Vapor barrier for the walls of the house is the most important element that will ensure warmth and dryness from the inside. Walls with wind vapor barrier will serve for a long time and will not become covered with mold, because when heating a house, vapors are formed that need to escape outside so that they do not settle on the very surface of the walls. Paraisolation and how to properly lay it on the walls will be discussed below.

Why do you need a vapor barrier for walls?

Water vapor barrier for walls is needed to prevent moisture and vapor from entering the insulation, as well as parts of the roof and wall surfaces. The advantages of dry surfaces include the following:

- If you protect a wall built from standard materials: brick, wood, foam blocks, aerated concrete and others. This will allow you to remove the dew point from the wall surface, or move it close to it from the outside. Which leads to a manifold increase in the service life of these structures;

- This insulation prevents the appearance of black mold, which is harmful to health and spoils the overall appearance of the surface;

- Pleasant and acceptable humidity is established inside the house;

- Less energy is spent on heating and air conditioning, which reduces the budget for these needs.

Water vapor barrier for walls is needed to prevent moisture and vapor from entering the insulation, as well as parts of the roof and wall surfaces.

Sealing cracks and preparing sheathing

It is better to replace damaged walls or carry out major repairs. Gaps in joints are sealed with natural materials or synthetic stone sealants .

Before insulating the wall, you need to take care of preparing the sheathing. The distance between its bars should be determined based on the width of the insulation slab . It is important to use a building level to check the vertical and horizontal surface for finishing. The sheathing bars should be directed perpendicular to the direction of the facing panel.

Brick wall sheathing

Do not forget about installing transverse sheathing to ensure high-quality ventilation.

For the convenience of installing intermediate elements of the sheathing, a rope is pulled from the corner beam from below and above the facade . Some people mark future elements with chalk.

Types of vapor barrier materials

You can find many different materials on the market designed for this purpose. To understand which one is better to choose, it is worth studying the main types on sale.

You can find many different materials on the market designed for this purpose.

Membranes

The vapor barrier membrane for walls includes polypropylene as the main material, with fiberglass mesh, which increases reliability. It also has a coating of cellulose-viscose fabric, it can be covered on both sides, or only on one; this fabric provides vapor and moisture insulation. Rough matter creates a barrier that prevents moisture from penetrating the wall and insulating element. This moisture then simply evaporates during natural ventilation.

Due to its multi-layer nature, the membrane “breathes”. By stopping moisture, the material allows a small amount of air to pass inside, which prevents the formation of greenhouses, the surface will “breathe” and can last for many years.

Rough matter creates a barrier that prevents moisture from penetrating the wall and insulating element.

Film

There are several types of film protection. The first polyethylene films are distinguished by the fact that they are reinforced with fabric or reinforcing mesh. What makes the product more reliable. They also have their own subspecies:

- Perforated, in which there are mini-holes that make them vapor permeable. But they do not perform this function well enough to obtain the necessary effect in the frame pie; they make a gap;

- Non-perforated, they are mounted using tapes created to fasten the canvases.

The downside is the tightness and fragility.

Polypropylene film materials have been used for a long time. The main positive properties are strength and resistance to UV rays. There is an anti-condensation layer that does a really good job of absorbing moisture.

The main positive properties are strength and resistance to UV rays.

Mastic

The coating vapor barrier for walls is mastic, it is easy to work with. They are a solution; before use, it is stirred and applied to the surface to be treated; it is suitable for working with smooth surfaces; it can be used to process joints and seams. After drying, the coating becomes vapor permeable.

Suitable for working with smooth surfaces, you can process joints and seams.

Liquid rubber

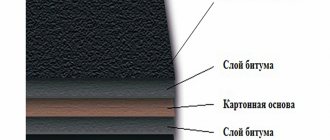

Liquid rubber is becoming popular today; it is a bitumen-polymer mixture based on water. It is very easy to work with and spreads easily on the surface. The coating appears after complete drying and takes on the appearance of rubber, which monolithically covers the surface.

This creates a vapor and wind insulation for the walls, as well as a sound insulation layer.

The types of this product can be distinguished:

- A composition that can only be applied using an automated method.

- Composition for manual application.

It is very easy to work with and spreads easily on the surface.

Other possible options

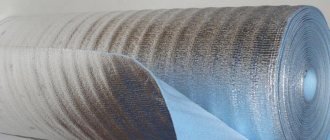

It is also necessary to mention this type of product, such as films laminated with aluminum foil, which also do an excellent job of vapor and waterproofing, but they can only be used in bathhouses and swimming pools.

Foil can only be used in baths and swimming pools.

