One of the most important tasks when building a bathhouse is the correct exit and sealing of the chimney pipe. Moreover, two problems need to be solved at the same time: ensuring fire safety and insulating the pipe joint from the flow of precipitation and condensate.

First of all, before solving the problem of water passage, it is necessary to determine where the pipe exits on the roof. The height of the pipe must comply with certain standards. The height depends on where the pipe will exit on the pitched roof.

[toc]

Chimney passage through the roof

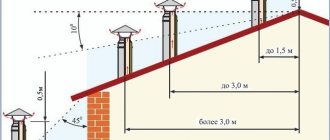

The chimney is designed to remove fuel combustion products (coal, gas, firewood, peat) and form stove draft. The method of exiting the pipe through the roof is determined at the design stage. The main condition for this is to ensure the fire safety of the roof, especially at its junction with the pipe, as well as to protect the joint from the ingress of atmospheric moisture and the accumulation of condensate. The height of the pipe is determined by SNiP standards and depends on the distance at which it is located from the roof ridge:

- if the distance from the center of the pipe to the ridge is no more than 1500 mm, then the height of the pipe above the ridge should be no less than 500 mm;

- when the distance between the center of the chimney and the roof ridge is from 1500 to 3000 mm, the height of the pipe coincides with the height of the ridge;

- if the distance exceeds 3000 mm, the height of the chimney should not be lower than a line drawn from the ridge at an angle of 10°.

The height of the chimney pipe is determined by SNiP standards and depends on the distance to the roof ridge

Chimney passage unit

This element can be located in different places on the roof. One of the preferred options by roofers is to pass the chimney directly through the ridge. This method is characterized by the easiest installation and avoids the accumulation of snow above the pipe wall. The disadvantage of this arrangement is that it reduces the strength of the rafter system, in which the ridge beam is either absent or sawn and secured with two supports on the sides of the pipe outlet, which is not always possible to implement.

The chimney outlet through the ridge is simple to install, but can compromise the strength of the rafter system

Most often, the pipe is located near the ridge. This way the chimney is least exposed to cold, and therefore condensation accumulates inside. The disadvantage of this arrangement is that the closer the pipe is to the ridge, the greater its height, which means that construction will require additional funds.

Exiting the chimney at a short distance from the ridge is the most common and convenient option.

It is not recommended to route the chimney through the valley, as snow can accumulate in these places, which will lead to a violation of the waterproofing and the occurrence of leaks. In addition, it is difficult to organize a chimney duct at the junction of the slopes. You should not place the chimney at the bottom of the slope - it can be damaged by snow coming off the roof.

The material from which the pipe is made also affects the organization of its outlet system. Typically, pipes are made of metal, asbestos cement or fire bricks, but sometimes ceramic ones are also found. The methods of waterproofing them will be different. In addition, each type of fuel has a certain combustion temperature, and this must also be taken into account when constructing a chimney.

Depending on the shape of the chimney pipe, the outlet hole can be square, round, oval or rectangular. To protect the roof covering from high temperatures and protect it from fire, a box is installed around the chimney. This happens as follows:

- Additional rafters are installed to the right and left of the pipe.

- Horizontal beams are laid at the bottom and top at the same distance and of a similar cross-section. The distance between the box beams and the pipe walls is determined by SNiP and is 140–250 mm.

- Inside the box is filled with non-flammable insulating material, for example, stone or basalt wool. It is not recommended to use fiberglass due to its high flammability.

The space of the box should not be filled with fiberglass - it can ignite under the influence of high temperatures

It is necessary to take into account that the construction of the box may disrupt the ventilation of the under-roof space, so additional ventilation systems can be installed.

Final works

Cutting a chimney pipe on the ceiling or roof with your own hands is finished. All that remains is to dry the oven. But before that, we check the draft in the pipe. To do this, we bring the torch to the open door of the firebox; if the flame draws inward, the draft is normal. If there is insufficient ventilation, you will need to remove construction debris from the pipes and only then proceed to the next stage of the final.

After the surfaces have cooled, we dry the stove a second time and check all the joints and the chimney itself for leaks and that there are no leaks of gases into the room. We eliminate possible malfunctions and only after the final check can we begin to operate the furnaces.

Only by qualitatively completing the main stages of work and carefully checking the finished chimney, you will be able to protect your home from fires and inhale the fragrant smell of burning wood, and not carbon monoxide pouring out of the cracks of the chimney.

←Previous article Next article →

Proper installation of a passage through the roof for a stove or ventilation pipe ensures not only the safety of the stove, pipe and building, but is also the key to the safety of residents. At first glance, designing a roof penetration for a chimney seems to be a simple matter. However, here it will be necessary to ensure impeccable hydro- and thermal insulation of the passage unit, choose the best place to bring the pipe to the roof, and not destroy the aesthetic design of the building.

