The size of the bath is chosen based on various considerations. This takes into account the characteristics of the site, the number of users and other factors. In this case, the main indicator should be the size of the steam room. This is the main room, without which the functionality of the bathhouse will not be complete.

It is necessary to determine the size of the steam room for various reasons - ease of use, safety, and the possibility of saving fuel or electricity. Any mistakes lead to a decrease in comfort and the appearance of a lot of problems. Therefore, it is necessary to have a fairly complete understanding of the criteria for choosing the size of a steam room. Let's take a closer look at this issue.

5/5 — (2 votes)

Why is this type different from interior ones?

Today, in almost any suburban area or dacha you can find a bathhouse. In most cases, it is erected independently, without turning to specialists. And, if everything is clear with the design and general requirements. The question may quite naturally arise - what kind of door to the steam room should be in the bathhouse? Are there any fundamental differences from the standard interior? What are the basic requirements for materials and characteristics?

The main differences from standard doors include:

- Good thermal insulation;

- Increased heat resistance;

- Moisture resistance.

The entrance door of the bathhouse may not meet all of the listed requirements. Its main purpose is thermal insulation and heat preservation. Therefore, the standard one can also be used. Doors for a steam room in a bathhouse must meet the listed requirements and are made using special technology.

Solid wood is always used for production, because... The classic technology for producing interior doors is not suitable. Heat-resistant glass can be used; plastic is not suitable for the door to the steam room. Of the wood species, preference is given to linden, aspen and larch; the use of pine is allowed.

Previously, for better heat retention, smaller openings were used. Now this rule has practically lost force; it is allowed to install a door of a standard size. In rare cases. You can find a door of reduced size, which requires you to bend down when passing through it.

Tempered glass has become widespread. You don’t need to make it yourself; it’s enough to know the necessary parameters of the sauna door and its dimensions. You can buy a ready-made sample of a glass door in stores that specialize in bath materials.

When can you go to the sauna after coronavirus?

The viral agent can persist in human sputum and blood for quite a long time, so individual dates are set for each patient when it will be possible to take a steam bath after coronavirus. Approximate parameters are shown in the table below.

Before visiting the bathhouse, it is recommended to check the condition of the cardiovascular system, since there are a number of restrictions. So, in the presence of arterial hypertension, atrioventricular block, arrhythmia and tachycardia, hot procedures should be abandoned, since there is a risk of exacerbation of any of these conditions.

Optimal entrance sizes, what they depend on and which ones to choose

The main purpose of the entrance door to the bathhouse is not only heat preservation, but also reliability. It can be performed in the following options:

- Wooden. The most optimal option, it perfectly retains and retains heat inside the room; it is necessary to monitor the condition of the door leaf to avoid deformation and the appearance of mold. It is recommended to treat with special compounds for wood.

- Metal. It will reliably preserve the owner’s property; if there is an additional seal and the cladding is practically in no way inferior to wooden. The handles on such a door must be made of wood to avoid inconvenience, for example, when going out in the cold.

- Plastic. The simplest and most convenient, but its use is allowed only in cases where the bathhouse is located in close proximity to the house, because it can be easily opened.

The choice of the size of the entrance door to the bathhouse is purely individual, but if you stick to the classic version, the following dimensions of the doors for the bathhouse are considered the most optimal - 1.80 x 0.65 cm, it should only open outward. It is imperative to install a threshold with a height of at least 15 cm. If possible, from the inside it should coincide with the upper edge of the floor, only in this case a gap will be formed that will work as a hood.

There are no strict requirements for the material, so you can use classic 5-centimeter tongue-and-groove boards or use ready-made samples. For better heat retention, you can additionally cover the door with insulation or make a box at least 10 cm wide.

Peculiarities

Wood was always used for the construction of baths and their interior design; sometimes there were buildings lined with brick on the outside. Today, this trend has continued, and work is being done tirelessly to improve the quality of the main raw materials. However, in addition to wood, saunas and baths are decorated with no less impressive materials - this applies to glass products, in particular doors.

The quality of glass panels and their operational parameters are not inferior to wooden door structures for baths, and in some respects they are even several times superior.

