Nowadays, frame construction is gaining momentum, as it has many advantages - buildings are erected quickly, their weight is not large, and the cost of a frame structure is not high. Building a frame bathhouse is a great way to save money (as opposed to building a bathhouse from timber) and time. But despite the fact that such a building has a small specific gravity, a foundation should be erected under it, otherwise there is a possibility of losing both time and money due to the destruction of the frame. What kind of foundation is suitable for a frame bath? How can you save on building a foundation? Let's take a closer look.

Kinds

There are several types of foundations that can be used in the construction of a frame structure.

When choosing a foundation, you need to take into account the weight of the building, the type of soil, and other loads that will be exerted on a particular foundation. So, let's look at the most common types of foundations that are built for frame baths. The types of foundations suitable for mobile frame and frame-panel baths are presented in separate articles.

On stilts

This is one of the types of columnar foundations in which the role of supports is played by piles that are driven or screwed into the ground. They are often used on weak, mobile heaving soils. Pile elements are driven into a dense layer of soil; they serve as support for the lower frame. This is an excellent option if the soil at the construction site is problematic, but to build such a foundation you need special construction equipment, so this foundation is used very rarely in private construction. However, the following two types are quite suitable for low-rise construction.

On screw piles

This type of foundation for buildings, despite the fact that it appeared just a few years ago, has already gained enormous popularity among both private developers and professionals. The piles are screwed into the soil until the tip reaches dense soil layers. The elements are arranged according to a pattern that allows you to evenly distribute the load on the soil and foundation.

Screw piles can be installed on any soil – rocky, heaving, on slopes. The advantage of this type of base is the fact that they can be screwed in manually, independently. It is worth noting that construction on such a foundation will not be difficult, since the piles are tied with a channel on both sides, which serves as the basis for the walls.

On bored piles

A type of pile foundation in which prefabricated columnar elements are not used. In this case, a well is drilled or dug, which is subject to reinforcement and then pouring concrete. The arrangement method is very labor-intensive. At the same time, not every private developer has access to this method for independent construction, since it requires the presence of heavy construction equipment, proper arrangement of the drainage system, and reinforcement directly on the construction site. It is also worth noting that finished pile elements are much stronger than those poured independently - they can quickly collapse if the pouring technology is not followed. And yet, many craftsmen make homemade poured piles, which you can read more about in the article about pile foundations for bathhouses.

Video

Tape

Perhaps the most common and popular type of foundation, especially among private developers. The strip base is a time-tested and reliable reinforced concrete continuous strip that completely follows the building plan. It is carried out under all load-bearing walls and under partitions if the weight of the structure requires it. More details about it here.

This is a fairly simple and economical base to build, which can be done with your own hands, without the involvement of builders and special equipment. The only disadvantage of this foundation is that it is very demanding on the nature of the soil - it is impossible to build on wet and heaving soils. There are several options for strip base:

- Monolithic strip is a durable reinforced concrete structure that is installed directly on the construction site. Formwork is installed, in which reinforcement is made, and only after that concrete is poured. The strength of the monolithic tape is quite high, capable of withstanding heavy loads. But there is a significant drawback - it cannot withstand soil movement, since the fracture resistance of the strip base is very low.

- Prefabricated strip base - this base is assembled from ready-made reinforced concrete elements. They are used very rarely in private construction, since special trucks are needed to deliver elements to the construction site. In addition, a crane is required to install the slabs into the trench. And the strength of such a foundation directly depends on the professionalism and experience of the construction team.

- Rubble concrete - instead of reinforced concrete, natural rubble stone is used, combined with mortar. The result is a tape with greater strength than classic tape and is less affected by moisture. The low price of the material used and the likelihood of working with your own hands make this kind of method extremely tempting, but this stone cannot be found everywhere, and delivery to distant regions is an expensive pleasure. This fact limits the use of this type.

Columnar

Despite the advantages of a strip base, it is preferable to equip it for brick, block and light monolithic buildings. For lighter buildings, such as wooden, timber and frame baths, it is better to use a columnar base, as it is much more economical. And everyone decides to choose a beam or frame independently.

There is a limitation in the use of columnar foundations - if the walls of the bathhouse are constructed from heavy material, and the soil at the construction site is weak-bearing. Before deciding on arranging a columnar base, it is worth considering the options for the material from which the pillars can be made:

- Made from a monolith , the pillars are installed directly on the construction site. The option is very good if you need to equip pillars of a certain size, but it requires a large amount of mortar, in addition, you will have to reinforce each element. For high-quality execution, you need to use a vibration machine or the bayonet method to remove voids, which can subsequently lead to destruction.

