Before purchasing or assembling a barrel sauna yourself, the question arises: is a special foundation needed for a barrel sauna and what can it be placed on? The questions are correct, let's figure out together what to install a barrel sauna on and what options there are.

The weight of a barrel sauna can be from 750 kg for the MINI model (2-meter steam room), to 2250 kg for a 6-meter barrel sauna of the Okta Exclusive model (with a side entrance). Therefore, you need to pay attention not only to leveling the site for the bathhouse, but also to building a foundation for its base stands.

Now we will look at several options for the foundation for a barrel sauna that can be made on your site.

Materials and tools

To install a barrel bath on the site you will need:

- Profiled tongue and groove board 45 mm thick and 90 mm wide. The length depends on the size of the bath. It is not recommended to use a tongue-and-groove board with a larger width - it will be difficult to join when laying it along a circumference;

- Edged board 50 mm wide 200 mm;

- Metal hoops;

- Door and window blocks;

- Canopy;

- Heater stove, wood or electric.

Lumber manufacturers offer ready-made kits for the construction of barrel baths of various sizes. To save material, time and effort, you can buy a ready-made kit and install it yourself.

The types of wood suitable for barrel saunas are coniferous: spruce, pine, larch, as well as deciduous species. At the same time, it is better to make the frame from coniferous wood, and use deciduous varieties for finishing the bathhouse - they do not tar and do not cause burns.

Miniature sample of a barrel bath

Stage 2 – assembly of end partitions

Assembling the end partitions

Now you need to assemble the end partitions. Their height and circumference depend on your plan. Connect the prepared boards by pressing them close to each other on a flat surface. To hold them together, use cross beams. Secure each board with screws to the cross beam. Also don't forget about openings. After all, partitions must have doors and windows in the right places. Therefore, when securing the cross beams, make sure that they do not interfere with the installation of window and door units. Once the required number of partitions have been assembled, you can proceed to the next step.

Advantages and disadvantages

Barrel-shaped baths stand out for their non-trivial shapes. Such structures cannot go unnoticed; they “catch” and cause surprise. It is precisely due to the fact that they are round that many of their characteristics exceed those of ordinary bathhouses by several times. The undoubted advantages of such barrel-shaped baths:

- the compactness of the structure implies a small volume for heating;

- original appearance;

- fast heating due to the fact that the steam is in a spherical space - in hot weather such a bathhouse can be heated in 15-20 minutes, and in winter it will take a little more time - about an hour;

- less energy required to solve this problem - if the stove is wood-burning, then literally 7-8 logs will be needed to light it;

- a barrel sauna is a fairly lightweight structure, so it can be moved if desired; in addition, there are even mobile trailed saunas;

- compared to log baths, the construction of a barrel-shaped building will take only a few days (and only if it is self-assembled);

- construction does not require a capital foundation;

- “thermos” effect – heat can last for a very long time;

- manufacturers claim that the service life of these buildings can reach 20 years or more;

- It is very easy to keep the room clean;

- this is a fairly low-cost alternative to the capital construction of a large building;

- there is a huge selection of a wide variety of designs of this type;

- The main building element is wood. Properly selected material, in addition to its outwardly attractive appearance, will also provide a real therapeutic steam room. Wood species such as linden and cedar can create a wonderful healing microclimate. But no one prohibits the use of aromatic oils during procedures.

So, if there is not enough free space on the site, you want exclusivity and originality, then you cannot find a better option than a barrel sauna. But still, like any other building, barrel-shaped structures also have their drawbacks. The main one is the relative crampedness of the internal space of the bathhouse. Even if we take the longest length of such structures, it will be only 6 meters. It is quite problematic for a large company to deploy on them. But 2-3 people will be able to swim, lose steam, and have a heart-to-heart chat.

There are also unscrupulous developers who use low-quality materials for construction. Having received a finished building and started using it, only over time can you find out that something is wrong in the bathhouse. As a rule, when defects appear, the manufacturer is no longer on the market.

Selection of design and dimensions

The building is similar to a barrel not only externally, but also structurally. The structure consists of the following elements:

- round end walls, knocked together from tightly fitted boards, are analogous to the bottom and lid of a barrel;

- side walls assembled from longitudinally laid thick boards with special recesses (following the example of a log house);

- external ties made of steel strip or cable, resembling barrel iron hoops;

- stands for horizontal installation of the assembled body on the ground;

- elements of interior design - stove, shelves, partitions with doors (if necessary).