Glass door structures stand out from other analogues for bathhouses and steam rooms with the following advantages:

- The raw materials are resistant to corrosion and are not subject to rotting. This resistance of glass to various destructive processes makes it possible to use products made from this material in rooms where the humidity level regularly increases;

- products do not lose their original shape when subjected to temperature fluctuations, unlike some wooden structures, which swell and dry out due to high temperatures, thereby losing their shape;

- environmental friendliness of glass - due to which, during the use of such structures in a bathhouse, the development of harmful microorganisms and mold on their surface is not expected. Which helps to improve the level of hygiene in the room;

- heat resistance - the specificity of such a structure as a bathhouse requires, first of all, compliance with fire safety standards. Glass doors are fire resistant, so they can be installed near heating units;

- aesthetic component - a variety of types of design and decoration of glass structures using inserts made of wood, metal, with painting or ornamentation on the canvas is the main advantage of the products;

- long service life - this is due to its resistance to the peculiarities of the microclimate in the room, due to which it does not have a destructive effect on glass doors during their operation in the bathhouse;

- ease of maintenance - the designs do not require the use of specialized cleaning compounds; to care for a glass door, non-aggressive cleaning compounds and a damp rag are sufficient;

- glass door models have an excellent ability to transmit light into the room, unlike solid wooden products. Due to this, you can save on electricity, which is necessary for lighting the steam room.

In order to create an objective picture, it is necessary to identify the disadvantages of glass door panels.

- Mass of products. As a rule, high-quality glass doors have quite an impressive weight, so several people will be needed to install the glass.

- The structures are highly expensive. However, the high cost of products is fully justified by the high quality of the product, for the production of which advanced technologies were used.

- The fragility of glass, due to which the product will have little resistance to mechanical stress. But this drawback is successfully minimized during the production of doors thanks to special processing associated with hardening of the material, after which the strength indicators of the product increase significantly.

Optimal sizes for a steam room

Before you start making doors, you need to decide on the dimensions. To maintain optimal temperature and retain heat, it is recommended to make doors up to 10 centimeters thick. Experts recommend using the following parameters for the steam room door size:

- the width of the door to the steam room is 65-70 cm;

- height from 150 cm but not higher than 185 cm.

By adhering to these parameters, it will be possible to maintain an optimal microclimate not only in the steam room, but also in other rooms. Indeed, often modern designs use not only a dressing room and a steam room, but also a washing room, as well as a relaxation room.

The presence of a threshold on the door to the steam room is mandatory; its size is at least 15 cm. The size of the door will be calculated from it. If we are talking about a sauna, it is not necessary to install a threshold; it is enough to leave a ventilation gap between the floor and the door leaf of 5-10 mm.

The size of the door leaf for self-made doors for the specified sizes is usually as follows:

- wooden beam with a section of 65x80 mm;

- tongue and groove boards 40 mm thick and 150 mm wide;

- lining 12 mm thick.

Canvas and box sizes

According to SNiP, the standard size of an interior door with a frame is divided into several separate indicators, which are reflected in the table:

| Indicators of the door leaf, cm/width*height | Opening, cm/width and height |

| 60*200 | 68-71/205-207 |

| 70*200 | 78-81/205-207 |

| 80*200 | 88-91/205-207 |

| 90*200 | 98-101/205-207 |

| 60*190 | 68-71/195-197 |

| 55*190 | 63-66/195-197 |

| 60+60*200 | 128-131/205-207 |

If we talk about the European standard, the ratio will be as follows:

| Panel parameters, cm/width*height | Opening, cm/width and height |

| 60*200 | 70-74/206-208 |

| 70*200 | 80-84/206-208 |

| 80*200 | 90-94/206-208 |

| 90*200 | 100-104/206-208 |

| 60+60*200 | 134-140/206-208 |

The Russian width of the canvas for the kitchen will be 70 cm, for the toilet or bath - 60 cm, and for the room - 90 cm.

What you need to make your own wooden

Anyone can make their own wooden steam room doors. You need to follow simple instructions. First of all, you need to prepare the necessary tools:

- screwdriver;

- roulette;

- plane;

- pencil;

- level;

- saw or hacksaw;

- milling cutter

What wood to make it from?

The choice of wood type is individual; there are no clear boundaries. The main requirement is resistance to high temperatures and durability. Conditionally wood for making doors for steam rooms. Can be divided into two categories:

- deciduous species - alder, linden, aspen and oak;

- conifers - larch, cedar, spruce, pine.

The main advantage of the latter is the low price, ease of processing and manufacturing of the necessary structures. The most common is linden. It is used not only for the manufacture of doors, but also for the internal lining of the steam room. Compared to others, linden is simple and easy to process, and does not warp or shrink over time. The aesthetic appearance of the wood is also important - a delicate creamy shade, without knots or wormholes.

