This completes the installation. Periodically it will be necessary to check the operation of the hinges and adjust the compression, since the springs weaken during operation.

Installation diagram of spring hinges. 1) spring 2) hole in sleeve 3) stopper 4) screw 5) top nut

Adjusting the hinges must be done extremely carefully, otherwise you risk breaking the spring.

If you did everything correctly, the door will open freely and then attract itself to the frame. It may be necessary to add a couple of degrees of inclination to make the task easier.

We recommend watching the video:

- Instructions for installing double-sided spring hingesDownload 636.89 KB

DOORS - AUTOMATIC | MODEL CONSTRUCTION

There are so many devices that can be invented to make the front door close on its own. These include special spring loops, cargo devices with counterweights and a block system, and all kinds of springs or rubber strips. There are also those produced by industry, however, unfortunately, they are not without drawbacks: some are too complex and quite expensive, others are inconvenient to use or unreliable, and quickly fail. Therefore, home designers continue to solve these problems on their own, as evidenced by the proposed selection of materials sent by readers. In winter, the entrance doors of our houses are often left open. This leads to excessive consumption of energy required for heating staircases. To preserve precious heat, simple automation is needed.

However, you can do without mechanical devices by ensuring a slight tilt of the entire door frame. The main drawback - the door hitting the frame - can be easily eliminated by laying strips of thick rubber along the vertical part of the door frame.

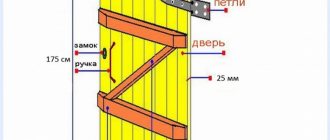

Rice. 1. Spring door closing mechanism:

1 — rubber shock absorber, 2 — door, 3 — spring.

To ensure tight closure, use a device with a weight connected to the door using a cable passed through a block. Depending on the installation location of the latter, the returning moment will either increase or decrease. To limit the angular velocity of the door when closing, the load is placed in a vertical cylinder filled with some liquid, preferably mineral oil. Under the influence of weight, the load will fall in a viscous medium, which will limit its speed and, accordingly, the angular speed of the door. The gap between the pipe wall and the cylindrical surface of the load should be no more than 1 mm.

Instructions. How to make a door closer with your own hands from various materials

A door closer is a very useful thing in everyday life. After installing it, using the doors in your house or apartment will become much more pleasant. In a hurry, did you not have time to close the door? The closer will do this for you - quietly, carefully, without annoying clap.

The door closer is quite easy to make and install with your own hands, you just need to be smart.

- A simple door closer option

- Door closer from car door lift

- Spring based door closer

- Door closer installation

A simple door closer option

To make your own door closer, you don’t need a lot of materials. First of all, before making a closer, you need to pay attention to its weight. To make the simplest design, you will need a weight.

The heavier and more massive the door in size, the heavier the closer should be. Those who are making such a useful household item as a door closer for the first time are advised to determine the weight of the load experimentally. There is no specific formula for calculating the mass of a load.

To make the simplest version of a door closer, you will need a rope or cable, as well as one more element - a wheel, which is necessary to move the rope up and down. The load is attached to the end of the rope or cable - it will pull the canvas.

To prevent the load from hitting the door leaf and wall, spoiling their appearance, it must be placed in a piece of plastic pipe. A weight is placed in the pipe and attached to a rope. Then they attach this structure to the canvas - and the simplest door closer is ready.

Door closer from car door lift

Is your car door broken? Don't rush to throw away the lift. Only three or five lifts from car doors will be needed to make a door closer.

The lifts must be attached to the canvas so that the closure bracket is located between the hinge axis.

This type of door closer is good because its manufacture does not require the purchase of any complex mechanisms.

Even if the doors are wide open, thanks to this closer they will close smoothly and softly.

Spring based door closer

With your own hands you can make another type of door closer for a wooden panel. The base of the design is a spring that gently returns the blade to its original position when opening and closing. Making such a door closer is quick and quite simple, but it is only suitable for light wooden panels, since with prolonged use the spring quickly becomes unusable.

The spring design of the closure can become stronger if it is complicated. But first, let’s figure out what elements are needed to install this structure on the door.

The basis of the closure is a spring. In addition, to slow down the movement of the door you will need a shock absorber.

The door closer shock absorber is designed on the principle of a conventional piston. The shock absorber consists of two chambers filled with oil. When the door is opened, one of them fills with oil. When the door is closed using this design, the oil flows into the second chamber.