There is an opinion that the efficiency and safety of an individual heating system depends on the design of the stove and the skill of the stove maker. Few people think that complete combustion of fuel depends more on the chimney and traction force

And only specialists know how important it is to install a high-quality passage through the roof

When building a furnace, the main attention is paid to the temperature stability of the materials. But the fire-resistant brick of the chimney and the mineral insulation of the sandwich pipe are defenseless against systematic moisture

Poor design of the pipe outlet to the roof entails serious consequences affecting the operation of the chimney. Violation of the standards for thermal insulation of pipes from flammable roofing materials and attic floors can lead to:

- to fire in places where the pipe and combustible materials of the house structure come into contact;

- to the formation of a large amount of condensate in the pipe, which will lead to its rapid destruction;

- to the formation of a thick soot deposit on the inner wall of the chimney and a decrease in its working clearance;

- to a decrease in stove draft and the formation of carbon monoxide, which is dangerous to human life.

Poor quality waterproofing of a roof penetration assembly threatens:

- penetration of atmospheric moisture into the attic, which provokes the formation of fungus and mold;

- getting the rafters wet leads to the initiation of wood rotting processes, no matter how well it is treated with an antiseptic;

- destruction of the brickwork of the chimney;

- increased corrosion of the metal pipe;

- by getting the thermal insulation (mineral wool) wet, after which this material becomes completely unusable and loses its thermal insulation properties.

A modern home is a complex system that cannot fully function autonomously. One way or another, various communications must be connected to the house, and some of these connections are made through the roof. In order to ensure the aesthetics and tightness of the roof in places where pipes, ventilation, antennas, etc. enter, it is necessary to select the right roof penetrations.

Algorithm of actions for the device

The chimney is installed and fixed in the base area.

During the construction of the canopy, it will be necessary to dismantle the pipe canopy, if it was already attached to it.

Next, perform the following steps:

- The size of the ring on the penetration is determined. It should be 20 percent less than the diameter of the chimney. Using a sharp knife, cut to the desired size. If the gap is unsuccessfully cut, do not rush to throw away the Master. You should try to correct such a flaw using a tightly installed clamp;

- The prepared Master pulls himself onto the pipe and with force lowers himself to the roof level. To make sliding easier, you can use soapy water as a lubricant;

- In the case of making a roof covering from ondulin, tiles, slate and other covering materials laid overlapping, the upper section of the base of the otter must be moved under the adjacent, outermost component of the insulation. This will create conditions for free drainage of water regardless of sealing;

- A moisture-resistant sealant or bitumen is applied under the base, and the flange is secured with self-tapping screws with a large press cap to the roof and sheathing. The distance between the screws should be maintained at 3.5 cm.

Expert advice: you should not screw in a large number of screws, since over time the sealant will gradually begin to lose its insulating qualities, and moisture will begin to enter through multiple punctures from the screws.

It is not recommended to screw self-tapping screws into depressions in the roofing material through which water flows. The flexible, sealing element can be easily bent to fit the roof profile and attached with minimal gaps. This completes the installation process.

In rare cases, a tight fit of the roof to the pipe is not observed. In this situation, the edges of the seal should be tightened with a clamp. This state of affairs serves as proof that the Master Flush was not selected accurately or the installation was carried out with errors.

Such auxiliary parts can be easily completed and installed with your own hands, or can be purchased at specialized construction stores. Such a “plate” is simply strung on the chimney on top of the otter. The size of the metal pad must be accurately selected to prevent it from oscillating due to wind.

The maximum operating temperature of Master Flash shows that the gasket cannot be used on every chimney. The otter will behave well if the chimney is insulated with a sandwich or on a chimney without insulation, which will heat up to no more than 100 degrees.

Expert recommendation: to avoid unpleasant situations - ignition or melting of the “master” during soot burning in an uninsulated pipe (temperature can reach 500-600 degrees), it is necessary to first perform thermal insulation work on the chimney.

For this purpose, basalt fiber is used, which is coated with galvanization.

According to numerous reviews, the widespread use of Master Flash roof seals is due to the convenience and speed of installation. Important advantageous factors are the affordable price, reliability of insulation, and long service life.

And there is no point in attracting highly qualified specialists or additional workers, since the instructions for the seals clearly and clearly describe the installation process, which any layman can handle.

Watch the video in which the master explains how to properly install and secure Master Flash for a chimney:

Arrangement of junctions

The main nuance in the question of how to remove a chimney through the roof is the creation of high-quality connections that will not leak. The issues of heat conservation at home also depend on this point.

The question of a quality connection also arises when paying attention to the fact that most roofing materials are flammable and should not be in direct contact with the pipe.

Let's consider how different types of chimneys are installed and the connection is organized in each specific case.

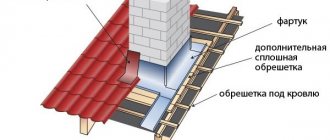

Classic apron method

This principle is standard and is suitable for almost all types of pipes and roofing materials.

- Film materials are cut in the form of an envelope and, when opened, attached to the rafter system;

- A continuous sheathing is laid around the perimeter of the created passage and an additional layer of waterproofing is laid, which is also trimmed with an envelope;

- About 10 cm is left around the created hole for insertion into the vertical areas of the pipe;

- The size of the hole means that there is 2-3 cm left around the pipe for convenient outlet of the chimney;

- Next, an apron is made around the chimney. Its options are different for each specific case; we will consider them below.