Making a box

When making a door to a steam room with your own hands, you need to know how to make it and install the door frame. To do this, you will need a wooden beam with a cross-section of 6x15 cm; the material should be selected in such a way that the thickness of the door leaf is at least 5 cm less than the width of the frame.

The elements are fastened using the tongue-and-groove method. The bath door must necessarily swing outward, so the joining grooves must be cut out on the outside of the crossbars. They are cut out on the top and side posts in the doorway.

Before the box is assembled, it is necessary to sand the entire surface with sandpaper to remove all irregularities and chips. Then connect the lintels and corners, and then check the assembled structure with a level to avoid future distortions and sagging of the door.

Making canvas from treated boards

After the dimensions of the door to the steam room in the bath are determined, we begin to manufacture the canvas. A board with a length of at least 164 cm is used; the protruding tenon is cut off from the first board with a circular saw to form an even end. All manipulations are carried out only on a flat surface, assembly using the tongue-and-groove method, and the width of the workpiece should be greater than the size of the future door.

After everything is prepared, the final assembly of the canvas is carried out using PVA glue. First, it is recommended to lay out the prepared boards together and make sure they are the same length.

During the assembly process, it is necessary to knock the boards with a hammer so that the grooves are better secured, after which it is necessary to leave it for several days, first securing it or creating a press effect. Then you need to cut a piece of the required size from the canvas and process it with a plane.

If gaps appear, they can be immediately sealed using a mixture of glue and sawdust. The final stage will be attaching the strapping and installing stiffening ribs, which are located outside across the canvas. After that. Once the door is ready, it must be coated with special protective compounds that will protect it from the formation of mold and rot.

Using moldings, you can give the room a finished look, especially in cases where the size of the doorway differs from the door. All necessary materials are baseboards. Thresholds and other things can be purchased in specialized stores.

Useful video

Determining the floor level in the bathhouse, for which a difference is created between the height of the floors of the steam and washing compartments, an educational video about creating a subfloor, design features.

Basic requirements for floors

The optimal functioning of the bathhouse, as a narrow-profile room, largely depends on the correct arrangement of the floors. This condition must be fully observed, since it is associated not only with the trouble-free operation of the complex itself, but also with the comfortable stay of a person in it.

Three fundamentally important requirements apply to floors in a bathhouse:

- they should not be cold, but warm;

- drain water easily and quickly;

- physical activity when cleaning them should be minimal.

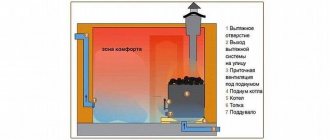

In bathhouses, like in no other room, the laws of convection of air masses apply. The floor temperature in any steam room does not rise above +30°C, no matter how hard the stove is heated. Therefore, the flooring can be created from any material, be it concrete, wood or clay.

But the main point in the construction of the facility is the creation of a two-layer floor - rough flooring and finishing with drainage arrangement. When installing a drain, the surface is mounted with a slope towards collecting waste water and discharging it into a sewer system or a pit located outside the foundation line.

Floor level in relation to the ground

The ratio of the ground level to the zero level of the final coating must be at least 300 mm. Calculating this distance is quite simple:

- support columns installed in the sand or concrete underlying layer are built flush with the top line of the foundation;

- wooden logs are laid on them;

- A covering consisting of a board, tongue-and-groove or edged, with a thickness of at least 25 mm is mounted on the logs.

By simple addition it is not difficult to calculate the value required for the installation of the lower ceiling in the bathhouse.

In a paired compartment, the flooring can be either pouring, when water flows freely between the cracks of the laid boards. Or non-leaking, with floorboards tightly adjacent to each other, made of tongue-and-groove boards. Through them, water flows into a specially equipped drain with discharge into the sewer system.

When installing non-drainage ceilings, an insulation cushion is created in the underground. A variety of materials are used as insulation - from waste slag, as the most inexpensive material, to extruded polystyrene foam, as the highest quality insulation, in which rodents do not live and there are no chemical reactions formed when exposed to hot air. The most common insulation material is expanded clay.

Video about installing lower floor beams and laying insulation:

Indoor floor level

To preserve heat, the main product produced by the steam room, the walkways in the compartment are raised above the zero mark of the finishing level by a distance of at least 100, but not more than 200 mm.

In the washing room, as in the most water-rich room, where streams of water are constantly pouring down, on the contrary, they are lowered below the zero mark of the finished floor to a distance of no more than 50 mm. Thus, water does not splash on the flooring of adjacent rooms, and does not flow out of the washing room through the threshold.