There is nothing fundamentally new in the design of such a mechanism. Even a novice craftsman can make such a door closer; the main thing is to correctly manufacture the inside of the device. To allow the oil to flow back, a bypass valve is installed inside the structure. However, you can go the other way by installing an ordinary pump instead of an oil shock absorber.

It is not easy to adjust the pump to the operation of the door. Like a door closer made of a primitive weight and cable, such a door closer can only be adjusted to the functioning of the doors through trial and error.

To make such a structure, it is necessary to select a rack-and-pinion gear, the size of which depends on the size of the structure. It is through it that the load on the spring comes. The strength of the rack and pinion determines how long the door closer will serve you.

For those who do not want to use such complex devices, there is a simple alternative - use a piece of old rubber or a car inner tube as a door closer. Such a door closer can work quite reliably for some time, but it does not look very aesthetically pleasing.

Door closer installation

Installation of the door closer is a very important part of the work. Its functioning depends on how correctly the closer is installed.

So, installation of a closer includes the following actions:

- Determining the door opening angle;

- Using the template from the kit;

- Marking the holes on the frame and the door itself;

- Drilling pre-marked holes;

- Securing the lever with screws;

- Spring adjustment.

Options for door closers that you can make yourself

Device and principle of operation

The design of a factory-made device is quite complex. The spring mechanism works on compression when opening, and the smooth movement when closing is ensured by a piston system filled with oil. The mechanism housing must be sealed. Making such a device with your own hands is quite difficult.

A homemade door closer, created with your own hands, like a factory-made device, can be based on the elasticity of the material. But at home it is easier to make a lining that acts like a spring, stretching when the door is opened. Returning the closer to its original position attracts the door leaf to the frame, closing it.

The gravitational design is no less simple. The principle of operation of a weighted door closer is that the door returns to its place under the influence of gravity, which puts pressure on the weight, which pulls the door into the closed position.

Options for door closers that you can make yourself

A simple door closer can be easily made with your own hands from a piece of rubber. The elastic material meets all the requirements for the product: it stretches and contracts with a force sufficient to return the door to its zero position. The rubber density must be selected depending on the weight of the door leaf: the heavier it is, the thicker the tape should be used for the door closer.

When installing the device, the ends of the tape are secured as follows:

To adjust the force when opening and closing the door, measure the distance at which the end of the tape is fixed to the door leaf. The farther it is from the hinged side, the more the rubber closer will contract.

To make a block mechanism, you need a bracket with an axle (for example, from a broken furniture roller or skateboard). If it is possible to use a ready-made block, the task becomes easier, but if it is not available, you can do it in 2 ways:

- the cable is simply thrown over the axle;

- make a wheel with a groove for the cord and install it in the bracket.

In the latter case, the cable will slide more easily. It will be possible to attach a weight to the free end of the cord that is sufficient to pull the door leaf to the frame.

Car enthusiasts have the opportunity to make a door closer with their own hands from the lifting mechanism of the luggage compartment of a sedan or hatchback car. This unit is distinguished by the presence of shock absorption and smooth opening functions. The device must first be modified by attaching plates with holes for attaching to the door frame and leaf.

It is easy to make a compact closer from a small holey rubber ball or a medical bulb:

- The round rubber product is attached to a wooden or metal plate using screws.

- The structure must be installed on the frame from the outside so that the edge of the ball is at the level of the junction of the box and the canvas on the hinge side.

- Place a metal corner on the door that opens outward, close to the ball, the length of one side of which is equal to the diameter of the ball.

When opened, the corner will compress the ball, squeezing the air out of it. By expanding, the ball will force the door to return to its original position.

A magnetic latch is more appropriate on an interior door. It does not perform a closing function, but reliably holds the door in the closed position in the event of a slight draft. To make the structure, you need a strong magnet and a small steel plate. The parts are attached to the frame and canvas so that when the door is closed they overlap each other. If the thickness of the elements is too large, then you can make recesses in the wooden door for them.

Spring closer

- in the middle of the box;

- on the top.

The last option is used if you want to hide a spring that is not decorative.

The spring stiffness must be selected depending on the weight of the door. To prevent the sash from slamming when the spring contracts, it is worth installing a shock absorber. The material for it can be a thin rubber hose: it will not prevent the door from closing smoothly when the door is close to the zero position.