The exception is flexible tiles, for which a special apron is not required. It is made from a waterproofing film that is simply glued to the walls of the chimney. After installing the water drainage element, flexible tiles are installed around the pipe.

To organize connections to a brick pipe, a metal apron made of galvanized sheet is used. The apron goes over the pipe and roof. The front and side elements are laid on top of the roof, which prevents water from entering the roof. The rear part is laid under the roofing. The upper part of the apron is placed in the brick groove and sealed.

Arrangement of junctions using self-adhesive tape

The modern waterproofing tape “Vakaflex” is presented in the form of mastic, which is reinforced with aluminum mesh. The tape is supplied to the market with a width of 28 cm and is rolled with a roller. Let's look at how to work with it:

- The required length of the tape is cut, taking into account allowances of 5 cm on both sides;

- The cut tape is bent lengthwise like a corner, where the lower part is slightly wider than the upper (16 and 12 cm, respectively);

- The wider part is rolled to the bottom of the pipe;

- The narrow part is rolled onto the coating. It is necessary to tension the tape, achieving a perfect connection;

- The allowances are cut at an angle of 45 degrees by approximately 1 cm and rolled onto the pipe.

In this way all connections are made. Next, strips filled with sealant are mounted on top of the upper part of the tape. They will prevent moisture and snow from getting onto the edge of the tape. The planks are fastened with screws.

Use of lead strip

The lead strip is applied like self-adhesive

It is important to do this on a dry and cleaned surface at a temperature of at least +8°

The lower part is cut with 10 cm overlaps on both sides; The cut strip is applied to the chimney so that there is 10 cm at the top junction; The strip must be profiled, repeating the surface underneath it, moving from the center to the edges; The protective film is removed from the reverse side of the strip and the element is glued; Excess is trimmed; It is important to pay special attention to the seams between elements. They are made with a material overlap of 2 cm; After gluing, the strips are tapped with a hammer to accurately replicate the roofing material.

Output of finished kits

The use of sandwich chimneys simplifies the installation of pipes through the roof. The modern market offers a wide selection of ready-made kits of various materials depending on the type of fuel burned.

The sandwich pipe set, which is discharged through the roof, consists of the following elements:

- Deflector to enhance traction due to the use of hot air flows;

- Skirt to protect the passage area;

- The roof passage itself is complete with an apron that leads the pipe through the roof.

Fire safety

The wooden rafter system and some layers of the roofing pie (waterproofing, vapor barrier) cannot withstand heat and can ignite or melt. The safety of system elements that are not fire resistant is ensured by installing a special box around the perimeter of the hole in the roof.

Violation of safety rules

The box is mounted from a wooden block; it should be located flush with the sheathing, on the outside of the roof. Along the perimeter of the box, on the outside, the edges of the vapor barrier are fixed - a carpet made of roofing felt or other waterproofing material, as well as the edges of the vapor barrier membrane on the room side, if we are talking about an insulated roof. In both cases, a cross-shaped cut is made in the panel and triangular fragments of material are tucked inside. For fastening, nails with wide heads or staples are used, and sealant or adhesive tape allows you to achieve a tight seal between the materials around the perimeter of the wooden box.

The passage through the roof of the chimney provides for thermal insulation of the chimney with basalt wool or other non-combustible materials. If possible, an air gap of 5–7 cm wide is left between the insulation layer and the chimney itself.

Box insulation with basalt wool

If the installation of a chimney involves the use of a special element - a penetration, when choosing it, first of all, make sure that the element is made of a material that is resistant to temperature changes.

Please note: do not use materials that are not designed to withstand high temperatures, such as pipes and roof penetrations for ventilation ducts.

Sandwich pipe design

Everything related to heating equipment is associated with the risk of fires, especially in wooden houses. Statistics say that more than half of fires occur because homeowners did not install the chimney correctly with their own hands. To facilitate this task and protect the house from fire, sandwich chimney pipes are used. At first glance, they look like ordinary stainless steel products, but in fact they have a three-layer structure:

Sandwich pipe design

- Inner circuit. A round cylinder made of high-strength stainless steel with a thickness of at least 1 mm with the addition of zinc or molybdenum. The inner pipe is made of a sheet of metal, using welding to obtain a sealed seam. Due to its high anti-corrosion properties, alloy steel is not damaged by interaction with water.

- Insulating layer. Between the inner and outer contours there is an insulating layer that performs two important functions: it “locks” the heat inside the pipe, preventing it from heating the surrounding materials, and it does not allow the smoke to cool down while passing through the pipe, so that soot does not settle on its walls. As thermal insulation, fibrous materials with the highest fire resistance class with an operating temperature of up to 700 degrees are used, for example, basalt-based mineral wool. The insulation layer between the contours is 40-60 mm, and the insulation density is 12o kg per cubic m.

- External casing. The outer shell of a sandwich pipe is made of stainless steel or another type of metal. The seam of the casing is made using laser welding, which does not damage the galvanic layer of stainless steel, which protects it from corrosion. The cost of brass and copper pipes greatly increases the cost of laying a chimney, and the installation is justified by its spectacular appearance.

Sandwich pipes consist of additional elements: straight sections, bends, tees. The diameter of the products depends on the manufacturer, so it is necessary to buy all the parts of the chimney from the same company, which are ideally suited to each other.

Basic rules for arranging a structure

By following simple instructions, you can assemble a safe and properly functioning chimney. However, if you deviate from the instructions below, the design may not only become ineffective, but also dangerous in terms of fires.

- The total height of the structure should not be less than 5 meters from the heat source to the head of the pipe.

- It is not allowed to use pipes of smaller diameter than the outlet of the stove pipe.

- The height to which the pipe rises above the roof must exceed the height of the ridge by 50 centimeters. If the chimney is located on the slope of the roof, then the distance above which it should rise by half a meter is calculated based on the following diagram:

- If the device has a height of more than one and a half meters above the base, it must be strengthened with guy wires.

- Connections of structural elements should not coincide with passages through the roof or ceiling.

- The length of horizontal or inclined sections of the chimney should not exceed one meter. This is necessary to prevent clogging of the pipes with soot, as well as to ensure the best ratio of traction force and furnace efficiency.

- If the roofing material is flammable, then it is necessary to equip the pipe with a spark arrester made of mesh with cells no larger than 5 millimeters.

It is not difficult to take all these points into account, and the efficiency and safety of the constructed device will comply with all necessary standards and regulations.

You can also read about other important parameters that need to be taken into account when creating a chimney here.

Insulation of the chimney structure

When installing a chimney on the roof, an insulated chimney has a number of advantages:

- The efficiency of the furnace increases several times.

- The level of safety during operation of the unit becomes higher.

- The stove acquires an aesthetic appearance.

To make three-level waterproofing on a gable roof, you need:

- First, prime the structure with polymer mastic and stick on a superdiffusion membrane, wrapping its edges, which will ensure a sealed joint between the chimney and the roof, even when moisture enters.

- Install metal corners at the top and bottom. The upper metal sheets are laid on the lower ones so that the moisture flows downwards by gravity. Experts recommend laying the bottom tie up to the eaves of the roof.

- Nail additional bars onto the sheathing to secure the corners.

- Treat parts with sealant.

- Secure the resulting structure with dowels.

- Lay ondulin end-to-end, using bitumen mastic to treat the seams.

- Place a special apron made of ceramics, plastic or other materials in a circle on top of the ondulin, using onduflesh to seal.

Elastic penetration

Most often in private construction they are faced with the installation of round metal pipes. To ensure the tightness of the passage, a special device is used - an elastic penetration. This is a product made of high-strength silicone or rubber, shaped like a funnel with a wide flange in the form of a square or circle, called an apron. Thanks to its properties, the elastic penetration takes any shape, adapting to the angle of inclination of the slope. It can withstand extremely high or low temperatures, exposure to aggressive chemicals and comes in a wide range.

Installation diagram of elastic penetration

Elastic penetration on a metal chain

When purchasing an elastic penetration, they are guided by the diameter of the pipe and the color of the roofing material. Universal models, in the form of a stepped pyramid, are suitable for any size; adjustment is carried out by trimming the penetration to the desired level. Installing an elastic apron on the roof is very simple, you need to place it on the chimney passage, apply a metal circle with holes for fasteners, treat the joint with fire-resistant sealant and secure it with a screwdriver. For roofs with steep slopes, a special type of plastic penetrations with a specified flange mounting angle is used.

Types of ceiling penetrations

When crossing the ceiling, it is necessary to protect the “pie” materials from heat, and also somehow fix the pipe in a certain position. This task is accomplished by a ceiling cutout or, as it is also called, a “passage unit.”

The pass-through units are industrially manufactured. They are a box made of metal or mineralite, to which a stainless or galvanized steel plate is attached on one side. A hole is made in the middle of this assembly into which a sandwich is inserted. The plate on the side of the room closes the hole in the ceiling, decorating it. It also serves as a support for the heat insulator, which is used to fill the gap between the pipe and the floor beams for better thermal insulation.

This is a mineralite ceiling penetration. View from the attic

There is no disagreement regarding what material to use for the penetrations in the bathhouse: only stainless steel. The fact is that at temperatures that are typical for steam rooms, galvanization releases far from the most useful substances. Therefore, there is only one option: stainless steel.

Everything is installed simply. If the ceiling was made without taking into account the passage of the pipe, a square hole is cut in the right place (between the beams), which is 1-2 cm smaller than the size of the decorative panel. Beams and boards are covered with a layer of thermal insulation. If available, you can nail down strips of mineralite, basalt or asbestos cement cardboard (asbestos is harmful, so use it only as a last resort), just a strip of stone wool insulation. In some cases, padding of the insulation with metal strips is required (when it is needed, see below).

You can't do that - you had to cut a square hole. And the lining on the ceiling near the pipe is already charred...

When installing a pipe on a stove, the device is placed on a straight section that will cross the ceiling. The passage unit simply rises to the desired level. A strip of thermal insulation is placed under its edges that touch the ceiling boards, then everything is fixed with self-tapping screws. In many units, manufacturers even make perforations for self-tapping screws, so even this is not a problem.