Installing floors at various levels in a bathhouse is very advisable, but not everyone resorts to this technique. The positive aspects of using floors with different levels:

- When the walkway is raised even by 150 mm, the volume of the room decreases. This leads to the heating of surfaces in the steam room much faster.

- By quickly heating surfaces, fuel consumption is reduced, and therefore energy resources are saved.

- The thickness of the thermal insulation layer increases in proportion to the raised level, which leads to other, higher temperatures inside the steam room, and the floor covering becomes even warmer.

- The difference in the height of the thresholds between the dressing room and the washroom plays the role of additional waterproofing, in which excess moisture does not penetrate into other areas of the room, but seeps into the underground.

In order for the temperature in the bathhouse or sauna to remain at the desired level for a long time, it is necessary to correctly select and install the doors that lead to the steam room, and to the bathhouse itself. Since bathhouses and saunas are premises with non-standard conditions and tasks, the equipment they require is not quite ordinary.

Entrance doors to the bathhouse

There are no special features here. You need to keep warm and protect yourself from thieves. Therefore, you can install any doors to the bathhouse from the street, even metal ones. The main thing is good thermal insulation: heat cannot be released. But there are problems with the iron door. They do not lead, they do not swell, they are reliable and retain heat well (if they are well insulated). But in winter, having opened it and jumped out to cool off, you will definitely close it - don’t let the bathhouse dry out. But back, if you accidentally touch the surface, you will freeze instantly. Here is a review of the entrance metal door in the bathhouse:

I have a metal entrance door in my bathhouse. There are no problems with opening and closing. But in a good frost I froze to it. I jumped out of the steam room - everything was fine. And when I came in, I touched it by accident and that’s it, I immediately froze. It’s good that you did it with your hand, although there was no time for jokes either.

Metal steel door to the bathhouse - reliable and warm, but you can freeze

This problem is also solved: the outside is sheathed with wooden slats or clapboards and varnished. No problem.

In general, there is nothing better for thermal insulation than a well-made solid wood panel. A thick board (you can use tongue-and-groove flooring) retains heat well, and also suits the style of most country baths. There are some for sale, but if you don’t trust factory-made ones, you can make the outer door to the bathhouse yourself. If you need good insulation, then you can knock down two panels, fill the bars between them, and fill the gap with insulation. Then connect both shields and decorate the perimeter with a thin strip. The result will be warm, economical and reliable.

Entrance door for baths and saunas made of wood

But the wooden entrance door to a bathhouse is not without its drawbacks: it rots and swells. Rotting can be combated with impregnations and antiseptics. There is no way to deal with swelling. This was the case in a bathhouse near Arkhangelsk:

We came to a friend’s dacha to take a steam bath. The door was swollen and did not want to open. In our attempts, we tore off the handle, then took the tire iron out of the car and picked it apart. We took a steam bath, left, but we couldn’t close it - the lock was inside. It was good to have a sledgehammer and nails. They scored. And then a friend says, how to open it later? Here's what we came up with: we'll bring an iron handle, fasten it with healthy self-tapping screws, tie it to the car and pull it. They did so, but the doors had to be changed.

And here is another review about a wooden street door to a bathhouse:

I have a wooden door leading from the bathhouse to the street. But I did it wisely: dry wood, which I impregnated before I did it, and after. But on the door there is a water barrier, insulation, and foil on the outside. The cladding on both sides is made independent.

The third option - the entrance door to the bathhouse - is plastic. If there are no security issues, then this is a good option. And the color can be made to order: exactly like wood. The imitation is so good that until you touch it with your hand, you won’t understand that it’s plastic. Their cost is higher than white ones for the door by about 2 thousand rubles.

Massage techniques using a broom

First of all, learn how to work with two brooms. This massage technique is the most effective. Hands with brooms move alternately with the required intensity and impact force, while the brooms are directed not parallel, but crosswise. Thus, one area of the body receives a double blow. Using two brooms, stroke along the body and circular massage of individual areas, when the hands, squeezing the handles, describe circles in the opposite direction. Some techniques involve synchronous movement of the hands, for example, when pumping hot steam to heated areas of the body.

