Despite the fact that every country house today has a bathroom with a shower or a comfortable bathtub, the bathhouse is an integral building on the site, because Russian people love to steam with a broom. And the main accessory of the bathhouse is the stove, which gives soft and light heat. Traditionally in Rus', sauna stoves were made of stone and brick, but in our time the approach has changed. Increasingly, owners are installing metal stoves and then covering them with brick.

This combination of metal and artificial stone is very successful: a metal stove heats up instantly, but cools down quickly, and brick retains heat for a long time. At the same time, it is not as intense and harsh as that coming from a metal stove, but rather soft and velvety. The lining also solves fire safety and the aesthetic side of the issue.

What materials are suitable for the construction of stoves?

First of all this:

- fireclay brick;

- red fireproof;

- alumina heat-resistant;

- clinker.

These materials are solid, they do not deform from heat, do not break - a stove made from such materials will last for many years.

You cannot build stoves from:

- hollow stones;

- silicate materials;

- slotted bricks.

The listed types of materials are not heat-resistant, quickly break down when heated frequently, become deformed, and do not retain heat.

Important: the stove can only be laid out of solid stone! Hollow ones are not able to withstand high temperature loads.

List of strengths and weaknesses of foam blocks as a material for a bath

Despite the recommendations of construction regulations on the strict selection of raw materials for the construction of bathhouse complexes (in particular, the ban on the use of cellular concrete and hollow bricks), many site owners prefer these items due to their availability and price category.

Analyzing the pros and cons of a bathhouse made of foam blocks, it is necessary to note the hygroscopicity of all concrete-based materials. This parameter is determined by the peculiarity of the internal structure of the raw material - the pores perfectly absorb water and steam molecules. The block is most noticeably destroyed when there is a sharp temperature conflict - hot air indoors and frost outside. Therefore, any building made of foam cellular concrete requires careful waterproofing of the internal walls with sheet foil, and the external walls with any facing material. These operations increase the cost of the project, making it unfeasible.

Considering the total costs of constructing a foam concrete building, it is better to build a bathhouse made of bricks.

Types of bricks for the stove

Chamotte

Fireclay brick can withstand up to one and a half thousand degrees Celsius! It is made from fireclay with the addition of fireclay chips and aluminum oxide. Then it is fired in a special way according to a strict scheme.

Externally, the stone looks porous, the color is faded red with a yellowish tint, dark inclusions are visible. It seems lighter in weight than usual, despite the fact that there are no cavities in it. Due to their lightweight weight, fireclay bricks heat up quickly and conduct heat well.

Most often, fireclay is not used for the entire stove - it is used in places that directly interact with the fire. This is explained by the high cost of the material: fireclay is 5 times more expensive than ordinary classic stone.

Fireproof red

This type of stone is cheaper than fireclay, so stoves are most often made from it. The base is refractory clay. The composition also includes coke and quartz powders, graphite chips.

Outwardly it looks like the well-known classic brick, but solid, without cavities. The color is yellower than the classic one. Suitable for laying out both the outer lining of the stove and those parts that come into contact with the fire.

The stone has a high heat capacity, that is, it is able to accumulate heat and then release it for a long time. From this material you can build a Russian stove, a barbecue stove or a bathhouse stove.

Alumina

The most popular material on the market in terms of price/quality ratio. It is fireproof and can withstand temperatures up to 1300 degrees Celsius. At the same time, it is durable, does not deform, and is not afraid of sudden temperature changes.

Bath stoves are often made from alumina brick: the material is so durable that cold water can be poured onto heated bricks to create steam. In this case, the stove will be suitable for use for many years.

Clinker

It is a heavy parallelepiped of dark color. The surface is smooth, practically without pores.

It is possible to choose such a stone for building a stove, but construction will be very expensive. Due to its high cost, it is rarely used in Russia. In addition, the maximum permissible heating temperature for clinker is 1300 degrees, which is slightly lower than that of fireclay.