Steam room, washing room and dressing room in the form of a classic round barrel

The first step is to decide on the design and layout of the bathhouse premises - the future dimensions and foundation of the structure depend on this. Please note an important point: the side walls are made of solid boards made specifically for the bathhouse, so the length of the structure directly depends on the length of the lumber.

The design and internal layout of the barrel is developed depending on the selected type of bathhouse and other wishes of the homeowner as follows:

- If you need to make an ordinary sauna, where dry steam is supplied to the steam room, take as a basis a drawing of a one-room building 2-3 m long. Such structures are located next to a pond or a swimming pool built in the yard.

- When making a traditional Russian bath, you need to provide a second bathing room, separated from the steam room by an additional partition, as shown in the drawing.

- A comfortable building with a dressing room, washing room and steam room is shown in the next sketch. The minimum length of 5 m indicated in the drawing should be increased and adjusted to the standard board size - 600 cm.

A beginner who decides to build a barrel-shaped bathhouse on his own is not recommended to start with large structures equipped with several internal partitions. Make a one-room sauna 2 m long - if desired, it can be loaded onto a car trailer and taken to a recreation area near a pond.

Spruce

Spruce belongs to the category of coniferous tree species. One of the positive qualities is that it is an accessible and pliable material. Its popularity is explained by its ease of processing and high strength, since after drying the wood, cracks do not form on it.

Spruce has the property of natural filtration, which helps prevent the appearance of dampness in the bathhouse. In addition, you can save on mobile foundation blocks due to the fact that this material is the lightest of those used in the construction of baths.

This species also shows itself positively in the visual component, because it retains the whiteness and integral structure of the board texture longer than other woods, regardless of the temperature and volume of incoming moisture.

In addition, the cessation of resin discharge is also associated with deformation of the boards - they will settle by 15-20%, which will negatively affect the appearance of the structure.

Tips for use

Caring for a barrel sauna is quite simple. The most important thing is to thoroughly ventilate the premises after use every time. Residual moisture in stagnant air can lead to mold and mildew.

From time to time, surface impregnation with linseed oil should be renewed. This will help extend their service life.

Also, once a season you should check the condition of electrical equipment by measuring the insulation resistance.

Making a barrel sauna with your own hands is a serious test of the construction and installation skills of a home craftsman. A bathhouse, built quickly and inexpensively, and made with your own hands, will be able to delight family and friends for a long time with pleasant relaxation and healthy procedures.

Columnar foundation

A foundation for a 4x6 m bathhouse with your own hands, the price of which will not be high enough compared to the cost of the entire building, can be made from ready-made materials at hand. This is due to the fact that the bathhouse is an auxiliary outbuilding with a relatively small mass.

In the event that timber or logs are used as the material for its construction, then a fairly easy-to-manufacture low-cost columnar foundation can serve as the foundation for it.

To make such a foundation, support columns are used, buried in the ground to a depth exceeding the depth of seasonal freezing of the soil, made from accessible, available materials.

In particular, one of the options for manufacturing a columnar foundation can be a structure consisting of pillars buried in the soil, made of burnt brick, rectangular piles made of reinforced concrete, reinforced concrete or stone pillars. Asbestos-cement pipes, the internal cavity of which is filled with concrete, can also be used as a basis for the foundation.

Brick foundation pillars are laid out on cement mortar, with corner pillars measuring 40x40 cm and side pillars measuring 25x25 cm. After engineering surveys on the site, the maximum depth of soil freezing is determined, as well as the level of groundwater, which is necessary to determine the depth of the foundation. .

To lay a columnar foundation, according to preliminary markings, rectangular recesses are dug in the ground, the bottom of which is filled with sand and gravel to a depth of about 10-15 cm. After which the supporting foundation columns are laid out. For a columnar foundation made by yourself, you can use burnt brick, rubble stone, pieces of reinforced concrete, etc.

A columnar foundation made of asbestos-cement pipes is quite simple to manufacture. The diameter of the pipes used must be at least 20 cm. To manufacture it, it is necessary to drill wells with a diameter of 24 cm and a depth of 1.5 m at the key points of the structure, then insert supporting asbestos-cement pipes into them, place 3-4 reinforcing rods inside them and fill them with concrete.