Article on the topic: How to make a fence with your own hands from a slab

Let's try to describe all the known methods of manipulating a broom in a steam room:

- Plowing or warming up. The broom captures the most heated steam from the ceiling and, with swinging movements, directs it to the body of the steamer, barely touching the skin. Warming usually begins with the feet, pushing hot steam towards them, and gradually moves along the legs, buttocks, lower back, back, and so on up to the neck-shoulder girdle;

- Shaking. The broom is shaken vigorously several times under the ceiling of the steam room to heat it up and then the hot leaves are quickly and briefly (1-2 seconds) pressed against different parts of the body: feet, legs, lower back, shoulder blades, neck, shoulders;

- Whiplash. Quite noticeable biting blows with a broom with an amplitude of up to 1 m. This technique is especially effective when working alternately with two brooms;

- Compress. The bathhouse attendant lifts the broom up to warm it up, and then quickly applies it to the body of the steamer and presses it on top with his hand in a mitten for 4-5 seconds. An extremely effective method, especially for the prevention of radiculitis and osteochondrosis. They start, as always, with the feet. It is believed that warming up the feet triggers the acceleration of metabolism. Particular attention is paid to problem areas: lumbar region, spine, neck, shoulder joints, forearms;

- Stroking. A well-heated broom with slight pressure is slowly passed along the entire body from the feet to the neck and this technique is repeated several times. Stroking is performed in the same way on the hands and even on the face;

- Quilting. This technique consists of a combination of alternating stroking and whipping. Once you get used to it, this type of massage is also more convenient to perform with two brooms.

Possessing such a rich arsenal of various techniques, an experienced bathhouse attendant can not only improve your well-being, invigorate and lift your spirits, but also put a real barrier to the development of many diseases. And you, having adopted this skill, will also be able to bring a lot of pleasure and benefit to other people.

Article on the topic: Sandwich pipes for a bath, what grade of steel?

After the massage, do not rush to get up from the bench, lie down and rest for 2-3 minutes. Only then slowly, without making sudden movements, rise and leave the steam room. In the bathhouse, everything should be done slowly.

To the washroom

The doors to the washing room from the rest room or dressing room are made of regular sizes, perhaps smaller in width - in order to minimize the entry of humidity, which is inevitably increased in such a room. The width of the door to the washing compartment is desirable 600 mm.

There are also requirements for resistance to moisture: this factor must be taken into account. If you choose wood, then leave a larger gap between the door leaf and the door frame. In normal interior doors it is 2-3 mm, but when installing a door in a washing room it is worth making at least 5 mm. Otherwise, the swollen door simply will not open or close.

Glass doors for baths and saunas can be opaque

Glass door panels are good in this sense: they don’t care what humidity is, the dimensions remain unchanged. They do not necessarily have to be transparent; rather, they are the exception. They are made from special heat-resistant glass, they are quite difficult to break, and are usually sold complete with hinges, and often with a door frame. So there should be no problems in terms of installation and operation. People have been using it for years and are happy. Glass doors in the washroom are an innovation that has caught on well.

Sometimes they put plastic doors in the washing area. They are good for everyone in this room: they keep warm, they are not afraid of moisture. There are not only white colors, but also “wood-like” ones, so they won’t spoil the interior. Not everyone simply likes the idea of using plastic in a bathhouse in principle, although there is plastic on the windows in a Russian steam room and nothing melts.

It is better to place the hinges on the outside, i.e. from the sink side

Baths and homosexuality

In the late 19th and early 20th centuries, bathhouses in big cities such as Moscow and St. Petersburg began to be used by homosexuals as dating places. The St. Petersburg steam rooms were especially famous for their “blue” contingent. Journalist Ruadze, who specialized in crime news, wrote in 1905 that the Znamensky Baths in St. Petersburg had turned into a real male brothel.

Article on the topic: How to properly go to the bathhouse in winter

In these baths, you could not only retire with your lover in a separate room, but also ask the bathhouse attendant for “additional services,” paid separately. It got to the point that regular visitors to the baths bought subscriptions for standard and non-standard staff services. The bath attendant or massage therapist was chosen according to their taste from special albums, similar to those offered to clients in expensive brothels.

Many famous personalities of that time and even persons of royal blood were regulars at the “blue” baths. For example, a famous lover of “taking a steam bath with additional services” was Grand Duke Konstantin Konstantinovich, uncle of the last Russian autocrat Nicholas II. Prostitutes also worked in bathhouses - by the beginning of the First World War they had become a real problem for big cities and offered their services wherever men gathered.

Did you know that we have Instagram and Telegram?

Subscribe if you are a connoisseur of beautiful photos and interesting stories!

Doors to the steam room

This is where the difficulties begin. The conditions that are sometimes created in this room are far from normal: high temperature and humidity. In addition, it is very undesirable to let off steam during the procedures. Based on these requirements, the door height is selected. Let's take a closer look.