The ends of the spring closer are attached to the frame and canvas with special plates with hooks. When installed on the side of the box, fastening to the frame is done from the hinge side. Depending on the distance from this point to the fastening on the leaf, you can adjust the force of slamming the sash.

The top installation option can be different, and the door closer can be fixed with your own hands in any convenient place on the upper side of the frame and near the edge of the door leaf.

It is convenient to install the shock absorber at the junction of the canvas and the frame on the side of the hinges. You can secure the hose with glue (liquid nails) or self-tapping screws. When the spring is activated to close, the edge of the canvas will rest against the rubber product, and then will be gently pulled towards the frame.

Door installation

You can install a homemade or factory-made door closer according to the rules common to all options:

- find the maximum door opening angle;

- make markings for attaching the ends at the desired height or location;

- make holes for fasteners;

- strengthen the ends of the spring or other type of structural parts;

- If necessary, adjust the tightness of the sash.

Settings

Setting up a homemade mechanism is as follows:

- the speed of movement of the sash in a homemade product is regulated by changing the length of the elastic element (in spring structures) or the weight of the load (in gravitational ones);

- To change the adjustment to the zero position, change the thickness of the shock-absorbing hose.

When setting up, you can take into account other design flaws, for example, install a shock absorber on the load if it touches the wall, enlarge the hole in the ball if the door is difficult to open, etc.

Spring hinges: selection and installation

Spring hinges belong to the category of hidden double-sided awnings and have several names: bar, subway, western. Their distinctive feature is the ability to open the door in any direction, which is why they are also called pendulum. The scope of application of such loops is in places with high traffic: bars, shops, medical institutions, industrial and retail premises. The installation of these elements has some features, which you can learn about by reading this article.

Spring hinges are usually installed in high traffic areas

Types of door hinges

The first door hinges in human history were made from animal skin, tree branches tightly woven together, and only much later - from a rough metal plate. Today, door canopies perform not only a practical function, but also a decorative one, decorating the door and the interior as a whole. Types of canopies differ according to several criteria:

- the material from which they are made (steel, brass, bronze, etc.);

- installation method (overlay, screw-in, insertion);

- design features of the mechanism (overhead, mortise, hidden, corner, double-sided).

Let's look at the last classification in more detail:

- Invoices. Hinges of this type are the most popular, due to their ease of installation and low cost.

To install overhead hinges, it is enough to secure them with self-tapping screws on the surface of the door frame and the door itself.

- Mortise. The design of these hinges is almost identical to overhead hinges; the only difference is in the installation method: hinges of this type are cut into the surface of the door.

Installation of mortise hinges requires experience with a chisel

- Screw-in, hidden. These are not the most popular hinges, which is explained by the fact that they are quite difficult to install (inside the frame and door leaf), and after installation, the door leaf cannot be removed without completely dismantling the hinges.

If it becomes necessary to remove the door, you will first have to remove the hinges

- Angular. They differ from all others by the absence of classic cards. Instead, corners are fitted to the central hinge. The advantage of such hinges is the possibility of installing hinge doors on doors with a rebate.

The advantage of corner hinges is that they can be installed on rebated doors

- Double sided. Outwardly, these canopies are similar to ordinary card canopies, but they have their own fundamental differences.

Spring hinges differ from simple double-sided hinges by the presence of a spring

Step-by-step installation instructions

To install the closer on the door, you only need a drill, a ruler, a pencil and a screwdriver. A drill is usually required “3” (three), but you need to look at the diameter of the fastener, which usually comes with the kit.

Most manufacturers, to facilitate self-installation of the closer on the door, complete the products with installation templates. These templates schematically depict the parts of the closer in full size. They also have mounting holes for each element.

In models that can create opening forces of different classes, the holes are drawn in different colors; in addition, they are labeled - the class of the closer is placed next to it.

An example of a template for installing a door closer. Click to enlarge.

The template is printed on both sides of the sheet. On one side - for opening the doors "towards you" - from the side of the hinges (pictured above), on the other - "from you".

The template has two perpendicular red stripes. We align the horizontal one with the top edge of the door leaf, the vertical one with the axis line of the hinges.

