Izospan is an insulating film coating. The main purpose of the film is to ensure that the original thermal insulation characteristics are maintained throughout its entire service life. It is difficult to imagine a modern construction project without the use of various types of thermal insulation. Mineral wool, Penoplex, Izolon, Izover, various polystyrene foams and simply polystyrene foam - all these materials require their own protection.

Thermal insulation materials practically envelop our house, retain heat on frosty and rainy days, create comfort in the hot summer, preventing the penetration of heat flows. But how to protect the thermal insulation belt from negative atmospheric phenomena? Reliable protection from moisture, rain, damaging winds is designed to be provided by 100% polypropylene, with the proud name - Izospan .

To create a barrier at the stages of the construction process, to perform the function of protective insulation for thermal insulation, this is the true purpose that isospan vapor barrier successfully fulfills. Despite its apparent simplicity, the material differs by type.

We bring to your attention – Izospan instructions for use. Figure it out: which side to lay the isospan on. Consider the isospan technical characteristics, and the installation method.

Worthy competitors of isospan:

- Tyvek vapor barrier;

- Vapor barrier TechnoNIKOL;

- Vapor barrier Nanoizol;

- Vapor barrier Ondutis;

- Vapor barrier Yutafol.

Before moving on to a detailed review, it should be clarified that the films are presented by the manufacturer in a wide variety and have different purposes. Vapor barrier films and membranes are divided into absolutely vapor- and water-tight and partially permeable to moisture only in one direction. Some of the materials successfully complement thermal insulation, enhancing its characteristics.

Questions arising during installation

Many questions arise for those who do not have the opportunity to build a house on their own and decide how to insulate their premises, what material to choose and what to do with the floor?

When the question arises about vapor barrier of an existing room with its own initial data, you need to take into account the condition of the ceiling. There are cases when owners stick isospan to a plastered ceiling and expect that condensation will not appear on the loggia or in another room, thanks to the magical properties of the membrane. They make a mistake in advance: isospan does not fit on structures that are already plastered or insulated with mineral wool.

Insulation of this kind does not require a vapor barrier, and plaster is already a type of interior finishing. Flooring will lead to consequences that will then have to be eliminated.

To insulate the roof from the outside, a different type of material, type A, is required. It will be installed according to different principles and reasons. And for insulating the roof from the inside of the room, the flooring technology remains the same.

Izospan in the attic type attic

If the film breaks during installation, you can seal it with construction tape. This must be done very carefully so that the sealed layer is not damaged later.

Izospan under galvanized profiles

In addition to vapor barrier of ceilings, similar work must be carried out on the floor or walls, but for this, completely different types of membrane film and technologies for its laying can be used. The main thing is to understand what type of film is needed for construction or repair work, so as not to purchase something that turns out to be unnecessary.

The use of isospan for ceilings is described in detail in the instructions for use. If you have doubts about the choice of material, it is best to consult with specialists. Installing isospan on the ceiling is easy to do yourself if you study the necessary information in advance.

Prices

Prices for polymer film depend on the type to which it belongs and the manufacturer that represents it on the market. Izospan is sold in rolls with the waterproofing side inward, the area of one roll is 70 sq.m.

The price for one roll of types A and B, which are suitable for use on the ceiling, can range from 1000 to 2000 rubles.

Self-adhesive Izospan tape is available for sale, which is used in different qualities. It costs about 500 rubles. per piece, it contains about 30 m.

Often, unscrupulous manufacturers want to pass off their products as isospan, so when purchasing, you should ask about the presence of a quality certificate and compliance with production standards. To calculate the amount of product, there are special online calculation calculators on the websites of special construction companies or intermediary stores.

By the way, you can buy good eurolining on the company’s website RealWood.ru. Good quality and reasonable prices.

Briefly about the choice of materials

Above, we dwelled a little on a rather important point, the better to insulate the ceiling of a bathhouse. Now we want to tell you a little more

First, let's look at basalite and isospan, intended for saunas.

Basalite is an excellent material for thermal insulation of bath ceilings. Click on photo to enlarge.

Basalite is a lightweight and elastic tile insulator. It is made from basalt fiber, hence the name.

The scope of application is quite wide. In addition to insulation, basalite is used for sound insulation. The main thing is that no significant loads are placed on the surface to be coated.

As for isospan, it is divided into two types. Izospan A performs the functions of water protection and vapor insulation. Essentially, it is a membrane that counteracts the influence of moisture.

The material is often used in the construction of wall structures and roofs of buildings. Not to mention the protective properties that prevent premature damage to the insulation.

Izospan B refers to universal vapor barrier products that include two layers. The main task is a vapor barrier for thermal insulators.

The material is installed from the inside of the insulation.

Sawdust, covered with an earthen layer on top, is also suitable. Frankly speaking, this is not the best way, as it has many disadvantages.

There is also expanded clay. The material is made in the form of clay capsules, fired under high temperatures. When swelling of the raw material occurs, it is sent for heat treatment. This is how finished products are obtained.

Despite the presence of many other insulators, insulating the bathhouse ceiling with expanded clay is not without meaning. The excellent thermal insulation qualities of the products are explained by their cellular structure. In addition, expanded clay is an affordable material that almost everyone can afford.

The only thing to consider is the thickness of the insulating layer. It should be at least 30 cm. Plus, do not forget about the vapor barrier and waterproofing, otherwise the efficiency of the system will leave much to be desired.

What is the situation with other parts of the structure?