Penofol insulation technology

It should be noted that penofol insulation of private houses and apartments is becoming increasingly popular for various reasons. There is also a lot of talk around this relatively new insulation, including about its unique properties and ease of use. Understanding what penofol is, as well as finding out the whole truth about its characteristics, is the purpose of this article. In addition, we will talk about how it is better to insulate walls and other structures from inside the house with this material.

DIY vapor barrier installation on walls

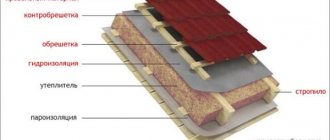

Today it produces fastening of various vapor barrier materials; several types can be used for different sides. In general, installation must be carried out both on the floor and on the walls outside, and in rooms with high humidity (bathrooms, baths, swimming pools). Also lay on the rafters from the attic side.

Operating rules:

- Which side should the vapor barrier be laid against the insulation on the wall? It is necessary to direct the smooth part towards the insulation, the rough part faces the room.

- Joints with an overlap of 10-15 centimeters are glued with double-sided tape intended for this purpose.

- They start laying the insulation from the bottom and then go horizontally (while working with the roof), working with the surface of the walls from the bottom up.

- Make sure the materials are tight.

- How to attach a vapor barrier to a wall. To do this, use the staples of a construction stapler, and through the slats.

- The easiest way to install vapor protection on the floor is to ensure overlaps and glue the joints.

It is necessary to direct the smooth part towards the insulation, the rough part faces the room.

Video description

About diffuse vapor and waterproofing in the following video:

- A two-layer anti-condensation film is spread with the smooth side facing the insulation, and the rough side facing the source of warm, humid air, the living quarters.

- The foil film is laid with a metal layer to the living spaces - this way it can return some of the heat inside, increasing the thermal efficiency of the building.

- Diffusion double-sided membranes provide the roofing pie with the ability to “breathe”. If both surfaces of the membrane are identical, it is laid on either side. If you have chosen a one-sided membrane, it is better to check the data on the front and back surfaces with the manufacturer (in most cases, the membrane is adjacent to the thermal insulation with a rough surface).

Laying a vapor barrier in a roof with steep slopesSource bostonglobe.com

The nuances of installing vapor barriers on different walls

When working with different materials, special conditions arise that change the installation process.

Wooden

If the work is carried out in a log house, then the vapor barrier is fixed directly to the wood, due to the presence of joints on the surface that form cavities that ensure the movement of air masses.

Vapor barrier for the walls of a wooden house in the case of the timber material used, air movement will be minimal and it will not be enough. Therefore, wooden slats are used, and the insulating material is secured to them with a stapler. A timber frame is erected along the vapor barrier, into which a heat insulator is inserted, then a waterproofing and external finishing is attached.

If the work is carried out in a log house, then the vapor barrier is fixed directly to the wood.

Frame

In this case, it is not necessary to carry out such work. But if it is decided to carry them out, then they act like this:

- The first option is suitable for temporary housing, where people do not live all year round; a membrane is fixed to the frame post, and finishing work is already carried out on its surface with siding, clapboard and other materials;

- For houses intended for permanent residence: a sheathing is attached over the vapor barrier material to provide a ventilation gap of 30-40 millimeters.

You can answer the question: which vapor barrier is better for the walls of a frame house, this way: the Onditus vapor barrier film has shown itself to be good.

A sheathing is attached over the vapor barrier material to provide a ventilation gap of 30-40 millimeters.

Brick

It is necessary to carry out vapor barrier work on a brick surface in a number of cases:

- If there is already an inner layer of insulation, so that it does not collapse, a vapor barrier should be installed;

- To ensure comfortable microclimatic conditions inside the house;

- To provide good wind protection.

If there is already an inner layer of insulation, so that it does not collapse, a vapor barrier should be installed.

Aerated concrete

Glassine or polyethylene can be used as a protective material; it is inexpensive. Foil and membrane products have better properties. The vapor barrier must completely cover the walls; the panels are attached to wooden guides, overlapping with a distance of at least 10 centimeters.

The vapor barrier should completely cover the walls; the panels are attached to wooden guides.

Video description

About the membrane installation technology in the following video:

The main condition for installation is that the film is fixed without tension, with a sag of approximately 2 cm. The reserve is created due to the ability of the wooden frame to change its dimensions with the change of seasons (with changes in humidity); otherwise there is a risk of the film tearing.

For horizontal installation, installation is carried out from above (from the ridge)

The strips are laid with a reverse overlap (the lower strip overlaps the upper), for additional protection of the insulation; they are connected with tape and secured to the structure with galvanized nails or a stapler. If the thermal insulation layer is not dense, the rolled sheet is fixed using slats, which must be antiseptic. Particular attention is paid to junction points (attics, windows, hatches, pipes, ventilation ducts); they are isolated especially carefully.