- Brick is an excellent option if the terrain at the construction site is uneven. Due to the small thickness of the brick, each element of the foundation can be adjusted individually.

From blocks

In this case, it is worth considering two options for block foundations:

- block strip – during construction, FBS blocks (foundation building blocks) are used as a strip. There are several advantages to assembling the bases this way:

- There is no need to wait for the concrete to harden.

- There is no need to construct a reinforcing frame.

- It is possible to provide a high-quality waterproofing layer.

- block columnar - they are made from small blocks that are stacked crosswise on top of each other to the desired height. Such pillars are very durable, since factory-dried concrete has increased quality and strength characteristics.

From tires

Old tires are excellent building materials from which you can build a foundation for a frame bathhouse. Several types of foundations can be made:

- columnar - lay tires in the form of columns;

- tape - in this case they are laid in the form of a continuous tape;

- slab - masonry is carried out across the entire site in two rows.

The advantage of constructing from old tires is:

- efficiency;

- long service life;

- no additional waterproofing required;

- resistance to temperature changes.

The only disadvantage can be considered that when exposed to direct sunlight, old tires emit substances harmful to health. There is more information about this type in this article.

Slab

This is a solid monolithic slab that is poured under different buildings. The strength of such a foundation is very high, so slab foundations are used on unstable, heaving soils prone to movement. If you install a structure on such a foundation, then it will not be afraid of deformation and destruction.

The disadvantage of slab foundations is; high material consumption, high cost and labor-intensive process. For a frame bath it is better not to use a slab foundation - this is often unreasonably expensive.

Installation of frame walls

We will pay special attention to this process, because the frame must be made and insulated correctly.

To make it, take an edged board 50 mm thick and 150 mm wide . will be the thickness of the wall. Select a flat area on the ground and assemble 4 frames for four walls. Don’t skimp on the dimensions, consider everything very carefully.

Accurately calculate the height of the frame, since the joists under the floor and the ceiling lining will be negative. Try to assemble the frame for the walls as accurately as possible, measure and align the diagonals. To ensure that the desired size does not “go away”, nail down temporary jibs, then remove them.

Please note the following point: the pitch of the racks in the assembled frame should be 600 mm. I’ll explain why this is so later.

Where there will be door and window openings, naturally the distance between the posts will be different. There's nothing wrong with that, just add overhead and sill racks and secure them with horizontal crossbars.

After all the frames are assembled, place them on the prepared foundation and secure them well together. Make sure the walls are perfectly vertical. Do not forget to treat all wooden frame elements well with deep penetration antiseptics. This must be done. By the way, all lumber used must be well dried. Otherwise, problems may arise in the form of fungus or mold.

For fastening, use self-tapping screws everywhere; they are more reliable and practical than nails. It would not be superfluous to use special metal perforated fasteners for wooden structures. At this point, the frame walls of the bathhouse are already ready. All that remains is to properly insulate them and sheathe them on both sides. This is what we will do next.

What does the choice depend on?

The choice of a certain type of foundation directly depends on the specific gravity of the structure and the type of soil on the site.

For example:

- Rocky ground

Rocky and stony soils are particles of different fractions, between which there are no soil elements. This type of soil is considered ideal for arranging any type of foundation, since the lack of moisture in the composition does not allow the soil to change its condition.

- Sandy soil - consists of coarse sand, which allows moisture to pass through it, while being well compacted during construction. The freezing depth of sandy soil is 1 meter.

- Clay soil is unstable, prone to heaving and soaking. Freezes to 1.5-2 meters. It is worth noting that if you do not equip a good drainage system and a gravel-sand cushion, then any foundation will collapse very quickly.

- Sandy loam and loam , which consist of clay and sand. Sufficiently stable soil if it contains more sand than clay. It freezes to 1.5-2 meters and is considered a good basis for arranging any foundations.

- Peat bogs are water-saturated, unstable soils with shallow bottom waters. Peat bogs are usually found in drained swamps and can very easily drag on foundations, especially if they are heavy.

For your information! On swampy and peaty soils, only pile or pile-screw type foundations can be used.