If you are new to insulation, the information above may have been misleading.

We examined the ceiling in detail, but did not touch other elements of the building at all. In fact, not only the ceiling surface, but also many other parts of the bathhouse need to be thermally insulated. These include the foundation, walls, floor, roof, etc.

And don’t expect to do anything quickly. Ultimately, you end up with a building from which heat escapes extremely slowly. It will not be possible to completely plug the leak. Yes, this is not necessary. Any building must be well ventilated, including the bathhouse.

In steam rooms, the warmth does not disappear immediately after the rooms are warmed up, but lasts for a certain time so that you can have a good steam bath.

Want to know what's coming? Check out the photo of how to insulate the ceiling of a bathhouse, and other images presented in the article. We recommend that you read our other publications on the topic. Have a hot steam!

Which side should the vapor barrier be laid to the insulation?

Knowing which side to lay the vapor barrier against the insulation on the ceiling, wall or floor is very important when working on insulation. It only at first glance seems that which side to lay the vapor barrier against the wall insulation does not matter, but in reality this is not the case. We will tell you in this material why a vapor barrier is needed and its purpose. Watch the video - which side to lay the vapor barrier on, how to distinguish the inside of the vapor barrier film from the outside.

The need for high-quality thermal insulation of premises arises very often. If you plan to insulate a wooden house with your own hands, then many questions arise about how to do it correctly. And one of the important questions concerns the need to use a vapor barrier, the place of the film in the thermal insulation “pie” and which side to lay the vapor barrier against the insulation on the wall.

Which side is the right side to lay the isospan on?

The first question that beginners have is choosing the right side of the material. The main purpose for laying isospan on the ceiling is to protect the insulation from moisture penetration. Therefore, for maximum efficiency in performing the required tasks, the smooth layer of material should always face the insulation. Along with this, external and roofing work with this insulator has some differences. When choosing which side to lay isospan on, remember that for the roof it is more important to ensure unimpeded escape of steam to the outside and protection of the insulation and ceilings from precipitation. In this case, the smooth side of the material should face outward.

Why should you use a vapor barrier?

The air inside the room is saturated with moist steam, which tends to leave the house through the walls and ceiling. In the cold season, it turns into condensation, settling in the insulation and on the surface of the building structures. High humidity significantly reduces the insulating properties of insulation and causes the appearance of mold and mildew on the surface of ceilings and walls.

The installation of a vapor barrier layer that retains moisture and does not prevent its evaporation will eliminate these problems. Among the numerous products designed to protect a building from negative impacts, materials from the Russian brand Izospan are deservedly popular. The company's films and membranes are made from polymer materials and receive special properties. The dimensions of the canvases are selected in such a way as to make installation as easy as possible, and high strength ensures long service life.

Self-vapor barrier of a bathhouse

Steam moves upward and to the sides, which means that the ceiling and walls are more susceptible to its influence. However, if the vapor barrier is of poor quality, it can rush into any loophole, causing damage to the material and freezing. Without waterproofing the washroom floor, all insulation measures will not be enough. When the floor is sealed and the walls are insulated, they begin laying a vapor barrier in the sauna or bathhouse.

Vapor barrier and insulation of the bathhouse ceiling protects it from maximum thermal loss. There are two options for the insulating “pie”:

- The surface is sewn up with a board or die from 5 cm thick.

- A vapor barrier is installed on top (outside the room).

- A 1-2 cm layer of clay is applied and mineral insulation is laid (foam glass, expanded clay, mineral wool, etc.).

- A boardwalk or cement-sand screed is made on top.

Particular attention should be paid to vapor barrier in the steam room, where the temperature under the ceiling is maximum. Even with thick sheathing, the plastic film can melt, and the impregnated materials will begin to evaporate toxic or strong-smelling substances

It is better to use lining made of hardwood, for example, aspen. When heated, resin emerges and drips from the needles. A high-quality product made of foamed polypropylene can withstand +100 °C, film foil insulation - up to +140 °C.

The second option provides an air gap:

- A finishing panel is assembled from a tongue-and-groove board 2-3 cm thick and attached to thick beams with a cross-section of 20 x 20 cm.

- The boards are rubbed twice with drying oil for water resistance.

- Transverse sheathing boards are placed over the beams.

- The vapor barrier is laid with foil inside the room and secured with mounting rails. The joints are sealed with aluminum tape.

- Sand, slag or specialized insulation is poured on top.

Save money with reflective film

Installation of foil vapor barrier on the walls of a bathhouse also requires an air gap. If it is in contact with the skin or other surface, heat is conducted by aluminum, like any metal. This rule answers a common question from home craftsmen: which side should the vapor barrier be laid on? Obviously, you need to reflect heat inward, not cold outward. When used correctly, this option pays for itself twice its cost.

If you want to save money by choosing cheap materials for the dressing room and washing area, remember that the service life of polyethylene is very short. First of all, it cracks at the folds left over from the factory packaging. They should be reinforced with tape when installing the vapor barrier. If the film has lost its tightness, the insulation will begin to dampen, so it is better to use hydrophobic products in advance. It will be more profitable to buy a vapor barrier for Izospan baths due to its exceptional durability and unique properties.

Foil vapor barrier Izospan FB is designed specifically for rooms with elevated temperatures. Its technical characteristics allow the film to be laid directly on the wall without additional thermal insulation. The rolled web is stretched with transverse strips and secured with vertical slats. The sheets are mounted from bottom to top, overlapping, with a margin of 15 cm and the joints are glued with heat-resistant aluminum tape. A wooden sheathing is placed on top of the vapor barrier. The gap between it and the foil should be at least 4-5 cm.