The configuration of these products varies. Sometimes a metal cylinder is made around the hole for the pipe. The edges of the decorative plate protrude significantly beyond this cylinder. When installing a pass-through unit of this type, the hole is still cut in a square shape. A circle is also possible, but from the pipe to its edge there must be a distance of at least 130 mm if the pipe is insulated, and 250 mm if it is without insulation

With this option, please note: the size of the plate should be sufficient to mask the hole. In addition, with this form of passage through the ceiling, it is imperative to protect the wood of the ceiling not only with heat insulators, but also to cover it with strips of metal

Pass-through units through the ceiling come in different configurations

There are passage units in which there is no cylinder around the pipe, but there are outer sides around the perimeter. They are made of metal, and can also be made of mineralite. If the sides are made of metal, the edges of the cutout in the ceiling must be lined with a heat insulator (for example, basalt cardboard or the same mineralite). If the sides are made of mineralite, then they themselves are a good heat insulator. So additional thermal insulation of the edges of the cutout is not necessary (but you can play it safe).

What thermal insulator to use

After the device is fixed to the ceiling, they go up to the attic or second floor and fill the gap between the outer wall of the pipe and the beams with heat insulator.

Basalt wool can be used as thermal insulation. But be sure to check that the operating temperature range should be greater than 600°C.

You can use mineral wool or clay to insulate the pipe.

Some people think this option is not the best. Firstly, during production, resins are used as a binder, which release formaldehyde when heated. Secondly, condensation sometimes runs through the pipe. And mineral wool (and basalt wool too) lose their heat-shielding properties when wet. And when they dry, they are only partially restored. So this option is really not the best.

The penetration is also covered with expanded clay of medium and fine fractions. This is a natural material that is relatively light in weight. Even if it gets wet, it then dries and restores its properties. When wet, the thermal conductivity increases slightly, but it is already worse for expanded clay than for mineral wool.

In the past, sand was often used. The option is not bad in all respects, except for one detail: it gradually wakes up through the cracks. Refilling the sandbox is not difficult, but constant sand on the stove is annoying.

If we talk about natural heat insulators, then you can use clay. It is diluted to a paste-like state and the entire gap is covered. Sometimes expanded clay is used as a filler.

One of the heat insulators is expanded clay

Here is a review of the use of clay when passing a bath pipe:

“Clay rules in cutting! I dismantled the chimney in my bathhouse. Or rather, I took apart what was left: there was a lot of snow, and when it melted, it blew off the entire top. Once you change the top, you need to look at the bottom: the pipe has been standing for 7 years. So here it is. There is zero burning inside, and there is no burnout of the pipe either. Condition: as soon as installed. My penetration is lined around the perimeter with basalt wool, and then everything is covered with clay. This is definitely the best option."

Not everyone recommends using insulation in the passage unit. There is an opinion that it is better to leave the gap unfilled: this way it will be possible to avoid overheating and burning out of this section of the pipe - it will cool better due to air blowing. This may be true, but the radiation from the heated pipe will dry out the nearby wood, and in this case the temperature of spontaneous combustion is significantly reduced - to +50°C.

As you can see, the pipe burned out

There are several ways to avoid overheating. The first, and most rational, is to use the heat that flies out into the pipe and heats it to extreme temperatures for your own needs. There are three options:

One way to avoid overheating is to place stones on the pipe

- Make a water jacket on the metal chimney and use hot water for showering or heating. The system is not so simple; it also requires a remote tank, as well as pipe connections, cold water supply, etc. But temperatures above the water jacket will not be nearly as high, and the pipe will not burn out.

- You can also heat water, but it’s easier: install a samovar-type tank. Hot water is also provided, the chimney does not overheat and is protected. But there are some nuances here: do not let it boil, drain the heated one in time, add the cold one. And doing this is not entirely convenient, since the tank is located quite high: above the stove on a pipe.

- Adapt a net for stones. The water will have to be heated in a different way, but the advantage here is this: after the procedure is completed, the stones dry the bath. Here, too, difficulties may arise: the weight of the stones is considerable, it is unlikely that you can do without support, unless you use the factory version (on the right in the figure). In a homemade version, a structure will be needed to redistribute the mass.

When using any of these methods, the pipe temperatures in the ceiling passage are significantly reduced. The likelihood of burning becomes very small. That's not all. There is a way - simply cool with air. To do this, another one of larger diameter is put on the heat-insulated pipe. A grate is made at the bottom and top through which air enters/exits. For a steam room this is not an option - it will draw out all the steam, but for a washing room it can be used. The method is especially good in the attic and when passing through the roof.

Chimney box

In order to properly remove the chimney through the roofing pie, you should install your own rafter system around the pipe. It must be separated from the chimney at the distance specified in SNiP. The structure consists of side rafter legs and horizontal transverse beams at the bottom and top, which are made of timber of the same section as the rafters.

To insulate the structure, it is necessary to use non-flammable heat-insulating materials, such as glass wool or stone wool - it is stuffed between the pipe and the wooden structural elements.

When passing a chimney through the roofing pie of a roof in use, the vapor and waterproofing is cut crosswise, like an envelope, the edges should be tucked in and attached with nails or staples to the rafter system.

