Installing a door in a bathhouse

Difficulties may arise when installing doors in a log house - made of logs or timber.

The technology here is different. First of all, doors and windows are not installed in a new log house. It must stand and shrink for at least a year. At this time, the crowns are periodically caulked, which constantly lowers and raises the logs, changing the geometry of the walls. How to install doors/windows here? They will not withstand such loads. You need to wait until the main shrinkage has passed.

To prevent the door frame from getting jammed or crushed during shrinkage, a casing is made

In an established log house, holes are made for windows and doors. Most often, they are cut out with a chainsaw. Marking is done only using a laser level or plumb line. Building-grade precision is not enough here.

In the resulting hole, logs can walk freely, which is unacceptable. In addition, a wooden house, even after many years, can rise a little - during caulking, and settle - after. All the same, you will periodically have to plug the gaps that form.

In such conditions, even the thickest door frame is unlikely to be able to withstand the load. That’s why they came up with the idea of making a frame or casing in the windows/doors. This is a doorway frame made of thick boards that compensates for changes in height and holds the free ends of the logs. They are made in several ways.

Method one

Such an installation is only possible on an established log house. The procedure is as follows:

- The logs are hemmed, leveling the surface around the perimeter so that platbands can later be installed.

- Nail two side posts, securing them into each crown with several long and thick nails. The length of the nail is at least three times the thickness of the board.

- The horizontal stand is nailed 6-8 centimeters below the height of the opening. This gap will serve to compensate for the shrinkage of the building. Later this hole is filled with insulation.

- The door frame is nailed to the finished frame, then the door leaf is hung.

- The last stage is the installation of platbands. First, they are nailed on one side, the cracks are foamed with polyurethane foam or lined with flax tow. The gap at the top is filled with insulation tightly folded in several layers. Then everything is closed with platbands on the other side.

Method two

This option for installing a door in a log house is more labor-intensive, but also more reliable. It also involves installation in a not fully established log house.

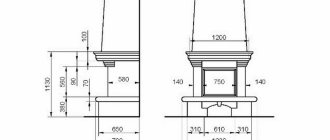

Casing box for door with groove and block

- At the end of the opening, a groove is selected in the logs. Its width is 50 mm, depth - 48-50 mm. This can be done with a chain saw or circular saw, but best of all, with a router. Everything is finished and leveled with a chisel and chisels (especially in the corners).

- A 50*50 mm block is hammered into the groove made. Its length with a settled log house is 2 cm less than the height of the opening, with a fresh one - 5 cm.

- The top bar is still fixed lower than the height of the doorway and also by 5 cm.

- The door frame is nailed to a block.

With this method of installing a door in a wooden bathhouse, it turns out that the entire load during shrinkage falls on the timber, and the door frame remains intact.

Method three: timber casing

This type of installation can also be used on an unsettled log house. There is more work to be done here: both the tongue and groove will need to be molded. It is more convenient to make a tenon with a circular saw and a little chisel and chisels. The groove depends on who you want, but the most convenient device for this is a router.

- A tenon 50 mm thick and slightly less than 40 mm deep is cut out on the vertical parts of the opening.

- In bars measuring 100*100 mm or 100*200 mm and a length slightly less than the height of the doorway (2 cm shorter for an established log house and 5 cm for a new one), a groove of 40*40 mm is cut in the middle of the width.

- At the bottom of the doorway we work on a threshold equal to the width of the casing beam - for its reliable fixation. It should be slightly recessed, about 5 mm.

- After installing the sidewalls, a transverse board is attached to the top. It turns out to be 5.5 cm (or 2.5 cm) below the doorway.

- With this method, you don’t have to install the bath door frame, but hang the doors. directly to the casing. When choosing this installation method, you need to cut out holes for the hinges in the sidewall, and then hang the door leaf.

Approximate dimensions and design of a casing box with a spike

Watch the video on the topic.

In this video, select a recess for installing racks.

Choose any bath door installation. All of them have been tested, but the best, according to experts, is the second. Even with a small amount of work, it guarantees that the frame will not be flattened and the doors will not jam.

Read more about making casings and sockets here.

Entrance door to the bathhouse

In order for the bathhouse to meet its purpose, a special microclimate is created in it. To maintain it, you need to choose a good entrance door that must meet certain requirements. Its main purpose is to create thermal insulation, since heat cannot be released. The safety of the structure is no less important. Entrance doors should not become hot at high temperatures or become hot in severe frosts. A plastic door fully meets these requirements.

