Wooden architecture has developed over the centuries in many countries. Today, for the construction of warm and durable houses, various types of logs and logs are used, which have successfully proven themselves in the northern regions of Russia, Canada and Norway.

Timber and rounded logs are widely used as building materials - strict geometric dimensions simplify and speed up the assembly of the log house, since a template can be used to mark the connecting grooves. Construction from chopped debarked logs is noticeably more difficult, since each connection is adjusted individually.

When it comes to houses made of wood for the private sector, we mainly mean either frame structures or ready-made turnkey log (timber) buildings. Is it possible to build log houses on your own, the way our ancestors did? The answer is unequivocal - yes, cutting a log house is within the capabilities of any skilled owner . You will learn about all its nuances from this article.

The construction of any building is a complex of various activities, including both preparation for construction and the phased implementation of individual technological operations. We will not consider them all, starting from the “zero” cycle, since the subject of conversation is precisely the felling of a log house. But one remark will not be superfluous. It concerns the most expensive part of the structure, the foundation, the costs of which can reach ⅓ of the estimate.

Which type should I choose? Considering the relative lightness of buildings made of wood, it is advisable to limit ourselves to a shallow-depth tape or a pile-grillage foundation. For any log house it is quite enough, if the presence of a technological (basement) floor is not an indispensable condition. Although in this case there is a good solution - to “raise” the house by installing a higher base.

The general order of work is unchanged: installation of the foundation - lower crown - laying wood samples in rows (from bottom to top) with simultaneous arrangement of openings for doors and windows. Next is the ceiling and rafter system. But what does “cutting a log house” mean? This is the connection of all blanks into a single structure with a preliminary selection of material at the designated “points”. The construction of the walls of a building is impossible without reliable fixation of all elements, therefore, when working with wood, cuts (cuts) are made in certain places of the log (timber).

But there is a difference in how the samples are fastened together. There are several ways to cut log houses. Each of the methods has both advantages and individual disadvantages, so we will give a general overview of the ones most used when doing DIY work, since there are quite a lot of them. And which one to choose is entirely at the discretion of the master.

Log house in a bowl

One of the common ways to make a log house with your own hands from a log is the method of assembling it into a bowl. It is most often used in the construction of a bathhouse, since due to its design features it retains heat well. In this assembly method, special semicircular recesses are made along the edges of the log, into which the upper elements of the structure are laid.

There is a 25-30 cm protrusion outside the corner, and the cutout is made to fit the size of the log that will be placed in it. This is necessary to increase the density of the connection, which will prevent the building from falling apart, and will also reduce the likelihood of heat loss due to drafts in the cracks. Thermal insulating material is placed between the parts.

Log house in winter Source skstroyider.ru

Cutting "in the tail"

This method of manual cutting is the same bowl, but improved. Corner structures have a more complex configuration - the presence of an additional spike called a fat tail. It allows you to form a stronger and tighter connection. In this case, the recess (bowl) can be oriented both up (traditionally) and down.

The type of log cutting “in the tail” makes it possible to avoid the wind blowing through the walls of the house. A home built in this way is warmer, more comfortable, and has less heat loss.

Technology selection

There are 2 main ways to cut a log into a bowl:

- “V oblo” (Russian cutting) is a method in which a cut is made in the lower crown. It can be smooth or with a spike (fat tail), which prevents the structure from moving.

- “In the okhlop” (Siberian felling) - in this method, a bowl is made at the bottom of the log, which is placed on top of the bottom.

The first method is used in most buildings that were made in the old days. For those who do not know how to build a bathhouse from a log with their own hands, it is recommended to use the “hollow” method, since during long-term construction moisture does not form in the bowl due to precipitation. It is also considered simpler than Russian cutting.

Types of log house in a bowl Source samdizajner.ru

How to decide on the size and location of the log house on the site

Before planning a bathhouse, you must decide on the following issues:

- how many people will your sauna be for?

- will it be combined with other outbuildings;

- for what purposes, other than bath procedures, you may need it.