As for other types of soils, the main attention is paid to the specific gravity of the structure. But since we are considering the construction of a frame bathhouse, its weight is not very large, so any type can be used depending on financial capabilities and experience .

Two important differences: shallow or deep

Before considering the types of foundations in detail, two main types should be distinguished - shallow and deep. The difference is in the depth of immersion in the ground. Why is this moment important?

In winter, the top layer of soil freezes, and all the moisture in it turns into ice. When it freezes, it expands, causing the top layer of soil to change its volume. This phenomenon is called “frost heaving”, it is typical for soils with a high moisture content, clay and loam.

The depth of soil freezing depends on average annual temperatures and soil composition. For deep ones, the basic rule is to immerse below the freezing point to eliminate the effects of heaving loads. For some areas, this type is difficult to implement - the soil can freeze to 2.4 meters. There is a way out.

A shallow type is used, the feature of which is a shallow immersion depth. Such a base is located in the upper layers of the soil, above the freezing point, but the loads from heaving processes are much lower - 2 or even 3 times.

The point is to properly arrange the foundation: the trench is dug a little wider, a sand cushion is installed, a concrete strip is erected, which is subsequently filled with sand on the sides. As a result, there is a sand cut-off on all sides.

Sand does not retain moisture; it goes deeper in warm weather, so there is nothing to freeze in winter.

Only loads emanating from the lower layers of the soil remain, so it is impossible to use a shallow type of foundation on soils with large seasonal heaves.

Harness

A grillage is a structure that connects pillars installed in the ground along the entire perimeter of the base.

You don’t need to think that it’s enough to install piles, weld special heels on them, and you can install a house on them. It is worth understanding that in a columnar and pile foundation, each element lives its own separate life, especially if the soil is heaving and unstable.

In addition, it is worth understanding that each pile will be subject to a different load. The piles can simply be driven separately.

Advice ! If you want to save money, you can tie it with timber, which is perfect for a frame bathhouse. But the strongest and most reliable grillage is a reinforced concrete strip.

This photo does not show a frame bathhouse, but you can see the piping of the screw foundation with a profile pipe

There are four types of pile foundation lining:

- timber;

- channel;

- I-beam;

- monolithic tape.

Only by arranging a grillage on pile, columnar and screw foundations can you be sure that the structure will stand for a long time and will not require repairs in the next few years.

Bottom harness on pile

At first glance, it seems that tying a pile foundation with a corner or channel seems simple; this work requires certain skills:

- it is necessary to be able to carry out welding work, and the level of training must be appropriate;

- you need to understand exactly how to connect the channel; without experience, the work will be of poor quality;

- The channel is a fairly heavy material, so you will have to attract help.

But nevertheless, the algorithm of actions is quite simple:

- the piles need to be leveled;

- cut the channel into elements of the required size;

- connect the channel to the piles using bolts or welding;

- Apply a special anti-corrosion primer.

When using welding to arrange the strapping, you need to remember that the thermal effect on the steel changes its structure - weakening the material. Therefore, incorrect or insecure proficiency in welding work can result from weakening of the points at which the channel is attached to the supports.

Particular attention should be paid to corner joints, since it is in these places that there is a high probability of weakening of the entire structure.

Bottom trim on columnar

It is best to use wood on a columnar base: firstly, it is not expensive, and secondly, it is easy to arrange and process. It is better to use coniferous wood. Advantages:

- increased strength;

- durability;

- low price;

- resinous properties help resist moisture.

Before using wood for strapping, it should be very well prepared:

- treat with antiseptic compounds to prevent rotting;

- impregnate with fire retardants to reduce flammability.

The most suitable material for a grillage would be laminated veneer lumber, since this material is produced using special technology and glued under high pressure.

Creating a wooden base

Self-construction of a small frame bathhouse, as a rule, does not require the construction of a foundation due to its lightness. But to prevent the walls from becoming damp, you need to make a foundation.

In the case where you plan to build a bathhouse no larger than 3x4 meters in size, and the walls and roof are light, then it is enough to create a simple wooden foundation, which is secured along the edges with stakes. Such a foundation is considered a particularly good solution when carrying out construction on clayey, seasonally mobile soils that do not have excessive levels of moisture.

The fence is the base of the bathhouse, which performs aesthetic and protective functions - it improves the appearance of the facade and protects the structure from the penetration of cold and dirt.

The optimal pick-up height is 40 cm.