Which side to lay the vapor barrier on?

For external walls (using Izospan A as an example):

The film is attached with the smooth side to the street, and the rough side to the insulation. The same principle is used in subfloors.

Side of laying the vapor barrier for the under-roof space (using the example of Izospan AM):

the white side is towards the insulation, the dark (brown) side is out.

Vapor barrier side on the basement floor inside the house:

rough side to the insulation.

Installation of vapor barrier from the inside - on floors, external walls and partitions:

The film is laid with the smooth side facing the insulation.

Options for completing insulating materials

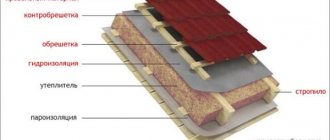

The schematic diagram of the construction of an insulated ceiling pie is applicable to all types of insulating materials. True, depending on their ability to pass steam, there may be some deviations, for example:

- When using extruded polystyrene, laying a vapor barrier on the ceiling located above rooms with “dry” operating conditions is not necessary. This type of insulation has almost zero vapor permeability and therefore does not require additional protection.

- When arranging the ceiling of rooms with “wet” operating conditions, a vapor barrier is installed in any case, regardless of the insulation layer used in the construction and its characteristic properties.

- When using mineral wool of all degrees of hardness and polystyrene foam, the ceiling must be protected with a vapor barrier layer.

The vapor barrier material is laid in the form of a kind of pallet, the “walls” of which should be higher than the thickness of the insulating layer. If the panel ceiling is assembled from boxes with insulation, then the vapor barrier material in exactly this form is placed in each of them. If thermal insulation is planned to be laid in the space between the joists, then they are wrapped with a vapor barrier membrane.

When using polyethylene film or glassine as a barrier, there should be a ventilation gap of 2 - 3 cm between the insulation and the vapor barrier. To do this, slats are fixed on the ceiling from the side of the premises, which at the same time serve as the basis for lining it with clapboard, decorative panels or plasterboard.

You need to think about how best to lay a vapor barrier on the ceiling when designing a house. It is at this stage that you need to choose the optimal installation option and think over the fastening scheme.

However, now there is always an opportunity to correct the shortcomings of builders and designers that appeared during the operation of the house. For example, you can correctly glue a polypropylene membrane to the ceiling. You just need to understand the characteristics and technological features of suitable materials.

How to lay a vapor barrier correctly

The question of which side to place the vapor barrier against the insulation depends on the manufacturer’s recommendations. If the packaging clearly indicates which side should be facing towards the structure and which should be facing inside the room, you must follow the instructions. If there is no marking or the packaging is damaged, it is worth considering the general installation rules.

First of all, the position of the “dew point” is taken into account.

Warm air from inside a building tends to escape into the cooler outdoor atmosphere (most of the year), with interior structures transferring heat relatively easily. Reaching the insulation, the heat flow gradually dissipates; the heat is absorbed by the loose mass of the insulating material. If the outside of the insulation is protected from atmospheric moisture by a waterproofing film, then the question of which side to place the vapor barrier on the roof is decided as shown in the illustration above - between the rafters and the insulation, the rough or reflective surface inside the house. For materials with identical sides (both smooth), the manufacturer does not give any advice regarding installation - the film can be turned towards the rafters with either side. Usually, in this case, it is customary to nail the film directly to the rafters with staples; accordingly, it is better to choose a material of increased strength. It will not sag in the spaces between the rafters and will not tear under the weight of the insulation.

When deciding which side to lay the vapor barrier in the attic from the inside, you should take into account information about whether the room is heated or not. For heating, the film is laid on the inside of the rafters so that there is a gap of 10...15 mm between the insulation and the film, with the reflective side facing the inside of the room. If the roof gets very hot and moisture condenses on the outside, you can turn the film the other way around. In this case, it is convenient to use a material with a rough surface for moisture condensation.

In the case of installing a vapor barrier in a room, the question of which side to place the vapor barrier on the ceiling is solved as follows: for ordinary rooms, the reflective or rough side turns into the room, for rooms above hot and humid rooms (for example, a relaxation room above a steam room) - vice versa. The same goes for gender. Vapor-impermeable films can be installed arbitrarily.

For walls, the general principle is used - you need to retain heat inside the room. Therefore, the vapor barrier is installed from the inside and usually with the help of dense, vapor-impervious, reinforced polyethylene films. Here, the question of which side to attach the vapor barrier to the wall is not fundamental - the films retain heat and moisture equally, regardless of the mounting side.

Recommendations for installation and use

Vapor barrier film Izospan

B is placed indoors. It is used for insulated roofs, floors, attic floors, and walls. The manufacturer's instructions and information about the material give you an idea of which side to turn the panel towards the heat insulator during the fastening process. The smooth surface always adheres to the thermal insulation, while the fibrous surface remains on the outside and stops moisture from steam, preventing it from penetrating inside the structure.

The vapor barrier is laid with an overlap of panels of 15-20 cm, installation is carried out from the bottom up. The connecting places require good sealing; for gluing, a specialized adhesive tape produced by the company and marked FL is used.

Izospan tape is also suitable

SL. The areas adjacent to the structure, sheathing, utility holes and niches are sealed using self-adhesive sealing tape, which is simultaneously pressed against the protective sheet and the contacting surface.

