The stove or fireplace is called the “heart of the home” for a reason. But taming fire inside a residential building requires a whole series of actions and a long set of rules. After all, any mistakes in the design of a chimney are too expensive, starting from suffocating smoke inside the room and ending with a fire. And most often it all starts with a violation of draft and destruction of the walls of the chimney, and then adjacent building structures catch fire.

Today, chimney height calculations are often carried out through special programs, although experienced specialists always check the obtained values manually, using formulas that it makes sense to get acquainted with for peace of mind.

They are not complicated; to understand them, it is enough to have a school knowledge of geometry and the ability to substitute values in the right place. And we, in turn, will try to explain to you why each indicator is so important for determining the height of the chimney pipe, and how exactly it affects it.

Chimney location and wind direction: how to prevent turbulence

According to all building codes and regulations, the chimney must rise above the roof at a certain distance. This is necessary so that the air on the protruding parts of the roof does not cause reverse draft due to turbulence.

Backdraft can be seen firsthand in the form of smoke that pours from the fireplace directly into the room. But the extra height of the chimney is also not needed, otherwise the draft will become too strong and you won’t get any heat from such a fireplace: the wood will burn to ashes like a match, without having time to give off heat.

This is why it is so important to calculate the height of the chimney as accurately as possible, especially taking into account the direction of the winds in the area:

If the pipe is located too close to dense trees or a high wall, it must be extended with asbestos-cement or steel pipe.

In this video you will also find valuable tips on installing a chimney and solving problems with its height:

How to calculate the height of the ridge of a gable roof

The required value depends on several factors, but, as a rule, the type of attic is considered decisive.

We recommend If you plan to install an attic, then the calculated value is equal to the sum of the heights of the racks for the purlin and the ceiling of the room.

In the general case, the slope of the slope and the dimensions of the building and, as a derivative, the type of material are taken into account. The calculations use data from a specially designed table, in which the width of the building and the magnitude of the slope are related through a coefficient.

Let’s say the width of the building is 8 m and the slope is 40°. The height of the ridge of a gable roof is calculated according to the following scheme: half the width is multiplied by a coefficient, the value of which is found from the table. Thus, the height or distance between the top point of the roof ridge and the ceiling is 4x 0.86 = 3.44.

Traction force: how to achieve ideal fuel combustion

The traction force itself is influenced by several important factors:

- chimney material;

- foundation height above sea level;

- flue gas temperature at the furnace outlet;

- cross-sectional shape of the chimney pipe;

- smoothness or roughness of the inner surface;

- violation of the internal tightness of the chimney;

- temperature and humidity of outside air;

- ventilation of a room with a boiler or stove;

- completeness of fuel combustion;

- degree of contamination of the boiler (or stove) and chimney;

- type of burner used (modulating or discrete).

First of all, you need to determine the value of the static draft of the chimney, which is measured in the value ∆p [Pa]. Here is the formula for calculation:

h[m]=(∆p·Tp·Tн)/(3459·(Tp-1.1·Тн))

Tp is the average temperature in the pipe, and Tn is the outside temperature. It is measured by default in degrees on the Kelvin scale, but you can also specify it in Celsius by adding +273.

Calculating the average temperature is not difficult. This is usually reported in the technical data for the boiler, but it is also important to take cooling into account. This is 1 degree per meter of brick pipe, 2 degrees per meter of insulated steel pipe and 5 degrees for uninsulated one.

In this case, it is advisable to take the value of the outside temperature that is typical for summer as the most problematic time for traction:

Make an aerodynamic calculation and find out the exact required height and diameter of the chimney. The amount of draft itself means the difference in the densities of air and flue gas, multiplied by the height of the house. It is 5 meters of the chimney that provide vacuum and draft for smoke .

But what to do if the height of the pipe cannot be set higher, and the draft for certain reasons is still insufficient? This often happens when flue gases cool down too quickly, especially in the cold season. Then, to restore traction, the required section of the pipe is simply insulated.

