Have you brought the chimney out through the roof and don’t know how or what to use to seal the gap between the chimney and the roof? But we know about this. From ultra-low-cost methods for sealing slate to labor-intensive ways to seal joints on metal tiles and corrugated sheets, we'll cover each in detail. Explore possible options and choose the one that suits you. Step-by-step instructions and a description of the features of all methods of sealing the joint between a pipe and a roof are included.

Where does waterproofing begin?

Heating devices will operate in a safe mode only if the waterproofing is carried out correctly and taking into account all existing rules and recommendations. Waterproofing is carried out taking into account:

- must be maintained between the rafter system and the roof , which depends on the materials used. Flammable – 150-300 mm, non-flammable – 100-250 mm.

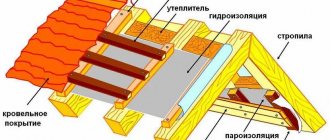

- The sequence of layers in a roofing pie cannot be disturbed. It is necessary to block the possibility of moisture penetrating inside the prepared cake, since any liquid will cause rapid destruction of the layers. The insulation must be separated from the pipe by a gap. Otherwise, there is a risk of fire, since most insulation materials are flammable.

- The box is the required device for separating the roof from the pipe. The distance should be approximately 150 mm. Inside, the created box is filled with any heat-insulating material that has non-flammable properties.

Films that perform insulation tasks must be cut “envelope”, and then pulled to the cross beam so that it can be attached with nails. Waterproofing must be fixed with lathing, vapor barrier - with a special frame. All joints of the box and insulation layers must be edged with special tapes.

Sealing a chimney is a difficult process and requires certain skills and knowledge Source stroy-krov.ru

Consequences of an unsealed joint

To bring the chimney through the roof, a larger diameter is cut out into it, so that a gap remains between the walls of the chimney and the roofing material. Regardless of the width of the gap, it is a big problem faced by homeowners and builders. To eliminate this defect and protect the under-roof space from the penetration of atmospheric moisture, use seals, aprons, collars, made by yourself or purchased. An unsealed gap between the roof and the chimney pipe is fraught with the following consequences:

- Increased wear of roofing material. Most roof waterproofing materials offer better protection against moisture penetration from the outside. Moisture penetrating through an unsealed gap gets onto the inner surface of the roof and eventually destroys it.

- Reducing the service life of the rafter frame. The pouring water hits the elements of the rafter frame, which are made of wood. This leads to rotting and premature destruction of the rafters.

- Reduced insulation efficiency. Roof insulation materials lose their properties when wet, becoming less effective.

- Increased humidity in the attic. Increased dampness in the attic causes heavy, stale air and negatively affects the interior decoration of the room.

Clearance to prevent rafters from catching fire from a heated pipe

Important! The method of sealing the gap between the chimney and the roof depends on its size, the type of roofing material used and the shape of the chimney. If the distance is less than 5 mm, it is quite possible to get by with a heat-resistant silicone-based sealant. You can close a gap whose width is 1 cm or more using cement mortar, an apron, or a special sealant.

How is it carried out?

If the owner of the property notices that a leak appears near the pipe, then in most cases the cause is poor-quality roof sealing. To avoid leaks, specialists install aprons. Installation must be carried out in accordance with the algorithm:

- It is necessary to lay a drainage gutter. It is required to remove moisture from the pipe.

- To ensure maximum tightness of the joint between the roofing and the chimney, an internal apron is used for the pipe on the roof.

- It is necessary to cut out the waterproofing backing , which should be placed under the lower edge of the apron. If the roof is covered with sheet material, then the edge of the substrate must be brought out between the sheets from below. It is imperative to create a side to direct the water along the slope.

- The roof covering must be laid around the pipe.

- using an identical algorithm . The only difference is in securing the top edge to the chimney.

- The insulating apron can be created manually or a ready-made version can be purchased. The chimney must pass inside the apron.

Attaching the apron to the pipe Source banya-ili-sauna.ru

See also: Contacts of construction companies that offer roof repair services.

Materials used

The materials used for sealing are divided into three types, each of which has its own advantages and disadvantages.

cotton wool

It is a roll or shortened fibers. Positive qualities of vata:

- soundproofing;

- low density;

- fire resistance;

- adheres tightly to surfaces;

- reduced heat capacity;

- reduced thermal conductivity;

- resistance to physical impact (shock, vibration);

- resistance to chemical attack;

- heat resistance;

- elasticity;

- electrical insulation.

Cotton wool is the most common material for insulation Source 1000dosok.info

Roll filters

They are a mullite-siliceous composition that is included in the fibers of the composition. Positive qualities of roll filters:

- flexibility;

- it is permissible to use inorganic glue;

- easy to cut;

- the mechanical fastening can be firmly fixed.

See also: Contacts of construction companies that offer country house design services.

Asbestos and kaolin boards

In production, mullite-silica fiber is used. The disadvantage of the plates is their immunity to alkalis and acids at high temperatures. To eliminate the deficiency, additional insulation will need to be installed. Positive qualities of the slabs:

- soundproofing;

- low density, but higher than that of cotton wool;

- low thermal conductivity;

- resistance to physical impacts, such as vibrations;

- resistance to steam, water and oils;

- resistance to melting non-ferrous metals;

- elasticity;

- electrical insulating properties will be maintained at temperatures up to 800 degrees Celsius.

Possible ways to eliminate gaps

There are three ways to eliminate gaps between the pipe and the roof:

- A special apron with protective properties. It can be purchased at a specialty store or built.