The bathhouse can become temporary housing during the period of home renovation, a room for drying berries, medicinal mushrooms, and for growing seedlings. You can equip a photo workshop in the bathhouse.

In ancient times, in Rus', construction of a new estate began with a bathhouse. The family lived in the bathhouse until the house was built. Subsequently, it was also used as a sleeping area for guests.

When designing the placement and installation of a bathhouse, it is advisable to consult with an architect or an experienced builder. Consider all your needs and capabilities, topography, shape and size of the plot, architecture and placement of the house and other buildings on your and neighboring plots, interests and interests of the family, etc. Choose a comfortable and beautiful place for the bath, optimal sizes, interesting design, necessary materials and equipment.

Basic rules for designing a bath:

- The location of the bathhouse should be away from a dusty and noisy road, closed from neighboring trees, bushes, and other buildings;

- Make the most of the terrain on the site (slides, slopes, stones and boulders). For example, a half-dugout bathhouse can fit into a steep slope. In this case, minimal depth will be required when constructing the drain. The terrace on pillars in front of such a bathhouse looks impressive;

- If you have the opportunity to place the bathhouse at a distance of 20-30m from a pond, river, lake. It is very important that this place is dry and does not flood during the spring flood of the reservoir.

- Having placed a bathhouse in such a place, you must consider draining water from it, eliminating the contamination of reservoirs with used water;

- Place the bathhouse windows to the west or southwest. Mostly the bathhouse is heated in the evening. The rays of the setting sun, penetrating the windows of the bathhouse, will create an atmosphere of comfort and peace. Make the windows small (in the old days they preferred to bathe in the dark - it was believed that the heat of the bath was more generous in the dark);

- It is advisable to enter the bathhouse from the south. There will be fewer snowdrifts on this side in winter;

- Consider the following fire safety requirements: if your bathhouse will be heated “black”, then the distance to other buildings on your and neighboring plots should be at least 12 m; locate such a bathhouse on the side of the residential building where the wind most often blows;

- If your bathhouse is smoke-free, then the distance between it and residential buildings should be at least 5-6 m. In Finnish cities, smoke-free baths are installed in the basements of multi-story buildings and even on the roofs. Moreover, on the roofs, bathhouses and solariums coexist with greenhouses and “vegetable gardens”;

- Next to the bathhouse you can dig a small pool or pond 1.5 m deep, which can be used in hot weather for bathing children;

- Combine a bathhouse with other outbuildings. This will help you rationally use the area of the site, materials, facilitate the electricity and water supply of the bathhouse, and the drainage of water into the sewer;

- The bathhouse should be compact, comfortable and economical.

Advantages and disadvantages of a log house in a bowl

The main advantages of the log house:

- High strength of the joints of the structure, which ensures its stability.

- Increased thermal insulation of the room, which is created due to the low thermal conductivity of wood and protection from blowing through the corners of the structure.

- Environmentally friendly material.

- Possibility of constructing a building of several floors.

- Decorative appearance.

Multi-storey log house Source pokter.ru

The disadvantages of a log house in a bowl include:

- The difficulty of manufacturing structural elements and assembling a building without experience. If a log house is made by a person without skill, then such a structure may have cracks, begin to rot, and also crack or fall apart.

- Due to the protruding corners of the structure, it is difficult to carry out external finishing.

- Wood for log houses must be treated with insect repellents, as well as antiseptics (prevent the formation of fungus) and fire retardants (reduce the flammability of the material).

- Protruding parts of the log reduce the useful length of the crown, which increases wood costs. Because of this feature, this type of log house does not require additional insulation of the corners. Therefore, the difference in price when assembling a log house into a bowl or into a claw will be unnoticeable.

The finished building has a smaller usable area due to the thickness of the walls and protruding corners. This should be taken into account when calculating the size of the foundation and the length of the logs.

