It is believed that cinder block is excellent for the construction of residential buildings and other buildings, due to its availability and compliance with the required characteristics.

To further reduce the cost of the material, many begin to produce it themselves.

This can be done either using improvised means or using a special machine. The device is not cheap, but you can also build it yourself.

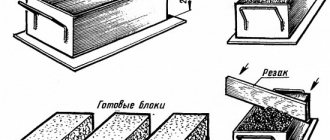

Block production process

Vibrating machine for block production.

Composition of concrete mortar for such blocks (in parts):

- slag (preferably blast furnace, without ash and coal) – 14 parts;

- coarse sand (expanded clay) – 4 parts;

- gravel with granule size 5-15 mm – 4 parts;

- cement (M400-M500) – 3 parts;

- water – 3-6 parts.

Slag, coal combustion waste, brick waste, expanded clay, perlite, crushed stone, sawdust, etc. can be used as filler.

It is important to monitor the water content in the mixture. The solution should crumble when falling to the ground, but when squeezed in a fist, it should come back together

First, the dry ingredients are mixed, and only then water is added to them.

The sequence of operations when making blocks on a vibrating machine:

- a solution with a slide is placed in the mold;

- the vibrator is turned on for 3-5 seconds, the solution settles;

- if there is not enough solution, add it, insert the punch (clamp) and turn on the vibrator again;

- molding is completed when the clamp sits on the stops;

- turn on the vibrator for another 5-10 seconds and remove the form while the vibrator is still running.

The blocks should dry within 5-7 days, but it takes about a month to completely harden.

Preparing a solution for cinder concrete

A concrete mixer is the best option.

Before we talk about how to make cinder blocks at home, let's consider preparing a solution for them. The solution for slag concrete blocks includes a filler, preferably slag remaining after the combustion of coal in the furnace, in an amount equal to seven parts by volume.

Coarse expanded clay sand - two parts, gravel, fraction 0.5 - 1.5 cm - two parts, cement, grade M500 - one and a half parts and water - three volume parts. But not only slag can be a filler; gypsum, expanded clay, ash, gravel, screenings of crushed stone, sand, brick waste and even processed sawdust can be used as such.

When using blast furnace slag as a filler, no unnecessary additives should be present: wood chips, earth or unburnt coal. Therefore, the slag must be sorted in advance and sifted using a special sieve.

If the filler is gypsum, then the components of slag concrete are taken in the following proportions: gypsum - one part, slag mixture - three parts and water. The solution is thoroughly mixed and used almost immediately.

This mixture is prepared within a maximum of six minutes. The slag mixture is pre-moistened. To prepare one cubic meter of solution, about 350 liters of water are used.

In order to make high-quality slag concrete blocks at home, a special plasticizer is added to the solution. As a result, the mixture becomes very plastic, and the blocks are strong, waterproof, frost-resistant and not brittle.

In addition to hollow ones, blocks can also be made solid. They are the strongest and most durable, and most often they are used to make the foundation. In contrast, hollow blocks are lightweight and have excellent heat-insulating and soundproofing properties.

Well, one more important property: cinder blocks can be colored if dyes are added to the solution, which can be chalk or crushed red bricks

Equipment for the production of cinder block

How to make a wooden barrel with your own hands - step-by-step instructions and drawings

Producing cinder blocks using special equipment will not be difficult. The casting process on a machine for the production of cinder blocks occurs as follows:

- A working mixture is prepared, consisting of cement, water and fillers. The latter must be passed through a sieve, removing large ingredients. Water should not completely fill the solution; the filler stays dry on the floor. The consistency is chosen independently, depending on the type of production.

- The mixture is loaded into the mold, compacted with packing or a special cinder block press. During the process, it is necessary to monitor the amount of the mixture; when compacted, it contracts.

- After which, the prepared block is removed from the mold.

Automatic production of cinder blocks

The drying process occurs under natural conditions, after 24 hours it is possible to move the finished material to the warehouse. Use in construction is available within a week after production, complete hardening occurs within a month. Special additives allow you to speed up the hardening process; maximum humidity and direct sunlight allow the cinder block to harden faster.

There are many designs, equipment, and machines for the production of cinder blocks. It is possible to make a machine yourself using the following elements:

- prepared cinder block matrix for molding the solution;

- necessary materials and tools;

- ventilated room with a leveled floor.