For the construction of the fence, it is allowed to use any building materials - brick, natural stone, cinder block. The finished structure can be faced with tiles, porcelain stoneware, decorative plaster, a ventilated facade, siding or ordinary roofing felt.

Before starting work on arranging the fence, it is recommended to make a cement screed 20 cm thick, which will provide the walls with reliable support.

The columnar foundation is reliable, durable and wear-resistant. Even a beginner can organize the work on its construction.

This foundation technology is successfully used in the construction of bathhouses, residential buildings, technical and utility buildings.

Which one is better to bet on?

There are many opinions about what kind of foundation to build for a frame-type bathhouse. Some experts believe that since the structure has a low specific gravity, it is possible to get by with a columnar base without a grillage, others give preference to piles, and advise making the frame from laminated veneer lumber.

There is an opinion that it is better to play it safe and install a shallow strip foundation, considering it the most reliable.

But if you don’t have the money to build a concrete foundation, a foundation made from old car tires is perfect. The main thing here is to correctly calculate the load in order to understand how many rows of tires to lay under the building and to correctly calculate the sand cushion for them.

Foundation for a bathhouse with drain

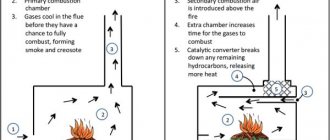

Floors equipped with a drain are sealed; the water goes into a prepared hole in the floor, towards which there is a slight slope. In both cases, after this the water either falls directly onto the ground or is drained outside the foundation, which is much more correct.

To eliminate the influence of water on the foundation, water should be collected in a specially equipped drainage pit, if the soil allows it to be absorbed without residue, or it should be drained from under the foundation - this option is good for clay soils that do not absorb water well. The foundation should facilitate ventilation of the underground space (this applies to all types of strip foundations), for which several holes must be formed in the walls - vents that ensure air movement.

This diagram shows a shallow strip foundation; it must be equipped with vents if you need a foundation for a bathhouse with a drain

Water drainage is organized in advance, during the construction of the foundation. The pipe system must be laid during pouring so as not to subsequently break the finished tape. On clay soils, you can simply make a drainage ditch with a slope towards the drainage, but the passage through the tape, however, must be formed with a pipe to prevent the concrete from getting wet.

How to make it yourself

Despite the apparent complexity, almost all types of foundations for a frame bath can be built with your own hands, for this:

- prepare the construction site;

- mark the territory;

- build a pit, trench or holes (depending on the type of foundation). When using a pile-screw foundation, this step can be omitted;

- construct formwork and reinforcement;

- pour concrete.

If you need details, then on our website there is a lot of information on installing any types of foundations with your own hands (how to do it correctly, how to do it yourself, how to pour it).

Foundation for a 3x4 bathhouse - cheap, fast and very simple

If you want to form a foundation at minimal cost, you should pay attention to tires. For this purpose, tires of the same thickness are prepared.

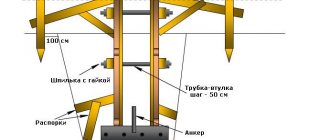

Installation work is carried out in the following sequence:

- A pit is dug, the dimensions of which in all directions are 20 cm larger than the dimensions of the bathhouse and 20 cm deep. The dimensions of the tires themselves are also taken into account. Tires must be laid without gaps;

- Sand is poured onto the bottom of the prepared pit, leveled and thoroughly compacted;

- Tires are being laid out. They are placed in a pit without gaps;

- Studs are installed in the center of the tires. Using reinforcement, their correct spatial position relative to the tires is ensured. The studs are laid to the depth of the tire. The height of the anchor must be sufficient to secure the supporting structure;

- Reinforcement is carried out around the perimeter;

- Waterproofing is installed;

- Formwork is installed;

- The concrete solution is poured. Concrete work is carried out in one step. To prevent cracking of the poured base, special plasticizers are introduced into the mixture.

The structure is left to dry. It takes a month to gain strength and completely dry.

When is it easier to order than to make?

It is not always advisable to fill the foundation with your own hands; for example, if you do not have experience and you have only heard how to pour the foundation yourself, then it is better not to take on the arrangement.

You must clearly understand that even a small mistake in calculations and installation can be fraught with negative consequences - the bathhouse will very quickly fail and you will lose both time and money. If you plan to order a frame bathhouse from a construction company on a turnkey basis, then you should entrust the pouring of the foundation to the same team that will assemble the building.