A wooden bathhouse is the best classic option

Of course, the first thing that comes to mind is to build a wooden bathhouse. Indeed, a wooden bathhouse is considered the most popular, practical and affordable building. But even here there are so-called subspecies. Let's start in order:

- bathhouse made of logs or, as it is also called, made of logs

- sauna from a gun carriage

- sauna made of rounded logs (from the so-called “pencils”)

- bathhouse made of ordinary timber

- sauna made of profiled timber

- sauna made of laminated veneer lumber

From the above it is clear that wooden walls can be made in different ways and using different technologies. We will not consider all of them, especially since much detailed information can be found on the website. Let's touch a little on the topic of laminated veneer lumber - the most advanced wood material.

Bathhouse made of laminated veneer lumber

Coniferous wood is used to make laminated veneer lumber. Mostly pine and spruce, somewhat less often you can find timber from cedar and larch. First, the trunks are sawn into separate boards (the “tension” is removed from the wood). Then the lamellas are pressed, during which they are connected using natural wood glue. Due to this, the appearance of cracks, as well as various distortions during construction and further operation, is eliminated.

During the work, the profiled elements are tightly connected to each other, which means there is no need to caulk the walls, as is necessary when using logs. Due to the fact that the timber consists of several elements (lamellas), it has increased thermal protection, that is, you do not need to do additional insulation. A bathhouse made of laminated veneer lumber is not afraid of moisture, is not subject to rotting and is fireproof, since the material is impregnated with special agents.

Construction time is noticeably reduced, since such timber requires less time for shrinkage. Even before the installation is completed, you can begin interior and exterior decoration of the bathhouse, installation of doors and windows. Glued laminated timber is characterized by high strength and low weight, maintaining a stable shape without bending or distortion. From the above it is clear that such material has practically no disadvantages, except for its “cosmic” price.

Stamps

In addition to the variety of building materials, you need to pay attention to their brands. The main characteristics are the brand in terms of density and frost resistance.

The density grade shows the strength of the material. If the stove is located in a house or in a bathhouse, a brick with a density grade of 200-250 is suitable. The above indicator is completely unnecessary, since then kindling will take too much time.

Frost resistance must be taken into account when constructing a chimney, as well as if you are building an outdoor barbecue oven. The frost resistance grade shows how the stone absorbs and releases moisture. For pipes and street buildings, you need to choose the most frost-resistant brands.

The most common manufacturers

There are many factories producing bricks in Russia and neighboring countries. The most common types for laying stoves are:

"Borovichi". Produced at the plant of the same name in Nizhny Novgorod. Frost resistance is high, density 250.

"Vitebsk workshop". Produced in Belarus. Density 200, but frost resistance is very low. They can be used to line stoves indoors; such stone is not suitable for pipes.

“Chamotte.” It is produced by various enterprises, for example, the Belokamensky plant in Ukraine, the Sukholozhsky plant in Perm. It is recommended to use in the construction of those parts of the furnace that directly touch the flame.

Laying the plinth

The base is made somewhat thicker than the wall, but it is not necessary to adhere to this rule. The increase in thickness is done by half a brick. A higher value is not practical. Also, the base should not be made thicker than the foundation in the bathhouse. This will negatively affect the stability of the entire structure.

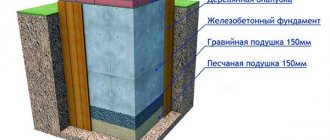

The foundation for a brick bathhouse is laid out in the same way as the walls. The sand cushion protects the foundation from soil antinodes. The bottom reinforced layer protects from failures. It is very beneficial to combine brick with concrete in the foundation. A concrete belt, which must be reinforced with long longitudinal reinforcement, will significantly add strength.

Choosing a brick by appearance

When buying a brick, you need to pay attention not only to what grade of density it has, how frost-resistant it is, but also how well it is made. To do this, carefully examine several stones from the lot. The edges of building materials must be smooth, without potholes. The edges of the stone are somewhat rounded.

Measure the angles: they should be 90 degrees. Measure the length and width of the stone: the maximum allowed difference is 1.5 - 2 millimeters from the dimensions declared by the manufacturer.

Ask the seller to show the chipped stone to evaluate its internal structure. In good material, the chip should be evenly colored over the entire surface. The uneven coloring of the chip and the presence of stains indicate that the internal structure is not uniform, and therefore not equally strong.

Another test option: lightly hit the largest edge of the stone with something metal (for example, a hammer). If the brick does not contain internal cracks, the hammer will bounce off with a ringing sound. A dull sound from an impact indicates defective material.