There are many types of machine designs available for do-it-yourself manufacturing, the drawings of which are available on the Internet

It is important to calculate the required production volumes before manufacturing; for your own needs it is enough to produce simple equipment

A small volume is produced by a hand-made matrix. The material can be any available - from hardwood to sheet metal. This process requires manual compaction of the material. Cinder block machines have a modification with a vibration motor, which will significantly save labor costs during production and speed up the process. The included electric motor with a vibration design for a few seconds allows you to fill the volume into the molds, adding filler in time.

In order to make a product not only for your own needs, you will need a full-fledged cinder block machine. The design will require the following tools in your arsenal:

- angle grinder;

- welding machine;

- marking tool.

According to the drawings, the structure is welded and processed with a grinder. The machine device for making cinder blocks may contain a vibration motor attached at the bottom. For convenience, the control panel and clamping mechanism are displayed.

Machine form

The prepared mixture is poured into the mold. A self-made cinder block machine requires a correctly marked form when pouring; the open cavity of the finished product consists of 30% of the area. Mold materials:

- metal corner;

- steel sheet 5 mm;

- pipes with a diameter of 8 cm.

Shapes of cinder block machine

The mold frame is prepared from sheet metal, markings are made in accordance with the double size of the part. Pipes are installed on the hanging plates to fill the technological voids of the blocks, and the edges of the machine are closed. The role of the plates is in the form of a limiter, which acts during operation of the vibration device. The lid is made to fit a mold with holes, the diameter of which should be slightly larger than the pipes themselves. Handles installed on different sides serve to raise and lower the mechanism.

Description of the device

A vibrating cinder block machine is equipment that helps compact the mortar poured into molds . This is done so that there are no voids or air bubbles in the mass for making the block. The finished cinder block must fully comply with GOST, otherwise it cannot be used for building a house.

Important! Blocks that were made using a brick press always have better frost resistance, resistance to deformation, and strength than those that were made using other technologies.

The vibrating machine consists of several parts. In its lower part there is a frame where the vibrating table is located. It rests on rubber cushions. The vibrating table has several vibrators with adjustable strength.

The design has a backfill device for pouring concrete mixture . This is a tin container that allows you to pour concrete into the mold evenly and quickly. There is also a punch and a die.

The design includes a device for pressing the matrix with the pallet to the vibrating table. Vibrators for cinder blocks are equipped with electric motors and a drive.

Some vibrating machines use void formers. They are inserted into forms with concrete mixture and make holes in them. The output is a hollow cinder block.

What are they?

Machines for the production of cinder blocks are:

- automated stations;

- semi-automatic machines;

- manual equipment.

A fully automated machine is more suitable for enterprises that constantly sell cinder blocks. The productivity of such equipment is up to 1000 blocks per hour.

All you need to do is simply pour the cinder block ingredients into the container and press the start button. The mini-station will independently mix, pour, and compact stones ; the operator only needs to monitor the work. The advantage of such a vibrating machine is the lack of human intervention, the disadvantage is the high cost. Similar devices are produced by Bess.

Semi-automatic machines already require human intervention. Some operations here are automatic, but others will have to be performed manually. For example, in different configurations, the machine itself mixes the mixture for the stone, and the operator needs to lower the vibropress.

In other machines, the operator only participates in pouring the finished solution, and the rest is done by the vibrating table. The production of such machines is carried out by the Sibir company.

Manual equipment is considered the least productive, but it fully satisfies the needs for cinder blocks in private construction. The average cost of such a device will cost 200,000 rubles. A good representative is a device from VibropressStroy .

Reference! Depending on the type of block formation, machines can be mobile or stationary. The first ones are small in size and stones can be produced immediately on the construction site. Stationary equipment requires a lot of space, but its productivity is higher.

Principle of operation

All of the listed machines operate on a similar principle:

- The prepared solution is poured into a special container.

- The mixture is transported into the matrix.

- With the help of vibration, the mixture is leveled and compacted.

- If there are devices for voids, they are inserted into blocks with mortar and are strongly compacted under pressure and vibration.

- The matrix rises above the blocks and the finished mixture, already formed into blocks of the required size, is sent for drying.

The only difference between the devices is that in a fully automated machine all operations are performed independently. Even the mixing and transportation of the solution occurs automatically .