Why is it difficult to process the external part? Source royalwoods.ru

Two “indigenous” families of cutters

The fundamental criterion for dividing cutting methods into two large classes is the presence or absence of bypasses. This is what folk craftsmen called the remains of logs, and then timber, extending at the ends beyond the contour of the wooden structure. Based on this indicator, in the technologies for constructing log houses, I distinguish two main cutting schemes:

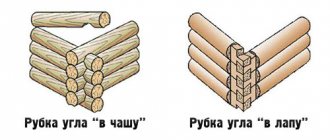

- “Into the bowl”, according to which the corners are cut out with a remainder . This is the most common method, which has a lot of variations of domestic and foreign origin. The downside of the nodal bowls is the significant consumption of material that is not cheap at all, but the plus is the excellent thermal insulation of the corner. And the buildings cut into a bowl look very impressive.

- “In the paw” or simply “without a trace . According to it, the outline of the building is built clearly according to the plan. With the same material consumption as the previous technology, the internal dimensions of the structure are larger. Corners cut into paws require obligatory lining, otherwise they will blow out and get wet. Log houses built without bypasses can be covered with clapboard, block house, plastered, faced with brick or sandwich panels. Unlike options with bowls, all finishing directions are applicable here, and sometimes even recommended.

One of the fundamental rules of wooden construction is that all corner connections must be made according to a single pattern. Since the cutting of beams and logs of load-bearing walls was carried out according to the “bowl” scheme, then the partitions will need to be cut in exactly the same way. Please note right away that all existing methods are applicable for corner joints in log crowns. But a bathhouse made of timber is cut mainly into the claw, but occasionally a number of bowl-shaped types are also used.

Both classes of corner notches have become overgrown with an impressive number of daughter subtypes, differing in manufacturing complexity and thermal properties. The choice of the best method is determined by:

- performer experience;

- climatic specificity of the area;

- the period preferred for taking bath procedures.

To assemble the crowns of a country bathhouse, which is used only in the summer, the simplest cutting methods are suitable. Especially if the owner is going to build a bathhouse on his summer cottage on his own. The customer of a team of craftsmen who needs a warm building for year-round use should not deny himself the choice of a complex technological scheme. Information about the differences and features of cuttings will help both the independent contractor and the prudent employer of builders, who wants to spend money well, to make a reasonable choice.

Materials and tools

To know how to cut a log frame into a bowl with your own hands, you need to choose the right cutting tools. To mark the logs, a tape measure, a level, a chemical pencil and a carpenter's line are used. This is a tool with two rigid plates with sharpened edges and a handle with which the distance between the ends is changed. This tool is designed to draw 2 parallel lines. Also, to cut out the bowl you will need:

- Carpenter's axe.

- Wood chisel.

- Chain saw (electric or gasoline).

- Hand saw.

- Hammer.

To blacken the recess when fitting logs, you will need coal. The cutout requires chemicals to treat fungus and insects, as well as insulation.

Tools for log house Source izba.spb.ru

Drawing up a project for a log house

This is the most basic stage of self-construction of a log house. The design of the house is the basis for planning all subsequent stages of construction: selection and layout of the site, calculation of materials, etc. Of course, for a complex structure of a house with a large area, the work of a specialist with experience is necessary. You cannot create such a project yourself. However, even an ordinary person with basic knowledge of mathematics can design a simple log house with a small area and a simple foundation, and calculate approximately the required amount of material. To independently draw up a project, you can use special programs on the Internet. The easiest way is to use a pencil, ruler and calculator to calculate the area of the house, its height, foundation, calculate the approximate amount of rounded logs, and, taking into account its dimensions, draw a rough plan on paper.

log house project

log house project

Stage No. 2.

How to caulk a log house

To know how to assemble a log bathhouse from logs with your own hands, you need to understand what kind of heat-insulating material is required to fill the space between the structural elements. It will help prevent moisture from penetrating into the bowl, as well as enhance protection from wind and cold. In order to caulk cracks and cavities, the following is used:

- Moss . An environmentally friendly material that can retain heat, withstand temperature changes, and also remove excess moisture, which prevents the appearance of fungus. It is believed to have antimicrobial and healing properties, which manifest themselves when the structure is heated.