You can drop a brick: a high-quality one will crumble into several large pieces, while a poor-quality one will fall into small pieces.

Ask the seller to provide documentation on the brick’s compliance with GOST standards. The papers must indicate GOST standards and their interpretation. It must also be stated that the brick is suitable for the construction of ovens.

A few final words

The labor costs and money spent on lining a sauna stove are more than justified.

A brick casing increases the operational safety of a metal stove; heat is distributed evenly, since the artificial stone first accumulates heat and then releases it. And the heat is retained much longer; you can steam in the sauna comfortably for several hours in a row. The benefits are obvious.

- Date: 01/18/2015 Comments: Rating: 45

It is known that the result of a trip to the bathhouse depends directly on the quality of the installed stove. Most owners prefer to use this attribute in a metal version.

Of course, stoves of this type can be installed in a short time, heat up quickly, have attractive appearance and are notable for their low price. However, they do not retain the heat of the base for long and cool down in a short time. Therefore, there is a need to periodically add firewood.

If you have a metal stove in your bathhouse, then to improve the distribution of heat throughout the steam room and increase safety, it is better to line it with bricks.

To heat the entire room, you need to spend a sufficient amount of time. The walls of the stove become very hot, as a result of which they quickly wear out. To increase the time of using this attribute and create conditions for more productive distribution of heat throughout the steam room, experienced craftsmen often resort to covering its base with a certain material. Let's consider what kind of brick to line a sauna stove and what material will give the best performance.

Let's sum it up

So, which brick is better for the stove? To build a high-quality stove, you need to choose the right brick. It should be:

- Full-bodied.

- High Quality.

- Refractory.

- Density grade 200 – 250.

- Possess high frost resistance.

- Comply with GOST.

One final piece of advice: always buy enough bricks to avoid a situation where there is not enough building materials. It is not recommended to purchase additional bricks later, since stones from different batches may differ in color and quality.

Watch the video: “Which brick to choose”

Which sauna is better to build and how to choose logs for a sauna

Which log is better for baths? The answer is clear: pine is usually used for the construction of log walls.

The wood is harvested in winter so that it is more moisture resistant and has a high density. The diameter of the logs can vary between 180-250 mm. The main thing is that the difference between individual logs is no more than 3 cm, otherwise they will not fit tightly enough to each other.

Having decided which logs to build a bathhouse from, be sure to make sure that:

- there are no blue spots on the cut of the log;

- the core occupies three quarters of the cut and has a dark, uniform color;

- the surface of the logs is dark or light yellow;

- Before choosing logs for a bathhouse, check if there are any branches with gaps on them;

- the cut of the logs is hard, not loose;

- There are no resin pockets on the logs.

Stage 3: Waterproofing and insulation

In order for your brick bathhouse to be complete and functional, it needs to be properly waterproofed and insulated.

Waterproofing can be carried out using two methods:

- Painting - the internal surfaces of the structure are carefully treated with coating waterproofing compounds: bitumen mastic, rubber mixtures or epoxy resins.

- Pasting - surfaces are covered with panel or roll materials: sheets of roofing felt or foil-coated polyethylene foam. Either adhesives or wooden slats with self-tapping screws can be used as a fixative.

Interior arrangement of the bathhouse

Insulation is carried out according to the following scheme:

- Walls: lathing is placed on the surface, its spans are filled with insulation, and then the structure is covered with fiberglass and foil.

- Floors: insulation is laid on the surface, it is fixed on top with a metal mesh and filled with a thin layer of cent.

- Ceiling: a sheathing is mounted on the surface, which is filled with insulation and covered with sheets of plywood or foil.

The following can be used as insulation in a brick bath: thermoplates, polystyrene foam, mineral wool, fiberglass, penoplex.

After these two procedures, proceed to the interior arrangement and finishing of the steam room.

As you can see, brick is a good option for those who want to get a bathhouse, but are not eager to deal with the usual wood. Of course, this material is not easy to work with, so you will have to work hard during the construction process, but if you strictly follow the above instructions, you will be guaranteed a successful result in the form of a functional and comfortable steam room.

Preparatory work

If a brick partition is planned in a wooden bathhouse, then before this the structure must be stable, that is, shrinkage.