Everything is clear with the upper edge of the door leaf, but to avoid mistakes during installation, you need to draw the axis line of the hinges. If the door closer is installed from the hinge side, there are no problems - use a long ruler and pencil to move the line of the middle of the hinges upward.

If installation will be carried out on the other side, measure the distance from the edge of the canvas to the middle of the loop. Mark this distance on the other side and draw a line.

Holes for door closer

On the template we find marks for holes according to the selected class. Using a drill or awl, we transfer them to the door leaf and frame.

Typically, the kit includes two types of fasteners: for metal (metal-plastic) and wood. We select a drill of a suitable size and use a drill to drill holes in the designated places.

Door closers are equipped with two types of fasteners - for metal and wooden doors.

Next, the actual installation of the door closer begins. Please note that for installation it is necessary that the housing and arms are disconnected. If they are assembled, they are separated (the washer is unscrewed, the screw connecting the levers and the body is removed).

Installation

We attach the parts to the holes made and install the fasteners. In the diagram we find the class of opening force that we need (in this case EN2) and install the parts as shown in the figure.

Door closer installation diagram

To open “towards you,” we place the body on the door leaf and install a rod on the frame.

Installing the case

We fasten the rod

Now you need to connect the traction lever to the body. There is a special protrusion at the bottom of the case. We put a lever on it and tighten it with a screw.

Now all that remains is to connect the lever to the rod. There are two options.

Connect the lever to the rod

The connection of the lever with the rod itself is very simple: the two parts are combined and slightly pressed with your fingers. They lock into place with a slight click. The trick is how to position them relative to the door.

The rate of movement of the door leaf at the final stage of closing depends on this. The position can change due to the fact that the rod consists of two parts and can be adjusted in length - one of the parts of the rod is a long threaded pin. Rotate the pin to shorten or lengthen it.

If you just need a smooth finishing, the rod is placed so that it is perpendicular to the door leaf. To do this, reduce its size slightly (pictured on the left).

Lever and rod placement for setting finishing force

If the door has a latch, a significant force is required to overcome its resistance. For this option, a shoulder is placed perpendicular to the door (the rod is untwisted, making it longer).

Having arranged the parts accordingly, they are combined and connected. That's all, the installation of the door closer is complete. And you can handle it with your own hands, and without much difficulty. The final stage remains - setting the closing speed. To do this, you need to understand the adjustments of door closers.

Features of spring hinges

A double-sided spring hinge is fundamentally different from a classic card hinge and consists of two cards on pins, inside of which a spring is installed that returns the door leaves to their original position. Depending on the direction of opening of the door leaf, spring hinges can be: left-handed, right-handed or universal. Left-handed - opens only on the left side, right-handed - on the right, universal - in both directions. Bar canopies have their own characteristics, advantages and disadvantages.

Advantages

The main advantage of bar hinges is their ergonomics, as well as the high throughput of doors equipped with them. The double spring hinge has the following advantages:

- ease of opening the door (using the body) when your hands are busy;

- preventing heat loss in the room through the door;

- the possibility of unhindered passage of a large number of people;

- preventing the formation of drafts in the room;

- automatic door closing.

Flaws

Door spring hinges, well made and installed correctly, have only one drawback: cost. The price of such canopies is several times higher than the cost of classic card canopies.

Structures and traction device

The main design element of a door closer is a spring that pushes the lever. There are two types of devices based on the method of transmitting force from a spring to a lever:

- With lever pull. Such models have a characteristic appearance - levers stick out perpendicular to the surface of the door leaf. The same closers are also called with a knee or articulated rod. The design works reliably, but the protruding arms are unattractive and easy to break if desired. There is another drawback: as the door opens, more and more force is required. For children and older people this can be a problem.

With linkage - With sliding channel. In these models, the lever is located parallel to the door leaf, which provides a more attractive appearance. Another plus: when opening the door by 30°, the force for further opening becomes much lower. Doors equipped with such door closers can be easily opened by both children and the elderly.

With sliding channel

Both of these types consist of two parts: a housing in which the spring is hidden and a force-transmitting mechanism and lever. They are mounted at the top of the door: one part on the leaf, the second on the frame. Which one goes where depends on the direction of opening. If the doors open “pull”, a housing with a mechanism is installed on the door leaf; when opening “pull,” a lever is attached. The photo shows a lever type closer, but similar installation rules apply to models with a sliding channel.

Installing a door closer depending on the opening direction

As you understand, they are not suitable for all types of doors - it is problematic to install them on glass ones. There is another design for them - floor-mounted. The housing with the mechanism is mounted on the floor, only the holder plate protrudes from above. A similar holder is installed at the top, but the mechanism is not always there, only for heavy door leaves.

Floor closer for glass doors

By the way, there are floor models for wooden and metal doors. They also have a linkage or sliding channel transmission. They are less conspicuous, but with this arrangement they are more often damaged.

Floor closer for glass doors

Do-it-yourself installation of interior doors is described here.

Criterias of choice

Choosing spring hinges is no more difficult than regular ones: the main thing is to know what to pay attention to. The first and main criterion for choosing canopies does not imply aesthetic qualities or even the quality of the products.

Let's consider the selection algorithm step by step:

- The first thing you should decide on when purchasing hinges is the direction in which the door opens: hinges can be right-handed, left-handed, or universal.

- The second most important criterion is the width of the part. It should also be remembered that spring hinges are selected in accordance with the width of the door leaf.

- The third thing you should pay attention to is the load weight that the loop is designed for (from 25 to 60 kg per loop). Depending on the weight of the door leaf, you may need from 2 to 4 hinges.

- Fourth: aesthetic qualities. Products may vary in length and color. The most common sizes are: 75, 100 and 125 mm; colors: brass (matte and polished), chrome (matte and polished), bronze.

Models made in antique design

In addition, when choosing, you should pay attention to the following possible options:

- possibility of adjusting the door closing speed;

- the presence of bearings ensuring soft, smooth and quiet running.

It is worth paying attention to products from trusted brands

Installation

Installation is a simple process and installation does not take much time. It is necessary to screw the hooks onto the door frame and the door leaf with self-tapping screws. Then put one loop on any of the hooks. The door spring should be tensioned on the second hook when the door is closed.

Another installation nuance is setting the spring tension. If its force is too weak, it is necessary to remove the loop and move the hook slightly to the side, thereby increasing the overall force of the device. This action allows you to adjust the operation of the doors in accordance with the power of the mechanism and the weight of the leaf.

Installation of spring hinges

The installation of spring hinges is not much different from the installation of conventional hinges of the overhead and mortise types. The sequence of actions is as follows:

- At the end of the door, as well as on the door frame, marks are made about the location of each half of the hinge.

- After this, the stopper should be removed from both cards, this will release the spring.

- Next, insert a pin (mandrel) into the hole on the bushing and turn it clockwise.

- The hinge plates are applied to the base and fixed with self-tapping screws according to the diagram below.

Before installation, the spring loop relaxes, and after completion of work it contracts.

- After this, you need to compress the springs. To do this, the door is closed, the pin on each card is turned clockwise and the stopper is inserted.

- First of all, the springs are screwed to the door leaf, and then to the door frame.

Intermediate stage for installing bar hinges

- Upon completion of work, you should check the smooth movement of the door and, if necessary, adjust the spring.

- When tightening the loops, it is important not to overdo it, since the spring is very easy to break. At this point the installation can be considered complete.

Spring hinges are often installed in restaurants and bars

To clearly understand what spring hinges are, as well as the principle of their installation, it is recommended to watch the video.

Adjusting the door closer

Closers that are installed on doors have different designs and the adjusting screws are located in different places. Everything is exactly indicated in the passport or installation instructions. But, in general, the technique is the same:

- turning the screw clockwise increases the speed/force;

- turning counterclockwise, we slow down/reduce the force.

When adjusting the closer, do not turn the screws several turns at once. Often just a quarter turn is enough, maybe a little more. Having upset the balance by tightening or unscrewing the screws too much, it is very difficult to adjust everything again. You can even break the device or cause oil to leak from inside.

Adjustments for the speed of door opening and slamming are located on the body. Most often they are either on the front part under the protective cover or on its side surface.

Pull back the cover and find the screws

In round or multi-faceted housings, adjustments are located on the side of the housing

Portal about construction

01/18/2019 admin Comments No comments

To protect the door from premature failure, closers are often used. These devices are designed to smoothly and accurately slam the door leaf. A specific model is selected based on many factors:

- temperature changes;

- expected load;

- the weight of the canvas itself;

- required level of reliability.