- Tow . As the log dries, it becomes damp and begins to rot. Therefore, after the structure dries, it is cleaned and re-laid.

Video description

In this video you will see how to caulk a log house with tow:

- Jute . An environmentally friendly type of insulation that retains heat well, but has a short service life (3 years) due to the fact that it strongly absorbs moisture.

Old jute is difficult to get out of the cracks, so it is rarely used. There are also differences between types of jute. For example, tow is too hard and has low density. Because of this, it is necessary to caulk the log house in several stages to achieve the desired density.

Flax-jute contains 50% flax fibers, so it requires additional treatment to prevent insects and rot. Jute felt consists of 10% flax fibers, but has high flexibility and good density. It also requires additional insect repellent treatment.

- Lnovatin . Due to heavy treatment with insect repellent chemicals, it is not environmentally friendly. It has a service life of 3 years and is attached to the structure using a construction stapler.

Felt made of jute Source drevtorg.rf

See also: Catalog of house projects made from hand-cut logs and timber

- Synthetic compounds . They cost more than other materials, but are easier to use.

Such substances are used in combination with natural material (cord). To do this, the thread is placed in the gap and filled with sealant, which is leveled with a small spatula.

The disadvantage of this method of sealing log cracks is that when exposed to sunlight, the sealant will dry out and begin to crumble. To do this, the place of putty must be covered with planks.

Also, synthetic compounds harden and can expand and contract with temperature changes, which can lead to cracks in the wood. To avoid this, it is necessary to use elastic compounds.

The right combination of sealing materials helps avoid the formation of damage and fungus, and also increases the thermal insulation of walls. This is necessary when constructing buildings in cold regions or when assembling a bathhouse, since in such rooms rapid cooling of the air can be critical.

Synthetic sealant for log houses Source td-artemov.ru

Construction of houses

0 votes

+

Vote for!

—

Vote against!

Houses built from logs are distinguished primarily by their environmental friendliness. It is a pleasure to be in such a room, as the air in it is fresh and the atmosphere is comfortable. There are several technologies for cutting a log house from logs; we’ll talk about the advantages and disadvantages of cutting a log house with your own hands below.

Table of contents:

- Cutting a log house: advantages and technology

- Log cutting: main methods - brief description

- Methods and technology for cutting logs

- Hand-cut log houses: Canadian technology

Cutting a log house: advantages and technology

A log house, in the cutting process of which all standards and technologies were adhered to, has the following advantages:

- high environmental friendliness of the room that is made from it - while the tree is a regulator of humidity and temperature, when the humidity increases, the tree absorbs moisture, and when it decreases, it releases it, while in the log house it is very warm in winter, and cool in summer;

- logs act as a filter - which protects the room from the aggressive external environment;

- there is no need to carry out additional interior decoration of a log house, since the appearance of the walls is attractive in itself;

- For exterior decoration, it is enough to coat the wood with special mixtures that will preserve it for a long time.

Hand cutting a house is a costly process both in terms of time and finances. To carry out this construction technology, vast experience in carrying out work is required. Only in this case will the result be satisfactory.

At the beginning of construction work, logs are selected in relation to the given diameter. This process is quite labor-intensive, but mandatory, since the integrity of the entire structure, its uniform shrinkage and the appearance of the building depend on the quality of the log connections.

Photo of the log house:

The next, no less important step is the processing of the logs that are needed to build a house. All logs are sanded, bark is removed and planed. To ensure maximum stability of logs before exposure to external irritants, a maximum of 50 mm of layer is removed from them. In order for the log house to rise evenly, its first crown should be laid correctly.

The final stage of construction involves external treatment of the log house using tinting impregnations, which help improve the natural qualities of the wood and protect it from ultraviolet radiation.

Log cutting: main methods - brief description

1. Construction from wild logs or dark forests is the use of wooden trunks cleared of bark. An ax and a plane are used to plan the logs. Each of the barrels undergoes careful, exclusively manual grinding and processing. At the same time, grooves, parts for key connections and other elements of the log house are cut out.