Also remember that real thrust is always less than static due to the resistance to the movement of gases inside the pipe walls. The narrower the flow section of the chimney, and the more bends, horizontal sections, etc. there are in it, the worse the draft will be, because the draft is affected by the loss of pressure along the entire length of the pipe.

Another problem with chimney height is cold air from the fireplace. So, when it is not working, cold air from the street is released from it. This happens when the chimney head is below the end of the ventilation hood, or when the attic is too large and poorly insulated.

Assembly Tips

After constructing the chimney, as well as some time of use, it is important to take care of regular cleaning of the system. The most proven way to clean a chimney is to use mechanical tools.

Special brushes, weights, and in some cases a crowbar and a sledgehammer are suitable for this.

Working as a chimney sweep is a dirty job, so everything is taken out of the bathhouse in advance, the surfaces are covered with newspapers or film:

The simplest method is to use a special brush that can be used to clean the chimney. Simply insert the brush into the pipe, then gently push it upward until the resistance due to accumulated soot disappears. It should not be rotated around its axis, otherwise there is a risk that it will get stuck in the pipe and will have to be removed in parts. Another effective method of cleaning a chimney is burning aspen wood. The method will help with a small amount of soot on the surface of the pipe. When burning aspen logs, a better traction force is created, which is capable of removing soot from the chimney.

- Potato skins have similar properties. But to prepare the required amount of material, you will have to get serious about cleaning more than one kilogram of vegetables.

- Modern methods of protecting pipes from soot using chemicals have become common in use. Modern preparations include special components that, when burned, carry away soot. The components can act as a soot separator; as a result, it will fall off the pipe walls itself.

It is believed that the best time to clean a chimney is after rain. In a humid environment it is easier to maintain the pipe. Timely cleaning of pipes will be the key to high-quality combustion of firewood. This will keep the bath warm. To learn how to make the right chimney for a bathhouse, watch the video below.

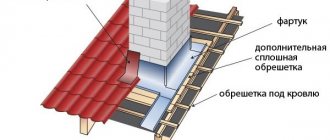

First, about brick structures, which are a continuation of the furnace masonry. The passage unit, called cutting, is performed by expanding the masonry to standard dimensions, as shown in the diagram above. It turns out that when crossing the ceiling, it is necessary to maintain a wall thickness of one and a half bricks (380 mm), and a roofing thickness of 1 brick (250 mm).

Steel pipes for exhaust gases are usually assembled from sections inserted one into the other. Moreover, the chimney must be installed in such a way that the condensate inside the flue can flow down without hindrance. That is, the upper section is inserted into the lower one, this is called a “condensate” assembly. As for modular sandwiches, the inner pipe of the inserted upper section should fit into the lower one, and the outer one should wrap around the casing of the lower one from the outside. In this way, sediments are removed and quietly flow to the ground.

- Be sure to use a ceiling passage box, even if you are using a sandwich. Fill it with expanded clay, foam glass or mineral wool. Do not fill the space around the pipe with earth, especially sand. Sand tends to get very hot and retain heat for a long time.

- The most optimal chimney height is 4.5-5 meters. Try to stick to these parameters.

- The upper edge of the pipe should rise above the ridge by at least 50 centimeters. But, if the roof is flat, then the height here should be at least a meter. For large chimney heights, special guy wires are installed.

- In a steam room, if the pipe passes near a wall or partition, then a protective screen must be installed on the wall. It can be in the form of stainless steel or basalt cardboard.

- When installing a flash drive, it is recommended to use a special thermal and weather-resistant sealant. He copes well with the task assigned to him. By the way, during the assembly of a chimney sandwich, the same thermal sealant, and sometimes crimp clamps, are often used.

- If flammable roofing material is used, a spark arrestor is required. You can do it yourself by using a used KAMAZ air filter.

- Try to avoid sandwich pipe joints in the ceiling passage. At this point the smoke channel must be solid.

We invite you to familiarize yourself with: Ventilation in the bathhouse diagram and device

Wisdom Quote: If you want the world to change, be the change.

Chimney design depending on heating configuration

Go ahead. What chimneys are installed most often today? These are brick, ceramic and insulated and non-insulated steel.