If the machine is manual, then the person must first prepare the slag mass in a concrete mixer, then pour it into molds, and then compact it well using a vibrating table. Again, you will have to carry the blocks to dry yourself.

Forming methods

Do-it-yourself bathhouse made of expanded clay concrete blocks: step-by-step instructions and the best projects with 52 photos and 2 videos

Factory molds for preparing cinder blocks are made of reinforced concrete or steel. Such parts can easily withstand the weight of a large volume of solution. As for do-it-yourself molds, they are most often made of wood or steel sheets. Such elements largely play the role of special formwork.

To save on raw materials and free time, molds are mainly assembled without a bottom. You can put a simple film under them. Thanks to this method, the entire process of block formation can be significantly simplified. It must be remembered that the forms themselves must be made of perfectly smooth wood parts. The working surface will be a concrete base, a table with a flat and smooth tabletop, or a sheet of iron, which also does not have any defects.

Let's take a closer look at how to make a mold for slag blocks:

- you need to choose sanded boards 14 cm long (the width should be a multiple of this parameter);

- then, using a hacksaw, you need to separate the segments, which will then play the role of transverse partitions;

- then you will need to connect the segments with longitudinal elements to form a rectangular frame;

- Next, you need to cut a sheet of steel or any other material with a smooth surface into separate plates measuring 14x30 cm;

- in the inner part of the resulting structure, cuts are made that will act as grooves, the width of which is equal to the dimensions of the dividing strips;

- then the sections responsible for the separation are fixed in cuts, creating a mold for the production of 3 or more slag blocks.

In order for the resulting container for hardening the solution to serve as long as possible, at the final stage it is recommended to coat both metal and wood structures with oil-based paint. This form is suitable for preparing cinder blocks, the dimensions of which are 14x14x30 cm.

How to make a block mold?

In production, the molds are made of iron or steel so that they can handle large volumes of solution, up to several tons. To produce such blocks with your own hands, you can use a wooden mold. In essence, you should get a formwork into which the cinder block mixture will be poured.

It is necessary to take into account the thickness of the wooden sheets when measuring, so that the dimensions of the future cinder block are the inside of the mold.

As a rule, to make it easier to remove the cinder block, the mold is made without a bottom, placing a film underneath. But it is necessary to ensure that the surface of the base is level, as are the wooden parts. The surface can be a flat table, a concrete surface or a sheet of iron.

To build load-bearing walls, hollow blocks are used, for which they use hollow bottles that form voids; they are pre-filled with water so that they do not float out of the solution.

Machine form

How to make cinder blocks with your own hands

Machines for making cinder blocks vary in design complexity.

This can be a collapsible device made of wood or metal. It has different sizes depending on the number of blocks that will be produced at the same time. This design can be made with your own hands; bottles of the required diameter filled with water are used to produce voids. In this case, a vibropress is not used.

Another option is a vibrating machine, which consists of a mold located on a table or a special stand. This device is equipped with a motor and can be equipped with a lifting mechanism for removing finished products from the mold.

Wood or metal structures are used as a mold for making cinder blocks. The standard size is 390×190×190 mm, but you can choose the dimensions at your discretion.

Since slight shrinkage will occur during pressing, it is necessary that the height of the mold exceeds the height of the block being produced by 5 mm.

Creating a Form

First of all, you need to decide what kind of machine you need. If you want to build a garage or temporary shed, then a machine with two or even one mold is enough. If you are going to organize a small business, then you will need a more productive machine, at least for 3-4 matrices.

Cinder block dimensions

The most important part of the machine is the shape. The remaining parts and assemblies are additions that allow you to perform various manipulations with this form.

For example - filling, lifting, compacting the solution, moving, etc.

When producing cinder blocks, the plant uses standard iron molds, as well as professional equipment that presses concrete into a mold under a weight of several tons. Do-it-yourself cinder block molds are most often made from wood. There are many types and designs.

In essence, the form is a container into which concrete is poured and where it remains until it hardens completely. It should be noted that the forms must be collapsible so that the finished cinder block can be easily removed. In most cases, they are even made without a bottom, and a plate of material to which concrete does not stick is placed under the bottom.

The easiest way to create voids in a block is to immerse plastic water bottles or glass champagne bottles, which is preferable, into soft concrete at the desired location. But, if you want to set up a small production of cinder blocks with your own hands, then the void formers must be fixed in the mold.