Plastic entrance door to the bathhouse

Special profiles are used to create plastic systems. They are divided into many air chambers. The profile has a reinforcing element inside. In plastic doors, a closed contour made of steel or durable plastic is installed around the perimeter, which gives greater rigidity and prevents the structure from sagging during thermal expansion. Reinforcing elements installed in the corners avoid distortions of the canvas due to weight and temperature changes.

Non-standard openings

In addition to standard openings, door sellers and manufacturers now increasingly have to deal with atypical opening parameters. Many people build houses according to individual projects, taking into account their own view of the interior. In addition to houses, new apartments now also delight with intricate layouts and, sometimes, non-standard heights and widths of doorways. But even if this is exactly your case, and you have not found suitable doors on the open market, there is always the opportunity to make them individually: most manufacturers accept such orders.

You will find all the information about seals for interior doors here.

If we talk about non-standard entrance doors, then most often they have a standard height and a more impressive width. So, if the width exceeds 120-150 cm, you can install a door with two leaves, thereby making the central entrance to the house more decorative and interesting.

As for non-standard interior doorways, both width and height can vary. The passages to the living room and kitchen are usually made wider and higher. For the bathroom and toilet, these parameters can be reduced without harm to household members and guests, making the doorways smaller and more inconspicuous. Sometimes the width of such openings can reach only 55-60 cm.

We also recommend studying the material about the types of locks for aluminum doors.

Dimensions

Everything is simple here. We measure the doorway (width, height) in which the frame will be installed. And we select the door according to size, no more.

For example:

the doorway shows 85 cm width and 210 cm height. In this case, a door with the indicated dimensions of 80 by 210 cm is perfect for us. The dimensions must be calculated from the clean floor.

Why is that? The dimensions of doors for saunas and hammams are indicated by the size of the opening, and the frame itself is 1 cm smaller. After all, you need space to fill with foam between the door frame and the opening. Maximum permissible gap between the frame and the opening: 30 mm. on each side (left, right and top)

What you need to pay attention to

When choosing a glass door for a steam room, you must first pay attention to the following details:

The metal heats up to a maximum of 45-50°C and does not pose a particular danger to the hands of visitors

Particular attention is paid to canopies. Doors with an opening width of 180x60 cm may have two hangers; heavier models may have three hangers.

In this case, it is desirable that the hinge mechanisms be manufactured in Scandinavian countries.

The seal is only silicone, regardless of what types of paired rooms the door is intended for. The leaf should be fixed not with a roller, but with magnetic points installed along the perimeter of the door frame.

Accessories

Canopies.

Glass models will require more canopies than regular ones. The best option would be to install 3 awnings. This is explained by the fact that such a solution is heavier and two canopies may not withstand the weight and break. The hinge material should be stainless steel or any other material that will not corrode. Latches. On lower-priced products, the latches can quickly fail, so they are equipped with ball latches. Ball latches have one significant drawback: metal quickly corrodes and because of this the door can jam at the most inopportune moment. An excellent option would be to install a magnetic lock, divided into 4-5 compartments. Their performance is more durable. Pens. In saunas and bathhouses, wooden handles are often installed on the doors made of glass.

It’s worth paying attention to this tiny detail. The location and girth should be comfortable. Some models have a silicone lining for a better grip on the handle.

Some models have a silicone lining for a better grip on the handle.

When selecting glass doors, you should also remember about the fittings

Combined type windows

The combined type of windows involves the use of several materials in different combinations, in particular:

- wood with plastic;

- wood and aluminum;

- plastic with aluminum;

- aluminum with wood and plastic.

The combination of several materials can improve the thermal insulation properties of windows. And most often the first two combinations of materials are used.

You can combine materials in windows in this way:

- The inside of the frame is lined with wooden planks, and the partitions and the entire frame are made of plastic. Such windows appear to be made of wood from the inside. For protection and additional decoration, the wood is coated with several layers of varnish.

- The entire frame is made from laminated veneer lumber, and aluminum or plastic strips are placed on the outside using clamps to allow the wood to “breathe.”

- First, two independent frames are made - the inner one is made of wood, and the outer one is made of plastic or metal. Along the perimeter, the frames are connected to each other with special brackets, and the glazing is done with ordinary glass, and not with bags. If desired, any of the frames can be removed.

Construction of doors, frames, openings

It was already mentioned above that three types of dimensions are taken into account - canvas, box and opening. The latter is finishing and wall, the first is the amount of free space between the jambs, and the second is the space between bare walls without a frame.

The door leaf is attached to the frame using hinges; the frame is secured in the opening in various ways (see our article about the simple and straightforward installation of doors in a bathhouse). The gaps between the canvas and the box do not exceed 2-3 mm, and between the box and the opening the gap unfilled with foam can be several centimeters (but no more than the width of the platband that covers it).

When laying an opening in the wall, you can be guided by either standard or non-standard dimensions of future doors. Usually it is 10 centimeters larger than the size of a bath door with a frame, which gives 5 cm on the sides and 10 on top (if without a threshold).

In the photo: uncut and not covered with casing foam holding the door

Dimensions with box

Very often, the main dimension that is taken into account when choosing a door is the external size of its frame. Below we provide a table showing new options for the interdependence of the dimensions of the module, box and opening:

Table 4. Door to the bathhouse: dimensions with frame

| Modular size (decimeters) | Outer box size(mm) | Doorway size (mm) |

| 10 x 20 | 990 x 1990 | 1000 x 1990 |

| 9 x 20 | 890 x 1990 | 900 x 1990 |

| 9 x 19 | 890 x 1890 | 800 x 1980 |

| 8 x 20 | 790 x 1990 | 800 x 1990 |

| 8 x 19 | 790 x 1890 | 800 x 1890 |

| 7 x 19 | 690 x 1890 | 700 x 1890 |

Dimensions of doors for steam rooms

The doors for the steam room in the bathhouse are usually made lower than the entrance doors. This is due to the fact that in this room, under the ceiling, when heated, steam should accumulate in a layer of at least 80 cm. Therefore, to determine the height of the structure, you need to subtract this number from the general parameter. For example, with a ceiling height of 240 cm, it will be approximately 160 cm. The width of the opening can be anything, it all depends on the wishes of the owner. If we talk about standards, then it is usually 60-75 cm. It is worth noting that the indicated numbers are only approximate, it is not at all necessary to adhere to them.

Where can I buy

You can buy doors for a bathhouse or steam room from one of the companies that are presented in a separate section of our website.

Few of the owners of “acres” do not plan to build a bathhouse on the adjacent territory. One of the questions that interests many people is what size bath doors should they be guided by? After all, it is clear that ordinary standards are not suitable for them, since the problem of heat preservation in this case comes to the fore.

What size bath door should I install?

Traditionally, doors made of wood are installed in the bathhouse - a material that can expand or contract depending on the level of humidity and temperature in the room

They usually open outward - this is very important for safety. A threshold 10-15 cm high must be made under the door, and a small gap of 5-7 cm is also left for steam to escape

Therefore, the structure cannot be too high. It shouldn’t be wide either, otherwise the heat will go nowhere. The most optimal door dimensions for a bathhouse are 180*65 cm plus or minus 5-10 cm. At the same time, the entrance structures and door frames are made more massive than those leading to the steam room or other rooms. In this way, maximum heat retention is achieved.

It should be noted that modern doors measuring more than 2 meters high and 80-100 cm wide should not be chosen for a bathhouse. They are not suitable for her. Everything in the bath should be small - windows, steam room, doors and other details. This is the only way to save the heat emanating from the stove and enjoy full water procedures. However, there is no need to make the doors too low either. The tallest member of the family should enter the bathhouse only with his head bowed, and not bent double.

Requirements to consider when choosing a product

Whatever model and size of bath door you choose, it is important that it meets certain requirements. The door should:

- made from a material that is of high quality, durable, resistant to fire, temperature changes and high humidity;

- easy to open (this will help you quickly and easily leave the premises if an emergency suddenly occurs);

- have suitable dimensions and dimensions;

- have a gap at the threshold to ensure high-quality air exchange.

Why is this type different from interior ones?

Today, in almost any suburban area or dacha you can find a bathhouse. In most cases, it is erected independently, without turning to specialists. And, if everything is clear with the design and general requirements. The question may quite naturally arise - what kind of door to the steam room should be in the bathhouse? Are there any fundamental differences from the standard interior? What are the basic requirements for materials and characteristics?

The main differences from standard doors include:

- Good thermal insulation;

- Increased heat resistance;

- Moisture resistance.

The entrance door of the bathhouse may not meet all of the listed requirements. Its main purpose is thermal insulation and heat preservation. Therefore, the standard one can also be used. Doors for a steam room in a bathhouse must meet the listed requirements and are made using special technology.

Solid wood is always used for production, because... The classic technology for producing interior doors is not suitable. Heat-resistant glass can be used; plastic is not suitable for the door to the steam room. Of the wood species, preference is given to linden, aspen and larch; the use of pine is allowed.

Information! If the bathhouse is located in close proximity to the house, you can use a plastic door with a regular lock as the entrance door; for other options, you need to select a more reliable design.

Previously, for better heat retention, smaller openings were used. Now this rule has practically lost force; it is allowed to install a door of a standard size. In rare cases. You can find a door of reduced size, which requires you to bend down when passing through it.

Tempered glass has become widespread. You don’t need to make it yourself; it’s enough to know the necessary parameters of the sauna door and its dimensions. You can buy a ready-made sample of a glass door in stores that specialize in bath materials.

Important! The temperature in the steam room is quite high, so it is not allowed to install additional locks and valves from the inside. the door should open out easily

Pros of installation

Plastic structures are easily installed in the wooden walls of a bathhouse. PVC is not susceptible to rotting or fungal attack. Plastic doors with glazing allow light into the steam room, which has a beneficial effect on the microclimate.

Large selection of door colors. In addition to classic white, you can choose to decorate with wood of different varieties and shades. There are two technologies for changing color - applying a colored film over the profile, or introducing pigment into PVC during production

In this case, the entire profile array is painted, but the color is uniform without simulating wood texture. If a design with sandwich panels is chosen, the panels can be easily changed if necessary. Products using a plastic profile with 5 or more chambers retain heat well, which is important for steam rooms. PVC does not deform from moisture.

Useful tips

When installing a door structure in a bathhouse, you should remember some nuances:

- It should be taken into account that the door will shrink after some time: a frame made of raw wood shrinks by approximately 8%, and a frame made of dry wood - by 2%.

- It is not recommended to install locks or latches on door structures leading to the steam room. This is done for safety purposes, so that it is convenient to get into the premises in case of accidents or emergency situations. In addition, at high temperatures, metal fittings heat up, and when exposed to steam, they quickly become unusable and can jam at any moment, which is very dangerous.

- It is strictly forbidden to treat the door leaf leading to the steam room with paints and varnishes.

- A threshold of 15-20 cm is always installed under the entrance door. Under the door structure leading to the steam room, a threshold is not installed, but a gap of 3 cm is made.

- The doors always open only outwards, and the hinges are mounted on the opposite side from the wet room.

Whatever doors to the bathhouse are chosen, it is important that they consist of moisture-resistant and sealed materials that can withstand constant pressure. It doesn’t matter at all whether the door structure is made independently, in production, or purchased in an expensive prestigious salon

The main thing is how comfortable, reliable, aesthetic and easy to use it is.

It doesn’t matter at all whether the door structure is made independently, in production, or purchased from an expensive, prestigious showroom. The main thing is how comfortable, reliable, aesthetic and easy to use it is.

Design

As a rule, matte or transparent raw materials are used for the production of doors. For a more harmonious combination with the overall style of the bathhouse, matte material can have a bronze tint; in addition, such products will help create a more private atmosphere in the steam room, which in some cases is important. The white matte canvas will also allow you to see only the outlines of a human silhouette in the steam room.

Manufacturers give doors made from transparent raw materials a wide variety of shades and textures. On sale you can find products with a corrugated or perfectly smooth base, with an ornament or a complex pattern.

For baths, canvases with multi-colored photo printing are in demand. This method of decorating the canvas will help decorate the interior with an original door. In some baths decorated in ethnic style, glass items painted in the style of Khokhloma, Arabic script, or intricate abstraction would be appropriate. Expensive canvases are decorated using exclusive elements. An interesting solution is mirror structures in combination with an aluminum frame.

The design of the door frame plays an important role, since it is this detail that largely determines the possibility of a harmonious combination of the door with one or another direction of room design. For example, for baths made in the traditional Russian style, it is better to install a wooden box. Modern style may require the use of a metal door frame.

Door materials

Each owner of the plot can independently decide which design and style of the bathhouse to choose. Manufacturers made sure that everyone could choose the most suitable material for the job.

Design option for a wooden door with forged elements

Most often, the choice is made on the following raw materials for making doors:

- Wood.

- Glass.

- Plastic.

- Metal.

Each of these materials has its own advantages, disadvantages and features. Therefore, before placing a bet on any of them, you need to familiarize yourself with the nuances.

Wood

There are different materials for making doors leading to the bathhouse. People choose to finish the structure using eurolining prepared for the process, while other owners prefer to buy a solid frame and carry out the construction on their own.

Homemade wooden door for a bathhouse

In any case, wood is at the top of the list of materials for bathhouse doors.

Material advantages

- Resistance to moisture.

- Adaptation to temperature changes.

- Wood itself is a heat insulator, so the owner of the site will not have to spend a lot of money on additional materials to insulate the canvas.

- And of course, aesthetic characteristics. Wood fits perfectly into the overall interior of the bathhouse. A wooden door will look harmonious and create a pleasant atmosphere in the room where you can steam.

Flaws

The material requires additional processing and not all types of wood are suitable for bathhouse door construction.

Important nuances

Also, due attention should be paid to the question of what material to make the door handle from. It makes the most sense to also use wood for this purpose, because metal, plastic and similar materials under the influence of high temperatures can become deformed and also heat up, which reduces the level of safety in the bathhouse; Therefore, when the question comes about what material the entrance door to the bathhouse should be made of, it is worth paying attention to wood

Therefore, when the question comes about what material the entrance door to the bathhouse should be made of, it is worth paying attention to wood

It is best to give preference to aspen or linden wood. Internal doors leading to the steam room can be achieved by installing a glass door.

Glass

To enter the steam room, as well as the shower room located inside the steam room, glass doors are often installed.

Advantages

- This design looks harmonious in the opening.

- The glass door is easy to clean.

- The material tolerates high temperatures well, which are not uncommon in a steam room.

- There are many designs of glass doors, so everyone will choose the best option for themselves.

Flaws

- the cost of such a design is quite high, because the glass must be durable and quite thick if the question is about a door;

- You won’t be able to make such a door yourself, unless the owner of the site with the bathhouse has his own workshop for the production of glass products.

In any case, the glass in the doorway of a steam room or shower looks elegant and harmonious.

Plastic

If you prefer plastic, you need to choose a heat-resistant one; other options are not suitable for installation in a bathhouse.

The process of installing a plastic door to a bathhouse

Advantages

- Heat-resistant plastic is a fairly durable material.

- This door raw material is durable.

- Withstands changes in air temperature.

- Able to tolerate high levels of indoor humidity.

Flaws

The material is not natural, which means it will not release aromas into the air that one would like to hear in a steam room or dressing room.

Design options for plastic doors for baths

Metal

If you wish, you can create an armored metal door with your own hands, however, this will require additional materials and tools.

Advantages

- Such a canvas will certainly protect the dressing room from drafts.

- This design looks harmonious.

- A large selection of designs of such canvases will help satisfy the needs of even the most demanding apartment owners.

Flaws

- high price;

- such a canvas is not suitable for installation at the entrance to the steam room.

The choice of material depends solely on the preferences of the owner of the land plot. Any raw material will fit perfectly into the space of the bathhouse, the main thing is to do the work with soul.

Varieties

To make the bath comfortable, a certain level of heat and steam must be constantly maintained in the room. Very often, two doors are used to decorate saunas, baths and steam rooms. One product is installed at the entrance to the bathhouse, and the second separates the steam room from the general area of the room. For premises of the above type, doors of various types are used. Let's look at the types in more detail.

Deaf

Such door leaves are made from solid wood. Each type of wood has special characteristics, both positive and negative. A variety of wood species are used in the manufacturing process.

Linden models are widespread. Products made from “local” wood have a more affordable price. When choosing a model, be sure to ask your sales consultant about the type of solid wood and its performance characteristics. A steam room decorated in solid wood will harmoniously fit into a rustic country or Provence style.

Glass

To produce durable and reliable glass, special high-quality raw materials are used, which can be safely used for installation in steam rooms. It is processed in a special way, ensuring safe and convenient operation. Considering the fact that a high level of humidity is almost constantly maintained in the bathhouse area, the resistance of glass to rot has played a significant role in the development of the popularity of this type of product. Models made of transparent material are chosen if it is necessary to fill the room with light.