And first of all, when designing a chimney, its minimum throughput indicators are calculated. If mistakes are made here, flue gases will begin to accumulate inside the pipe and cause a lot of problems.

The general layout of the chimney looks like this:

If the temperature of the exhaust gases is low, as in modern low-temperature boilers, then so-called electric smoke exhausters are installed in the upper part of the chimney.

They are a small fan with blades. Such a device forcibly removes combustion products from the pipe, thereby increasing the traction force. And then the traction force no longer directly affects the height of the chimney, because it is achieved in a different way, and not by “catching the wind.”

If there is no additional device, then you will still have to catch the wind. And in this case, you need to build on the available power of the boiler, stove or fireplace, which can be found in the technical documentation. It is expressed in the amount of fuel that is burned in one hour of work.

If the amount of fuel volume is known, then the volume of gases is calculated using the following formula:

Vg = B∙V∙(1+t/273)/3600

The result will be in m3/s. This is the speed of gas movement in the pipe. We calculate the cross-section of the pipe using the following formula:

F = π∙d²/4

And the resulting value is determined in m2. This is the cross-sectional area of the chimney, and the diameter is calculated using the formula:

dt = √4∙B∙V∙(1+t/273)/π∙ω∙3600

The remaining characteristics are almost the same for most heating devices. Thus, the exit speed of gases in the chimney is usually no less than 2 meters per second, and the temperature of the gases at the entrance to the pipes is from 150 to 200 degrees.

Also, the standard gas pressure per 1 meter is no less than 0.4 mm H2O, or 4 Pa:

Therefore, according to SNiP, the height of the chimney from the grate must be at least 5 meters.

Channel requirements

The location of the chimney relative to the ridge is not the only issue during construction. It is important to take into account the recommendations and pay attention to the following:

- The material is selected depending on the fuel the boiler runs on. For a gas, stove or solid fuel unit, a stainless steel pipeline would be a good option.

- The number of heating devices should not exceed two per chimney. Otherwise, there is a high risk of incorrect diameter calculation. When using two heating devices, one type of fuel must be used, and the diameter of the pipes can be no larger than the chord of the chimney itself.

- It is preferable to construct a cylindrical or round pipe. This design allows you to create ideal draft, preventing smoke from returning to the room.

By following these simple rules, you can achieve efficient operation of your heating system.

Dependence of the chimney height on other roof elements

Of great importance is also how close the chimney itself is located to the ridge of the roof, parapet or its other elements:

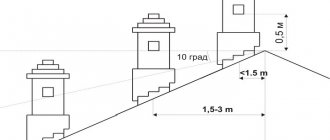

So, regarding the elevation of chimneys above the roof, there are the following rules:

- No less than 1.2 meters above a flat roof.

- No less than 50 cm above the roof ridge, if the pipe is located up to 1.5 meters from the ridge.

- Not lower than the ridge level if the pipe is located from 1.5 to 3 m from the ridge.

- Not lower than the line that can be drawn from the ridge down to the horizon at an angle of 10 degrees, if the pipe is located more than 3 meters from the ridge.

In this case, the smoke duct must be located at a certain distance from other elements of the building, minimum:

- 150 mm for pipes with insulation;

- 500 mm for pipes without insulation.

The minimum permitted pipe height is 50 cm. But these are too low pipes, which are only allowed to be installed on flat roofs without any protrusions. If the roof has a more complex configuration, you will have to tinker and take into account all the protruding parts.

So, if all these parts are located at a distance of 1.5 meters from the pipe itself, then the pipe only needs to be higher than all these elements. If they are closer than 1.5 meters, then the chimney must exceed their height by at least 59 cm:

Pipe section

This design parameter is critical to ensuring the efficiency of the heating system. It is determined primarily by the shape of the chimney.

When using a classic cylindrical or round channel, it is enough to follow a simple rule: the cross-section of the pipeline should be proportional to the combustion chamber in the amount of 1 to 10. If a square shape is used during construction, the proportions should be 1 to 1.5.