- Stainless steel passage. It is thrown over the pipe itself, after which the joint that appears must be closed with a clamp.

The joint is covered with a rubber clamp Source uteplovdome.ru

- Silicone sealant. Best suited in cases where the gap is small.

Depending on the materials, sealing methods also change. For example, sealing a pipe on a metal roof is only possible with the installation of an apron. In some cases, depending on the roofing material, individual sealing methods may be used.

Tape sealant

Tape sealant is a solid material. Many builders consider it the most cost-effective option for roof sealing. Material Features:

- it is based on butyl rubber;

- The sealant tape is highly resistant to ultraviolet radiation and high temperatures;

- it has high adhesiveness, making it easy to install;

- Ideal for sealing joints between chimneys and roofing.

The tape has an aluminum coating, which increases the service life of the sealant for outdoor use. The tape is easy to install and operate. The average service life of the product is 10 years. Thanks to a wide range of colors, the tape can be used to seal various roofing coverings. The sealant has exceptional adhesion to various surfaces. The tape is used when it is necessary to seal wooden, plastic, and metal surfaces. The tape is also successfully used for sealing translucent roofs.

How to use

The surface of the pipe and roof on which the tape is applied must be cleaned and dried. It is important that the area being treated is level. To apply the tape, you need to cut a piece of a certain length, then remove the protective film and press the product tightly against the joint (crack). At temperatures below +5, the tape is first kept indoors at a temperature of 15 degrees for 12 hours.

Using the tape in sub-zero temperatures involves heating the surface to be treated. The tape is not used for surfaces with an operating temperature above 80 degrees or when the roof slope is more than 55 degrees.

Sealing a square pipe on a slate roof

A slate roof adds its own nuances when it comes to creating a sealed pipe. Because of the slate, it is impossible to use any other parts for insulation, so the protection effect was achieved through a cement-sand apron, which was created as follows:

- All cracks must be covered with galvanized steel collars. This material does not corrode and can last a long time.

- The cement-sand mortar is poured so that it is above the roof level. If a cardboard cylinder was used in the process, then the procedure will be easier and simpler.

- Water drainage must be carried out using an inclined ledge, which must be located on the side of the ridge.

When sealing the chimney, do not forget about the water outlets Source dom.dacha-dom.ru

If, for convenience, a cardboard cylinder with plastic film or a plastic side was used when pouring, then these parts must be removed after the mass has hardened. Despite its appearance, this method of sealing is in no way inferior to alternative ones, which cannot be used on a slate roof.

Sealing round multi-layer chimneys

It is much easier to install sealing on modern round chimneys. The simplicity of the process is due to the fact that no additional equipment is required, since the pipe is already equipped with everything necessary. Installation takes place in three stages:

- Prime the edge of the pipe where the waterproofing will be attached.

- Make a hole in the waterproofing, then glue it to the pipe using mastic.

- The sheet must be attached to the sheathing. The pipe is passed through a cap, between which a clamp with a heat-resistant gasket must be located.

Round metal chimneys Source pinterest.com

If there are no caps, then flexible elastic seals for pipes are used instead. The sealant can also be used anywhere else where roof insulation needs to be improved.

Important points

The waterproofing of chimneys, if it is damaged, can be restored in several ways: the choice of the most suitable one depends on several factors:

- A pipe installed on a slate roof must be freed from the cement apron, and then the slate sheets adjacent to the pipe must be removed. After checking the condition of the pipe for mechanical damage, an apron should be made from sheet metal. The joints are treated with oven clay with the addition of Portland cement or fire-resistant mastic. Now you can lay slate sheets on the apron, and then coat them with cement mortar.

- Fused insulation can be used to insulate leaky areas, but damaged slate sheets should also be replaced.

- If the pipe is made of brick and the first two above points are completed, it is enough to coat it with clay-cement mortar.

- For a metal roof, you need an apron made of the same material: it can be made using special scissors. The outlets of round pipes can be sealed using special corrugated rubber elements.

- If the distance between the pipe and the ridge is large, special bitumen tapes with metal inserts are used.

The exit points of round pipes are sealed using rubber corrugated inserts

Sealing a pipe on a bitumen roof

In this case, the chimney must be sealed using Wakaflex tape. In this case, the following procedure is observed:

- Creating a cutting from tape.

- The cutting is pressed using the case.

- Any gaps that appear must be sealed using bitumen mastic.

Bitumen mastic best protects against bad weather Source www.drive2.ru

Sealing on the roof made of metal tiles and corrugated sheets

Sealing on a roof with such a roof is only possible when using an abutment strip. When sealing a chimney on a corrugated roof, the following procedure must be followed:

- Decide on the installation location of the chimney.

- Partially remove the waterproofing membrane in this area.

- Create a metal apron, which should be assembled from the outer and lower abutment plans.

- Lay roofing material on top.

- The resulting joints must be treated with sealant.

Waterproofing a chimney on a roof covered with metal tiles Source vl-fasad.ru

Popular brands

There are many products on the market that are suitable for sealing roofs. The most famous:

- “Titan” - easily withstands frost, can be used with any materials, perfectly seals flat and seam roofs,

- “Sazilast” - it can be applied even at sub-zero temperatures, after hardening it exhibits a high degree of adhesion,

- SOUDAL Aquafix - suitable for wet and underwater surfaces, allows repairs in rainy weather, ideal for metal tiles and gutters,

- Ceresit is resistant even at abnormally low temperatures, after curing it resembles plastic, therefore it is not used on deformable substrates,

- RoofPlast is based on bitumen and is considered one of the highest quality sealants.