Installation of the film when insulating a roof with an inclined surface is carried out according to the following scheme:

- the roll is cut into strips of the required size;

- the first strip is attached from below parallel to the floor, with the smooth part to the heat insulator;

- the next tape is installed, covering the fixed film by 15 cm;

- the panels are fixed with a stapler for construction work or with galvanized nails to the rafters of the building;

- the joints are covered with sealant using specialized SL tape;

- a frame frame is placed on top of the vapor barrier, forming a clearance of 40-50 mm;

- The cladding material is attached to the wooden slats.

Fastening Izospan B when insulating the floor (floor) occurs in stages:

- the canvases are laid with the rough side towards the base floor (ceiling);

- the places where they adjoin the surface of the walls and the joints of the tapes are coated with glue using SL tape;

- the heat insulator

lies on a smooth film surface; - waterproof Izospan C is laid on top;

- The floor covering is being installed.

When attaching a vapor barrier to internal walls and partitions, the panel is placed directly on the heat insulator

and is attached to wood slats. First of all, a frame frame is stuffed on top of the film, creating a gap for ventilation of at least 30 mm. During further gypsum cladding, installation is performed on a zinc profile.

Application of Izospan B, which protects the heat insulator

and the wall surface from moisture, extends the service life of thermal insulation and the entire structure of the building.

Laying vapor barrier Technology, errors

The purpose of vapor barrier work

Wooden structures are very susceptible to moisture. This can cause the wood to swell and warp. The floor is an area that can come into contact with moisture on both sides. Soil moisture, as well as the constantly changing microclimate of the room, negatively affects the floor of the building.

In kitchens and bathrooms, water can often spill on the floor, although the humidity in these rooms is always high. This two-way bombardment of moisture can very quickly destroy the foundation or lead to the appearance of mold or mildew in the house.

In view of this, it is advisable to hydro and vapor barrier the floor in a wooden house. Thanks to such building material as Izospan for flooring, it is possible to qualitatively protect wood from moisture and condensation.

Some features of a pie on the ceiling

In general, when constructing an insulated ceiling pie, the same ceiling vapor barrier scheme is used, regardless of the type of materials used for insulation

However, their capacity may make some changes, so it is important to know how to properly lay a vapor barrier on the ceiling

In particular we are talking about the following:

- The use of extruded polystyrene foam in rooms with low humidity levels allows you to skip the vapor barrier layer. This is explained by the fact that insulation of this type practically does not allow moist warm air to pass through, therefore, it does not require additional protection.

- In rooms with high levels of humidity, a vapor barrier layer must be present regardless of the type of thermal insulation material and its characteristics.

- Laying mineral wool of any hardness and foam is always accompanied by the use of vapor barrier material.

In the process of deciding how to lay isospan on the ceiling, it is necessary to ensure that the edges of the insulating material are located at a higher level than the upper edge of the insulation. In other words, the thermal insulation is placed in a kind of bowl made of vapor barrier material. In the case of a panel ceiling, a vapor barrier material is placed in each box under the insulation. When laying thermal insulation in the space between ceiling joists, they should be wrapped in vapor barrier material.

The method of using vapor barrier material must be considered at the design stage

It is important to choose the right installation method and options for fixing the material. With the advent of new technological insulation materials on the market, it has become possible to correct mistakes made during the installation of the vapor barrier layer

The main thing is to know the characteristics of the insulation used, how to lay isospan on the ceiling, as well as the technological features of the selected material.

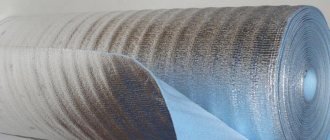

Vapor barrier with reflective layer Izospan F

The third group of materials is vapor barrier films with the effect of heat reflection. They differ in that the outer layer is a metallized film (lavsan or polypropylene). They can be used instead of similar materials (vapor barriers) in all of the above structures. If there is an air gap, the material is able to reflect thermal radiation back into the room.

| Name | Type of metallized film | Maximum elongation in transverse/longitudinal direction N/50 mm | Vapor permeability | Withstands water pressure, mm.water.st. | Withstands ultraviolet radiation (without protective coatings) for at least months |

| Izospan RF | polypropylene | 450/300 | No | 1200 | 3-4 |

| Izospan FD | polypropylene | 800/700 | No | 1200 | 3-4 |

| Izospan FS | polypropylene | 300/330 | No | 1200 | 3-4 |

| Izospan FB | lavsan | 350/340 | No | 1200 | 3-4 |

| Izospan FX | lavsan | 176/207 | No | 1200 | 3-4 |

Energy-efficient vapor barrier Izospan F is installed on the side of the room. When installing, turn the shiny side toward the room. The use of this group of materials can reduce heating costs by about 10%, but there is still debate about this: not everyone believes in it.

Metallized vapor barrier Izospan

The second area of application for Izospan F is the underlay for finishing floor coverings. Under laminate, parquet boards, and film heated floors, it is recommended to use Izospan FX. This is foamed polyethylene 2-5 mm thick with a metallized film glued. In addition to reflecting heat, it also acts as thermal insulation. Any other material of this group can be placed under all other coatings.

Using Izospan F in a heated floor system

When laying a heated floor system in a screed, the cake remains the same. Only a pipe or cable is added. But they need to be laid according to a certain pattern, so a metal mesh is also needed. Water heated floor pipes or an electric heating cable are tied to it.