To connect the main walls of the bathhouse with the partition, pieces of reinforcement are mounted at one end into the wall and at the other into the masonry joints. The diameter of the rod should be 6 mm. If a brick partition in a bathhouse is placed near the stove, then it would be correct to leave a window for the combustion channel. The progress of masonry work is carried out in the following order:

- The first thick layer of mortar is laid, leveled with a trowel, and creates the base of the wall. We need to give it time to catch on.

- Then another layer - thinner - under the first row of bricks. The mortar is applied to the ends of the outer bricks with a trowel, pressed tightly against the wall and excess mortar is removed. Using a stretched string, the evenness of the rows is controlled. And the level shows horizontal and vertical.

- The laying of the second and each even row begins with halves of material. This - dressing - is done to evenly distribute the load.

- Every 3-5 rows, pieces of reinforcement or steel wire are placed on the cement to provide strength.

- In a similar way, the entire wall is driven completely up to the ceiling. The remaining gap is filled with small pieces and fragments soaked in solution. Small cracks are sealed with tow.

- If the bulkhead is planned with a door, then the frame is set up in advance. It is attached to the brickwork using steel strips. The bricks are laid close to it. Do not forget to control the horizontalness and evenness of the masonry by moving the stretched string higher.

- After the solution has hardened, the seams are sanded.

Between the sink or rest room and the steam room for ventilation during drying, you can place a small hole that can be closed during bath procedures with a shield or plug. After the partition is erected, the wall on the washing side is tiled, and in the steam room it is insulated, thermal insulation foil is laid and covered with clapboard.

Areas of use

Furnace laying

Currently, a lot of different stoves for baths are being produced, but we will consider a classic heater stove made of brick.

It is rightfully considered the most durable and beneficial in terms of healing effects.

Important: the foundation for the furnace must be laid separately from the main foundation, the distance to the nearest wall is made at least 50 mm and covered with sand. Plus, the size of the foundation itself should be 50 mm larger than the furnace around the perimeter.

Important: from the metal sheet and above, the stove is laid on fatty clay or modern special fire-resistant solutions. The thickness of the seam is made about 3 mm, it is convenient to control it; initially, 2 wires with a cross-section of 3 mm are placed on the brick; after laying, the wire is pulled out.

Screen in the bath

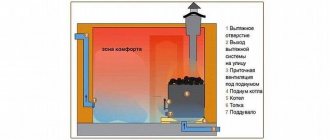

Quite often, metal stoves are used in the bathhouse. Modern metal stoves heat up the steam room quite quickly, but technologically many models require a brick screen.

The brick screen in the bathhouse acts as a case for the stove; it has channels for hot air convection and promotes smooth heating.

But when arranging the screen, you should take into account some of the design requirements.

Screen for a metal stove.

Salt screens

Nowadays, everyone knows the therapeutic effect of salt chambers, lamps, and therapy in salt mines. By installing a small salt screen in your bathhouse, you will greatly increase the healing effect of visiting such a bathhouse.

To arrange the screen, special salt bricks for the bath are used. This is a natural material that is cut from a single monolith of salt and has a strictly defined shape. Salt blocks can withstand temperatures up to 500˚C, so they can be used to create protective screens around a metal heater.

It is possible to completely or partially lay out the partition between the steam room and the relaxation room from salt blocks. The blocks are laid using special fasteners or an adhesive solution based on caustic magnesite and magnesium chloride 3:5, initially salt is dissolved in the water, and then magnesite is added. It can be laid on liquid glass, but it is not durable.

Walls made of salt blocks in the steam room.

Walling

A brick bathhouse is a structure that will last forever. But if you decide to build directly from brick and do not have practical installation experience, we advise you to turn to professionals, since the walls are laid in 2 layers, providing an air chamber between the walls, which can be filled with thermal insulation. For an amateur, this installation is quite problematic.

The most affordable material for building walls with your own hands is aerated concrete or foam concrete. The blocks are large and light and are fastened together using special glue. The blocks are easily cut with a hacksaw. In addition, their price is lower than brick or wood.

Important: aerated concrete and foam concrete absorb moisture, so during construction, the walls must be properly finished, and when finishing, the rule should be observed that the thickness of the interior decoration should be 2 times greater than the exterior.