced concrete monolith can ensure this, so most often either slab foundations or shallow strips are poured under aerated concrete houses.

Accordingly, developers involved in non-design construction have a question: which reinforcement is better for the foundation, to which we will try to give a comprehensive answer.

Calculation of reinforcement for strip foundations.

- Strip foundation technology Tools and materials

- An example of calculating reinforcement for a strip foundation

The popularity of strip foundations is associated with its high efficiency and simplicity of its implementation technology. It can also be used to solve the problem of construction on soft soils. But at the same time, the construction of a foundation of this type is characterized by an increased labor intensity of the process and a significant increase in the consumption of building materials, including reinforcement.

Diameter of reinforcement for strip foundation.

Calculation of strip foundation.

Reinforcement of a strip foundation is a mandatory condition, without which one cannot talk about the reliability and durability of the entire structure.

Range of metal products

Classes of reinforcing steel

For reinforced concrete structures, the following reinforcement is used:

- hot rolled, smooth or with a periodic profile (ring or crescent) with a diameter of 6 to 40 mm;

- thermally and mechanically strengthened with a periodic profile, 6–40 mm;

- cold-deformed periodic section (3–12 mm).

It is recommended to use smooth reinforcement with a class not lower than A-240 (A-I). For ribbed (periodic profile) choose class A-300 and higher.

In areas where the temperature drops below 30°C, class A-300 is prohibited from use.

It is preferable to use products with a periodic profile - with tides in the form of rings or a sickle. Irregularities increase the adhesion area of the rods to the concrete and the strength of the entire structure.

Recently, composite reinforcement has appeared on sale. The manufacturer recommends using it instead of steel products.

SP 295.1325800.2017 does not allow the use of composite products for foundations.

Strip foundation technology.

How to properly knit reinforcement for a strip foundation.

Reinforcement of the corner and junction of the strip foundation.

To answer the question of what kind of reinforcement is needed for a strip foundation, you must first remember what it is and what loads it is subjected to. The concrete strip itself can withstand vertical and lateral compression loads quite well, but works very poorly in bending. To protect the foundation, it is reinforced, and, thanks to the interaction of ductile metal and durable concrete, a very reliable and durable structure is obtained.

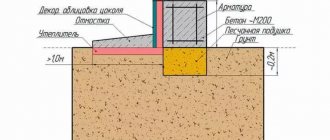

The technology for constructing a strip foundation is quite simple. After clearing the land, anchoring the building and securing the axes according to the project, they proceed to earthworks: dig a trench, level and compact the base. The next mandatory step is the construction of a sand cushion. The sand cushion will help to evenly distribute the weight of the building over the area of the sole.

After this, the formwork is installed and the installation of reinforcement begins. the diameter of which must correspond to the calculated value. After making the reinforcement frame, they proceed to pouring concrete, each layer of which is compacted with a vibrator. When the concrete has hardened, the formwork is removed and the strip foundation is covered with a layer of waterproofing, and the remaining cavities are filled with sand and thoroughly compacted.

Tools and materials.

What kind of reinforcement for a strip foundation.

Scheme of strip foundation reinforcement.

To perform work on the installation of a strip base, the following materials and devices are used:

- sand;

- formwork panels;

- fittings;

- knitting wire;

- concrete;

- roofing felt or mastic;

- roulette;

- level;

- cord;

- shovel;

- wire cutters;

- pliers;

- tamping;

- deep vibrator.

Strict adherence to technology will allow the construction of a truly reliable and durable structure. Particular attention should be paid to the question of what diameter of reinforcement on a strip foundation is advisable to use. This issue is resolved at the design stage of the entire building.

Percentage of foundation slab reinforcement

For concrete to become reinforced concrete, it is not enough just to lay reinforcement. There is such a concept - the minimum cross-sectional area of longitudinal reinforcement in reinforced concrete elements. If the percentage of reinforcement is below the minimum, then the transition from concrete to reinforced concrete will not occur, the concrete will still remain concrete. Magic? No. It’s just that in order for the reinforcement to play its role, there must be a sufficient amount of it. SNiP 2.03.01-84 clause 5.16 states that the minimum percentage of reinforcement for the foundation slab is:

- 0.05% of the cross-sectional area of concrete. Reinforcement S in bending and also in eccentrically tensioned elements when the axial force is located outside the working height of the section

- 0.05% of the cross-sectional area of concrete. Reinforcement S, S” in eccentrically tensioned elements when the longitudinal force is located between reinforcement S and S”

- From 0.1 to 0.25%. Reinforcement S, S” in eccentrically compressed elements

- In elements with longitudinal reinforcement distributed evenly along the contour of the section, as well as in centrally stretched elements, the minimum cross-sectional area of all longitudinal reinforcement should be taken to be twice the values indicated above.

You can't spoil the porridge with oil, but you can ruin the foundation with reinforcement. Therefore, there is a maximum percentage of reinforcement. Exceeding the standards will worsen the technical characteristics of reinforced concrete. The maximum percentage of reinforcement for columns is 5%, and in all other cases 4%. It must be taken into account that the concrete mixture must penetrate freely between the reinforcement.