Often such mechanisms cost a lot, and if for external doors this is justified by the reliable service of purchased devices, then for internal doors or a summer house it is more economical to make a homemade closer.

How does the closer work?

A standard door closer is divided into three components:

- main fastening body;

- barbell;

- fastening element.

There is a spring inside the device body, which compresses when the door is opened. As soon as the canvas is released, it will begin to return to its original state. A special composition helps slow down this process and make it smooth - due to its viscosity, it prevents the door from abruptly slamming.

One of the internal mechanism options

The case has two compartments, in one of which the composition remains as long as the door is closed. When the composition changes, the oil flows into the second compartment, where the spring movement is inhibited.

The spring is closely connected to the rod - a movable element of the mechanism that connects the main body and an additional one - attached to the wall or door (depending on the model).

What functions should the slamming mechanism perform?

Before you make an automatic door closer with your own hands, you need to have an idea of what it should ultimately provide. The main function is shock absorption - preventing the door leaf from hitting the frame. Along with this, the following functionality is highlighted:

- adjustment - the ability to set the closing speed;

- attraction - if the closure is not tight, the mechanism will close the door itself;

- fixation - the ability to fix the closer in one position.

The last point is not mandatory for factory models either, so in the homemade version, any suitable objects are used as a stopper.

Its closing mechanism must attract and smoothly close the door. For these purposes, ready-made parts from cars or improvised means are used.

Car door closers

The trunk of a car is an ideal example of using an automatic closer. Smooth opening, closing and shock absorption make this part a worthy alternative to factory models.

Fasteners are attached to the part. Depending on the design, these can be brackets of various types. With their help, the finished device is attached to the door and wall (or frame).

Springs from a car closer

The advantage of this method is the ability to fix the door leaf in the open position: other homemade closers acquire this function only with the help of additional devices.

You can get the part in your car, by asking friends or at the market. It is cheaper to buy a used working part than to purchase a factory model of the slamming mechanism.

Classification

According to global standards EN 1154, door closers are classified according to the closing force they can generate. They are divided into 7 classes, which are designated EN1-EN7.

When choosing a class, pay attention to the inertia of the door, that is, the width of its leaf and weight at the same time. If different door parameters correspond to different classes, install a device of a higher class.

For example, the width of the door corresponds to class EN2, and the weight is EN4. They put it in 4th class, since a weaker force will not cope with the load.

There are door closers that belong to the same class. The characteristics then indicate a class with one digit - EN5. They have a small range of force adjustment - within one class.

There are devices whose closing force is regulated within several groups. In this case, the range is marked with a hyphen - EN2-3, for example. The latter are more convenient to use - you can adjust the closing speed depending on the weather. But the cost of such models is higher.

Rubber door closers

To make such a door closer with your own hands, the thrifty owner will not have to spend money. They can act as an attracting and shock-absorbing device;

- pieces of rubber;

- pears;

- hoses or tubes.

An example of pipes suitable for use

Located on the door leaf, these elements are easily deformed when the door is opened, but just as easily restore their shape, ensuring the door closes.

The advantage of this type is its cost, ease of installation, and the ability to regulate mechanical force. Rubber has different densities, which allows you to select the best options for a particular door. The only drawback is that it is not aesthetically pleasing, since a piece of rubber or a pear as a closer does not look very attractive. However, for storage rooms and other non-public premises this is the best option.

Springs as a slamming element

One of the simple and affordable ways is to install a spring as a closer. The advantages of this method include:

- ease of installation;

- availability;

- possibility of exposure regulation;

- relative aesthetics.

Springs have a number of characteristics, due to which the optimal option is selected. There is no clear formula for which spring to use for a door of a certain weight. Therefore, you will have to choose empirically.

Simple spring mechanism

Installation involves installing one end of the spring on the door leaf, and the other on the frame or wall.

What is a spring mechanism

The simplest mechanism is a product that is attached at one end to the door frame and at the other end to the door leaf. Tension adjustment occurs by moving either end. Door springs are inexpensive, easy to design and install, and therefore are in constant demand.

Over time, closers appeared. They do not have tension adjustment, so they always close the door with the same force. Such devices are well suited for industrial and utility premises.

Using a weight as a slamming mechanism

This method is becoming one of the oldest and is rarely used today. With this method, a cable or rope is attached to the door leaf, the second end of which is passed through a wheel attached to the wall or frame. A weight is attached to the end, which closes the door. Its weight has to be selected manually, since there is no exact formula for calculating it.