Which Izospan to use under heated floors

In order not to heat the ceiling of the neighbors below, it is advisable to direct the heat as high as possible. To solve this problem, insulation is laid on the slab, and waterproofing with a heat-reflecting effect is placed on it. In this case, the material does not allow water to enter the slab and reduces heat loss during operation. For heated floors, it is recommended to use Izospan RF, FX, FD, FS.

Izospan B characteristics and specifics

Regardless of the purpose of the building being built, protection from steam and moisture should be installed. It is for this purpose that Izospan B film was developed. It is a sheet of propylene, one side of which is smooth, and the other is covered with perforations, creating roughness. After unfolding the material, the question arises which side to the heat insulator should be installed

? To properly fix the vapor barrier film, you need to understand how it works.

The main purpose of the film is to protect the thermal insulator from getting wet, and the room from the penetration of small particles of thermal insulation material. This is especially necessary when placed as insulation for min. cotton wool, which is more sensitive to moisture and has the unpleasant tendency to distribute small fibers.

The smooth surface of the canvas forms an airtight barrier for steam, and the non-slip coating is a place to collect condensation, which subsequently erodes. The film has the following technical properties:

- resistance to direct ultraviolet exposure for 3-4 months;

- steam resistance - 7;

- density - 72 g/m2;

- tensile load - 130 (longitudinal), 107 N/5cm (transverse);

- composition - 100% polypropylene;

- moisture resistance - 1000 mm water. pillar;

- operating temperature - from ?60? up to +80? C.

Membrane fabric is distinguished by its reliability and elasticity; it protects metal structures well from corrosive processes, and the heat insulator

and wood elements from fungus and mold. The product is produced in rolls with a width of 1.4 and 1.6 m, area - 35, 70 m2.

Material properties

Polymer-type membranes have earned positive reviews due to their room protection properties:

- Ability to conduct heat.

- High density due to membrane type structure.

- Waterproof.

- Strength, resistance to external influences, breakthroughs.

- Ability to protect against ultraviolet rays.

- Modern technologies make it possible to produce building materials with a high degree of environmental safety - this applies to all types of isospan.

Floor vapor barrier instructions

Installation of Izospan on the floor

Everyone knows that moisture is the enemy of wooden buildings. It has a significant, sometimes negative, effect on wood. You can avoid disastrous results only through high-quality vapor barrier.

Why Izospan

The advantages of using Izospan in comparison with other methods of vapor barrier are obvious:

- on the one hand, it insulates the wood from moisture;

- on the other hand, it in no way affects the flow of air, without which, of course, the wood will not last long.

Types of Izospan for the floor

This material has gained popularity among consumers as a non-alternative option for floor insulation. Which Izospan is right for you? It’s difficult to answer unequivocally, but let’s imagine the varieties that are most suitable for insulating the floor from moisture.

- Izospan AM is a universal product that can act as insulation for both roofs and walls, and for floors to protect insulation in unheated attics. Mounted with the white side to the insulation.

- Izospan AS is a three-layer membrane, durable, suitable for floors. It is used similarly to Izospan AM.

- Izospan B is a two-layer material that copes well with its function. The best option for vapor barrier of indoor floors.

Preparatory work before direct installation of Izospan

You need to start with the fact that all the boards that make up the floor are treated with a special mixture, which does not allow them to rot, attract the attention of insects, etc. If the floor has already been rebuilt, then this action will need to be carried out by dismantling the floor. After dismantling, it is necessary to replace particularly worn materials, processing new ones according to the already announced scheme.

Laying vapor barrier

Isopan laid on the floor

Even a non-specialist can carry out this procedure, guided by the presented sequence of actions.

When vapor barrier of interfloor ceilings, Izospan B is laid on top of the insulation, securing it with a stapler and sealing it by gluing the joints. Be sure to provide an overlap of 15–20 cm.

Application in certain areas

The use of a vapor barrier material greatly extends the service life of the insulation and, as a consequence, the entire building structure. Its main task is to prevent the penetration of condensate and the formation of fungus.

Insulated roof

A membrane or polyethylene film is a mandatory element when constructing an insulated roof. It is mounted on the elements of the supporting frame, less often - on the rough finish. It is necessary to ensure that moisture formed due to temperature differences does not get on the insulation. To enhance the characteristics of the joints (overlapping), Izospan SL is glued.

|

External wall insulation

The structure of the product is such that it is equally successfully used for both external and internal insulation. The main thing is that the film should not be exposed to direct sunlight - they significantly reduce the service life and generally have a negative effect on the canvas. For exterior finishing, the smooth side also faces the heat insulator.

|

Floor structures

Installation of Izospan is recommended when arranging interfloor and basement floors to isolate the insulation from moisture and at the same time to prevent its fibers from entering the living space.

Polyethylene is laid between the cladding and the rough ceiling with the perforated (reverse) side down and directly above the insulation itself, with the rough surface facing it.

To seal the joints, it doesn’t matter whether they use series B or FX; when they are laid end-to-end, they are glued with KL or SL tape

|

Flooring

When laying any floor covering on a concrete, brick, cement or other base (with the exception of wood and its derivatives), be sure to lay a layer of vapor and waterproofing to compensate for temperature differences and absorb condensation. They lay the canvas directly on the screed, they can lay it with insulation if the decorative coating is thin, or they can immediately lay parquet or laminate on the base.

|

Types of Isospan

Let's start with what Izospan is. This is the trademark under which the Tver company Hexa produces non-woven building materials - films and membranes for various purposes. In short, there are vapor barrier, windproof and waterproofing roll materials. There are a lot of materials, so the names, applications and features are summarized in a table. It's easier to navigate this way.