Sketch of a wooden mold

Made of wood

First of all, you will need planed boards, the width of which will correspond to the height of the cinder block. Then it is necessary to make the outer cross members, which will be connected to the longitudinal boards with “sliding grooves”.

Then cuts are made from the inside of the longitudinal boards at a distance equal to the length of the cinder block. The transverse grooves should have a depth of 7 - 8 mm. The width of the cut corresponds to the thickness of the separating plates, which can be made of iron, getinax, textolite.

Sketch of a form filled with solution

The plates can be made from other sheet material, the main thing is that it is smooth. The drawing above shows how to make wooden molds for cinder blocks with your own hands. It is advisable to open the mold details with any oil paint. This will make it easier to remove the cinder blocks from the mold.

Please note that the sketch shows smaller dimensions than a standard cinder block requires. Before creating the mold, you can make your own cinder block drawings

This procedure will not be superfluous and will not require much work.

The above forms are used without a vibrator. The solution in them should be poured into a softer solution with a higher water content. However, with a little effort, you can create a more advanced vibrating machine.

Form-stretcher

The molds for the vibrating table look a little different. Handles must be attached to the sides so that two people can lift them and place them on the vibrating table. There should be two cones at the bottom of each cell.

You should not make a mold with a large number of cells, as such a stretcher will be very difficult to lift. Such forms cannot be disassembled, and the cinder blocks from them are shaken out by tipping them over. The internal surfaces of the mold must be smooth so that the products can be easily removed.

The photo shows a metal form

Made of metal

When creating a machine for making cinder blocks with your own hands, you will need a steel sheet 3-5 mm thick. Shape elements should be cut out of it based on the size of the cinder block. The standard is 190x190x390 mm; in accordance with these dimensions, do-it-yourself cinder block drawings are made. The height of the form should be 5 mm above the block so that you can pour the concrete mixture and press it on top with a plate

Since the cinder block must be hollow, it is important to make the void formers correctly. The easiest way to use pipes for these purposes is

Please note that they need to be given a conical shape. Thanks to this, the product will be easily shaken out

Blanks can be ordered from a turner so that he can remove a few mm from one side of the pipe. Sometimes rectangular void formers are made. Their shape doesn't matter, the main thing is that they are conical. Keep in mind that the cinder block should be no more than 30% hollow.

A wooden or rubber seal should be made at the bottom of the mold along the perimeter to avoid deformation of the edges of the matrix. You can also weld metal plates 20 mm wide along the edges.

Vibrating table of the simplest design

Features of the material

Cinder block is a building material that has proven itself to be one of the most durable and unpretentious. It has considerable dimensions, especially if you place an ordinary brick next to it. You can make slag blocks not only in a factory setting. Some craftsmen undertake this work at home. If you strictly adhere to the technology, you get high-quality and strong blocks from which you can build a house or any outbuilding.

If a decision has been made to independently produce such products, then a number of its features should be taken into account.

- Cinder block is a fireproof material. It does not ignite itself, and does not intensify an existing flame.

- Really good quality blocks make long-lasting and sustainable homes/outbuildings. Such buildings will not be harmed by harsh climatic conditions, hurricanes, or constant gusty winds.

- Repairing cinder block buildings does not require extra effort and free time - all work can be completed in a short time.

- Cinder blocks are also distinguished by their large sizes, thanks to which buildings made from them can be erected very quickly, which pleases many builders.

- This material is durable. Buildings built from it can stand for more than 100 years without losing their previous characteristics.

- Another feature of cinder block is its soundproofing component. Thus, in dwellings made from this material there are no annoying street noises.

- The production of cinder blocks is carried out using various raw materials, so it is possible to select the optimal products for any conditions.

- What distinguishes cinder block is that it is not subject to attacks by various kinds of parasites or rodents. In addition, it does not rot, so it does not have to be coated with antiseptic solutions and other similar compounds designed to protect the base.

- Despite their decent dimensions, such blocks are light in weight. This feature is noted by many masters. Due to their lightness, these materials can be easily moved from one place to another without calling a crane. However, it must be taken into account that some types of such products are still quite heavy.

- Cinder block is not afraid of low temperatures.

- These blocks are distinguished by their high heat capacity, thanks to which they make cozy and warm homes.