Waterproofing a chimney on a roof requires special attention. When installing a duct for a pitched roof chimney, the vapor barrier and waterproofing membrane are fastened as follows: the edges of the films are folded up and tightly fixed with brackets to the duct; in addition, the fastening points should be additionally sealed using sealing tape or some other adhesive material. On the outside, protective elements are installed on top of the roofing covering to prevent moisture from entering the joints between the box and the roofing pie.

It is important to consider that installing a duct can negatively affect air exchange in the under-roof space. To avoid deterioration of moisture removal, you can install additional ventilation systems, for example, roof tiles, roof aeration grilles, etc.

The slope is a small roof of its own that drains water and snow from the pipe. Its installation is quite complicated, since the slope includes all layers of insulation; in addition, it must be properly combined with the main roof using shaped elements. To avoid installing a bend, it is worth making a smaller pipe.

Using ready-made kits

Standard modular chimneys (“sandwich”) can significantly simplify the process of running a pipe through the roof. A wide range of materials are used for the manufacture of structures, including

:

The choice of a modular chimney depends on the fuel used, since they differ significantly in their technical characteristics. The advantage of such systems is the ability to install the pipe not at a right angle. This is especially true when installing a chimney in a building in use and allows you to choose almost any place to install a fireplace, stove or automatic boiler.

A modular chimney passes directly through the roof, consisting of parts such as

:

- deflector (a device that increases draft in the chimney by using a flow of hot air);

- clamp for guy wires (allows you to additionally secure a tall pipe on the roof);

- skirt (an element protecting the place where the pipe exits through the roof);

- roofing passage (an element with a fixed apron, which is directly mounted into the roofing pie).

Modular chimneys have an attractive appearance.

Steel chimneys can be installed if the temperature of the exhaust gases is no more than 500 °C. Prohibited for installation on coal-fired stoves. For asbestos-cement pipes, this parameter is 300 degrees; such chimneys are also unsuitable for coal stoves.

If the chimney is made of concrete or brick, or a prefabricated passage is installed, the structure should not be rigidly attached to the roofing system. Under the influence of external factors, the roof may be deformed, and these forces will be transferred to the chimney, which may lead to its destruction. When the chimney exits through the roof, all connections between the chimney and the roof are made using flexible elements.

What can result from poor installation?

Often, the list of works of a stove maker or installer of a gas or electric heating boiler does not include work on installing a chimney. It is assumed that the passage of the chimney pipe through the roof is laid at the construction stage, or the homeowner will install the chimney on his own. The apparent simplicity of such work provokes owners to refuse to use professional roofers. They don’t think about what serious negative consequences a poor-quality chimney outlet to the roof can lead to. Frequently encountered problems:

- through a poorly sealed pipe passage, dampness can enter the masonry, eventually destroying bricks and cement joints;

- increased humidity of the chimney pipe itself or the elements in contact with it provokes an increased spread of various microorganisms, mold, and mildew. The spores of some of them can pose a danger to human health and even human life. If traces of infection are visible on the pipe, it is not recommended to use it, and in special cases it is necessary to completely replace the entire smoke exhaust system;

- water seepage in places where the chimney passes through the roof elements leads to a reduction in the thermal insulation properties of the insulation by half. You need to understand that after such a layer dries, the insulation characteristics will no longer be able to return to their previous level;

- a poorly installed chimney affects the durability of the materials of the roofing elements and rafter system. Penetrating moisture accelerates the process of wood rotting, which will lead to the destruction of the power frame;

- large gaps near the passage of pipes lead to the cessation of normal circulation of warm and cold air in the room under the roof. This leads to additional energy losses, and hence to unnecessary heating costs;

- Poor-quality chimney lining significantly spoils the appearance of the entire building.

Not only chimneys from stoves, fireplaces and other solid fuel devices are raised above the roof. Exhaust pipes from gas heaters, as well as ventilation pipes, are also discharged there. When installing them, exactly the same methods are used as for chimneys.

Features of the structural design of chimneys

Installation of chimneys is required in houses where there is a Russian stove or fireplaces operating on solid fuel. If you want to have a real heating structure made of brick or stone, you need to choose the right location for its installation. In ancient times, people first laid out the stove, and only then built the walls.

In order not to provoke a fire hazard, you must adhere to a number of rules. Thus, it is impossible to place a large number of wooden ceiling elements above the stove, since there is a high air temperature there, which is fraught with big troubles, including the ignition of beams and ceilings.

Rapid cooling of gases appearing in the furnace shaft as a result of fuel combustion should not be allowed. Therefore, it is necessary to ensure not only the correct installation of the chimney on the roof, but also its high-quality insulation. If this is not done, condensation will constantly appear at the point of contact of warm air masses with cold ones - it will eventually saturate the chimney and begin to descend lower, destroying the structure and clogging it.

Passage through the roof of a brick chimney

The passage of a chimney through the roof must simultaneously solve two not so simple problems: ensure fire safety and tightness. According to fire safety rules, in places where the chimney comes into contact with flammable materials, the temperature of the chimney walls should not be higher than 50°C. For brick chimneys this is solved by increasing the wall thickness. For this purpose, stove makers lay out a special penetration. There is no single solution here, since much depends on the angle of the roof. That’s why this option is not very popular today - it’s hard to find a person who can competently and safely make such a penetration through the roof.