When pouring concrete, the pipe must be slightly raised so that a supporting concrete pad is formed at the base of the pipe. In order to attach beams or logs to the foundation pipes, a threaded rod about 50-60 cm long is inserted into the pipe when pouring concrete. Installation of the lower crown of the log house or beam can begin after the cement has completely hardened, i.e. in 5-7 days.

Definition

A barrel sauna is a non-stationary structure consisting of composite modules. Its area does not exceed 6 meters.

Despite its external compactness, this is a full-fledged bath complex with three necessary sections: a locker room, a steam room and a bathing room. The most popular is a three-section 5-meter bathhouse, which can comfortably accommodate 6 people.

The minimum size of this structure is 2 meters. It includes: a room that combines the functions of a steam room and opportunities for swimming, and a dressing room

It is important to note that all measurements are given taking into account the span of the porch.

Preparatory work

The drawing does not depend on the size of the structure. The bending radius is the same for any size, only the length of the structure differs. The simplest diagram includes an image from the end, where the internal and external radius and parameters of the doorway are indicated.

The second projection shows a section of the barrel. The plan indicates the location of the partitions, if a washing room and dressing room are planned, the placement of the stove, chimney and water pipes. Internal doorways are also designated.

It is recommended to include a list of materials with parameters on the diagram. This makes it easier to calculate the required amount of materials for construction yourself.

With your own hands? Easily!

The length of the barrel bath comes in different sizes - from 2 to 6 m; this is usually associated with the internal filling of an unusual bath structure.

It is usually built from coniferous wood, fir, cedar, spruce, and larch are used. The choice of the creators of the unusual structure fell on coniferous species due to their high moisture resistance. After all, in the open air, a barrel bath is exposed to precipitation, changes in temperature and humidity.

Often, tongue-and-groove boards with a pre-prepared tongue-and-groove joint are used to assemble a barrel bath. This connection allows you to create a rounded surface when the tenon and groove are cut out according to special stencils, which can be seen in the photo with the naked eye. For this, lathes with numerical control are used, and craftsmen work on them - special craftsmen who can easily read any drawings and perform the most interesting tasks.

Drawing of a barrel sauna

The shapes of the blanks are made on a well-planed edged board, or on tongue and groove boards. Ordinary flat boards are also suitable, but in this case, narrow blanks with a radial size are selected, allowing you to create a rounded structure. When using any material, a do-it-yourself barrel sauna always looks attractive, and naturally beautiful wood does not need additional finishing. Except that with the roof, craftsmen use various options, giving the building individuality and even greater attractiveness.

We build a sauna stove with our own hands

You need to create a solid foundation

When constructing such a structure, there is no need to build a special foundation. A platform is required on which to place a base for a round-shaped bathhouse.

Drawing

Good fit:

- concrete or asphalt areas;

- compacted soil;

- platform with paving slabs laid along the slope.

Do-it-yourself drawings of a barrel sauna allow you to choose on which site their structure will stand (see photo above). A wooden panel or reinforced concrete slab is laid on the ground area.

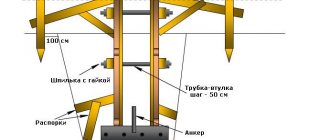

A support base is first installed on any site chosen by the owner of the dacha. To construct it, you must follow the basic rules:

- use an edged board at least 5 cm thick;

- pre-treat the boards with impregnation to protect against putrefactive fungus;

- lay transverse support boards at a distance of 1.5 m, their number is determined by the model of the barrel bath;

- the transverse boards must be equipped with a recess according to the design pattern; there is a nuance here: the board should remain untouched at least 10 cm;

- The rigidity of the structure must be imparted using metal corner parts that secure the joints of the elements of the barrel bath.

First, partitions are installed on the supporting base; they are secured with metal corners on transverse boards. The partitions are pre-equipped with openings for doors and windows. The wood of the partition is also pre-treated with a protective impregnation.

Assembly

The owners of the future building choose the drawings themselves, based on the composition of the family and the number of expected guests. Even for one family, especially if children are accustomed to the steam room from an early age, the room should be spacious, this creates more comfortable conditions.

Photo of installation

The finished oval-shaped base with installed cross members allows you to begin laying the side boards using the tongue-and-groove method.