The main advantage of using this technology is the fact that after processing, protective wood of a more compact nature remains on the logs, which helps to improve the resistance of the logs to external factors. This technology requires a lot of effort and time, but the result and service life of the house are well worth all the costs.

2. The use of rounded logs in construction is characterized by the construction of houses from logs with a diameter of 200 to 500 mm. The most successful, in this case, is a groove connection. To make logs, wood with increased density is used. The period from December to March is chosen for harvesting wood. The drying technology is carried out in a log house. To avoid the occurrence of cracks, it is recommended to arrange a compensation cut, which will help the moisture evaporate without leaving a trace. In the process of manufacturing rounded logs, the following cutting methods are used:

- Canadian bowl method - has the most important advantage, which is the presence on each log of connecting elements of a self-jamming type, thus, the logs are very tightly adjacent to each other and a high-density corner connection is formed and with good thermal insulation characteristics, no gaps are formed after shrinkage, for caulking which requires the use of sealants, building a house using this technology is an expensive, but high-quality and completely justified undertaking;

- the most common and accessible type of log house is the use of a Russian bowl; this type of log house requires the use of hewn logs of a rounded shape, having crown grooves in the shape of a semicircle, thanks to which the logs fit well together; to fold the corners, a bowl is cut out in the shape of a crescent and the log is left on 200-400 mm, this log manufacturing technology has the highest strength characteristics.

Methods and technology for cutting logs

We invite you to familiarize yourself with the main methods of Russian felling, which were used by ancient carpenters and for the selection of which, the building materials used in the construction process, the type of building, its purpose, climatic and relief features of the region, etc. were taken into account.

The main elements of the connection should be:

- key;

- thorns;

- grooves;

- dowels;

- wedge-shaped cutting;

- grooves;

- bowls.

1. Cutting voblo.

This type of cutting comes from ancient words denoting roundness. The outermost sections of logs that can be cut down become round or cup-shaped after cutting. Each subsequent log is laid directly into a pre-cut bowl-shaped joint. A bowl is also cut out of the laid log and thus a log house is constructed. To ensure a tighter fit of the upper leaf to the lower one, a groove or groove in a longitudinal or semicircular shape is selected in one of them. After the final assembly of the log house, moss is placed in the grooves, which acts as a sealant for the cracks. To increase the strength of the log connection, the bowl is placed at a certain distance from the end section of the log. The protruding part of the log house is called the remainder; it is thanks to it that the logs are tenaciously connected to each other.

The longer the remainder, the higher the strength of the connection, and the more material is required for the construction of the log house.

There are two ways to cut the bowl and groove. The first option involves cutting them down on the surface of the lower log, in the second - on the upper one. The use of the second cutting method is characterized by higher reliability. Since in this case, precipitation is not allowed to enter the inner part of the groove, and, therefore, the wood does not get wet, is deformed and does not collapse. A log house made using this type of cutting will last more than a hundred years.

The person constructing such a log house must adhere to maximum precision in cutting out four bowls on the surface of the upper logs. The shape of each log is cylindrical, so two logs connected using this technology look like two intersecting cylinders. They have complex and closed lines of intersection, and to construct such a curve, you have to work very hard. In addition, a special tool in the form of a scribble or dash is required.

When cutting out a bowl on the surface of the lower log, the line moves apart by half the diameter of the upper logs. Next, it is installed in such a way that one end touches the upper log, and the other the lower one. The surface of the sharp claws is directed downward, and the upper claws slide on the upper log.

An ax or adze is used to cut out a bowl in the lower logs. First, large pieces of wood are cut down, this happens thanks to the precision of the master’s blows. As the craftsman approaches the pre-drawn line, he begins to work with caution and gradually removes small layers of wood.