Calculation of strip foundation reinforcement.

Tying reinforcement for a strip foundation.

Calculation of reinforcement for the foundation.

The standard width of the tape is 0.3-0.4 m, with a height of 0.7 m, that is, its cross-section is quite small. Therefore, the diameter of the reinforcement used usually does not exceed 12-14 mm. Laying of reinforcement on a strip foundation is carried out in the form of two belts. The reinforcement is located in the upper and lower parts of it in 4 rods. The diameter of the reinforcement is calculated based on data on the parameters of the foundation and the materials used for its construction.

It should be remembered that when constructing a massive house or carrying out construction on moving, weak soils, longitudinal reinforcement is laid in 3-4 rods in each belt.

The bottom of the base in cross section experiences a bending load, which is taken on by the transverse reinforcement. Vertical reinforcement ensures the rigidity of the entire frame, while avoiding inclined cracks in the foundation body in the future.

An example of calculating reinforcement for a strip foundation.

Reinforcement for the strip foundation of a house.

Foundation installation diagram.

Let us calculate the required amount of reinforcement for a strip-type foundation of a building measuring 6 x 6 m, strip width – 40 cm, height – 70 cm. Load-bearing wall length – 6 m.

For longitudinal reinforcement, class A-III rods with a ribbed surface, the diameter of which is 12 mm, are used. The rods are laid longitudinally in 4 rods along the tape along the entire perimeter and under the load-bearing wall (2 rods each in the lower and upper chords). The total length of the tape is 30 m, where 24 m is the length of the perimeter and 6 m under the load-bearing wall. The total amount of reinforcement with a diameter of 12 mm is 120 m. The weight of 1 m of reinforcement of such a section is 0.888 kg, therefore, to reinforce the entire monolithic base you will need 106.56 kg.

Since transverse and vertical rods do not experience significant loads, for reinforcement it will be sufficient to use smooth reinforcement of class A-I, the diameter of which is 6 mm. Transverse and vertical rods are installed in increments of 0.5 m, the distance from the foundation surface should be 5 cm. Taking this into account, the number of rods with a diameter of 6 mm per connection is 1.8 m. There are 61 such connections in total, therefore, the total length of the rods will be 109 .8 m. The weight of 1 m of reinforcement, the diameter of which corresponds to 6 mm, is 0.222 kg. Consequently, its total quantity required for reinforcement will be 24.38 kg.

We choose the diameter of the knitting wire and the method of knitting the frame.

The amount of binding wire per bundle is 0.3 meters, there are 4 such bundles in one connection. Multiplying by the total number of connections - 61, we find that you will need 73.2 m of binding wire. The diameter of the wire used to tie the rods in the corners of the frame is 0.8-1.2 mm. In the manufacture of the reinforcement frame, steel wire knitting is used, which guarantees the durability of the entire structure. It is strictly forbidden to use welding to avoid corrosion of the metal at the joints of the reinforcement.

The knitting technology is as follows: at the intersection of the rods, the wire is first tightened, and then the remaining ends are twisted with pliers. In addition, a special gun is used for tying reinforcement, which significantly reduces labor costs. The disadvantage is the fairly high cost of this tool.

The diameter and quantity of reinforcement used directly depends on the massiveness of the structure, on the type of soil at the construction site, as well as on the type of strip foundation (shallow or buried). The process of calculating the reinforcement frame should be carried out at the design stage of the entire building. Only strict compliance with the requirements of design documentation, construction technology and professional execution of construction work can guarantee a service life of a strip foundation of at least 150 years.

Linking the reinforcing frame

Installation of reinforcement can be done both into already assembled formwork and before it. It all depends on whether it will be an enlarged assembly, when sections of the frame are assembled first and then connected on site, or whether the frame is completely assembled from individual rods. In the second case, it is easier to mount the reinforcement first - so that the sides of the formwork do not interfere with connecting the ends.

Everything here is individual, each team of installers independently determines the procedure, also taking into account the configuration of the foundation. If it is a tape, it is definitely more convenient to first assemble the individual sections of the frame, and then install them in the finished formwork.

Reinforcing bars are cut along the length of one side of the foundation and the bottom row is laid out at a given distance. Clamps are put on them and each working rod is secured with knitting wire. When the bottom row is completely fixed, the rods of the top row are inserted into the clamps one by one and tied, resulting in a fragment of a spatial frame that can be installed in the formwork.

From below, the thickness of the protective shell is ensured by chair stands of the required height. On the sides, so that the rods do not come into contact with the wooden panels, star-shaped clamps are installed. From above, the mark of the top of the foundation is applied to the shield above the frame by 20-30 mm.

Corner connections

Most often, shallow strip foundations are provided for aerated concrete and other houses, since they are the most economical. For a system of mating beams that are almost not immersed in the ground, the correct connection of the reinforcement is extremely important, which ensures the reliability of the foundation of the house as a whole.