Designers and ordinary users especially loved products made from transparent material with a bronze tint. The rays passing through it acquire a warm and pleasant hue, creating an atmosphere of coziness, comfort and peace in the room. Sliding glass options are also widely used. This option is ideal for decorating a bathhouse in an apartment of a residential building, decorated in a modern style. Models made of gray glass or mirror canvases will harmoniously fit into high-tech.

Depending on the type of opening, the door can be of two types.

Sliding

Doors of this type are most often combined. It is worth noting that this option is ideal for small rooms, due to a special opening mechanism. However, sliding panels have a significant drawback. They will not provide the same reliable joining as swing products.

Door installation

The door structure always consists of two main parts: the frame and the leaf. Its installation may be accompanied by various nuances:

If the structure is made of wood, then the places where the fastenings will be located can be marked as markings

You will have to attach them yourself. If you plan to buy a glass structure, it is important to correctly calculate the dimensions of the entrance doors for the bathhouse. In case of an error, it will be impossible to redo them

Therefore, measurements can only be taken after the doorway is finally installed. The door leading to the steam room can be mounted on a frame made of wood or metal. The metal box is installed even before the wall is finished. Installation of the wooden box is carried out after completion of the repair work. That is, this can be considered the final stage. The doors that can be seen in baths have some differences. In the steam room below, near the threshold, there must be a gap that allows air to penetrate inside and remove excess steam. There is no need to make such a gap for a sauna. This feature should be taken into account when choosing the size of doors for a bathhouse.

Massive wooden door in a bathhouseSource birzhaplus.ru

The door is installed in the following sequence:

- After purchase, the glass door is carefully detached from the frame. To do this, you need to loosen the fastening system. For safety, the canvas is laid on wooden planks.

- Before installing the doorway, it is necessary to take measurements (vertical and diagonal parameters are determined). They will help you install the door so that the structure does not become distorted later. Using wedges, the box is installed. The screws located on the top bar are tightened. To do this, using a building level, check the evenness of the installation of the structure. When it is level, the screws are tightened to the limit. If necessary, a threshold is set.

- The door leaf is being fastened. To do this, it is inserted into the loops, which are then carefully tightened. If the door is made of glass, you need to install it with an assistant. According to safety regulations, the door must be installed in such a way that it opens outward. To check the correct installation of the door leaf, you need to close the door and measure the resulting gaps. They should be the same size around the perimeter. The canvas itself should fit snugly to the box.

- Finally, the handle and latch are attached. If you buy a glass door, then a hole for them should already be made in it. If you choose a wooden door, then you may have to do it yourself.

Flaws

Like any other material, glass has its disadvantages:

- This is a fairly fragile material in its normal form that requires careful handling;

- Glass surfaces have a high thermal conductivity;

- High cost of finished glass products.

But for door blocks made specifically for a bathhouse or sauna, special pre-tempered glass with a thickness of at least 8 mm is used. Therefore, such structures are characterized by increased strength, impact resistance, and low thermal conductivity. And their cost is fully recouped due to the long operational period.

How to insulate?

Insulation of a doorway is most often carried out at the time of installation of the door frame. As a rule, insulation occurs when the residents of the house are going to insulate the walls or floor. Initially, it is necessary to insulate all main structural elements, including load-bearing walls. Then you need to prepare a place for the door frame and install it, and after that you can insulate it using various seals. In this case, all the cracks that appear are filled.

Thus, you can carry out subsequent insulation only when replacing the door frame, but not when replacing the door leaf. To insulate a doorway in a private house during its construction, you can create an additional layer of thermal insulation, which will include the entire space of ceilings, walls and floors, and also imply insulation of the door frame. In this case, a dense material is used, which will subsequently shrink

It is important to pay attention to its strength and density

Reducing the degree of transparency of the glass sheet

Many people in the steam room are confused by the transparency of the glass door. But this inconvenience can be easily corrected, without reducing the reliability of the door unit. The glass can be painted, a special tint film applied to it, and there are other ways.

Using tint film

Before tinting, the room and the door itself must be prepared. The room is wet cleaned and the glass door panel is thoroughly wiped.

Next, the tint film is cut to the size of the canvas. In this case, an allowance of 20 mm is added on all sides of the finishing material.

Next, you need to prepare a soap solution, apply it to the glass surface and the film on both sides. The protective layer is removed from the tinting material, its adhesive side is also treated with a soap solution.