Steam in the steam room accumulates under the ceiling. The normal thickness of this layer is 60-80 cm. This is exactly enough for normal vaping, subject to its periodic renewal (it needs to be updated during the procedure). It is at this height - 60-80 cm from the level of the finished ceiling - that the lintel (the upper edge of the door) should be located.

Let's give an example. With a ceiling height of 230 cm, we get the height of the bath door: 230 cm - 60 cm = 170 cm. But it is better to leave a larger pocket for steam. In general, the normal height of a steam room door is considered to be no higher than 160 cm.

To maintain heat in the bathhouse, a threshold is needed, and the door should be low

With all this, we still need a high threshold - about 20 cm. It performs more than one task:

- Does not let in cold air when walking back and forth.

- Prevents drafts across the floor.

- Serves as insurance against hitting the top of the head against the ceiling: when raising a leg, a person instinctively bends lower. So a high threshold is a cure for cones.

The height of the door to the steam room has been determined; we need to decide on the width. It’s all at your discretion: you can make it wider than the standard, and by a lot. It will be more convenient this way. With a door height of 160 cm, its width can be 130 cm - this makes it more convenient to enter. We have decided on the size of the door to the steam room, but when planning, you need to take into account that they should only open from the steam room. This is a safety requirement: if necessary, it is easier to knock it out.

There is no disagreement with the materials for the door to the steam room: wood. There may be a question about the breed. Some people don’t install conifers because they contain a lot of resin, and hot resin is no joke. But if this is a Russian steam room, then there are no temperatures capable of “melting” the resin in it - the maximum to which the air is traditionally heated is 70-85°C. So, both pine and spruce are suitable for a Russian bath. For saunas - only hardwood, but about the doors to the sauna - a little lower.

Here is a review from an experienced bathhouse lover from Chelyabinsk:

Everything in my bathhouse, except the floor (larch) and ceiling (aspen), is made of pine. There are pine tongue and groove boards on the walls. There is resin only in two places, and then in the corners where its presence does not bother me at all. The doors are made of pine imitation timber, the jamb is made of thick boards, there are no drips. The window is varnished pine, does not leak, the shelves and the one are made of pine - 50*150 mm board. The feeling is great. I often have guests: it’s cold, they run in to warm up. Everything is fine.

So you can use pine in the steam room. Nobody got burned.

The dimensions of the door to the steam room are determined based on the height of the ceiling and “working” conditions

Another option is glass doors to the steam room. It doesn't suit everyone, but they look really good. Their main advantage is that you can see the silhouettes of people inside, and if someone feels bad, you can come to the rescue in time.

General calculation parameters

The basic formula that helps determine the principles of construction is as follows: the tallest person who plans to go to the new bathhouse raises his hand, and you add 50 cm to the distance from his fingertips. You will get a value that will range from 2. 3 to 2.5 m. It cannot be lowered below 2.1 for a number of reasons:

- The steam will be dispersed by brooms.

- Cold air masses will mix with warm ones not gradually, but abruptly. The latter will rise up, envelop your head and it will be difficult to breathe, and therefore just be in the bathhouse.

It is in the summer that the body not only gets used to hardening faster, but also gets rid of fat more readily. It turns out that a bath in the heat increases the effectiveness of weight loss by more than 50 percent, because metabolic processes accelerate significantly. It is not surprising that in summer the demand for baths especially increases among the fair sex. Before going to the sea, every woman wants to melt off those extra centimeters in a hot steam room.

Tip No. 2: a bathhouse will bring health if you do not combine it with alcohol. It would seem, what would a trip to the bathhouse be without foam? So conversations flow better, and songs are sung louder. In fact, drinking in a bathhouse gives a double blow to the body. The blood vessels dilate, and alcohol only enhances this effect.

Article on the topic: How to wrap a bathhouse in white

“The poison itself is alcohol, and in combination with high temperature it only enhances its effect,”

– said cardiac surgeon Alexander Chepurnoy.

Insulation of bathhouse doors

There is no need to make a hermetically sealed room out of the steam room. Fresh air should come in at least a little. If the bath door is made of a thick board, there is no need to line it with anything. Neither on the canvas, nor around the perimeter. A good wooden door made of solid wood (tongue-and-groove boards, imitation timber, etc.) in the steam room will retain steam without problems.

Insulation is only necessary in one case: if they are made of thin boards. Then you can cover it with felt, which is sometimes done. But you’ll be tired of drying the felt.

Wooden paneled doors for a bath

If the steam in the steam room does not hold, then the door is most likely not to blame. There could be many reasons for this:

- Incorrectly made pipe passage through the ceiling.