When the part of the circle needed to attach the partitions is prepared, they are securely connected with metal elements.

The necessary rigidity of the structure is given by metal hoops that tighten the “barrel” using iron clamps. With their help, after the wood dries, the entire “barrel” is evenly pulled together so that cracks do not form.

Exterior finishing is carried out according to pre-prepared drawings; with your own hands, a barrel bathhouse can receive either a soft roof on top of a “barrel”, which is customary for such buildings, or a gable roof, which looks original on a round building.

Any selected roof must be covered with waterproofing and thermal insulation according to the rules for constructing a conventional roof.

Video:

Step-by-step construction instructions

After the procurement of materials is completed, the wood must be treated with protective antiseptic impregnations, dried thoroughly, after which the assembly of the structure can begin.

Laying the foundation

Before you make a barrel sauna, you need to lay the beams for the base, which will bear the entire load of supporting the building above the surface.

The base beams are laid as follows:

- Prepare the required number of beams 3.5-4 cm thick and 30-35 cm wide - from 2 to 4 pieces, depending on the length of the building. In them, according to the drawings, recesses are cut into which the boards of the lower part of the barrel for the bath will be laid and secured.

- Next, the beams are placed at equal distances from each other, positioned in such a way that the first supports the wall with the doorway, and the last is under the back wall.

- At the end, all laid beams should be fastened into a single rigid frame so that during installation and operation of the bath they cannot move to the sides.

Working with front and back walls

At the next stage, they begin to manufacture the bottoms of the future barrel, that is, its front and rear walls. They should be smooth and even, without cracks or defects. They need to be marked for windows and doorways. Depending on the location of the openings, bars will be fixed to the walls, along which the boards of the sides of the barrel itself will be sewn. These bars are fixed across the structure.

First of all, they assemble a frame from bars and sew a board onto it to get a square. Having calculated its middle, a circle is drawn on the surface and a circle is cut out along the contour. Both walls are marked in the same way.

Next, in each circle, markings are made for one or two windows and a doorway, after which holes are cut out. If necessary, the resulting holes are reinforced with bars.

Marking boards for the side walls of the bathhouse

Further actions will be related to the preparation and marking of boards for the side walls of the barrel bath. In those places where the front and rear panels will be adjacent to the sheathing, you need to cut special grooves that match the width of the boards in the walls and reach 8-10 mm in depth. The so-called bottoms will be inserted into these recesses.

And if the bathhouse consists of two adjacent rooms, in the place of the partition between them, grooves must also be provided in the cladding boards to secure the wall.

Window and door frames

Since windows and doors must close absolutely hermetically and not let air out of the steam room, not everyone can cope with this task on their own. Therefore, it is recommended to place an order for ready-made windows and glass doors, which will be produced in compliance with all standards.

This way, you will receive high-quality products so that you can create an optimal microclimate inside the barrel bath and get the maximum benefit from the process.

How to assemble a barrel sauna

The assembly of a round bathhouse begins with the installation of support beams on a prepared site, located slightly at a slope, to which communications for drainage are connected. They will subsequently be connected to the low tide from inside the bathhouse.

In each of the cut out recesses of the base, a center is marked to which the first bath board is attached.

Next, the remaining boards are sequentially secured on each side until the base arc is filled. In this case, you should pay attention to ensure that the grooves located on the boards form a single contour. Thus, the floor of the building will be sheathed.

The next step is to fix the front and rear walls of the bathhouse in the grooves. They should stand firmly and not require additional support. At this stage, it is already possible to determine the shape of the future building.

After installing the walls and internal partition, they move on to covering the sidewalls. All subsequent boards are fixed directly to the walls. They are laid out and fixed parallel on both sides of the barrel.

When the fastening of the boards is completed, the entire structure must be secured with metal tape. Such rims can be installed in several places from two to four. Holes are made at both ends of the tapes and, after inserting bolts and nuts into them, they are tightened, tightening the ends.

After this, you can install windows and doors.

At the last stage of construction, the roof should be arranged. It can be made of flexible tiles or soft sheet metal laid directly on top of the barrel on a waterproofing substrate. As an option, you can install a gable roof covered with corrugated sheets or metal tiles.

If you install benches outside the building on both sides of the front door, you will get an impromptu veranda.