2. The method of chopping into ohryanka is also ancient. It consists of a certain form of cuttings located in logs. Based on the technology of this cutting method, it is necessary to make cuttings on both the upper and lower logs, and they have the shape of a rectangle. At the same time, the strength of the connection is significantly improved, but its tightness suffers. This method is common in places where there is no quality timber and buildings are built from small-diameter logs. In addition, this connection option is popular when laying the first or first three crowns. The ohryanka cutting method is well suited for the construction of outbuildings or unheated buildings.

3. The chopping method has been known since the fifteenth century. It involves a residue-free connection of logs. Overlay boards are used to sew up the end sections. It is used in the construction of wooden buildings, which are based on four-rope beams. This method of cutting is much more complicated than the previous one and is performed only by those craftsmen who have extensive experience in carpentry. It is necessary to carry out accurate calculations and markings of logs.

4. The linear cutting method involves the use of thin logs, which are installed in the spaces between logs of larger diameter, thus adjusting the entire structure. The installed logs are pre-hewn on both sides.

5. Cutting is used when it is not necessary to achieve a tight connection of logs, but it is enough to have small gaps between the logs. Mills were equipped using this method.

6. The pole cutting method involves the arrangement of buildings for economic purposes. Four logs in the form of pillars are installed in the ground, and they have pre-prepared and cut grooves. The end sections of the logs are equipped with spikes, which form a tongue-and-groove joint.

7. The needle method of Russian felling is used in the presence of logs, the diameter of one side of which is twice the diameter of the other side. Using this method, outbuildings are also erected. This method was developed for their strong connection. The logs are stacked alternately with the larger side on the smaller side. To connect the butt sections, the round connection method was used. In this case, the thin part of the log was hewn and took the shape of a needle, which was installed in the thicker part of the second log.

8. To cut walls made of timber, the method of cutting in a bandage is used. A tenon joint is cut out in one beam, and a groove joint in the second. To avoid displacement of the crowns, holes are drilled in the beams using a brace. Dowels are hammered into them to ensure the strength of the structure.

9. Semi-wood cutting - used in the process of tying four-rope beams. At the junction, the beams are cut to the center, then they are cleaved using a trim. To fix the crowns together, dowels and a tongue-and-groove type of connection are used.

Hand-cut log houses: Canadian technology

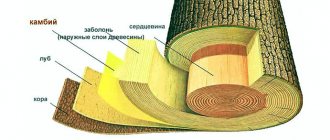

All houses made using Canadian cutting technology are made entirely by hand. This cutting method has many advantages, the main one being that the appearance of the tree, namely the sapwood, is completely preserved in the building. The thickness of this layer is no more than five centimeters, but it is very important for wood. Since it is this layer that is distinguished by the highest strength and provides reliable protection of the tree from the negative influence of the external environment.

Due to the fact that the sapwood is preserved, the service life of a building made using Canadian technology is significantly increased. There is an improvement in heat exchange in the building: in winter, heat does not escape through the sapwood, and in summer, coolness does not escape.

This cutting method was invented in Russia, but gradually became widespread in Canada, which is why it was named so.

Advantages of a Canadian log house made from hand-cut logs:

1. Scrupulous selection of each log, its careful sanding, hand planing.

2. All work is carried out exclusively by hand.

3. The use of high-precision fitting of logs, the absence of even minimal gaps, the attractive appearance of the walls in the form of a solid mass, behind which the surface of the insulation is not visible.

4. Preservation of the outer wood layer, which has a positive effect on the service life of the entire building.

5. Higher resistance to the formation of mold, mildew, ultraviolet radiation and moisture.

6. Self-filtration of indoor air, creating a unique indoor microclimate.

7. Attractive appearance, each log has an individual bend.

8. The service life of a house made using Canadian logging technology exceeds a hundred years.

Canadian cutting technology consists of heaving on the cup. In addition, Canadian technology involves the presence of spikes, thanks to which the house is insulated, and even after shrinkage, cracks do not appear in the building.

Canadian felling is based on the high-precision fit of logs and the trapezoidal shape of the bowl. Thanks to this, it is possible to create self-clinging joints that are strong and highly durable.