If the requirements are met, the heat output will be sufficiently effective to ensure proper operation of the stove heating. In this case, the boiler itself will not be overloaded, working at 100%, but without wear.

Location of the chimney exit from the house

There are also rules for installing a chimney through the roof and wall. Here is an example of installing a pipe directly through the roof:

Maintaining a chimney height of 5 meters from the firebox grate to the top cut of the pipe is not difficult if a one- or two-story house was built. But problems arise if the fireplace was installed on the upper attic floor - the height of the ceiling and attic is insufficient.

The installation of a chimney through the wall of a house or bathhouse occurs a little differently:

Please note that stoves should be connected to chimneys using chimney pipes no longer than 0.4 m.

What is it for

There are several reasonable excuses for calculating the height of the chimney above the ridge:

- with the correct height, heating efficiency increases. The heating device will produce maximum heat transfer and fuel costs will be the lowest;

- in order to maintain the health of those living in the house. Incorrect calculations lead to smoke and carbon monoxide entering the building. It is necessary to provide the necessary draft for the operation of the chimney;

- in order to prevent fire. A short pipe prevents the gases from cooling, which can lead to a fire.

A correctly calculated chimney saves fuel and protects the health of people living in the house.

Environmental considerations for industrial buildings

In a word, the throughput of the chimney pipe must ensure the unhindered passage of smoke and its release into the atmosphere. Moreover, the environmental aspect is also important here, namely, whether the products of fuel combustion are properly dispersed in the atmosphere.

Thus, during the construction of commercial and factory enterprises, certain sanitary standards are taken into account. And they depend on the weather conditions of the area, the typical speed of air flow, the topography of the landscape and many other factors.

So, what value did you get and is it exactly equal to 5 meters?

Important nuances of calculating a chimney

Even with the help of a seemingly simple formula, it is not always possible to achieve the desired result. During construction, it is necessary to take into account several more important details. One of them concerns the diameter of the outlet. If you select it correctly, you can achieve additional advantages:

- Reduce fuel consumption.

- Regulate the operation of the heating system.

- Ensure absolute safety.

When making calculations, it is necessary to take into account the material used and existing ventilation. It depends on them how well the exhaust gas will be removed.

Preparatory work

Before proceeding with installation, it is necessary to clarify several basic factors. When selecting a channel, you need to take into account the height of the building, the diameter of the future channel, and others. Give special attention to the installation site and location of the heating equipment. Installation of a sandwich chimney, like any other, can be done in two main ways:

- Internal.

- External.

For example, when installed internally, the installation of a sandwich chimney is carried out directly in the heated room, and in this case additional sealing is not required. But, there is a nuance, if the attic space is not heated, in this case, it would be useful to additionally insulate the pipe during installation and carry out a seal to prevent exhaust gases from entering the rooms with the ensuing consequences. In addition, at the initial stage, think about what to do with those materials, walls, next to which, in contact, the chimney will pass. Surfaces must be treated with special fire retardants.

Do-it-yourself sandwich chimney installation

As for external systems, the assembly of the external sandwich chimney must be carried out taking into account the mandatory insulation. These types are much safer, since they immediately remove the pipe to the outside during installation, reducing the likelihood of exhaust gases entering the premises.

Which type and shape should I choose? Here it is worth giving preference not only to aesthetic indicators, but also to functional ones. Keep in mind that it is easy to fix or fasten a square chimney, it is quite easy to use and does not require special skills during installation. But the main disadvantage of such a system is the accumulation of condensation and other unnecessary dirt and dust inside. Round elements in this part are much preferable, given their shape; they retain much less not only a variety of debris that can get in from gusts of wind, but also form less condensation, naturally taking into account proper insulation. The only thing is that such systems are difficult to install and you will need skill. In addition, do not forget to prepare the necessary tools for installation in advance. So, the tools needed to install a chimney:

- Drill, grinder.

- Jigsaw, screwdriver.

- Hammer.

- Screwdrivers.

- Protective ammunition.

- Spatula and chisel.