Instructions for use of Izospan depend on the area of its application

| Name | Purpose | Application area | Structural features | Properties |

| Izospan AQ proff | Vapor-permeable hydro-wind protection | Sloping roof (insulated and non-insulated), frame walls, wall insulation, ventilated facade, attic and interfloor ceilings | Three-layer reinforced membrane | Protects from wind, allows steam to pass through, but retains moisture |

| Izospan AQ 150 proff | Vapor-permeable hydro-wind protection | Sloping insulated roof, frame walls, wall insulation, ventilated facade, attic and interfloor ceilings | Three-layer membrane | -//- |

| Izospan AS 130 | Vapor-permeable hydro-wind protection | Sloping insulated roof, frame walls, wall insulation, ventilated facade, attic and interfloor ceilings | Membrane | -//- |

| Izospan AS | Vapor-permeable hydro-wind protection | Sloping insulated roof, frame walls, wall insulation, ventilated facade, attic and interfloor ceilings | Three-layer membrane | -//- |

| Izospan AM | Vapor-permeable hydro-wind protection | Sloping insulated roof, frame walls, wall insulation, ventilated facade, attic and interfloor ceilings, internal walls | Three-layer membrane | -//- |

| Izospan A base | Windproof membrane with vapor permeability | Basement over ventilated subfloor | Windproof membrane | Protects from wind, allows steam and moisture to escape |

| Izospan A with OZD | Vapor-permeable hydro-wind protection with increased fire resistance | Ventilated facades | Membrane with fireproof impregnation | Protects from wind, allows steam to pass through, but retains moisture and reduces the risk of fire |

| Izospan AF+ | Non-flammable wind protection and waterproofing does not prevent the release of vapors | Ventilated facades | Non-flammable membrane | Reduces blowing heat, releases steam, protects against moisture, does not burn or support combustion |

| Izospan B | Vapor barrier, waterproofing | Sloping insulated roofing, frame walls, wall insulation, attic, basement and interfloor ceilings | Two-layer material (smooth on one side, rough on the other) | Does not allow steam, moisture, or insulation particles to pass through |

| Izospan RS | Vapor barrier, waterproofing | Sloping insulated and flat roofing, frame and internal walls, attic, basement and interfloor ceilings, floors on concrete bases | Three-layer reinforced material | Does not conduct moisture in liquid or vapor state |

| Izospan B fix | Vapor barrier, waterproofing | Sloping insulated roofing, frame walls, wall insulation, attic, basement and interfloor ceilings | Izospan B with two adhesive strips for easier fixation of panels | Does not allow steam, moisture, or insulation particles to pass through |

| Izospan C | Vapor barrier, waterproofing | Sloping insulated roofing, frame and internal walls, attic, basement and interfloor ceilings, floors on concrete bases | Two-layer material (smooth on one side, rough on the other) | Does not allow steam, moisture, or insulation particles to pass through |

| Izospan RM | Reinforced vapor-hydro-insulation | Flat roofs, floors on concrete bases | Three-layer material with an additional reinforcing layer | Does not allow steam or liquid moisture to pass through |

| Izospan D | High-strength vapor-waterproofing | Flat roofs, non-insulated sloping roofs, floors on concrete bases | Two-layer material based on woven polypropylene fabric | High resistance to steam and moisture, increased mechanical strength |

| Izospan D fix | High-strength vapor-waterproofing | Flat roofs, non-insulated sloping roofs, floors on concrete bases | Izospan D with two adhesive strips for easier fixation of panels | High resistance to steam and moisture, increased mechanical strength |

| Izospan DM | High-strength vapor-waterproofing with anti-condensation surface | Sloping insulated and non-insulated roofs, all types of floors, frame walls | Izospan D with anti-condensation properties | High resistance to steam and moisture, increased mechanical strength, no condensation |

| Izospan RF | Reflective vapor barrier, high strength waterproofing | Insulated pitched roofs, all types of floors, frame walls, heated floors | Multilayer material based on non-woven fabric with a reflective (shiny) layer | Reflects thermal radiation, retains moisture in any condition |

| Izospan FD | Reflective vapor barrier, high strength waterproofing | Insulated pitched roofs, all types of floors, frame walls, heated floors | Multilayer material based on woven fabric with a reflective (shiny) layer | Reflects thermal radiation, retains moisture in any condition |

| Izospan FS | Reflective vapor barrier, waterproofing | Insulated pitched roofs, all types of floors, frame walls, heated floors | Non-woven fabric+metalized film | Reflects thermal radiation, retains moisture in any condition |

| Izospan FB | Reflective vapor barrier, waterproofing for saunas and baths | Saunas and baths | Kraft paper with metallized surface | Reflects thermal radiation, retains moisture in any condition, tolerates high temperatures |

| Izospan FX | Reflective vapor barrier, waterproofing | Insulated pitched roofs, all types of floors, frame walls, heated floors, parquet and laminate flooring | Foamed polyethylene + metallized layer | Reflects thermal radiation, retains moisture in any condition, has thermal insulating properties |

| Izospan KL | Double-sided adhesive tape | Sealing vapor barrier connections | Adhesive layer - acrylic | Width 15 mm, tape length per roll 50 m |