It is more profitable to construct a log house using Canadian technology from large and massive logs. Before starting to operate the building, it is mandatory to wait at least 12, and preferably 24 months, after construction.

Log cutting video:

Main types of wood for felling and their processing

To know how to cut down a bathhouse, you need to select the appropriate types of wood for production. Most often, coniferous types of wood (pine, spruce, larch) are used for the manufacture of such structures. It is best to choose material from cold regions (for example, Siberia), since in winter the flow of sap along the trunk is least. This reduces the risk of cracks forming when drying the material.

Also, trees that are felled in winter have a higher resin content, which increases its resistance to rot. The diameter of the logs must be at least 21 cm (but not more than 35 cm), and the length of all elements must be approximately the same to simplify processing and assembly. All wood must be smooth and free of knots. The area from the root to the beginning of the crown of a pine tree is best suited for this.

Wood for a log house Source sm-news.ru

See also: Catalog of companies that specialize in log baths and sauna vats

When laying structural elements, it is recommended to make the first 2-3 crowns from larch, as it has high resistance to moisture. When choosing a material, it is not recommended to use crooked trunks or wood with cracks and rot. The bark should be removed with a scraper, as it hardly touches the working surface underneath. After this, you need to let the material dry for 3-4 days. Also, before cutting, the wood is treated with an antiseptic and impregnated with a fire retardant.

Processed wood for a log house Source im0-tub-ua.yandex.net

Log cabin cutting technologies: description, pros, cons, examples

Let's find out how many technologies exist for building log houses, as well as their advantages and disadvantages.

Let's talk about what log cutting technologies exist and are actively used now. We will not only tell you how to build a log house, but also point out the advantages and disadvantages of each technology. For clarity, we provide photographic examples of different types of log cabins.

Material calculation

How to make a log house and calculate the amount of money spent, if the dimensions of the proposed structure are known - this is an important point in the manufacture or ordering of a finished building. For example, for a bathhouse with dimensions of 3x4 m and a height of 2.4 m with a frame in a bowl.

Due to the fact that the corners of such a structure will protrude 25 cm on each side, when calculating the length and width of the building, 50 cm is added.

If the diameter of the log is known (for example, 24 cm), then the volume of wood can be calculated using the formula 3.5 x 4.5 x 2.4 x 0.24 = 9.072 m³. During assembly, a groove is made in each log, which differs in width from 0.5D to 0.67D. This reduces the final volume of wood, so this formula requires further refinement.

Wide logs for a log house Source promdrevo.ru

Hook cutting

This method is considered quite difficult to implement. In addition, under the general name “hook cutting” two different methods of making notches in wooden blanks are combined:

- the log is trimmed in two directions (by half the diameter and by a quarter);

- ¼ of the diameter is trimmed with additional formation of a tenon-cut.

Each of these varieties is very labor-intensive and requires a perfect match of all sections. But the end result is worth the effort: wooden houses built in this way are very durable and warm.

Marking and cutting logs

To know how to cut down a log house, you need to understand the method of marking logs. To do this, they need to be laid perpendicular to the lower crowns. It is recommended to use staples to secure the structure. This will prevent the log from turning around its axis. Next, using a line, you need to draw the contours of the bowl and longitudinal grooves using several rules:

- One leg of the feature should rest on only 1 log.

- The distance between its points should be half the diameter of the log, depending on the log house used: “to the edge” - the upper one, and “to the edge” - the lower one.

- It is recommended to start drawing with a bowl and end with a longitudinal groove.

- The prepared logs are placed in bowls, and after that it is necessary to process the joint: if there is a large gap, insert wedges, if it is small, remove the excess layer.

Features of technologies for constructing log houses using hook cutting

The semicircular bowl is cut down to the middle thickness of the log, sawed along the axis and processed with an ax.

This type of cutting provides protection from drafts. This work can be done by a professional; it is complex and time-consuming. By trimming ¼ of the diameter of the inner edge of the frame, clear sides of the corner are achieved. The tenon comes out straight and is fixed on the untreated part of the log. This fastening is called a hook, due to its extreme strength.