Why monolith?

Of all the foundations, it is the monolithic foundation that is most suitable for a frame bath. Why? There are several explanations for this.

- A single slab, poured in accordance with all technological standards, is capable of withstanding heavy loads, which, by the way, are not noticeable in a frame bathhouse.

- Due to reinforcement reinforcement and the use of concrete prepared strictly according to technology, such a foundation is durable.

- High degree of stability even on unstable soils.

- A monolithic slab is used as a subfloor, and tiles can be laid on it without prior preparation.

If all technological standards for pouring a monolithic foundation are observed, a frame bathhouse will last as long as possible, even in regions with sharp temperature fluctuations. Even floating soils will not affect the build quality. Small deformation movements will also not affect the integrity of the structure.

Hole design

After completing the installation of the fittings, you need to think about where the technological holes will be for the future water supply and sewerage, ventilation, etc. and attach a plastic tube to the fittings in the right places.

The base of the bathhouse may not have vents if artificial ventilation is installed in the basement or it is filled with expanded clay or other material that absorbs moisture.

When pouring a monolithic tape, technological holes are made as follows: holes are made in the formwork for the pipe through and through, after reinforcement, a piece of pipe is installed perpendicular to the trench and sand is poured into it for resistance against concrete mortar.

The pipe passages can be sealed with roofing felt and a protective frame made of reinforcement around the vents. After pouring the concrete, remove the formwork and blow out the sand. For ventilation, grilles are installed to prevent the entry of rodents, birds, and the ingress of debris or snow.

Cost of various options

The cost of installing a foundation on driven piles is not too high. But for the event it is necessary to use special equipment, which is why this procedure is quite complicated. The cost of reinforced concrete pillars is 1000 rubles per piece.

Screw piles are versatile, they are durable and guarantee long-term operation.

Such supports have many other advantages. A foundation built on screw products provides maximum cost savings. The cost of one pile varies between 1000–3500 rubles.

Bored piles are very popular because they are distinguished by their affordable price. At the same time, they guarantee excellent load-bearing capacity; such supports are universal in their application.

Preparation for construction: project drawings

Creating a drawing requires certain skills. If they are not there, then it is better to entrust this work to a specialist or use a ready-made drawing.

Before drawing up a diagram, it is important to decide on the following points:

Location of the building on the site

It is important to consider sewer and water drainage. Quite often, the main factor when choosing a location is the laying of communications.

Soil at the construction site

If you plan to make a swimming pool in a bathhouse, then groundwater should not be located near the surface of the territory. The type of foundation to be built will also depend on the type of soil. Bathhouse construction plan and number of floors. If you plan to make a two-story building, it is important to take into account the additional load on the frame structure and foundation. At this stage, you should think in advance about the placement of the stove and what material it will be made of. This will allow you to understand where and which chimney to install, as well as the ventilation passages in the room. Laying communications. It is important to take care of ventilation, electrical wiring, vapor barrier and thermal insulation. It is worth considering the features of water drainage. An important element of any building is the roof. The service life of the structure will depend on it. You should take into account the material of manufacture, as well as its shape. This will allow you to calculate the power of the floors.

You need to include all the information received in the drawing, as well as supplement the project with the necessary details. The more detailed the diagram, the easier it is to build a bathhouse.

The more detailed the project, the easier it is to make a frame bathhouse yourself

It is recommended to draw up a separate plan for communications. If you have little experience, you should not create a complex project. You can use a ready-made diagram, slightly supplementing it based on your own needs.

A standard bath includes a corridor, a dressing room, a washing room and a steam room.

A standard frame bath consists of a dressing room, steam room, shower and rest room

Quite often a separate room for recreation is provided. It is recommended to mark the installation location of the stove on the diagram. If this is a steam room, then it is best to place the stove in the corner closest to the door. The stove can be stone or brick.

It is recommended to determine in advance the dimensions of each room and indicate them in the drawing. The standard dimensions of the steam room are 200x240 cm. The optimal ceiling height is 220 cm. This design can accommodate 2-3 people at the same time.

In the drawing you can see a bathhouse for a suburban area with a balcony measuring 1.5x4 m. The overall dimensions of the building are 4x6 m. The project is suitable for organizing gatherings in an open area in the summer.

A frame bath can be equipped with a terrace for gatherings in the warm season

This bathhouse consists of 3 rooms:

- steam room;

- washing and shower;

- rest room.