- Temperature fluctuations do not harm the cinder block.

Cinder block buildings are usually decorated with decorative materials to give a more aesthetic appearance.

However, it is very important to remember that the cinder block cannot be covered with ordinary plaster (any “wet” work with this material should not be carried out). You can also use a special decorative block, which is often used instead of expensive cladding. When working with cinder block, it is important to take into account one important feature - this material is characterized by high water absorption, so it must be protected from contact with moisture and dampness

Otherwise, the blocks may collapse over time. Unfortunately, the geometry of the slag blocks leaves much to be desired. That is why, when laying floors from such material, you will have to constantly adjust individual elements - trim them and saw them. Cinder blocks have a relatively low cost.

Choosing which machine to use for making cinder blocks

When deciding on a device, it is worth considering the following design options:

- a simplified device that makes it possible to produce block products at home;

- an improved unit, the design of which includes a mechanism for compacting and extracting finished products.

The choice of the optimal option is carried out depending on the need and availability of funds.

Simplified cinder block machine with your own hands - drawings and recommendations

If the need for material is small, there is no need to manufacture a complex unit equipped with a vibration motor and special mechanisms. A simplified method allows products to be manufactured in special molding boxes.

The technology involves performing the following work:

- Assembling molds and oiling the surface inside the box.

- Pouring cinder block mortar into collapsible containers.

- Leave for 5–6 hours until the composition sets.

- Disassembling the box and carefully removing it.

- Drying manufactured products under a canopy or indoors.

To build this kind of machine, you must have skills in working with a welding machine and metalworking tools.

The use of wooden or metal liners, as well as glass containers, allows you to produce hollow blocks. It is not difficult to make a simplified machine for cinder blocks with your own hands - it is a metal or wooden container, the size and shape of which correspond to the parameters of the product.

Vibropress in the production of cinder blocks

The brick press is a powerful tabletop, which is equipped with special springs

The brick press is a powerful tabletop, which is equipped with special springs. On an industrial scale, such equipment is always at hand, but at home it is not. In order to make a vibrating machine for the production of cinder blocks you will need:

- high-speed electric motor with two shafts, with a power of at least 0.5 kW;

- grinder and electric welding;

- iron sheet (thickness 3 mm);

- fittings (diameter 12 mm).

The vibration process will take no more than 15 seconds, then the vibration form is removed in a vertical position and within a day the finished blocks can be laid.

In essence, a brick press for cinder blocks is a regular tabletop equipped with springs. The vibration process occurs due to a shift of the center of gravity to the eccentric (see example of a brick making press in the photo)

Cinder concrete blocks - characteristics and purpose of the material

One of the reasons for the increased popularity of slag-filled concrete blocks is the low cost of the material. It is associated with the use of waste from metallurgical enterprises - slag - in the production process.

Along with traditional components, Portland cement and river sand, various aggregates are used:

- brick break;

- crushed stone screening;

- granite chips;

- various slags and ash;

- expanded clay particles.

The use of cinder blocks in construction allows you to reduce the cost of constructing walls several times

The manufacturing process is carried out in various ways:

- industrial method at specialized enterprises with processing of products in drying chambers;

- at home from available raw materials, using a self-assembled machine for making blocks.

Using homemade equipment you can produce various types of slag concrete products:

- full-bodied, with an increased margin of safety. They are used quite rarely, as they retain heat less well;

- hollow, characterized by high thermal insulation properties. To ensure strength, the volume of cavities should not exceed 1/3 of the total volume of the product.

The dimensions of the products are determined by the dimensions of the mold. When making products yourself, the size of the molding box can be any. However, many people prefer the standard dimensions of 19x18.8x39 cm.

The increased volume of the slag concrete block can significantly reduce the duration of various types of construction work:

- construction of capital walls;

- construction of internal partitions.

It is perfect for the construction of utility buildings, sheds, and storage buildings.

If you need to make a cinder block yourself, the machine allows you to quickly solve the problem. The resulting material has many advantages:

- high thermal insulation characteristics. Due to reduced thermal conductivity, the material prevents heat loss;

- increased dimensions and low weight. This makes it easy to transport products and quickly build walls from them;

- resistance to the development of microorganisms. This is achieved due to the properties of the slag included in the structure of the block;

- low price. A cinder block machine with your own hands allows you to make products that are cheaper than purchased blocks.

The material also has weaknesses:

- low durability. The period of operation of buildings made of slag concrete is up to three decades;

- reduced safety margin. The characteristics of the material allow the construction of buildings no more than two floors high;

- the appearance of cracks under the influence of shear forces. During shrinkage, cracking occurs along the cinder block mass.

To ensure an attractive appearance of buildings, the cinder block surface needs external cladding. These disadvantages do not stop developers who want to build a utility building or a small building in a limited time at low costs.

You can use homemade cinder blocks a month after they are made.

Homemade machine with a vibrating device: what is required for this

Tools and materials you will need:

- electric welding machine;

- angle grinder for metal work;

- vice;

- locksmith tools;

- electric motor (500-750 W);

- metal sheet and strip (3 mm);

- pipes (75-85 mm);

- bolts, nuts;

- sheet rubber.

Sequencing:

- The size of the form is determined. You can use standard sizes (400x200x200 mm). If blocks of a different size are needed, they are measured and the shape is designed based on the obtained values.

- A drawing is being prepared.

- Using a grinder, the walls of the mold are cut out of metal. The number of side walls is determined by the number of compartments. You can make 1,2 or more identical compartments. The output will be the same number of cinder blocks. The simplest machine contains 1 compartment.

- The side edging is assembled by welding. First you need to grab the metal and make sure that it is connected correctly. After this, weld it completely.

- Metal tubes are cut to the height of the mold. You need to make longitudinal cuts on the sides and form cone-shaped cylinders.

- The cones are welded to the bottom of the matrix. A transverse jumper is made between them, and plugs are placed on top.

- The bottom is welded to the side edging.

- The matrix tray is lined with rubber to protect the bottom edge from damage.

- For stability, you can weld strips from profile pipes with a small cross-section.

- Handles are attached to the side for moving and lifting.

- The thread is installed and the electric motor is attached to it.

- The top cover is screwed in, in which holes are made for the cones. The cover must correspond to the internal dimensions of the matrix.

- An anti-corrosion coating is applied.

- A test run of the installation is performed. It will show you what adjustments need to be made.

Additional Information! A homemade vibrating machine for expanded clay blocks works on the same principle.

How to make a vibrating machine for cinder blocks with your own hands

Many people wonder whether a cinder block production machine should be vibrating. Here we can safely answer that, yes, the presence of a vibrating machine will allow us to make cinder blocks of the best quality, without voids inside. The drawing of a vibrating machine for cinder blocks in itself is not too difficult to master, and the main elements of a vibrating machine are:

Matrices for pouring the solution, which are mounted on top of the vibration installation. To make a matrix for a cinder block, you will need to take a steel sheet with a thickness of at least 0.2 mm. The metal sheet is cut into rectangles having the following dimensions: 390x190 mm. Their number is determined individually, depending on exactly how many cinder block matrices need to be made.

Typically, no more than three matrices are installed on one block vibrating machine. After welding the cut pieces of metal, it remains to provide voids inside the future matrices. For this purpose, you need to take a metal pipe 90 mm in diameter, and then cut it into 9 pieces, 190 mm long. To weld pipes to each other, a metal strip should be used.

At the next stage of manufacturing a vibrating machine for cinder blocks, you assemble the press yourself. There is no point in refusing to manufacture it, since using a press for a vibrating machine, it will be possible to exert the necessary pressure on the mixture poured into the matrix. To make a press for a vibrating machine, you will need to cut a rectangle out of metal exactly to the dimensions: 385x185 mm. Then, in the same way as the pipes are installed in the matrix, three even holes will need to be cut in a piece of metal.

Vibrating table assembly

The third stage in the manufacture of a vibrating machine for cinder blocks includes assembling the vibrating table. Here you can go in two ways: make a vibrating table, with eccentrics on the axes and a subframe, or significantly reduce the cost of the entire structure.

In this case, directly to the side of the tabletop, which would accommodate three matrices, you should screw fasteners for an electric motor with a power of at least 0.5 kW. Then a nut with an eccentric is attached to the motor shaft, which will create the necessary vibration while the motor is running.

It is very important to use a closed-type electric motor when manufacturing a vibration machine. If nothing else is at hand, then you should provide a special apron from a piece of metal that would completely cover the engine and prevent water and solution from getting inside it

The final stage in the manufacture of a vibrating machine is the installation of the table top with the motor on the supports. To do this, you will need to weld a frame from a metal corner; at the bottom of it, if desired, you can easily attach wheels if you need to have a mobile vibrating machine for cinder blocks on hand.

Types and advantages of cinder blocks

Cinder blocks are a popular type of building materials that are created by hardening a concrete mixture in a special form or using vibration pressing technology. The name itself comes from the name of the filler, which can be used as ordinary furnace or blast furnace slag.

As construction technologies developed, the range of fillers used expanded greatly, although the previous name remained unchanged. The choice of filler determines the performance properties and cost of the product. Currently, monolithic or hollow cinder blocks are offered for sale. Representatives of the first group are characterized by increased strength, but are much cheaper than monolithic models. Most often they are used when arranging foundations.

The concrete mixture used to create blocks may include ash, slag and a number of other waste products from coal combustion. To make high-quality material at home, you can take fillers such as waste bricks, sawdust, expanded clay, perlite, gravel and others.

By the way, cinder blocks do not necessarily contain slag. Fillers can be very different, but the name remains the same.

The key advantages of slag concrete blocks include the following:

- Excellent heat and sound insulation of walls.

- Low cost - cinder blocks are much cheaper than traditional bricks, foam blocks or any other building material.

- Simplicity of installation and ease of further use.

- No difficulty in making it yourself. You can create a set of good building material with your own hands. This opens up wide opportunities for private developers to erect a wide variety of buildings without using the services of masons. (by the way, one block can replace 3-5 bricks).

What can you make a cinder block from?

What cinder blocks are made of is clear from the very name of the building material. One of the components of the cinder block solution is slag, which is formed as a result of coal processing.

Additionally, the blocks may include other materials: sawdust, crushed or old brick, metallurgical waste or products of coal combustion in boiler houses. All these materials will not interfere with the production of cinder blocks, as they will give them good thermal insulation properties.

The mixture also includes coarse sand, water and cement. To increase density, you can add concrete strengthening mixtures.

The standard composition of the mixture for blocks includes sand (2 parts), cement (1.5 parts), gravel (2 parts), slag (7 parts), 1.5-3 parts water. But in fact, not all craftsmen adhere to the standard recipe, preferring to make the composition depending on the available slag and the parameters of the future structure.

To ensure plasticity, when making cinder blocks at home, you can add a plasticizer to the composition (5 g per block). This component allows you to improve the strength of the block, its frost resistance and water resistance, and prevent the appearance of cracks. A plasticizer is added during vibration casting.

Mixture composition

The production of slag blocks at home obliges the craftsman to adhere to a specific composition, as well as certain proportions of all components. Thus, the binding ingredient in this material is usually cement of a grade not lower than M400. As for the filling component, it can consist entirely of slag or be mixed. The last option is obtained by adding a small amount of crushed stone, sand (simple or expanded clay), crushed brick and fine expanded clay.

When making cinder blocks, the following proportions must be observed:

- 8-9 parts of the filling component;

- 1.5-2 parts of astringent ingredient.

For example, out of 9 parts, at least 6 are accounted for by this component, and the rest is made up of crushed stone and sand. In theory, when making it yourself, it is permissible to use concrete or brick scraps, screenings.

The standard proportions of cinder block are:

- 2 parts sand;

- 2 parts crushed stone;

- 7 parts slag;

- 2 parts of Portland cement marked M400.

As for water, it is customary to add it in an approximate ratio of 0.5 parts. The result is a semi-dry solution. To ensure its high quality, you need to take a small handful and throw it on a hard surface. If the thrown lump crumbled, but under compression conditions regained its previous shape, then the composition can be considered suitable for further use.

If you plan to obtain colored cinder blocks, then the recipe is supplemented with colored chalk or brick chips. To increase the strength characteristics of this material, special plasticizers are used. In some cases, they resort to adding gypsum, ash or sawdust.

What is the best way to fill the forms?

If you are setting up the production of cinder blocks at home, know that there is no universal composition; each master selects his own unique recipe, which is more suitable for a particular bathhouse and which depends on the existing slag. But the standard cinder block recipe is as follows: 7 parts slag, 2 parts sand and 2 parts gravel, 1.5 parts good cement (grade M400) and from one and a half to 3 parts water. The accepted dimensions of a cinder block are 39x19x20 cm, but dimensions of 40x20x20 cm are also used in private construction.