- Errors in vapor barrier of walls and ceilings.

- Gaps in the walls.

- The door size is incorrectly selected or the window is located at the wrong level - steam escapes into the door and window.

- There is not enough oven power.

Doors in the sauna

Since the humidity in a dry-air steam room is low, there are no problems with wood swelling. There are definitely only two options here: wood or glass with wooden handles. Plastic in the sauna is definitely contraindicated. In any case, it is not worth installing doors to the steam room from it. You can go to the washing room, but not to the steam room.

The doors in the sauna are installed so that there is a gap of at least 2 cm at the bottom

The size of the door here is simpler than in a Russian steam room. Here the situation is different with the threshold: it either shouldn’t exist, or it should be low. And in any case, there should be a gap of about 2 cm between the threshold and the door leaf. Only with such an installation will there be normal air movement in the sauna steam room, and it will be possible to breathe there even at temperatures above 100°C.

Shelf sizes

The linear dimensions of the shelves are directly related to the configuration of the steam room. If their height is the same for any room, then the length depends on the size of the walls.

On average, the height of the shelves is 1.1-1.2 m (for the highest), 0.6 m (for the middle) and 0.2-0.3 for the lowest bench). You can get by with two shelves, a bed 1.1-1.2 m high and a bench 0.5-0.6 m high.

The length of the shelves in a Russian bath should be at least 1.8 m. Making them shorter is impractical, since it will not be possible to lie comfortably on a short bed, and all the comfort from taking bath procedures will be lost. In the sauna you can get by with shorter sitting positions.

Installing a door in a bathhouse

Difficulties may arise when installing doors in a log house - made of logs or timber. The technology here is different.

First of all, doors and windows are not installed in a new log house. It must stand and shrink for at least a year. At this time, the crowns are periodically caulked, which constantly lowers and raises the logs, changing the geometry of the walls. How to install doors/windows here? They will not withstand such loads. You need to wait until the main shrinkage has passed.

To prevent the door frame from getting jammed or crushed during shrinkage, a casing is made

In an established log house, holes are made for windows and doors. Most often, they are cut out with a chainsaw. Marking is done only using a laser level or plumb line. Building-grade precision is not enough here.

In the resulting hole, logs can walk freely, which is unacceptable. In addition, a wooden house, even after many years, can rise a little - during caulking, and settle - after. All the same, you will periodically have to plug the gaps that form.

In such conditions, even the thickest door frame is unlikely to be able to withstand the load. That’s why they came up with the idea of making a frame or casing in the windows/doors. This is a doorway frame made of thick boards that compensates for changes in height and holds the free ends of the logs. They are made in several ways.

Method one

Such an installation is only possible on an established log house. The procedure is as follows:

- The logs are hemmed, leveling the surface around the perimeter so that platbands can later be installed.

- Nail two side posts, securing them into each crown with several long and thick nails. The length of the nail is at least three times the thickness of the board.

- The horizontal stand is nailed 6-8 centimeters below the height of the opening. This gap will serve to compensate for the shrinkage of the building. Later this hole is filled with insulation.

- The door frame is nailed to the finished frame, then the door leaf is hung.

- The last stage is the installation of platbands. First, they are nailed on one side, the cracks are foamed with polyurethane foam or lined with flax tow. The gap at the top is filled with insulation tightly folded in several layers. Then everything is closed with platbands on the other side.

When cutting an opening in a bathhouse from a rounded log, half of the log should remain intact at the top and bottom - this way there is less chance that the doors will jam.

Method two

This option for installing a door in a log house is more labor-intensive, but also more reliable. It also involves installation in a not fully established log house.

Casing box for door with groove and block

- At the end of the opening, a groove is selected in the logs. Its width is 50 mm, depth - 48-50 mm. This can be done with a chain saw or circular saw, but best of all, with a router. Everything is finished and leveled with a chisel and chisels (especially in the corners).

- A 50*50 mm block is hammered into the groove made. Its length with a settled log house is 2 cm less than the height of the opening, with a fresh one - 5 cm.

- The top bar is still fixed lower than the height of the doorway and also by 5 cm.

- The door frame is nailed to a block.

With this method of installing a door in a wooden bathhouse, it turns out that the entire load during shrinkage falls on the timber, and the door frame remains intact.

Method three: timber casing

This type of installation can also be used on an unsettled log house. There is more work to be done here: both the tongue and groove will need to be molded. It is more convenient to make a tenon with a circular saw and a little chisel and chisels. The groove depends on who you want, but the most convenient device for this is a router.