Fixing the filmSource pro-uteplenie.ru

Criteria for choosing a vapor barrier material

When choosing a material, you should pay attention to several important criteria, including the following:

- Vapor permeability, the ability to absorb moisture and let air pass through is one of the most important factors; it is measured in g/m2 per day;

- Life time. Cheap materials can tear very quickly; membranes made of non-woven artificial fibers show the best indicator of this criterion;

- Difficult to install. When choosing, you should find out how the material is attached (what kind of overlap is made, and what tapes are needed); it must be attached tightly to the insulation, or leave a gap;

- Price. Products for this purpose are sold in rolls. In a store, they usually pay attention only to the price, but do not take into account that rolls come in different sizes; in order to sensibly assess the cost, you need to compare these two factors and calculate the real price.

The ability to absorb moisture and allow air to pass through is one of the most important factors.

The main enemy of modern insulation

Water vapor is always present in residential areas.

Cleaning, washing, cooking, even the breathing of people in the house become their sources. And the higher the air humidity in the room, the more forcefully these water vapors will seep out. Neither the floor, nor the ceiling, nor even walls made of reinforced concrete slabs can stop them. If these elements of the house are protected by a thermal insulation layer, vapors will easily pass through it. The vapor barrier layer helps protect the structure from environmental influences.

For most modern insulation materials this does not create any particular problems, since they have good vapor permeability. Simply put, modern insulation has the ability to pass steam through itself without compromising its main purpose - not to allow heat to pass through.

But at sub-zero temperatures, a dew point forms at the point of contact of the heat-insulating layer with the surface of the home, upon reaching which the water vapor turns back into water, settling partly on the surface and partly on the adjacent layer of insulation. As a result, both the surface and the insulation become wet.

For the surface, be it the surface of the floor, wall or ceiling, this is fraught with the appearance of mold, and moisture that gets into the thermal insulation layer reduces its effectiveness by 30 to 80%, not to mention reducing the service life of the insulation several times. To prevent such disastrous consequences, a vapor barrier layer is inserted between the surface and the insulation.

Tips and tricks for vapor barrier walls

You should first consider which option for installing a vapor barrier will be better and more effective. To correctly determine the appropriate installation order, you must consider:

- House type.

- Use of the premises, whether permanently occupied or only temporarily.

- The time of year when the building is most often used.

You should first consider which option for installing a vapor barrier will be better and more effective.

Vapor barrier work is an important stage in protecting a home; carrying out this work will have a positive effect on the microclimate of the house and its durability. The main thing is to choose the right material and follow the working rules. It is not difficult to install a vapor barrier yourself.

How to check if the vapor barrier is working

There is a very simple way to check the effectiveness of a vapor barrier. You need a small piece of material and two glasses of the same diameter. Pour boiling water into one glass, cover it with a piece of the material being tested, and place the second glass upside down on top. If the material works as it should, the second glass remains dry.

If drops form on the walls, “fog” appears, the material conducts steam. Perhaps you have a vapor barrier with one-way conductivity, then you need to turn it over and repeat the tests. The situation has not changed? This is a vapor-permeable material with two-way vapor conductivity.

Membrane film:

This film is available in two versions, which differ in vapor permeability:

- limited, to control the removal of humidity from the room, leaving a minimum specified residual moisture;

- variable when permeability increases with changes in humidity.

To determine the location of the vapor barrier installation, it is necessary to understand where exactly the contact of cold and warmer structures, humid and dry air occurs. For the construction of a private house type, such areas are the basement, attic, roof and wall elements.

Membrane film

Types, manufacturers, characteristics

Izospan - high quality at an affordable price.

When answering the question of which vapor barrier to choose for walls, the first step is to determine the scope of its application. For different operating conditions, the materials differ:

- for the walls of the basement, foundation or pool - bitumen (liquid or in rolls), liquid rubber;

- for wooden and stone above-ground walls with internal insulation - polypropylene films, foil insulation.

Polypropylene material for vapor barrier of walls is produced by domestic and foreign manufacturers. The most popular brands are Izospan, Yutafol, Technohaut, Spunlight, Izovek. You need to understand that the film does not protect 100%, for example, Izospan has a vapor permeability of 7 mg/m*h*Pa - this is not much, nevertheless, the fact is obvious. Among foil insulation, the most widely used brands are: Penofol, Izover, Tepofol.

All polypropylene films are reinforced with fiberglass. There are two reinforcement methods:

- the mesh is pressed into the still uncured polypropylene;

- fiberglass fabric is laminated with polymer on both sides.

The second method allows you to create a stronger material. All types of vapor barriers for walls are subject to high requirements regarding their tensile strength. Foil insulation can be with or without a polyethylene foam base. The preferred material is a damping cushion made of polyethylene foam with a closed-cell structure.