| Izospan KL+ | Double-sided adhesive tape | Sealing of material joints, fastening them to building materials (concrete, plastic, wood, metal) | Adhesive layer - acrylate | Width 25 mm, length 25 m |

| Izospan SL | Double Sided Joint Tape | Sealing joints of materials, fastening them to rough surfaces (stone, brick) | Butyl rubber tape | Width 15 mm, tape length per roll 25 m |

| Izospan SL proff | Double-sided high-adhesion bonding tape | For reliable fastening and sealing of junctions with other materials | Butyl rubber tape | Width 15 mm, tape length per roll 22 m |

| Izospan FL | Metallized Joint Tape | To connect the vapor barrier to the reflective layer | Polypropylene with metallized layer | Width 50 mm, length 50 m |

| Izospan FL Termo | Metallized connection tape with increased heat resistance | For connecting vapor barrier with a reflective layer in baths and saunas | Aluminum tape with adhesive layer | Width 50 mm, length 40 m |

| Izospan ML proff | High Strength Single Sided Adhesive Tape | For gluing materials to building materials | Acrylate | Width 50 mm, length 50 m |

| Self Adhesive Sealing Tape (SAL) | Foamed polyethylene with adhesive layer | Protection against leakage at the junctions of materials with rafters on roofs | Foamed polyethylene | Width 50 mm, length 30 m |

As you can see, all Izospan materials can be divided into three groups:

- Wind protection. This is a group of Izospan A materials and varieties. These are materials that protect the insulation from blowing, retaining heat. At the same time, they remain permeable to steam, but do not conduct/permeate moisture.

- Steam-waterproofing materials. These are Izospan B, C, R and several of their varieties. They do not allow moisture to pass through in any form.

- Energy-saving vapor-waterproofing Izospan F. It is distinguished by the presence of a metallized layer; it does not allow moisture to pass through in any form - neither steam nor liquid.

There are also connecting materials - single- and double-sided connecting tapes on different bases. They are needed during installation and allow you to avoid deterioration of performance at joints. Some allow you to achieve tight connections.

How to distinguish by name

The name of the materials contains a key letter, by which the group and main properties can be determined. So Izospan A with all other indices means a vapor-permeable membrane. Izospan V, D, C - hydro-vapor barrier. The difference between the films of this group and the first is that these materials (B, C, D) do not allow steam to pass through. The materials of the first group (A) conduct it (steam) and retain only water. The exception is Izospan A base. It does not retain water and conducts steam.

Instructions for use depend on the type of material

The third group is also hydro-vapor barrier. It differs in that it has a metallized coating. The names of materials in this group contain the letter F: FD, FX, FS, FB, RF. They are used to more effectively retain heat, since heat rays are reflected from the shiny coating. But reflection is only possible if there is an air gap in front of the film of 3.5 cm (or more).

After the first letter in the Izospan marking there is often a second one. It describes the special properties of a material. It can also be an abbreviation or short word. For example, the presence of the letter M or S indicates the presence of reinforcement. The fix prefix means that strips of glue are applied along the edges, so there is no need to use tape.

What tools and materials will be needed

To cut and lay vapor barrier you will need:

The material based on polypropylene fibers is quite durable, so there is no fear of damage. The only drawback is the rapid wear and dullness of the cutting edge of the knife. After laying it on the floor and fixing it on wooden slats, you have to cut the joint along the entire length so that the edges of the panels match perfectly without gaps or overlaps.

Preparing the base

All you need to do is clean the concrete base and try to make it as level as possible. If it is possible to fill the screed, then you need to make it, or sand and level the floor surface so that the difference in levels within a segment within one meter is no more than 3 mm.

For a wooden base, the concrete floor will need to be made at least 40 mm thick and must be reinforced with mesh. The last stage is to treat the concrete base with an acrylic primer. This will reduce the amount of latent water vapor on the concrete and simplify installation.

How to properly lay Izospan on a concrete floor

Technology for laying vapor barrier on concrete:

Izospan can be secured with a special KL+ tape; on wooden slats, in places where the edges of the waterproofing meet, we fasten it with ML-prof tape. To prevent the panels from coming apart when walking on them, the laid sheets are additionally glued with double-sided tape. It is clear that the subsequent screed should not be higher than the line where the insulation overlaps the wooden walls.

How to properly install Izospan when installing laminated and parquet floors

For parquet or laminate, the only option used is a polypropylene mat of the FX brand. A vapor barrier is laid out depending on the degree of preparation of the floors in a wooden house. Izospan is laid end-to-end if a wooden panel sublayer made of OSB or plywood was previously sewn onto the concrete base.

If the floor is concrete and has errors, then the vapor barrier is installed with a slight overlap at the edges. All that remains is to fix it on the leveling wooden slats on the walls and cut the seams to remove the overlap. It is recommended to stick double-sided tape under the laid Izospan. Wooden slats can only be removed after the installation of laminate or parquet flooring has been completed.

How to lay Izospan in the Warm Floor system

To install the heating system, special leveling mixtures are used to ensure acceptable floor geometry. This should always be done, even if the base of the floor is made of tongue-and-groove boards.

For the installation of a heating system, Izospan RX is mainly used for prepared floors; if the concrete base in a wooden house has small defects no more than 2 mm high, then Izospan FD can be installed.

The canvas is mounted on concrete with the foil facing up, always with an overlap of 15 cm without cutting at the joints. The edges of the panels are glued with metallized FL tape; regular or even double-sided construction tape cannot be used.