When a brick pipe passes through the roof, it is surrounded on all sides by a box of additional rafters and cross beams

How is the question resolved then? They simply make a square or rectangular pipe, which is placed between the rafter legs, and transverse beams are installed above and below the pipe. The distance between the pipe and the wooden structural elements is 13-25 cm. If the distance between the rafters is greater, additional ones are installed. In this way, we minimize the damage that we will certainly cause to the hydro- and vapor barrier of the roof: in order to remove the pipe, we will have to violate the integrity of the films and membranes. When installing the chimney, it ends up in a separate box. The films and membranes inside this box are carefully cut. The cut geometry is similar to the geometry of a pipe or box, but smaller than the dimensions of the rafter box. In the corners, the films are cut at an angle (envelope), the edges of the films are folded and fixed with staples or clamping strips to the elements of the rafter system. The edges and entry points of fasteners are sealed with adhesive tapes or sealants. This operation should be carried out carefully - the durability and reliability of the roof depends on it.

There is another option. This is possible if the temperature of the pipe in the roof area is not higher than 50°C. In this case, the edges of the films can be glued to the pipe with sealants or the same adhesive tapes (trying to seal everything as best as possible). Now there is free space between the rafters and the brick pipe. It is laid with a heat-resistant heat insulator.

Drainage of water from joints

It is most difficult to seal the joint between a brick pipe and a roof if a rigid roofing material is used.

When venting the chimney through the roof, you need to solve the problem of waterproofing. To do this, use a system of two aprons: a lower one and a decorative one.

First, a lower apron is installed around the pipe. It is usually made of tin and consists of four elements: two sides, a top and a bottom. How to do it, see the next video. Everything is told in detail.

A so-called “tie” must be placed under the lower apron. This is a section of roofing material, a sheet of tin or galvanized metal, which will drain water to the drain (the tie should be this long - extend slightly into the drain) if the chimney is located low or into the valley, if it is closer. The following video further demonstrates the technique for installing an internal brick chimney flashing and also shows how to install a tie and external decorative flashing.

In general, as many materials as there are, there are as many ways to install a pass-through unit. Another video that demonstrates another technique for waterproofing a brick pipe. They use modern materials that are produced here.

It is much easier to waterproof the joint between the chimney pipe and the roof if soft tiles or other soft flexible roofing material is used. On a plastered pipe, coated with impregnation for better adhesion, this material is simply bent and trimmed. You can apply a layer of sealant along the edge of the curved roofing material and secure everything using a pressure strip. The place where the roofing material is connected, the pipe and the strip are also treated with sealant. This video demonstrates the technique of sealing a chimney using soft tiles.

How to route stove pipes through ceilings and roofs

First, a stove is installed in the room, and then a pipe is laid out for it. Finally, the stove pipe rests on the ceiling, and the craftsman begins to make a hole in it, observing fire safety rules.

- The chimney is installed at a distance of no less than 350 millimeters from structures unprotected from fire, and from protected structures the distance should be no closer than 250 millimeters. It is customary to close this gap with metal or asbestos-cement non-combustible sheathing with decorative patterns, which is covered in the attic with fine expanded clay.

- The chimney is routed through the roof and the roof, if the roof is not insulated, with a gap distance to the rafters of at least 250-300 millimeters. And with an insulated roof - the same standards that applied to the exit through the attic floor.

When a stove pipe is released through the roof, there is a desire to make a small hole for it, exactly the size of the pipe. Here it is necessary to take into account the quality of the material from which the roof is made. Roofing felt, roofing felt and wood are easily flammable; for them it is necessary to create a gap that complies with fire safety regulations.

For a roof made of non-combustible material, it is enough for the gap to be only a few centimeters. Arrange the removal of the sheathing at a safe distance.

The craftsmen have a technique that allows them to determine the exact location of the pipe exit. They take a sheet of cardboard and wrap it around the pipe in order to follow its contour. The resulting cardboard pipe is lifted up along the same axis as the stove pipe, until it stops with the roof. After this, markings are made on the roof, obtaining the outline of the hole. Round pipes fit exactly into such holes. And for brick pipes, the outlet location is determined by a vertical strip. It is applied to all edges of the pipe under construction and rests against the roof with the other end, marking the outline.

Exiting the chimney through the ceiling

The choice of design and materials depends on the type of chimney. Let us analyze the rules for organizing work for the main materials of pipelines in detail.

Round metal

The whole process is divided into several stages:

- The most popular today for the manufacture of steel chimneys are double-sided metal sandwich pipes with an internal layer of thermal insulation. For such chimneys, you can easily make a homemade box from tin or buy a ready-made one in a store.

- According to the dimensions of the box, we cut out a cavity in the ceiling, insert the box so that it is securely fixed with its curved edges on the floor of the attic or 2nd floor.

- We insert the pipe into the prepared hole and secure it to the wall with self-tapping screws. Fill the remaining gaps with heat-resistant sealant.

- We fill the entire remaining cavity of the box with insulation. You can use mineral wool, penoizol, polystyrene foam and any other material. The use of asbestos is prohibited in residential premises.