Next, the film is applied to the glass plane and slowly smoothed out. At the same time, it is necessary to remove any air bubbles that form. After applying the tint, the soap solution is removed from the surface of the canvas. This must be done carefully with a squeegee. The final stage is to cut off the excess finishing material with a sharp knife.

You can use the steam room only after the tint material has completely dried - after 3 days.

other methods

The list of services provided by many organizations whose activities are related to the renovation of premises includes the item - decorative spraying on glass surfaces.

If you have artistic skills, you can apply some kind of design to the glass doors. Waterproof paints in all colors of the rainbow are produced especially for painting on glass surfaces.

Sauna and Russian bath: is the size of the door to the steam room and other door parameters different?

If bath doors have any peculiarities, they did not arise from the superstitions of their ancestors, which later became a tradition, but from the need to comply with certain conditions of each specific national bath.

Let's take the most popular: Russian and Finnish. In Russian, the main thing is not to lose steam. Light, transparent steam obtained from hot stones has a temperature of more than 100 degrees. It rushes upward and over time a “steam cake” forms under the ceiling, from where the steam is scooped up with a broom and lowered onto the body.

It is clear that the main enemy of such a “pie” is a draft. This means that the stove should be designed in such a way that at the right moment it almost completely blocks the draft, and there should be no draft or draft in the steam room itself. And the door in this regard is an important element on which the presence or absence of drafts depends.

But in Finnish it’s exactly the opposite. There is supposed to be a draft in it, so that in an hour the air is completely renewed five times. Of course, it must have time to heat up to 90 degrees. Therefore, the stove works with all its might, convection quickly heats the air, which means the influx must be sufficient. And again the door is the very element that can help.

Do you understand what needs to be done in the first and second cases? It is logical that in a Russian bath you need to seal the door, but in a Finnish one, on the contrary, you need to open a constant influx, preferably at the bottom. It could be just a gap between the door and the floor, or it could be closing blinds, that is, an adjustable inflow.

It is also logical that the size of the door to a Russian steam room should be the minimum required, but in a Finnish one the size is not critical, if you do not take into account the large heat loss for uninsulated surfaces.

However, nowadays you can find the wildest mixtures of sauna and Russian bath conditions everywhere, which indicates the loss of tradition. In such a bathhouse the door can be anything you want. But if you care, read below for practical tips that will help you create a traditional steam room.

Kinds

Modern manufacturers of glass door panels use the latest generation technologies in their work, which allows them to assemble high-class products. Glass production occurs when it is heated to +700 degrees and cooled sharply. This method provides the material with heat resistance, which affects the safety of operation of the raw material, as well as resistance to damage.

The standard door thickness is about 8 mm. The production features eliminate the formation of sharp fragments if the glass breaks. In such cases, the fragments of material will contain obtuse angles, which virtually eliminates the possibility of cutting yourself on them.

Taking into account the technological features of the production of glass bath doors, we can say that such products are a solid or combined sheet of fire-resistant glass.

Products are classified as follows:

- Based on the opening method - the designs are sliding, swing or pendulum type. The latter variety is used only in the sauna;

- according to the production method - the canvases are made entirely of glass or with the inclusion of decorative elements. Usually wood or plastic is used;

- by type of design - the material can be matte, transparent, colored, or contain an image or pattern.

Door frames for glass bath doors also come in the following types, taking into account the type of raw materials used:

- most often wood is used to create a structure;

- There are models made of aluminum alloy.

The first type of structure can be installed at any time, regardless of what stage the work on decorating the bathhouse is at. The metal box option requires its installation and adjustment before finishing the room. For a Russian bath, experts recommend choosing the latest type of door frame.

Functional Features

Doors installed in paired rooms are selected according to the following criteria:

Heat resistance, fire safety, resistance to deformation. These are some of the most important qualities required from bath products. The canvas must easily withstand difficult operating conditions and retain its original shape under the influence of humidity and high temperature. High-quality designs are designed for operation in conditions of sharp temperature fluctuations.

- Ability to effectively preserve and retain internal heat. Good doors are sealed, small in size, equipped with a thermal vapor barrier that ensures minimal heat loss.

- Wear resistance - due to the enormous load that bath doors have to withstand in the above conditions, their strength also plays an important role.