Let's get to know each other better

Imagine a large cylinder that was laid on its side, decorated with an original roof, a porch and an entrance were added, from where the tempting aroma of a steam room flows, and a cozy smoke comes from the chimney. The attractive buildings include wooden barrel saunas. The smallest bathhouses are only 2 meters long and consist of a single room - a steam room. A mini-bath can be made up to 6 meters by changing only the internal structure of the room and installing partitions there.

The barrel sauna looks unusual and very original

The barrel sauna is a large cylinder that is laid on its side

If desired, sewerage and water supply can be installed. It’s simple and very easy to build a barrel sauna with your own hands, and you don’t need to spend money on hired workers, while getting a lot of advantages:

Mobility. Thanks to its light weight, the mini-sauna is easy to transport. You can take it with you fishing, at the cottage, or just on an outing.

Due to its light weight, the mini-sauna is easy to transport

You can take the barrel sauna with you on a fishing trip, at the dacha, or just on an outing.

Barrel sauna or mobile sauna

Compactness. The small size allows you to install it in a small area. And the stylish appearance of the steam room will become a real decoration of your personal plot.

Due to its small size, the barrel sauna can be installed in a small area

Economical. The bathhouse will require minimal energy costs, this allows the owners to receive healing procedures as often as they want. The bath heats up very quickly, which is also beneficial for lovers of bath procedures.

The minimal energy consumption of a barrel sauna allows owners to receive healing procedures as often as they want

What are the disadvantages of a barrel bath? Reviews from owners indicate the following inconveniences:

- When using a steam room in winter, the bathhouse must be insulated. For insulation, it is better to use rolled heat-saving materials so that it is possible to bring the internal temperature to the required level. They increase labor costs and overall cost.

- The largest mini-sauna will not fit more than 3 people. It is not suitable for a large company.

Unfortunately, barrel baths are not very spacious

When using a steam room in winter, the bathhouse must be insulated

- When additionally laying water supply and sewer systems in cold winter, ice plugs often form there, and the pipes themselves freeze heavily.

- But considering that Finnish barrel saunas are planned as an economical and budget option, these disadvantages can be classified as trifles, which in comparison with the advantages of a crumb steam room are simply insignificant.

The stylish look of the steam room will become a real decoration of your garden plot

The barrel sauna is an original invention of our northern neighbors, the Finns.

Strip foundation for a bath

For the construction of a small bathhouse, a shallowly buried strip base is ideal. In order to determine the optimal depth for the foundation for a bathhouse, you need to know the composition of the soil. For stable soil, not heaving, with a normal level of humidity, a ditch with a depth of 40 cm is sufficient. If your site is located on black soil, peat soil or sandy soil, feel free to increase the depth to 70 -80 cm.

The width of the base is influenced by the material from which the bathhouse will be built. If it is light, 25 cm is enough. For walls made of brick and stone, you need at least 35 cm in width. The ditch itself is dug with a width of 5 cm more.

On a previously prepared, level area, it is necessary to find a point at the lowest level from which the construction of the foundation will begin. Also, a very important point is that in the process of constructing the correct foundation for a bathhouse, it is necessary to make a slope in order to drain rain and melt water. Otherwise, the accumulated water will lead to the destruction of the building. The tilt can be done in any direction except north.

Metal rods are installed at the corners; this must be done in order to stretch the jute around the perimeter. If we are talking about a strip foundation, then two contours are made (external and internal). To do this, pull two jutes parallel and at a distance that corresponds to the width of the base with an additional 5 centimeters.

The next step is to dig a ditch. If work is carried out on heaving soils, the ditch must be made in the shape of an inverted trapezoid.

A cushion of sand and gravel ensures the stability of the foundation and smoothes out possible soil movements. The first layer is sand, which must be moistened and compacted thoroughly. Next, crushed stone is poured, which is also compacted, and then sand again. Alternating layers must be done until the ditch is 50% filled.

After completing the work with the sand and gravel cushion, they begin to create the formwork for the foundation of the bathhouse with their own hands. It is constructed from boards, leaving the fasteners outside. The structure must be complete without gaps between elements. The evenness of the formwork ensures the evenness of the foundation. Otherwise, you will have to perform additional work on grinding the finished base. The bottom of the ditch is lined with reinforcement made of wire and rods. The inside of the formwork is covered with roofing felt or polyethylene. This provides protection from moisture.