The technologies for corner cutting of a log house into a hook are completely different, but first you need to make the bowl itself:

- the log is placed in the recess of the log house

- we make an inter-crown furrow at the end of the lower log

- We make recesses in the upper part, draw a line along the width of the future groove

- the legs of the drawing compass are moved apart along the width of the mounting groove

- a line is placed on the laid log, on the lower log, the exact profile of the upper log is marked on all sides

- Having finished drawing the groove, move the legs of the compass-line apart half the distance from the average radius of the log

- we put the legs again on the log that lies across the bottom one, we outline the semi-cylinders of the corner notches that should be made in the log

- The upper part of the log is removed, 7-10 mm recesses are sawed under it

- then carefully refine the surface with Sherhebel

The work of cutting with a hook is complex, painstaking, and requires effort and endurance. It is necessary to constantly try on, trim off the excess, then the timber will “fit” correctly and perfectly into the structure.

Advantages of cutting a log house with a hook:

- Significant advantages of a log house with a hook are the strength of the structure and additional thermal insulation, which does not interfere with air circulation

- The porous structure of the wood allows vapor to pass through, ensuring comfortable living in this house.

- due to the lightness of wood, there is no need to build a powerful foundation, which significantly reduces costs

- The wooden structure of the hookhouse is clean, environmentally friendly, does not emit toxic substances, which will have a positive effect on the health of residents.

- comfortable, complete rest is ensured by a high degree of noise absorption of wooden walls

- connoisseurs of aesthetics will undoubtedly be pleased with the exquisite external and internal appearance of a log house built in a hook, which will not require material investments, and the smell of the forest will create a positive mood and put you in a good mood

Disadvantages of cutting a log house with a hook:

- The disadvantage of a log house with a hook is that the required length of the building is reduced by approximately 1 m due to unused protrusions at the corners

- Also, do not forget about fire safety when operating with wood.

- you should pay attention to the quality of wiring, electricity, gas supply and furnace heating

- The disadvantage is that wood is the best habitat for insects, mold and fungi; to avoid this when constructing buildings, logs are impregnated with a special solution

All of the listed shortcomings are not critical; they should be taken into account by specialists when installing and manufacturing hook-and-loop log buildings, and to reduce risk factors, you should choose proven building materials with a warranty period.

Thus, hook cutting is a rather complex type of log cutting. Log houses built using this method of cutting logs are characterized by strength, reliability, and good heat retention in winter.

Assembling a log house

Before assembling the log house, it is necessary to make a strip-type foundation, since the wooden structure has a large mass, and put waterproofing on its upper part.

Next, it is recommended to lay 2-3 larch crowns and level the horizontal surface of the log house using a level. During assembly, insulation is placed in the longitudinal groove, and to compact the log, the log is tapped with a wooden mallet or log. Also, after laying each crown, it is necessary to check the horizontal and vertical position of the structure.

After assembly is completed, all cracks and joints are caulked, and excess insulation is removed. After six months, it is recommended to repeat this operation, since the insulation can become saturated with moisture from the drying logs. All wooden structural elements must be treated with an antiseptic 2 times.

Log house Source metasold.com

Work is done. What to do after shrinkage of the log house?

After shrinking the log house, the log house is finished:

- floor installation,

- ceiling,

- partitions,

- covering the attic and veranda,

- installation of doors and windows.

There are many options for interior decoration of log houses, so we will not dwell on it in detail. Let us only note that in order for a log house to be truly warm, a year and a half after installing the log house, it is necessary to caulk the log house.

Briefly about the main thing

The log house is most often made from pine or other coniferous wood.

The main advantage of a wooden log house is thermal insulation and environmental friendliness.

When choosing a log manufacturing technology, it is recommended to take into account the level of knowledge and skill. If it is not high enough, then it is better to contact specialists.

It is necessary to use high-quality thermal insulation and means to combat fungus and insects. This will extend the life of the building.

All logs for a log house must be treated with a fire retardant to avoid fire in the structure.

Ratings 0