The corridor is shown separately in the diagram. There is no room for a locker room. There is a small changing area in the washing room. The terrace connects to the living room.

The optimal wall thickness of a frame structure is 100 mm or more. The wood that is used in the process of making a bath must be treated with an antiseptic. It is recommended to use dried, calibrated lumber.

It is mandatory to perform a vapor barrier of the insulating material on the internal base. In the steam room you need to use foil vapor barrier. The reflective layer can increase the temperature inside the steam room.

Supply and exhaust ventilation is required in all rooms. Floors in the sink should be made with a slight slope or along a screed. The top and bottom floors need to be insulated in the same way as the walls.

The minimum size of a frame bath is 3x4 m.

The minimum size of a bathhouse for a comfortable stay of several people is 3x4 m

The budget version of the frame is made in this way: the racks are sheathed on the inside and outside with boards up to 25 mm, basalt insulation or ecowool is laid inside the frame structure.

If you plan to use ecowool inside the walls, it should be carefully compacted and horizontal platforms for unloading should be installed. The frame must be sheathed inside and outside. To do this you will need to make a sheathing. On the outside, the insulation material is covered with a membrane to protect it from the wind. In the horizontal plane, the use of ecowool is a more economical option compared to basalt insulation.

The outside of the frame structure can be covered with any facing material. The inside of the building is covered with clapboard, plasterboard sheets with tiles or imitation timber.

Trench

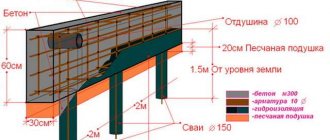

Carefully, so as not to disturb the markings, a trench is dug using special equipment or manually. Its width must necessarily be wider than the foundation strip in order to subsequently arrange the formwork. The depth of the trench has already been calculated and should be at least 0.5 m.

After it is ready, the bottom must be carefully leveled and the soil compacted well. To make the strip foundation of the bathhouse resistant to groundwater, sand is poured into the trench. The thickness of the sand cushion in the trench should be at least 10 cm.

To compact the sand, fill it with water and compact it well, repeating these steps several times. After the sand mass has dried, gravel is poured to the same height and compacted also well. To do this, you can use a vibrating plate or do it manually.

The cushion is designed to exclude any interaction of moisture with the base, as well as under construction conditions on heaving soil or peat bog.

Attention! The thickness of the sand cushion should be higher if a deep or floating foundation is planned. This number can be 2/5 of the entire thickness of the foundation.

Roofing production

The rafter structure is assembled on the ground. It includes several identical elements. The mounted trusses are lifted and installed above the racks.

It is recommended to make a ventilated roof - for this, a special film is laid, and the sheathing is nailed directly to the beam. The choice of roofing materials is a matter of personal taste and wallet size. You can, for example, use ondulin. This material is characterized by a long service life, low weight and aesthetic appearance. In addition, it has fire-fighting properties (does not burn).

Ventilated roof design diagram

Important points in the design and construction of a bathhouse

How to make a bath project?

Distinctive features of the frame structure:

- ease of construction;

- significant savings on materials, due to which the final cost of the bathhouse is reduced;

- no shrinkage;

- light weight.

The main disadvantage is the possibility of moisture penetration between the joints of the frame. Therefore, the structure needs protection, both outside and inside. A do-it-yourself bathhouse – projects, photos – is protected from condensation falling on the walls using a vapor barrier. The outside of the frame is sheathed with mineral or glass wool. The interior decoration is made of wooden boards/lining made of hardwood, and the exterior is made of pine or larch.

Where to start building a bathhouse?

A country house often has a small plot of land. And I really want to build a steam room. Then you should use Canadian technology, according to which the price of construction is minimal, and the construction time is the shortest. The dimensions of the bathhouse, finishing/insulation/steam protection options are selected by the owner depending on the expected budget. The construction of a bathhouse video lesson offered below, using a frame, can be carried out at any time of the year. This type of construction does not shrink, which makes it possible to immediately carry out finishing work. All engineering communications are hidden under the casing. The main thing is not to forget about good steam and thermal insulation. Then there will be no problems during operation.

The video tutorial will show you how to build a frame bath in detail:

https://youtube.com/watch?v=V5CYEThxdz0

How to make a drawing of a bathhouse with your own hands?