The concrete solution must be poured into the formwork at one time. The slightest interruption in this process must not be allowed, otherwise the foundation will turn out to be fragile and unreliable. To ensure the work is carried out quickly and efficiently, order a concrete mixer with a ready-made cement solution.

The formwork can be removed after 7 days, and the construction process of the bathhouse can begin after 3 weeks. During this time, the concrete will gain strength.

Features of construction work

For low-rise buildings, this type of foundation is more suitable than others, since it does not require high foundation stability. Pouring the foundation with concrete should be done in one approach for the reason that this will achieve strength and eliminate the possibility of delamination. It is not recommended to form horizontal seams near horizontally located reinforcement bars. The metal should be placed in one layer.

We fill the foundation with our own hands immediately with a volumetric amount of the mixture. It is not possible to produce a large amount of mortar yourself, so it is recommended to order concrete from a factory. If you are faced with the question of what kind of concrete to fill the foundation with, you should choose one that has a grade of 300 or higher.

Material for the construction of a barrel sauna

To make the construction as comfortable as possible, it is worth paying special attention to the choice of the main material – wood. Almost any material can be used for a stationary bath, but the inside can be lined with more noble and expensive types of wood

But when building a barrel, this difficult choice should be made first. This issue should be approached with all seriousness. For example, the use of coniferous species is not recommended, since they contain a huge amount of resinous components, which will begin to actively evaporate when heated. Heated resin vapors can not only damage the respiratory tract, but also leave serious burns on the skin.

What types of wood can be used:

An excellent solution would be to choose oak as the most durable and hard option. This will allow you to build a bathhouse that will last for many years. Over time, wood soaked in moisture will only become stronger, which cannot be said about other varieties

You should immediately pay attention to its high cost, which is why oak is often used to make individual elements of a bathhouse. Real oak will always have dark natural shades and a characteristic pattern

It has a number of healing properties that are also inherent in cedar. It is possible to use aspen, which is also used in the construction of baths. Its characteristics are similar to linden. Their sets of positive and negative qualities are almost the same. Generally not subject to deformation and cracking. Its cost is more than affordable, so a barrel sauna made of aspen can be called the most acceptable budget option. The most traditional material is considered to be linden, which can create a stunning and at the same time therapeutic microclimate in a small bathhouse. A well-heated linden bath will help cure many diseases associated with the respiratory tract, kidneys and even the liver. After visiting the linden bath, the skin will become more elastic, attractive, clean and youthful. The material practically does not shrink and is easy to process. This material allows you to quickly heat up the room and keep it warm for a long time. The main disadvantages include the fragility of the material used, which is characterized by a low level of strength and weak resistance to fungal infections, which contribute to the rapid destruction of wood. Among coniferous species, it is possible to use cedar for the construction of a small bathhouse. The advantages of its use include the incredible healing qualities of this type of wood, including aromatherapy. In terms of its technical indicators, it also surpasses most of its analogues. Thus, the material will not crack from regular exposure to high temperatures and will not deform. It practically does not shrink and is not subject to infection by parasites. In addition, wood has a considerable number of color and texture shades, which will only add aesthetics to the bathhouse premises. Alder, birch or fir can also be used. But they are strongly not recommended for use in baths. It is better to refuse this option immediately.

Beautiful examples

One of the advantages of a barrel sauna is undoubtedly its original appearance. He can't help but attract attention. Many people, having heard that their friends have such a bathhouse, want to visit it and try its steam in person.

The interior of the barrel bathhouse also looks very original from the inside. Most of the furniture is made of wood. The spherical wooden room promotes additional relaxation. Psychologically, it is comfortable, a person feels protected. In cross-section, it looks like a “sandwich” of several rooms: locker rooms, dressing room, steam room. And if the bathhouse is made of medicinal wood, then it also becomes a home clinic, which improves not only immunity, but also mood.

But over time, even such an exclusive can become boring. Many owners begin to decorate the building, and the bathhouse turns into a space shuttle or submarine or other buildings that have a cylindrical shape. Some people make a bathhouse that looks like a fairytale hut, but with an elongated oval shape. The use of glass on a large part of the facade will give the building a touch of high-tech or industrial style. Such a bathhouse, of course, will not be suitable as a winter option, but in the summer it will always delight the eye with its original appearance.

Other owners begin to emphasize the shape of the barrel or additionally adapt it to the structure of the house (leaving the necessary “gap” of 6 meters), equip it with a roof and veranda, and adapt it to a pool or water container. (If initially these architectural elements were not included in the bathhouse package).

With proper care, a barrel sauna will last for decades. Main:

- Do not forget to ventilate the steam room, and other rooms, for at least 4-5 hours, preferably after each use and if the sauna has not been heated for a long time.

- Do additional “drying” of the bath. It is necessary to run the oven at full power within one to two hours and keep the doors and windows open.

- Treat the structure with protective agents at least once a year.

- If a wood-burning stove is installed, it is advisable to use non-coniferous wood for heating. Firewood must be dry.

The water tank must be at least half full

This is very important when burning. After use, it is advisable to remove the remaining water from the tank. Check and clean the chimney regularly. Make sure that the water in the drain does not stagnate or freeze. In the autumn, the hoops that tighten the bathhouse frame should be loosened

It is during the cold season that wood tends to expand slightly due to the surrounding moisture. In summer, the reverse process occurs, the wood dries out, and the hoops need to be tightened.

Choosing a foundation for a bath

When choosing which foundation is best for a bathhouse, you need to consider three factors:

- weight and size characteristics of the structure;

- geological conditions on the site - presence of a slope, type of soil and its bearing capacity, freezing depth and groundwater level;

- budget allocated for construction.

In most cases, the best option would be a strip foundation for a bathhouse. The different depths of the strip foundation allow you to build in any soil conditions - on stable soil it is rational to construct a shallow strip (deepened by 30-80 cm), in heaving soil - deep strips (the support base is 20-30 cm below the depth of soil freezing).

However, the arrangement of a buried foundation is accompanied by serious costs for materials, and in order to save money, it is better to give preference to screw or columnar foundations.

The screw foundation for a log bathhouse consists of steel piles tied with a grillage, the blades of which open the surface layer of soil and rest on solid deep soil. The advantages of this option are low cost, quick installation time (installing a foundation for a bathhouse takes 2-3 days) and reliability.

Shallow strip foundation for a bathhouse

A good analogue for the construction of light buildings (log house, frame panels - area from 3x3 to 6x6 m) is a bathhouse on a columnar foundation. To install a log bathhouse on poles, the soil on the site must not be prone to horizontal shifts, otherwise there is a high risk of the supports overturning. The pillars can be monolithic (concreted asbestos pipes) or prefabricated (from FBS blocks).

In complex soils - mobile, heaving and low-density - a foundation slab is needed. This is a monolithic structure made of reinforced concrete 30-50 cm thick, the dimensions of which correspond to the area of the building. The slab is a reliable and durable foundation for a frame bathhouse or log house, but its cost is higher than other analogues.

A simple foundation for a bathhouse, suitable for light frame buildings measuring 3x3 and 3x4 m - a base made of car tires. It is possible to erect a building on such a foundation in stable soil that is not prone to heaving. A bathhouse without a foundation can only be built on rocky soils.

Collection of characteristics and calculation of the foundation

Before building a foundation for a bathhouse with your own hands, you need to calculate the foundation and find out whether it will withstand the building in specific soil conditions. You need to determine the type of soil on the site (sandy, clayey, sandy loam) and, using standard tables, find out the value of its resistance per 1 cm2.

Next, you need to calculate the loads that will be transmitted by the foundation to the soil. Load calculations are performed using the following algorithm:

- Calculation of the mass of a building - the weight of the roof, floors and walls is separately calculated and summed up by multiplying their area by the specific weight of the building material (tabular data).

- Calculation of snow loads - multiply the roof area by the weight of m2 of snow cover in your region.

- Calculation of operational loads (furniture, stove, wall cladding) - multiply the area of the basement floor by the average load of 100 kg.

- Calculation of total loads - we summarize the obtained data and add a safety margin by multiplying the amount by 1.2.

It remains to determine the supporting area of the foundation, multiplying its perimeter by its width, and calculate the load per 1 cm2 of soil.

For example: the standard width of the tape for log walls is 30 cm, for a bathhouse with an area of 6 × 6 m (perimeter 24 m) its supporting area will be 240 * 30 = 7200 cm2, for a 3 × 3 building - 3600 cm2, for a bathhouse 3 ×4 - 4200 cm2, and so on. Now you need to divide the total loads by the supporting area and compare the resulting value with the resistance of 1 cm2 of soil; if the result exceeds the bearing capacity, you will need to increase the area where the foundation rests on the ground by adding the width of the tape or the diameter of the pillars.

Material selection

A smart and prudent builder will make a barrel sauna from such types of wood as:

- oak is a tree that is undeniably strong and resistant to dampness, and also has a beautiful pattern when cut;

- linden, famous for its healing properties and excellent ability to retain heat, but quickly deteriorates when exposed to moisture;

- aspen, comparable in strength to linden, is impervious to dampness and does not change its shape.

A bathhouse made from quality material will last longer

Pine needles are definitely not suitable for making a barrel bath. This type of wood is enriched with resins, which scatter through the air at high temperatures. In extreme cases, only the skeleton of a non-standard bathhouse can be built from coniferous trees.

The only coniferous tree that will not make you regret building a room for water treatments is cedar. The structure of the material created from this wood is dense and therefore does not change under the influence of hot steam.

It is not entirely advisable to use metal when constructing a barrel sauna, since under the influence of heat it becomes heated and can burn the skin. But it is not prohibited to use metal parts for the construction of a non-standard bathhouse. We are talking about corners, rims and other elements responsible for the reliability of the structure.

Nuances of arrangement

The internal arrangement of the sauna-barrel is determined by the needs and capabilities of its owner. If the bathhouse is planned to be used only in the warm season, insulation will not be required. Otherwise, it is necessary to insulate the walls with basalt wool, and in the lower part it is better to use penoplex that is not afraid of moisture.

In addition to the shelves in the steam room, it is necessary to make benches and a table in the dressing room. If there is a rest room, it is also better to equip it with wooden furniture that is not afraid of moisture.

The surfaces of walls and furniture can be impregnated with linseed oil or special compositions for baths.

It is imperative to equip the oven with protective guards to prevent burns.

For relaxation in the summer, a canopy-veranda is equipped at the entrance. To do this, the roof and wall boards are released above the entrance end wall.

Round or square?

Barrel baths come in a classic round shape or the so-called quad. The latter is a structure closer in shape to a parallelepiped. The corners of the quad barrel are more beveled and smoother than those of this geometric figure. The principle of constructing such a bath is the same as that of a round barrel.

The difference lies only in the described external features. They do not affect the functionality of the bathhouse or any other characteristics. The only advantage of the quad is that it is more convenient to make a side entrance (if there is such a desire). It’s up to you to choose what to install in your home – a “square” quad or a round barrel sauna. This is a matter of taste and individual preference.

Briefly about the main thing

The barrel-shaped sauna is light, mobile, compact and at the same time ergonomic, economical and original in appearance. There are three main types of it:

- Traditional - Russian, with a steam room and a washing room.

- Finnish - only with a steam room.

- Japanese - in the form of a vertically installed barrel without a roof.

The best materials for their manufacture are linden, cedar and aspen. When used correctly, they provide a healthy microclimate and do not rot or deform. When choosing a location for installation, you need to proceed not only from personal preferences, but also take into account the regulatory requirements of SNiP - 1 meter to the border, 3 meters to the house, 12 meters to the water source.

A barrel sauna consists of a base, end and side walls, partitions, iron ties and furnishing elements - stove, furniture, drainage, windows, door trim and trim. The installation of all elements has its own characteristics. You can do it yourself, but it is better to entrust it to specialists.

Drainage system and flooring

For obvious reasons, the floors in the barrel bath are not straight, but flat. This is very good for the design: the water simply flows into the center, where a special drain should be installed. Used water can be poured directly into the ground. Some of it will be absorbed into the soil, some will simply evaporate. You can also connect a pipe and feed wastewater into the sewer system. This is necessary if you plan to use your sauna very often.

Photo 7.

Don’t worry that the “sloping” floors will make using the bathhouse inconvenient. This is wrong. The most sloping parts of the barrel are hidden under the shelves. In the center there is an almost flat surface, which is very comfortable to walk on. In a barrel bath you can make not only a steam room, but also a washing room. Connect cold water to the stove, connect the mixer and shower head to the pipe (photo 7).