Preparation for installation of a water vapor barrier layer

Laying a vapor barrier involves carrying out a number of preparatory work. First you need to select materials for all layers of the so-called pie, and also decide which vapor barrier is best for the floor. This “pie” consists of the following stages (starting from the top):

- Decorative floor covering. Plank floor. Vapor barrier. Counterrail. Insulation (counter slats between boards). Waterproofing. Rough floor.

Preparation begins with the subfloor. All boards, joists and other wooden parts must be treated with a special antiseptic composition that prevents rotting, the appearance of fungus, and also protects against insect attacks.

If we are talking about repairing the floor, and not about constructing a new building, then the finished floor boards, floor covering and existing vapor barrier on the floor must first be dismantled. All debris must be removed and then the wooden structure must be treated with an antiseptic.

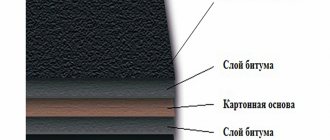

Types of vapor barriers for insulation

Among the modern materials for hydro- and vapor barriers presented on the construction market today, three main types can be distinguished:

The film is a blind vapor barrier that does not allow moisture to pass through. The main advantage of polyethylene film is its low price. Two-layer vapor condensate films are also produced - these are smooth on the inside and rough on the outside. Drops of water do not pass through the film, but are retained.

A diffusion membrane is a vapor barrier with limited vapor permeability, consisting of non-woven polypropylene and polymer film. It has an outer and inner side (see video), which allows steam to pass through it in an optimal amount. Water vapor does not linger in the insulation, but quickly evaporates.

The vapor barrier membrane (energy-saving) film has a metallized outer layer that is resistant to high temperatures. The material is more often used when insulating the walls of baths and saunas, because the material additionally reflects infrared radiation (works like foil penofol).

If glass wool is not protected with a vapor barrier during installation, then as moisture is absorbed, the thermal conductivity of the material will increase.

Roll waterproofing - used to protect building structures from moisture. When using this material, it does not depend on which side the waterproofing is laid to the insulation, since TechnoNIKOL roll and coating waterproofing does not allow moisture to pass in both directions.

Which side should the vapor barrier be laid against the insulation?

At first glance, it seems that there is nothing complicated - attach the waterproofing film over the insulation on the side of the warm room and you're done. However, there are some important nuances in this matter that you need to be aware of. It is also important to take into account which side the vapor barrier is laid to the insulation on the ceiling and what the installation features are. This is where previously acquired knowledge about the types of film used comes in handy.

How to distinguish the inside from the outside

If the manufacturer’s instructions are missing or do not contain the necessary information about which side of the film is considered internal, then you should independently determine this based on external factors. Please pay attention to the following points:

1 . If the waterproofing film has a different color on both sides, then the light side of the isospan is laid against the insulation ; 2 . The side of the waterproofing that faces the floor when rolled out is considered internal and should face the insulation; 3 . The outer side is made fleecy so as not to allow moisture to pass through, and the inner side is smooth and is laid towards the insulation.

Which side should the vapor barrier be placed on the insulation?

The polyethylene film is laid on either side, because they are no different from each other. The diffusion membrane (vapour-condensate film) is correctly laid with the smooth side on the insulation, and the rough side towards the warm room. Thus, it prevents the insulation on the ceiling or wall from getting wet, and excess moisture from the material can freely pass through the smooth side.

Also, diffusion membranes are mounted on the floor or wall with the smooth side facing the insulation. Vapor barriers with a foil side are attached with the reflective side facing outwards, as it reflects heat back towards the warm room. And it should be remembered that laying vapor-tight materials, for example, isospan, requires the installation of a ventilation gap to remove excess moisture.

If the internal cladding (false wall) is made closely without a gap, then it will be exposed to the influence of moisture settling on the film. If there is a gap, air movement will facilitate the unhindered evaporation of excess condensate from the surface of the film. It is important not only to know which side to put the isospan towards the insulation, but also to maintain the integrity of the vapor barrier itself.

Why do you need vapor-waterproofing in a floor structure?

In some floor structures, a vapor barrier is required. If we talk about insulation from steam, then there are two types of Izospan for floors:

Where is vapor barrier required? For example, in the construction of a floor on the ground. The soil under the floor always has some moisture. It may be more/less depending on the season and groundwater level, but moisture is always present in the soil. If the room is warmer or drier, moisture will move from the ground into the room. If a vapor barrier is not installed in its path, it will end up indoors and then there will be constant dampness in the house that cannot be overcome by anything.

Izospan is used for waterproofing and vapor barrier

Sometimes a vapor barrier layer is also needed in interfloor ceilings, but not always. Only where there are conditions for condensation. In apartments and on the second and higher floors of cottages, it is needed only where there may be high humidity below. If the room is located above the bathroom, kitchen, above the staircase, etc., then we add a vapor barrier to the cake. Downstairs in a room with normal humidity? You can save money on this layer.

In houses with basements, vapor barrier is needed, but, again, not always - only if the temperature in the basement can be below freezing. Even if the basement is unheated, but does not freeze, you can do without a vapor barrier. It is necessary to organize ventilation (vents) and you can do without using a vapor barrier. If you want to play it safe, please. It wouldn't hurt, but it's not necessary.

Which floor structures require vapor-permeable types of waterproofing? Where mineral wool insulation is used. In this case, we choose Izospan for the floor, which allows steam to escape, otherwise the insulation will get wet and lose its properties.