Since the strip foundation consists of mating or intersecting beams, bent L- or U-shaped elements are required to join the reinforcement at the connection points. Like connecting clamps, they are sold ready-made, but can also be bent directly on site. The main thing is to do it correctly, avoiding bends at right angles without a diametrical transition.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Please note: Under no circumstances should you heat the bend or file it! To produce bent frame parts from steel reinforcement, manual or powered machines are used on construction sites.

On straight sections, the reinforcement is connected with an overlap, with the joints in two parallel rows offset by at least 2 diameters of the reinforcement. In designed construction, the amount of overlap, like everything else, is determined by calculation, taking into account the class of concrete used and the diameter of the reinforcement.

In design-free construction, average values are usually used; in the case of an overlap, this is 30 reinforcement diameters. In places where the working reinforcement overlaps, it is advisable to provide an additional clamp or transverse rods. In foundations with a span of less than 10 m, such connections are not required; you just need to buy reinforcement of the required length.

In the corners, connections must be made, for which several methods can be used:

- By bending the main reinforcement. In this case, at all levels of the frame, the longitudinal rods are bent at a radius right angle with a bend value of 50 diameters of the reinforcement, and connected with wire twists.

- Using L-shaped overlays. When the length of the main reinforcement is not enough to make a bend, the transition to a perpendicular row is made using a pre-bent L-shaped element. It is important that its arm has a length of at least 50 reinforcement diameters. Such brackets can be installed at all levels of the frame or used in combination with the previous method.

- Using U-shaped clamps. U-shaped clamps, which are installed with the spherical part at an angle to each other, are also very convenient for connection. One connection requires two such elements, the shoulders of which are additionally connected by transverse rods.

- Obtuse angle overlay element. It may be necessary when the house has, for example, a bay window with a trapezoidal configuration. The principle of connection is the same as with L-shaped overlays, but a transverse rod must be installed at the bend.

Corner connection with U-shaped elements

What is it made from?

First, let's talk about the materials used in the manufacture of fittings. Today there are metal and plastic analogues on sale. The latter, due to their novelty, attract great attention, and not always justified. We list the advantages of both options so that the reader can decide which reinforcement to use for the foundation. Let's start with the advantages of metal:

- Even with a significant load, the metal rod does not bend, which ensures high reliability of the structure - the plastic analogue can be deformed under such a load;

- can be bent directly on the construction site with a special tool. The plastic analogue cannot be bent - you can only pre-order products of the desired shape at the factory;

- The price, although a little, is lower than that of plastic.

Now let's talk about the advantages of plastic:

- It has less weight, which greatly simplifies the process of transporting and assembling the frame;

- not subject to corrosion, which is the scourge of all metal products;

- works well in tensile strength, in some cases withstanding loads twice as high as those for a metal material.

As you can see, it is quite difficult to answer unequivocally what kind of reinforcement is needed for the foundation - each option has its own advantages that should be taken into account in order to make the right choice.

Fastening with plastic clamps

This is another way to connect reinforcement elements. The cost of such fastenings is higher than traditional wire.

Similar special plastic clamps are also used when securing elements of composite reinforcement.

Excavation and preparatory work

One of the advantages of a strip foundation is the relatively small amount of excavation work. A couple of people, working every day with short breaks, can easily dig a pit of a suitable size on normal soil. When the foundation pit is ready, you can begin to arrange it.

The first step is making the foundation cushion. Thanks to it, the negative impact of groundwater on the foundation is reduced, and the load from the foundation itself and the entire building is distributed as evenly as possible over the ground. Here you can use different materials. Most often sand or crushed stone is used. They do their job well - the main thing is that the thickness of the pillow is at least 15-20 centimeters.

But some experts recommend a concrete pad. Yes, it costs the most. Expensive cement and the need to reinforce the cushion greatly increase the cost and time of construction. But as a result, you get the most reliable foundation for the foundation, guaranteeing that it will last for many years. Therefore, we can say with confidence that this money will not be thrown away.

An example of a reinforced strip foundation

If work is carried out on weak, heaving soil, or if you plan to build a heavy brick house, but the use of a monolithic foundation is undesirable for some reason, then you can use a strip foundation with a sole. The widening (glass) can significantly reduce the load on the ground. Of course, do not forget about the reinforcement of the foundation shell - on heaving soils it will regularly withstand significant tensile and bending loads. It is very important to provide it with sufficient strength.

When using a foundation with a sole, the volume of excavation work increases. In addition, you will have to spend additional money on reinforcing the base of the strip foundation - if it fails, this will lead to the rapid destruction of the entire structure.

Formwork is installed on top of the finished cushion. When choosing the width, keep in mind that the finished foundation should be 10-15 centimeters thicker than the external load-bearing walls.

The next step is to install waterproofing. Some builders use roofing felt, but this is a rather expensive material. And the heavy weight makes the installation process difficult. Therefore, it is quite possible to use construction polyethylene. Yes, it is less durable. But it is only needed for a few days - so that the cement laitance does not go into the sand. Therefore, cheap and lightweight polyethylene is quite suitable. It is laid on top of the formwork. At the joints, make a larger overlap - at least 10-15 centimeters - and glue with wide tape.

This concludes the preparatory work. Now we’ll tell you about pouring and reinforcing the foundation with your own hands.