- The thermal insulation layer should protrude slightly beyond the metal sides. All that remains is to cover the surface of the box with decorative wood trim. You can buy a polished stainless steel plate that will decorate your ceiling.

Stages of work on removing a steel chimney through the ceiling

Brick chimney

Here everything is much more complicated:

- Before the floor slab, the mason must fluff the pipe and gradually expand the outer size of the chimney. If you have skills in laying bricks, you can do the job yourself. If not, you will have to hire an experienced stove maker.

- An opening is cut in the slab (ceiling) according to the dimensions of the pipe, even with a small margin. After laying the bricks and the chimney exiting the surface of the ceiling, we cut the slab insulation material to the size of the pipe.

- You can use mineral wool or prepare foam blanks. The main thing is that the thickness of the layer compensates for the high temperature of the exhaust gases and does not allow them to affect the surface of the walls and ceilings.

- Then we lay the blanks around the pipe and secure them with special screws or simply wrap them with tape. The main thing is not to leave large gaps, but to fill small gaps with fire-resistant sealant. Having filled the entire cavity with insulation, we cover it with a layer of decorative finishing.

Scheme of the outlet of a brick chimney through the ceiling and roof of the house

The final stage of installation

The design of the unit is completed in the following stages:

- Remove the protective film from the sandwich pipes. It is highly undesirable to free parts from polyethylene earlier - they may be damaged during transportation or installation.

- Seal the joints properly with sealant. Ideally, the composition should withstand temperatures within 1000 degrees.

Which areas need to be coated with sealant:

- seams at the junction of internal sandwich pipes - the plane located on the outer part from above;

- joints of external pipes - the entire outer surface area;

- the junction of sandwich pipes with other components of the system - the entire area or diameter, if we are talking about round pipes.

Do not rush to use the new chimney right away; first check that it is working correctly:

- Turn on the heating device (boiler, stove or fireplace) at low power.

- Now inspect the device to see if it is leaking smoke in the wrong places.

- Check for excessive heating of components of the entire system, especially in the wall or roof transition area.

What is good about a chimney made from sandwich pipes? It looks aesthetically attractive and provides the fireplace with a modern style; even a beginner can assemble it. And also, if installed correctly, it will last a long time and will delight the owners with uninterrupted operation.

Exiting the chimney through the ceiling

The choice of design and materials depends on the type of chimney. Let us analyze the rules for organizing work for the main materials of pipelines in detail.

Round metal

The whole process is divided into several stages:

- The most popular today for the manufacture of steel chimneys are double-sided metal sandwich pipes with an internal layer of thermal insulation. For such chimneys, you can easily make a homemade box from tin or buy a ready-made one in a store.

- According to the dimensions of the box, we cut out a cavity in the ceiling, insert the box so that it is securely fixed with its curved edges on the floor of the attic or 2nd floor.

- We insert the pipe into the prepared hole and secure it to the wall with self-tapping screws. Fill the remaining gaps with heat-resistant sealant.

- We fill the entire remaining cavity of the box with insulation. You can use mineral wool, penoizol, polystyrene foam and any other material. The use of asbestos is prohibited in residential premises.

- The thermal insulation layer should protrude slightly beyond the metal sides. All that remains is to cover the surface of the box with decorative wood trim. You can buy a polished stainless steel plate that will decorate your ceiling.

Stages of work on removing a steel chimney through the ceiling

Brick chimney

Here everything is much more complicated:

- Before the floor slab, the mason must fluff the pipe and gradually expand the outer size of the chimney. If you have skills in laying bricks, you can do the job yourself. If not, you will have to hire an experienced stove maker.

- An opening is cut in the slab (ceiling) according to the dimensions of the pipe, even with a small margin. After laying the bricks and the chimney exiting the surface of the ceiling, we cut the slab insulation material to the size of the pipe.

- You can use mineral wool or prepare foam blanks. The main thing is that the thickness of the layer compensates for the high temperature of the exhaust gases and does not allow them to affect the surface of the walls and ceilings.

- Then we lay the blanks around the pipe and secure them with special screws or simply wrap them with tape. The main thing is not to leave large gaps, but to fill small gaps with fire-resistant sealant. Having filled the entire cavity with insulation, we cover it with a layer of decorative finishing.

Scheme of the outlet of a brick chimney through the ceiling and roof of the house

General rules and location selection

How to route a stove pipe through a wooden ceiling - this must be done in such a way that there are no problems, as in the photo. The main task of the preparatory stage is to determine the location of the stove installation and the installation of the chimney to the street. Depending on the materials of the floor slabs and chimney pipes, work will need to be done taking into account several sizes:

- the maximum distance from the ridge to the pipe canopy is 1000 mm, and the minimum protrusion is 350 mm;

- distance to wooden wall surfaces – at least 250 mm;

- length of the horizontal section of the chimney up to 1000 mm;

- When choosing a passage location, take into account the passage of the pipe through the roof structure. This place should be located between the rafters;

- When passing steel pipelines through wooden slabs, finishing elements and roof structures, we must use homemade, industrial boxes or couplings with an internal layer of thermal insulation.