- The absence of harmful fumes when heated - visiting a bathhouse should improve health, and not create a threat to it. Therefore, the thermal and vapor barrier filling of doors must be made of environmentally friendly materials that prevent the release of toxins under the influence of high temperatures.

- Appearance - any owner wants his bathhouse to be different from others in design. Installing original doors provides this opportunity.

- Security. Single-leaf structures that open outward not only contribute to the rational use of the usable space of the steam room, but also allow you to quickly leave it in emergency situations.

External

There are no special requirements for entrance doors

It is important that they provide good thermal insulation and close tightly, helping to retain valuable heat throughout the bath. Any wooden or metal model presented in the manufacturers’ lines fits these criteria

Ordinary street doors are single-leaf and have a high threshold. In a black bathhouse, which is rarely used today, the entrance is equipped with double-leaf products.

Interior

Many modern bath complexes have a large number of recreation areas. Therefore, the density of door structures that isolate rooms from each other is fundamentally important here in order to limit the access of moisture to them as much as possible.

Openings

When installing the canvas, it is placed in such a way as to leave a small gap at the bottom for a ventilation gap. If the bathhouse is equipped with a ventilation system, then there is no particular need for this. Clearances may also be necessary for sauna equipment to function properly.

Manufacturing Standards

Entrance doors come in a variety of sizes, taking into account the individual characteristics of the architecture of bath structures. The classic option is external doors with dimensions of 1800x650 mm and a mandatory high threshold.

For washing

Washing room doors are of the usual dimensions, although sometimes they are narrower in width to prevent the spread of humidity, which is necessarily increased in this compartment. The recommended width of doors to the sink is 0.60 cm.

The requirement for resistance to moisture must be taken into account. When choosing solid wood doors, you need to leave a ventilation gap - a gap from the bottom of the door leaf to the door frame, as already mentioned. For ordinary interior doors, a gap of 2 to 3 mm is enough, while when installing a door for a sink from below, leave at least 5 mm, otherwise the swollen door will jam when closing and opening.

For the steam room

In the steam room, clouds of steam form under the ceiling. On average, such a layer has a thickness of 0.6-0.8 m. Therefore, it is necessary that there be a pocket of 0.6-0.8 m between the lintel - the upper edge of the door and the finished ceiling.

The optimal door height is 1.6 m. A high threshold is required. Its height should be about 18-20 cm in order to successfully solve several problems at once:

- Limit access to cold air when entering and exiting the steam room.

- Prevent drafts.

- Act as insurance against hitting your head on the top edge of the door: when we step over something, we automatically bend down lower. That is, thanks to the threshold, we avoid possible injury.

Now about the width of the doors for the steam room. Regardless of what most sources call the standard sizes 700x1900 and 800x1900 mm, there are other opinions regarding the width of the canvas. Many craftsmen advise installing wide doors, and, interestingly, much wider than the standard, recommending 900-1000 mm or even more for the frame. For example, if a door is 1600 mm high, then with a width of 1300 mm it will be very convenient to enter, especially when you need to bring in and take out some equipment.

It is better to refuse non-standard 2-meter structures produced by foreign factories.

general information

Opinions on this issue vary. Some believe that, taking into account the quality of the products offered by manufacturers, first of all, samples with a high degree of insulation, there is no fundamental difference when choosing bathhouse doors in size; the main thing is that it is convenient to use.

Opponents of such a simplified approach believe that one should focus on the linear parameters of structures installed in openings, the optimality of which has been tested for centuries. The fact is that when you open a door, heat tends to come out, and the higher/wider the door leaf, the more of it will be lost. And the door to the steam room should be chosen especially carefully.

Recommended dimensions (in mm):

- Height – 1650±150.

- Width – 650±50.

- Thickness – 85±15.

And if we compare the specified data with the standard parameters of commercially available sauna (bathhouse) doors, we can see that they are significantly less than 2000 and 1000 mm (height and width, respectively). And this is understandable, given their main purpose - maximum heat conservation. Indeed, in such buildings it is recommended to make even window openings small.

And if you decide to build a real Russian bathhouse, then it is still worth taking into account the experience of your ancestors and purchasing (making it yourself) structures (especially the door to the steam room) according to the above dimensions.

But there are a number of nuances here too. Even the smallest bathhouse has some kind of layout, that is, it has not one, but at least three rooms (including the vestibule). And at the entrance to each one a door is installed. And here the question arises: is it worth purchasing the same designs for all rooms? What do experts think about this?