In addition to the slag itself, ash, other coal combustion waste, gravel, processed sawdust, perlite, stone and granite screenings, gypsum, broken bricks and the like are used as fillers for such blocks. For greater plasticity of the blocks, a plasticizer is also added - this is 5 grams per block, during vibration casting. For what? It is this substance that significantly increases the strength of the block, its frost resistance and water resistance, and eliminates cracks.

You need to measure the amount of water especially carefully: the blocks should not spread during removal. You can conduct the following test: if the solution crumbles when it falls to the ground, but comes together in your fist, this is what you need. By the way, concrete for the construction of a small bathhouse can be prepared manually, but for a more serious structure it is better to initially acquire an electric concrete mixer designed for a volume of 0.2-0.5 cubic meters.

Drying

Drying is another important step in the production of slag blocks. The production process itself usually takes about 2-4 days. Sufficient strength characteristics that allow you to proceed to the use of blocks are usually achieved after 28 days. This is exactly the amount of time needed to obtain high-quality building material suitable for carrying out certain works. Cinder blocks can also dry naturally. Typically, this process takes place using a simple method of producing materials (in conventional forms).

To dry cinder blocks, special chambers are often used to prevent cracking during the hardening process. To prevent the blocks from becoming cracked, they must be moistened from time to time. This process is especially relevant if the production process is carried out in hot weather.

Basic requirements for cinder block production

Standard product dimensions are 180*90*390 mm, each block usually has 3 holes

The standard dimensions of the product are 180*90*390 mm, each block usually has 3 holes. The production technology involves the use of M400 type cement mortar, as well as the addition of the required proportion of blast furnace slag and sand. Cinder block production involves hand-making and the use of a cinder block machine. It is worth noting that one bag of cement mixture allows you to make about 36 blocks. The product must be in perfect shape, otherwise small irregularities or deviations can lead to poor wall laying. To obtain the correct geometry, the cinder block mold is filled to the end with a small slide; during vibration, the solution will shrink and lie flat. The solution is prepared in the following proportion:

- 7 parts slag;

- 2 parts sand;

- 1, cement parts;

- no more than 3 parts water.

Additional components you can add are ash, broken brick, sawdust or gypsum. But to increase the moisture resistance and strength of the product, you can add a plasticizer (see example in the photo), only 5 grams is enough.

If you are planning to make building material yourself, it is important to know that it is better to carry out the production process in a room where the resulting material can be properly dried. It is advisable to choose a location for the production of cinder blocks close to sand quarries or cement plants.

It is advisable to choose a location for the production of cinder blocks close to sand quarries or cement plants.

General requirements when performing work

You can make good blocks in the garage - the main thing is to know the technology and stick to the recipe. So, a standard cinder block is 39x19x188 mm, with three small holes. And to make it high quality and durable, it is important that:

- The sand was coarse;

- Slag – blast furnace;

- Cement – high quality, not less than M400;

- Equipment – with vibrocompression.

The slag itself is obtained by processing coal, and, in fact, it is an ideal filler for blocks. However, recently, thanks to the active conduction of gas, much less slag and ash from coal has begun to be produced. Therefore, slag is increasingly being replaced with zito concrete, which, unfortunately, is much more expensive.

This building material is rapidly gaining popularity mainly due to the fact that it is inexpensive and has excellent heat and sound insulation. In addition, let’s make calculations: making cinder blocks at home requires 0.011 cubic meters of solution at a ratio of 1:7 (this is for one piece). This means that one bag of cement will yield exactly 36 blocks – which is not bad at all!

One of the most important requirements for the quality of cinder blocks is their geometry. After all, the larger the unevenness and flaws in the blocks, the more money you will have to spend on building the walls. And in order for the cinder block to turn out perfectly smooth, it is important that the vibroform itself is always filled to the brim - otherwise the blocks will turn out crooked. And not just to the brim - but with a slide, because the vibration will then slightly shake the concrete.

The whole process looks like this: the vibrating mold is turned on once, after 5-15 seconds it turns off, and the level of the solution in the mold is assessed - if it is below the edges of the mold, you need to put a clamp on, turn on the vibration again - and when it hits the limiter, turn it off. This must be done at the same time: turn on the vibrator and pull out the shape.