When developing a plan for a future building, it is worth taking into account possible construction options, starting from the amount that is planned to be spent. An inexpensive option, in contrast to the traditional wooden chopped bathhouse, is construction on a frame basis. It does not need a serious foundation, because its weight is light; it will only be enough to drive a few piles. The frame bathhouse does not shrink; work on its construction and finishing is not interrupted and can be carried out at any time of the year. The scheme is simple: steam room, shower, dressing room. There are many finishing options; you can buy boards or lining made from deciduous/coniferous wood. But before covering the frame, it needs to be insulated from the outside, and protected from steam inside.

What should the roof be like for a 6x4 bathhouse?

In order to save space on a small plot of land at the dacha, the construction of a steam room is combined with an additional room and bathroom, which are placed in the attic. The foundation for a 6x4 bathhouse must be reinforced, because such a two-story structure will be much heavier. Although the use of frame technology, which came from Canada, will significantly facilitate construction, both in terms of weight and time. In addition, it will allow you to save on materials. The composition of the roof is rafters made of timber, sheathing made of boards. It can be covered with any available material - metal tiles, ondulin, corrugated sheets. The main requirement for it is light weight.

Stages of work:

- laying the foundation;

- frame installation;

- roof construction;

- laying insulation;

- cladding outside and inside.

How to properly build a panel bathhouse with your own hands?

You can quickly build a steam room using a frame and covering it with OSB boards. This method allows you to save on materials and makes construction easier. A panel bathhouse is much cheaper in cost than a log house. The basis of a structure is its foundation. In this case, it is enough to simply dig and drive piles no longer than 2.5 m, which will speed up the work time. Then the frame is installed and sheathed with slabs. Insulation is laid on them - on the outside, while a vapor barrier and waterproofing must be installed on the inside. The last stage is finishing. It is carried out with clapboards or boards, and it is advisable to use deciduous wood inside, and coniferous varieties outside.

What are the differences between a frame bath and an attic?

The use of prefabricated structures greatly simplifies the construction process. So a frame bathhouse with a 6x4 attic does not take long to build. The cost of materials for such a structure is low. And the benefits are significant. In this case, work can be carried out even in winter. Such a bathhouse will not shrink, therefore, finishing can be carried out immediately after the construction of the frame with the roof. You just need to think about how to properly insulate such a structure and what material to use to protect the steam room from condensation. A bathhouse on a frame basis, even with an attic, will not be too heavy, so the foundation for it is not complicated. And to remember the stages of construction, you can create a photo report.

Vapor barrier, waterproofing of walls and ceilings

We provide vapor barrier on the internal walls and ceiling using foil materials. You can use the same Penotherm, Izospan FB or their equivalent. We shoot the foil to the frame with a furniture stapler, and glue the joints with foil tape. It is necessary to achieve the least loss of steam and heat. The purpose of a vapor barrier is to prevent steam from leaking into the ceiling and walls. Otherwise, no amount of insulation of walls and ceilings will save you.

We waterproof the walls from the outside, that is, we cover the mineral insulation on the street side. The goal is this: to release moisture that accidentally appeared in the wall and not let atmospheric moisture back in. Here you can use protective membranes or films from Izospan. The result will be good. That's all, let's build further.

Stage III. We lay and insulate floors

In short, to make floors in a frame bath, you need to nail bars with a section of 5x5 cm to the bottom of their logs in the relaxation room, the steam room, and the dressing room, and lay subfloor boards on top of them, then roofing felt, and finally - mineral wool 10 cm thick or expanded polystyrene. And already under the boards of the finished floor you should lay glassine for vapor barrier:

In the washing room, the floor needs to be done differently:

- Step 1. So, in order for it to always be warm in cold times and dry quickly, you need to make a separate foundation along its entire perimeter.

- Step 2. Next, remove a layer of soil by half a meter, and fill the resulting pit with gravel and sand to a 10 cm layer. If water gets into such a drainage well, it will go into the ground, and there will be no need to make a pit.

- Step 3. For the logs of such a floor, it is best to use asbestos-cement pipes with a diameter of 10 cm, which are placed directly on the foundation and filled with concrete so that it keeps them from moving.

- Step 4. Then, in the washing room, a 4-5 cm thick edged round board is laid over the pipes, but with a gap of 6-7 millimeters with rubber gaskets, which are nailed.

- Step 5. After all this, the floor can be pressed down with baseboards.

More details in the video: