And further. The article will not replace training in construction, but a roof is, after all, a complex structure that requires knowledge, so for those who, without experience, intend to build a roof for a bathhouse with their own hands, we advise you to at least read books on roofing, after reading it will be clear whether you can handle the task or not.

Let's start with the theoretical part.

Height

When it comes to the height of the roof of a bathhouse , you need to understand that we mean its angle of inclination .

And it is not an arbitrary value, but depends on what winds blow in your area and how much precipitation falls. ADVICE! Proceed from the fact that increasing the angle of inclination simultaneously increases the wind load and prevents the retention of precipitation on the roof surface.

The minimum angle of inclination at which a roof is considered pitched starts at 2.5 degrees . Less - flat roofs, and up to 10 degrees - pitched roofs, but even these will have problems with removing precipitation and will require manual cleaning. But the accumulated snow is hundreds of kilograms pressing on the roof!

The maximum angle of inclination will be considered equal to 60 degrees . It is believed that the maximum amount of snow will put pressure on a roof with a slope of 30 degrees, and with a slope of 45 degrees the snow will slide down on its own.

Another factor associated with the choice of angle of inclination is the technical characteristics of the roofing material. You can select the material for the optimal angle of inclination for your area, or you can rely on the material and look for a compromise with climatic optimum.

BY THE WAY! An increase in the angle of inclination will also entail an increase in cost.

Maps and explanations for them , as well as simplified calculation formulas, can be found in this article. We strongly recommend that you familiarize yourself with them and study the formulas that will determine the load and affect the calculation of the roof mass.

However, you can use a simple life hack: you are not the first to build, take a closer look at your neighbors’ buildings, talk to them about problems with the roof, if there were any, and the optimal degree of inclination will be determined without unnecessary hassle. And the material will also be clearer.

Operating Lessons

A pitched roof is in many ways a compromise. For example, if you make an entrance to the dressing room from a high part and place a full-fledged window there to maximize the use of natural light, you will certainly encounter the problem that the chimney will be in a low part of the roof and its maintenance will be somewhat difficult. In addition, there will be no objective possibility of using the roof overhang to create some kind of veranda.

To avoid this problem, you can try to place the entrance to the bathhouse from the end wall, because in this case the change in ceiling heights can be smoothed out in some way. But then the urgent question arises of raising the walls to a greater height in order to fit into the requirements of building codes regarding the distance from the stove to the ceiling, the rational placement of shelves in a vertical projection, smoke ducts and other important factors. In addition, you should not neglect the location of the bathhouse relative to the cardinal directions, for optimal illumination and removal of atmospheric moisture from the roof and at the same time from the adjacent neighboring area.

Types of rafter systems

First we will show you the types of pitched roofs . Rafter systems are something like ribs that are easy to imagine under the outer layer of these structures. Accordingly, you can imagine the complexity of each specific system. Rafter systems are named according to the type of roof.

taken from the book by Savelyev A.A. - “Roof structures. Rafter systems" (2009)

Rafters according to the material can be made of wood or metal. In our case, consideration of metal structures is unnecessary, so only wood.

The principle of connection and load transfer differs between layered and hanging rafters. The first are attached at one end to the ridge, at the other to the wall frame. This transfers the load to the ridge and from it to the gables/gables, interior wall or supports, and the other end transfers the load to the exterior wall. With this transmission, the rafter works only to deflect in the middle part.

Hanging rafters rest against each other with their upper edges, creating a spacer. In this case, the skate is missing. To compensate for this expansion, the bottom of the rafter legs is connected with a tie.

All this can be seen in the figure below. It also clearly shows the rafterless system that was used in traditional log construction - instead of rafters, slabs were made that were laid on the projections of the gables (males). The orientation is slightly perpendicular to the rafters.

taken from the book by Savelyev A.A. - “Roof structures. Rafter systems" (2009)

Making rafters for a bathhouse with your own hands is a feasible task, but it must be preceded by many calculations of the loads to which the roof will be subjected. The full calculation is done by professionals; both complete and simplified calculations can be found in the literature.

IMPORTANT! Since intermediate supports for the rafters are made with a leg length of more than 4.5 meters, and the rafters for the roof of the bathhouse are unlikely to be of this size, we do not provide diagrams of the struts here.

Construction standards for pitched roofs

The roof for a bathhouse is an enclosing structure that is designed to protect the building from negative atmospheric influences, as well as to maintain comfortable living conditions in the premises. Therefore, modern roofs must meet a number of requirements:

- High weather resistance.

- Waterproof.

- Thermal efficiency.

- Wear resistance and increased strength.

- Fire safety.

- Resistance to biological effects.

- Environmentally friendly.

- Durability.

When constructing pitched roofs, it is important to comply with certain standards and regulations. If the bathhouse building is adjacent to a residential building, then it is rational to install a pitched roof - a more accessible and cheaper option. In this case, the height of the roof can be arbitrary, but taking into account the height of the residential building.

For full-fledged bath complexes or private baths equipped with an attic space, the best option is gable roofs. With the right approach to heat and waterproofing, such a structure can be used for living. When organizing a gable structure, it is important to choose the correct location for the ridge and calculate its height.

Types of roofing coverings

In addition to wind and snow loads, the weight of the roofing is an important factor influencing the calculation of the rafter system, which must withstand all - static and dynamic - loads during the operation of the building. Therefore, it is worth deciding on the type of coating in advance, even before developing the project.

The specifications of the roofing material also include the minimum or maximum roof pitch at which it can be used. Take this into account when choosing the height of the bathhouse roof.

Metal tiles

The low weight of metal tiles is its main advantage, because it reduces the load on the rafters and the structure as a whole.

Made from iron, copper and aluminum. Iron - in the form of steel, which is susceptible to corrosion and therefore needs protection - for example, galvanizing. It is clear that copper and aluminum varieties are much more resistant to corrosion and would last for several decades, but they are also less durable.

BY THE WAY! The service life of conventional galvanized steel tiles is 10-15 years.

Regardless of the metal used, metal tiles are coated with polymer on both sides . This is done to give it the desired color, as well as for additional protection.

The thickness of the metal layer varies, the weight of a square meter of coating depends on this, but the recommended thickness is 0.5 mm . Weight is approximately 5 kg per square meter.

Bathhouse with a gable roof made of metal tiles. Photo StroyDom

The minimum roof slope for metal tiles is 12 degrees. (More is possible.)

With its help you can make a pitched roof on a bathhouse, a gable roof and a broken roof (with an attic).

Slate

Slate can be different - from natural (slate plates) to ceramic plastics. However, most often you can find the asbestos-cement variety - these are flat or wavy sheets of material in which cement is mixed with asbestos.

IMPORTANT! The presence of asbestos makes it harmful to health.

A common roofing material weighing about 11 kg per square meter with a thickness of 4.8 mm.

Laying a slate roof for a bathhouse. Photo StroyDom

Fragile, brittle, but non-flammable and quite durable - it will last quietly for 30 years. Especially if it is treated with protective compounds and moss does not grow on it, its waterproofing properties will become much better, and it will be more durable. In addition, it has good noise insulation performance.

Installation of slate is cost-effective when the roof slope is more than 12 degrees. It is quite possible to make a roof for a bathhouse from it.

Ondulin

Similar in appearance to slate (the same corrugated sheets), but a completely different material. It is made from cardboard, which, to obtain the desired properties, is corrugated and impregnated with bitumen, as well as heat-resistant resin and dyes, giving it bright shades.

Due to impregnation, the material becomes waterproof. In addition, it is quite flexible and not fragile. The weight of 1 square meter of ondulin is slightly more than 3 kg. Available in sheets of 2 m by 0.95 m. The advantages include a variety of colors.

Fragment of the roof of a bathhouse made of ondulin. Cromwell Photos

Mounted on slopes with a slope of at least 6 degrees . At the same time, it is not necessary to remove the old roof, if any. A good option for covering the roof of a bathhouse.