The advantages of this method include its low cost, simplicity and efficiency. If necessary, you can even lock the door.

The obvious disadvantage is that while moving, the load swings and hits the door or frame. In order not to spoil the surface, it is placed in a pipe with the appropriate diameter. This approach will preserve the door and give the composition a more attractive and neat look.

Homemade or factory made?

Factory closers have an undeniable number of advantages:

- easy adjustment;

- aesthetics;

- increased reliability.

In fact, their only drawback is the price: it is unwise to spend a lot of money if you need to take care of closing the door leading to the cellar, pantry or garage. In such situations, homemade analogues come in handy. With proper installation and assembly, they regularly perform the functions of a door closer, and at the same time, the cost of creating such an analogue is often limited by the price of the part itself.

What is a door spring and what types are there?

There are several options for solving the problem of automatically closing doors. The simplest of these is to install a door spring. This is a very cheap device, easy to install and replace. It is a regular steel spring, which is attached to the door at one end and to the wall at the other. When the leaf is opened, the spring is stretched, which ensures its return to its original position. The closing force depends on the rigidity, length, number of turns, diameter and other characteristics. Springs are the most reliable and durable type of closing mechanism. It is not afraid of temperature changes, high humidity, mechanical stress and vibration.

In addition to the classic spring mechanism, there are several more modern solutions that provide automatic return of door structures:

1. Door closers. These devices are equipped with a spring mechanism, which is enclosed in a housing. The design also includes an oil or other type of shock absorber designed for smooth movement of the door leaf. It prevents the loud slamming and sudden closing of doors that is typical of a conventional spring. Some models of door closers allow you to adjust the maximum opening angle and closing speed of the door, and have the function of fixing the door leaf in the open position. Depending on the type of spring used, devices are divided into two types: gear-driven and sliding-rod. The first type has a simpler and more compact design. The second option is more cumbersome, but its level of reliability and durability is higher than that of a gear drive. Among the main disadvantages of door closers are the rather high cost and the need to strictly adhere to operating rules (for example, you cannot open the door too sharply or apply force when automatically closing the door).

2. Spring hinges for the door. Very compact and convenient devices. They are ordinary door hinges equipped with a small but quite powerful internal spring. Products come in both overhead and pin, corner, and hidden. A special type of spring hinges are double-sided, which are also sometimes called bar hinges. They ensure that the door swings open in both directions and returns to the neutral position. Such hinges can be installed on entrance doors in cafes, shops, public institutions, etc.

How to attach a spring to a door?

One of the main symbols of discovery, boundary and protection are doors. The durability of their operation depends on various parameters, but the most important in the installation and installation process is the installation of the door closer. Made with your own hands, it will allow the door to perform its main functions: to retain heat inside the room without letting air in from the street, to hermetically protect the interior of the room from noise and drafts.

Doors can be external or internal, but in both cases they are not fully functional until the door closer is installed.

It protects doors from strong slams when closing, ensuring sufficient acceleration for latching the lock, which is necessary, for example, in an entrance door on which an intercom or coded bell is installed.

It doesn’t matter what shape the door is, what material it is made of, whether it is a massive structure or a small gate in the garden; without such a device it ceases to be predictable in use, and, therefore, safe and convenient.

Types of device

Installing a door closer guarantees its smooth closing automatically. If you have a poor understanding of the principle of operation of the mechanism, remember the gate at the dacha. Often a regular spring is attached to it, one end of which is attached to the door itself, and the other to the support to which it is attached. The action of a spring is determined by the application of force to it; the more you stretch it, the faster it contracts.

The design of the mechanism has been significantly improved, as has the external device of the closer. The type of door affects its choice, so the door closer can be:

- Top invoice;

- Hidden;

- Bottom mount.

The top type of door closer installation is suitable for external doors and heavy metal structures. Sometimes it can be used in public spaces, dividing offices, hallways, and used for fire exits and technical rooms. Such a door closer can also become an art object, emphasizing the high-tech style of the room.

Hidden type of door closer.

A hidden type of mechanism is installed in interior doors, so it does not spoil the view, allowing you to enjoy the beauty of wood or glass covering. The lower fastening is used less frequently, mainly for fixing on glass doors installed in shopping centers and offices.