- A tenon 50 mm thick and slightly less than 40 mm deep is cut out on the vertical parts of the opening.

- In bars measuring 100*100 mm or 100*200 mm and a length slightly less than the height of the doorway (2 cm shorter for an established log house and 5 cm for a new one), a groove of 40*40 mm is cut in the middle of the width.

- At the bottom of the doorway we work on a threshold equal to the width of the casing beam - for its reliable fixation. It should be slightly recessed, about 5 mm.

- After installing the sidewalls, a transverse board is attached to the top. It turns out to be 5.5 cm (or 2.5 cm) below the doorway.

- With this method, you don’t have to install the bath door frame, but hang the doors. directly to the casing. When choosing this installation method, you need to cut out holes for the hinges in the sidewall, and then hang the door leaf.

Approximate dimensions and design of a casing box with a spike

Watch the video on the topic.

In this video, select a recess for installing racks. Choose any bath door installation. All of them have been tested, but the best, according to experts, is the second. Even with a small amount of work, it guarantees that the frame will not be flattened and the doors will not jam.

Which door should I install?

We will talk specifically about the steam room and what type of door leaf should be. Many put it blank, citing thermal conductivity. But from a safety point of view, it is advisable to see at least the silhouette of a person in the steam room. If someone becomes ill, there will be an opportunity to react and come to the rescue. With a solid door to the steam room there is no such possibility.

Glass doors for baths and saunas look very stylish

What other options might there be?

- Glass doors. They are not necessarily transparent. Matte, tinted, with or without different patterns performed very well. The main thing is that the silhouette is visible. Nothing more is needed.

- Combined. In this case, an insert is made of tempered glass. For those who are concerned about temperature or steam retention, you can install double glass (also opaque). In order to see the movement of a sufficiently narrow long strip. Where to place it is a matter of taste.

When choosing a door, do not forget about this aspect. Still, high temperatures, humidity, hot metal objects and more. High risk area.

Combined doors to a bathhouse or sauna

Selection of materials for bath doors

Modern bath door designs are made from practical and durable materials: wood, metal, glass, plastic, combined materials (MDF, chipboard and plywood). Each of them has exceptional performance characteristics.

Made from wood

A classic version of door designs for a private bath. Wood has a number of significant advantages: safety, environmental friendliness, high thermal insulation, ease of processing and maintenance, and attractive appearance.

Since wood is prone to moisture absorption and is partially susceptible to temperature changes, certain tree species are used to make the structure:

- Oak. Durable and practical, but prone to cracking when overheated.

- Larch. It has antiseptic properties, is resistant to rotting and insect damage.

- Linden. It has a mild tonic effect, has a pleasant odor, but is prone to darkening and rotting when exposed to moisture for a long time.

- Pine. Strong and durable, with a light pine aroma, resistant to temperature changes and overheating.

- Aspen. Cheap and easy to process. Resistant to cracking and deformation when dry.

- Spruce. Capable of quickly absorbing excess moisture, so it needs frequent drying.

Increased demands are placed on a wooden structure: it must withstand temperature changes and high humidity, but at the same time retain heat indoors. All this can lead to condensation accumulation and rotting of the wooden surface.

The best solution to the problem is to treat the wood with moisture-proofing compounds or install a frame structure with internal thermal insulation.

From glass

Glass doors are often installed in hammams and saunas. They are distinguished by aesthetics, convenience, resistance to high temperatures, humidity, rotting, and ease of use.

The steam room and washing room can be equipped with glass doors.

Among the design disadvantages are the following: the high cost of raw materials and components, the difficulty of manufacturing the product on our own. In addition, the glass sheet requires a technical gap of 3 cm from the floor level, which can lead to constant drafts.

Made of metal

Entrance doors are often made of metal due to its high strength, wear resistance and durability.

In addition, the metal structure is easy to use, resistant to deformation, mechanical damage, rotting, changes in temperature conditions, and high-quality thermal protection reduces the likelihood of corrosion and heat loss.

Insufficient insulation can lead to the formation of condensation, so for a private bath it is better to use a door made of a metal frame with a heat-insulating layer. It is a metal base, the interior of which is filled with insulation, and the outer surface is sheathed with plywood, board or chipboard.

Thermoplastic

The thermoplastic product is highly resistant to temperature changes, high humidity, hot steam, practicality and durability. The door leaf can have a classic design or be an imitation of wood, glass and metal surfaces.

Plastic doors can be installed for any room - washing area, steam room, relaxation room and dressing room.