INTERESTING! The noise absorption of ondulin is such that the noise from rain hitting the roof will be practically inaudible, unlike all materials made of metal.

The shelf life from the manufacturer is 15 years, in practice it may be longer.

Roof tiles

It is unlikely that many bathhouse owners will cover them with ceramic or slate tiles - these are expensive materials that cannot be found on outbuildings. Their main advantage is, of course, their service life, which reaches (for slate) two centuries! But this is not only expensive, but also heavy material that requires a reinforced rafter system. In general, it is unprofitable.

In addition to ceramic and slate tiles, there are also cement-sand and silicate tiles, they are a little cheaper, they also have a long service life, but we will not recommend them either.

But there is another class of tiles, so called very conventionally, from which it is quite possible to make a roof for a bathhouse with your own hands.

Bituminous shingles

This is a flexible roofing material made from fiberglass (a dense sheet of glass fibers), coated on both sides with bitumen and sprinkled with stone chips (basalt or slate).

ADVICE! It is better to prefer basalt chips to shale chips - they crumble less.

Flexible tiles are easy to install and are completely undemanding to surfaces. Of course, you won’t see the dome in the bathhouse, but she could handle it. The minimum roof slope for its installation on the roof of a bathhouse is 12 degrees .

Bathhouse made of double timber with a gable roof made of bitumen (soft) tiles. Teplokrepost Photos

The weight of asphalt shingles varies quite significantly depending on the amount of bitumen and the manufacturer. There are single-layer ones that weigh 5-8 kg per square, there are laminated multi-layer ones that weigh 13 kg per square.

IMPORTANT! Since bituminous shingles rest only on a solid(!) sheathing made of moisture-resistant plywood or OSB, the weight of the plywood (or OSB) and their cost should be included in the project in advance.

Corrugated sheet

Another type of metal roofing material that is noisy during rain. However, it is cheap and in demand.

The metal that goes into corrugated sheeting can be different - it can be steel that needs galvanizing, aluminum, copper , or chromium-nickel steel. The types of corrugated sheets differ in the presence or absence of a polymer coating, the height and shape of the corrugation (profile).

ON A NOTE! The height of the corrugated sheeting intended for roofing work is 44-57 mm. What is smaller is wall corrugated sheeting, what is larger is for permanent formwork of reinforced concrete floors.

The weight of corrugated sheets ranges from 4-9 kg per square. Install the sheets overlapping, on a roof with a slope of at least 8 degrees.

Bathhouse with a corrugated roof. Photo StroyDom

A bathhouse roof made of corrugated sheets is a completely acceptable, budget solution.

We evaluate the design

If you are finally convinced that your bathhouse will be crowned with a pitched roof, then undoubtedly it is worth taking into account a number of other features that confirm the old truism: “There are no trifles in construction.”

By strength

We have already mentioned that bathhouse roofs of this particular type are easy to construct, require significantly less building materials for their arrangement, and as a result, they place significantly less load on the load-bearing walls and, through them, on the foundation. Taking into account the fact that bathhouses of small dimensions are designed for such roofs, it is quite reasonable to assume that the foundation can be designed to be simpler and less material- and labor-intensive.

The construction of the walls of such baths, in principle, meets all the basic requirements that must be observed during the construction of other types of bath structures. Logs seem to be the most irrational of building materials, but we’ll talk about the reasons a little later.

As for the rafter set. It must be taken into account that if the length of the rafter leg is more than 3200 - 3250 mm, additional supports must be installed in the middle, which will provide the necessary sagging rigidity

This is especially important in cases where the roof is flat or low-slope, and in the region where the bathhouse is located there are often cases when a stable snow cover with a height of 85 - 90 mm or more may fall simultaneously or within several days

By practicality

As we already mentioned above, the most irrational type of building material when constructing baths of this type is a log. There are several reasons:

As a rule, baths of this type are small in size and log walls will eat up the already small interior space. For the same reason, material consumption will not be optimal. Do not forget that it is necessary to equip the bathhouse with door and window openings, and this means a lot of sawing of dimensional round timber, which very often leaves unclaimed “tails”. In terms of thermal characteristics, the log is inferior to profiled timber of a similar cross-section

In small-volume baths this is fundamentally important. Obviously, installing logs even when building a small bathhouse is extremely difficult. The same beam simplifies this problem by an order of magnitude. Finally, with logs it is not so easy to clearly and along the entire length set different heights to the load-bearing walls, which provide the angle of the slope

But with timber and pieced building materials, such as bricks or building blocks, this procedure is easier and of better quality.

Gable, do-it-yourself: based on wall material

Those who have decided to make a gable roof for a bathhouse with their own hands need to know what role the material from which the bathhouse walls are built will play in their choice.

How to make a bathhouse from a log house

We have already said that wooden construction traditionally does without a modern rafter system, replacing it with logs (slabs) laid perpendicularly on the gables (gables). Such a solution requires professional skills, just like the construction of a log house.

Let's start with the fact that the log house must stand for 2-3 years, so that later its roof does not “go.”

The usual tilt angle is 45-60 degrees. The easiest way to adjust pediments on the ground is to remove the top crowns, lay them on the ground and achieve the correct geometry of the pediment - the logs form steps, gradually decreasing in length. The legs are placed in two or three rows; for this, the cutting method is used, for example, “into the paw”.

At the very top of the gables, the ridge will lie, and the ledges of the males are cut down to a regular triangle. A log with a diameter of 18-20 cm is used for the sledges. The slegs should protrude 50 cm beyond the roof.

Bathhouse roof slats on which the roofing material will be laid. Photo StroyDom

Laths are laid lightly on top onto which the roofing material will be attached. A traditional slab roof is made without nails at all.

How to make rafters for a gable roof on a bathhouse from other materials

In principle, the usual rafter system is applicable to log houses and timber buildings, so what is said below can be applied to them as well. The walls can be made of brick, block cellular concrete, or frame. Brick and concrete will require the installation of a wooden mauerlat on top of the walls , and in frame structures its function is performed by the top beam of the walls . If we are talking about a log house, then the Mauerlat will be the upper crown .

A gable roof involves supporting the lower end of the rafter leg on the mauerlat, and the upper end on the ridge, or with emphasis on the top of another rafter leg. In the latter case, the bottoms of the rafter legs are tightened with a tie.

The gables are made from the main material of the walls and serve as a support for the ridge beam. If the roof is heavy, the ridge will require intermediate supports. Usually in such cases there is an internal wall running under the ridge, on which the bed and the ridge supports are supported. But in our case, the roof should not be too heavy - and the dimensions of the bathhouse do not contribute to this, and the roofing materials are quite light.

The end of the rafter leg can rest entirely on the Mauerlat, or it can continue further in the form of an overhang, while the support on the Mauerlat comes from a notch in the rafter (or extension).

Due to the fact that the structure is subjected to various loads, it is better to make gable roof rafters for a bathhouse with a movable fastening, which will relieve unnecessary stress at the joints.

Video description

How to determine the required amount of roofing material is described in this video using ondulin as an example:

See also: Catalog of companies that specialize in the construction of baths

Frame materials

How to make a roof for a bathhouse so that it is reliable and stable depends on the correct choice of lumber for constructing the frame. They must be of high quality, without rot or cracks, and always dry, otherwise over time the beams and docks will begin to warp and bend, deforming the roof and creating stress at the attachment points.

The roof skeleton consists of the following elements:

- Mauerlat - timber with a section of 10x10 or 10x15 cm. The length of each is equal to the length of the supporting wall;

- rafters, the manufacture of which uses logs with a diameter of up to 12 cm or thick boards with a cross-section of at least 5x15 cm. The same materials may be required for the installation of supports, tie rods and other elements of roof trusses. The length of the rafters depends on the width of the bathhouse and the height of the ridge and is calculated according to the drawings. And their number is determined based on the distance between rafter pairs, which should not exceed 100-120 cm;

Note! If the roof will be insulated, the pitch between the rafters is chosen equal to the width of the insulating material. As a rule, it is 60 cm.

The insulation should fit tightly between the rafters Source nauchite.com

- Floor beams also often become elements of the under-roof structure. They can serve as supports for rafters instead of a mauerlat or as tie-downs for rafter legs. Their cross-section depends on the habitability of the attic space and the load on the floors, but cannot be less than 5x15 cm. The number of beams is equal to the number of trusses, and their length depends on the roof structure and can be equal to the width of the bathhouse or be greater by the amount of extension beyond the walls;

- For sparse sheathing, boards 20-30 mm thick are used, unedged ones are possible. The quantity is calculated taking into account the step between adjacent elements. Solid flooring for a soft roof or tiles can also be made from boards with a gap of 1-2 cm between them, but it is better to use sheet materials - OSB or plywood. A good solution would be to use SIP panels - a composite material consisting of two layers of OSB, between which polystyrene foam insulation is glued.

Before making a roof in a bathhouse, all lumber must be treated with fire-retardant impregnations to protect it from moisture, which contributes to rotting, and fire, the risk of which is much higher in a bathhouse than in any other building.

How to build a lean-to: according to the wall material

What was said above about a gable bathhouse applies, in part, to a lean-to bathhouse. Only here for a log house there is no classical solution for this type of roof, but a frame roof is quite capable of claiming specialness, because the lean-to version is very suitable for it.

ATTENTION! The site has an article entirely devoted to how to build a pitched roof. There you will find calculations and step-by-step instructions for building a bathhouse roof with your own hands.

Frame

Tips for those who want to make a frame bathhouse themselves can be found in this article.

To build a pitched roof, you will need to raise one of the walls (it will become a ridge and set the angle of the roof). The video below shows that the height of the ridge wall is set initially, and there is no need to increase it. The video demonstrates the stages of constructing a frame structure of a non-attic type, that is, the ceiling is the roof.

However, it is worth noting that pitched roofs may well be of the attic type. We recommend reading the book by Miller M.R., Miller R. “Guide to the construction of a frame house and roofing work.”

SIP panels as the wall material of a frame structure can use them to cover the roof. This is cost-effective if the length of the roof plane does not exceed 5-6 meters. But if you make a frame bathhouse with a pitched roof, then this is quite possible. All that remains is to choose a lightweight roofing material and cover the outside of the roof with it.

Other options

In all other options, you will also have either a wall made of the main material extended above, or a superstructure, possibly made of wood, with which you form the desired height of the ridge wall.

The videos below are not entirely relevant to our topic, but you can extract useful information from them that will help you correctly make a roof for your bathhouse.

Here we demonstrate an interesting way of attaching rafters to the mauerlat using a beam. The base is walls made of cellular concrete. You can adapt this idea to make a pitched roof for a bathhouse with your own hands as follows:

Make one wall higher than the other, put a Mauerlat on both, as shown in the video.

Then attach a board that will hold the beams parallel to the ground.

On a high wall, it will not be possible to attach the rafters to the beams, so they will have to be trimmed and laid as described in the article we have already mentioned.

Next, see how to waterproof a roof:

Sequence of roof battens and counter battens:

Here are the answers to how to fasten the battens:

The author’s choice for his construction was corrugated sheeting, here he shows its fastening:

However, do not forget that the rain will drum loudly on such a roof, and it will last for 10 years, no more. He chose not the roof height, but the wall height (20 mm profile), though. And soon I encountered a problem: the corrugated sheet covered with film collected condensation and began to rust. And if condensation was easy to deal with, the quality of the sheet cannot be corrected:

So be more careful when choosing material when building a bathhouse roof!

Of course, we have already mixed theory and practice, but still there will be more practical things to come.

What is important to note right away

The final stage of construction is the construction of the roof.

However, even at the design stage, it was preceded by many calculations designed to guarantee in the future the ability of this roof to withstand wind, snow, condensation and other inevitable misfortunes. We remind you of this so that the reader who intends to do the roofing with his own hands soberly assesses his skills and gives the calculations to professionals, if he is not an architect or civil engineer . It’s easier to collect according to calculations. Perhaps this is the best option for those who are determined to build themselves.

Engineering formulas cannot be called simple. Simplified versions can be found in books on roofing, but even they are very cumbersome. Therefore, we will limit ourselves to a rather superficial description of the available types of bathhouse roofs. In the text you will find links to other materials where the issue raised is discussed in much more detail than in this review.

Construction and installation of the ceiling step by step

Attic roofs automatically imply the presence of a ceiling, which will become the ceiling of your building from below and the attic floor from above. There are two types of such ceilings: flooring and hemming.

In the first case, you don’t even have to install floor beams - just fix the flooring boards on opposite walls. However, do not rush to rejoice - if we are talking about a log house, then you need to choose a ceiling crown that will not be the last one (there are 1 or 2 more crowns above it), remove it on opposite walls, and make a recess for laying the boards.

In other cases, you can attach a beam to the wall, which will serve as a “stand” for the ceiling boards.

IMPORTANT! The boards must extend onto the wall/beam to a depth of at least 5 cm.

5 cm is the optimal value, allowing you not to worry that the ends will deteriorate and the board will not hold.

False ceiling in the process of installation. Photo StroyDom

You can use a tongue and groove board or fasten the outer (top) side of the board with bars so that they do not fall apart. It is also possible to fasten the boards into a shield while still on the ground, and install it in its proper place.

ACCORDING TO STANDARDS , flooring should not be used in spaces larger than 2.5 meters, because the boards sag. Or you need to use partitions as intermediate supports.

So, the boards are laid, fastened, foil or film can be stapled underneath for vapor barrier, kraft paper can be placed on top and expanded clay or vermiculite with a layer of 20-30 cm. In our opinion, this is excellent insulation. Only the boards must be strong enough, for example, 50 mm thick.

A false ceiling begins with beams. For them, a recess is made in the walls, on 2/3 of the wall - in the log house it is cut down, during construction from block ones an empty space is left. There is no need to make a through hole. Beam spacing is 0.6-1 m.

The video below shows how to calculate the cross-section of a beam taking into account upcoming loads. The author also provided a link to a program that will do all the calculations for you:

ATTENTION! Instead of a notch, you can use a metal “beam holder” fastening.

Metal fastening “beam holder”

is nailed to the installed beams , which will be a “stand” for the rough ceiling. Rough flooring boards are laid on the projections of the skull beam .

Vapor barrier can be done from below, from the ceiling. Then insulation is laid in the spaces between the beams, waterproofing is attached over the beams , a rough flooring or joists are placed on it, the next layer is the finished floor . From below, on the ceiling side, a finishing ceiling is made on top of the vapor barrier, for example, from lining.

Well, let's move on to building a bathhouse roof with our own hands.

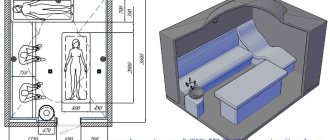

Planning

Initially, the idea of a frame bath should be born on paper. To do this, you need to know exactly how much area will be allocated for it. Below is a possible plan for a frame bath. It takes into account all the main premises. The number 1 indicates the steam room room. It has an area of 5.5 m2. This will be enough to comfortably accommodate five people at a time. There are two tiers of shelves. The entrance to the steam room is from the washing room, where you can take a shower, washing off all the toxins that came out in the steam room. There is a relaxation room with an area of 10.3 m2. You can chat there between bath cycles.

There are only three windows in the entire room. One of them is in the steam room so that natural light can be provided. It can also be used for ventilation and ventilation. There is another window in the washing room. The largest one is located in the recreation room. It opens onto a terrace where you can place another table for relaxation or a bench with a swing. If the site does not allow for the allocation of the area required for such a project, then you can sacrifice the veranda and plan the three main rooms differently. In exceptional cases, you can refuse the rest room and leave only the washing room and steam room.

To implement the frame bath project, you need to stock up on timber with dimensions of 10x10 or 15x15 cm. It will serve as the basis for the walls, lower and upper trim. You will need 15x5 cm boards. They will be used for the roof of the frame bathhouse, as well as for additional spacers. You should take care of a sufficient amount of waterproofing material, insulation, material for interior decoration, as well as roofing. It is important to think in advance about what will be used to cover the outside walls and what doors will be installed in the frame bathhouse. It is also worth assessing the need for windows and in which rooms they will be installed.

Construction instructions and step-by-step guide

Any construction involves a phase of preliminary calculations. In the case of a roof, you will need to take into account the weight of all components of the roof itself (rafters, roofing material, insulation, etc.), as well as snow load (which you can find out from the regional map) and wind load (another map in the already mentioned article).

Next, you will need formulas for calculating sections of wooden structures . They are quite complex and even in books they are often presented in a simplified form. We advise you not to rely on “average indicators” on the Internet, but to calculate your own case from books.

Construction of a bathhouse with a garage under one roof. Photo StroyDom

Perhaps there are programs not only for calculating the cross-section of beams, they could make your task easier. We found online calculators that calculate the rafter system, material weight and much more for you: Stroy-calc - Professional construction calculators.

When all calculations are completed, lumber is purchased, the processing phase begins. Do not forget that antiseptics and fire retardants on the roof are your friends (in the steam room they were enemies). It is customary to waterproof something: mastic, roofing felt, etc.

In addition to lumber, you also purchase fastenings. The fastenings themselves are also described in books - in some places it can be rigid, in others it can have degrees of freedom in certain planes. Freedom is needed so that the roof is not blown off by the wind, so that the elements do not collapse when the soil moves, the log house dries out, etc.

An example of calculating a roof on a bathhouse 6 by 6 meters

Suppose we need to calculate a gable roof on a bathhouse 6 by 6 meters in plan. We decided to make the slope 30 degrees, and chose metal tiles as the roofing material. The bathhouse itself is located near Nizhny Novgorod.

We go to the appropriate calculator and enter our data. Nizhny Novgorod is in zone 4, we’ll figure out the rest as we go - for an angle of 30 degrees, the rise will be about 175 cm (trigonometry, the leg and the opposite angle are given). The length of the overhangs suits the pitch of the rafters and the parameters of the sheathing too. We will use 1st grade wood for the rafters.

As a result, we have: roof area - 47.68 sq. m. Metal tile weight 286 kg. Rafters 22 pieces, with a minimum cross-section of 40x150 mm, length of each 297 cm, total weight 241 kg. The same data for the sheathing.

As you can see, the calculator eliminated unnecessary engineering pains, and with such data you can already start working.

Video description

The process of manufacturing and installing rafters is shown in a very detailed and accessible video:

Roofing device

All that remains to do on the finished rafter system is to fill it with sheathing and cover it with the selected roofing material. If the roof needs to be insulated, then the insulating material is laid between the rafters, and on the inside it is covered with a vapor barrier film, securing it with transverse slats that will hold the insulation.

A waterproofing roll material is attached on top of the rafters, thus protecting the insulation on all sides from moisture penetrating into it. To create a ventilation gap, counter-lattice slats are fixed to the rafters, and the sheathing is mounted on them.

Diagram of an insulated roofing pie Source stroyvopros.net

Finally, the ridge is attached, the gables are sewn up and the eaves overhangs are formed.

Making a choice

Now let’s try to answer the questions that often arise among bathhouse owners.

What is better to cover: corrugated sheeting or metal tiles

Above we have already described the properties of corrugated sheets and metal tiles. Now let's think about what is better to cover the roof of the bathhouse, if the choice is between these two.

Approximately, the price of metal tiles is two times higher than corrugated sheets (approximately). Consequently, its advantages should also be “twice” more noticeable.

Both materials, as mentioned, are susceptible to rust if they are not made of copper or aluminum, but the use of non-ferrous metals sharply increases the cost of the material.

Metal tiles usually have a well-protected top layer in contact with the atmosphere, but the bottom layer needs protection, so you need to do a good vapor barrier and ventilation to prevent condensation.

Installation of metal roofing. Cromwell Photos

Corrugated sheeting also has a coating, but, as you saw in the video, it is sold as “made in Italy”, and it begins to rust after the first condensation.

In essence, here both materials are equal and depend too much on the manufacturer and his honesty.

In both cases, by the way, the attachment because they are penetrating. Therefore, it would be a good idea to varnish them and cover them with wide fastener caps.

Both materials are noisy, this was also mentioned. Both have low thermal insulation . Both weigh little .

Actually, the whole difference comes down to one single subjective factor - beauty. Metal tiles look prettier and “richer” than corrugated sheets, which are traditionally used to cover garages, sheds and other outbuildings. If appearance does not matter, corrugated sheeting will cost less. Otherwise, rely on metal tiles.

How to cover inexpensively and efficiently

Here we dare to present our own vision of what can be used to cover the roof of a bathhouse inexpensively and with high quality.

Based on real budget savings, the optimal material can be called ondulin or economy-class bitumen (flexible) tiles. Both materials are bitumen based.

Ondulin costs approximately the same as corrugated sheeting, while flexible tiles cost the same as metal tiles. Of course, bituminous shingles come in very different prices, but they are cheaper than the tiled variety of ondulin - onduvilla.

It’s also convenient that if you have to make repairs, it’s much easier to replace a sheet of ondulin or flexible tiles than corrugated sheets (they try to take them in such a way that there are no horizontal joints, which increases the area of the sheet).

Insulation of the ceiling in a bathhouse with a cold roof

In order for the bathhouse to retain steam and heat inside the main room, which is its main function, the space under the roof must be filled with insulating material.

In this regard, the question arises of how to insulate the roof. Since there is high humidity, you should ensure against damage to the insulation and use a vapor barrier. Taking this fact into account, you should find out what is the best way to insulate the roof of a bathhouse.

There are bulk and solid materials, but for a bathhouse it is recommended to use the two most popular ones - expanded clay and mineral wool. To choose, you should decide which insulation for the roof of a bathhouse is better.

Expanded clay

Expanded clay belongs to the class of insulation that is used inside the roof, since it is free-flowing. It can be used to fill the overlap of the sheathing, after which you can make a deck and even create an attic roof.

It allows not only to reduce heat loss, but also has a number of other advantages:

- increases noise insulation characteristics;

- frost resistant;

- fireproof;

- does not change structure with temperature changes;

- It’s easy to calculate the required amount of insulation.

Expanded clay is not of interest to rodents and insects, so damage to thermal insulation for these reasons is unlikely.

With prolonged use, the insulation will not harm human health, since it is created without the use of chemicals. The cost makes this material one of the best even for a budget bathhouse made of blocks, because with good characteristics, the purchase will not hit your wallet.

The list of disadvantages includes the fact that a thick layer is filled with expanded clay, which at a level of 50 cm will take away a significant living space.

Important!

If you add less, the insulating qualities will be worse, heat and sound will pass through the insufficient layer.

Expanded clay will require high-quality waterproofing, which will protect the material from increased moisture; this makes repairs more expensive. The insulation is poured into the bottom layer, a vapor barrier is laid above and boards or lathing are placed on top of it.

Photo

Bathhouse with a pitched roof, frame. Photo by Stroydom

Photo of the company We Build a House

Project. Photo by NZSK

Photo by Uralekodom

*** While this article was being written, more than once or twice I wanted to tell the reader that it is not worth taking on such work without any experience. To some extent, experience can be replaced by reading books on the topic. For example, we can recommend Savelyev’s book “Roof Structures. Rafter systems." The pictures in the article are taken from there.

More information on the topic:

- Pipe in the bathhouse through the ceiling and roof

- Bathhouse with barn under one roof

- Do you want a house with a bathhouse under one roof?

- What can a bathhouse with a veranda/terrace/gazebo under one roof look like?

- Advantages and disadvantages of a bathhouse with a garage under one roof and other combinations

- Bathhouse with a terrace under one roof

For more information, see the Roofs of Baths section.