Before starting the construction of a bathhouse, it is good to estimate in advance how much it will cost, whether you will have to involve professionals or you can do it yourself. Laying the foundation is one of the most critical stages. After reading our article, you will get an idea of how to make a foundation for a bathhouse - with examples of calculations for each type.

We hope that this will be enough to estimate the estimate and scope of work at this stage, given that the foundation makes up from 20 to 50% of the total cost of building a bathhouse .

Columnar foundation

When considering a columnar foundation for a bathhouse, it is worth evaluating the following options:

- pipe;

- tree;

- brick;

- concrete block;

- concrete.

The standard formwork for a bathhouse is made of wood. The foundation itself can be made of brick or pipes. The correct foundation for a bathhouse is also made from other materials. It is not considered a mistake to use concrete blocks.

Base with pipes

Foundations for a bathhouse made of pipes look simple in design, but are complex in execution. Special equipment is often used to install elements. The diameter of the pipes is 200 mm, so a bathhouse on a foundation in this version can be expensive.

Wood base

Filling the base for a bathhouse with your own hands is not required when choosing wood:

- oak;

- aspen;

- pine.

Builders speak well of oak or aspen racks. The problem is that the material needs to be treated so that high humidity does not destroy it.

Brick base

The foundation for the bathhouse is made of brick. For this, a sand cushion is prepared in a depression of up to 0.2 meters. The pit can have straight or sloping edges. Sand-lime brick is suitable for a number of reasons:

— high strength;

— reasonable price;

- durability.

In construction, sand-lime brick is used specifically for foundations.

Made from concrete blocks

The base for a bathhouse made of concrete blocks is an option for permanent buildings for many years. The main advantage is simply execution. This type of material does not require additional processing. The blocks used are 20 by 20 by 40 cm.

Made from concrete

For soil, you can consider the option of formwork and pouring concrete. Advantages:

— monolithic design;

— durability;

- ease of execution.

The concrete base does not require additional processing during installation.

Formwork

Formwork diagram

Formwork for a strip foundation can be assembled from panels, slate, fiberboard and other similar materials. By the way, shields made of plastic or metal can be rented, which will significantly simplify the construction process. It is advisable to wrap the formwork materials with film, then they can be reused in the construction of other objects.

Board formwork

The formwork is installed in trenches, supported from the outside with lumber and stakes. Between the walls of the formwork, wooden transverse struts and metal pins with a pitch of 50 cm are installed so that the panels do not move apart under the mass of poured concrete. The panels are fastened to the ground with long nails (20 cm), and to each other with self-tapping screws or a stapler.

Formwork, diagram

The panels must immediately have openings for the outlet of sewer pipes and other communications. Otherwise, after pouring you will have to drill through the concrete, which will negatively affect the strength of the foundation.

Formwork

Advice! If you do not use film to protect wooden formwork, then staple glassine. It will prevent the tree from quickly absorbing moisture from the concrete solution and, as a result, cracking the foundation.

Video - Do-it-yourself wood formwork

Prices for various types of construction boards

Construction boards

Video - Non-removable formwork for strip foundations made of EPS

Tape base

If you choose a strip foundation with concrete pouring, it is worth considering the stages of work:

— marking;

- trench;

— soil preparation;

- styling;

- concrete works.

When the marking is completed, you can move on to the trench. Experts recommend preparing the soil and only then doing installation.

Marking the foundation for a bathhouse

Using markings, builders are able to make a frame for the foundation of exact dimensions. The secret is that all factors are taken into account:

— height of the structure;

- recess.

The upper slots of the foundation should be covered. Roofing felt is suitable for this - it is an inexpensive but practical material. The horizontal platform must be in the center, plus the level is checked.

View this post on Instagram

Post from Fundament. Screw Piles (@fundament_guru)

Foundation trenches

When clearing the ground for the foundation, it is worth looking at the markings. When removing each layer of soil, it is important to monitor the level. The edges remain at a slight angle. If you have special equipment, it is easier to throw the soil into the right place.

Preparation for construction

The first stage is preparatory, so the bottom of the trenches must be compacted with a vibrating plate. To make the structure stable, a cushion and backfill are made. There should be markers near the trench. Appropriate materials are prepared for the walls in the bathhouse and ceiling insulation. At the second stage, concrete solution is prepared. The builders are placing beacons and the formwork can be prepared.

Features of arranging a foundation on heaving soil

Interested in the foundation, step-by-step instructions. However, on heaving soil it is worth performing preparatory work. Builders prepare a mixture of sand and crushed stone. Next, the trench is prepared.

A cushion of sand and crushed stone is prepared at the bottom and only after that the formwork is placed. Filling with the solution will be possible after fixing the supports. The level and strength of connections is checked. For saunas, it is important that the base is stable.

Features of laying a columnar base

A column foundation is the easiest to install. Construction can only be hindered by bad weather. To begin work, markings are made. The interval between pillars is 0.3 meters. You can mark with a regular ruler. If the meter is missing, this is a good solution. Using the marked beacons you can make indentations. To do this, you don’t have to use machinery, a shovel is enough. The calculated design must take into account the diameter of the supports.

Laying a slab foundation from tires

While beginners are wondering how to make a foundation for a bathhouse, professionals simply use tires. This is a universal material for this matter. First, the site is cleared and the soil is prepared. The powder can be made from ordinary crushed stone.

If you are interested in a foundation for a bathhouse with your own hands, step-by-step instructions, you should look at the work plan:

— site preparation;

— tire fixation;

— installation of the ceiling. If you are making a foundation like this, it is important to align the tires at the same level. Builders are able to use different schemes for arranging tires. This determines how effective the foundation will be. The square pattern is the most common. Users prepare the site and prepare materials.

Builders are considering a structure in several rows. It has its advantages:

— presentable appearance;

- Possibility of raising the ceiling.

At the same time, shortcomings are noted. They are associated with the instability of the structure. Builders are trying to find a high-quality floor, but roofing felt is not suitable for these purposes. Beginners are recommended to use putty. The distance between tires should be no more than 0.1 meters.

With the arrangement of insulation, the situation looks simple. First, the primer is made, and then the putty is prepared. Experts recommend using thick mixtures. To prevent the base from taking on excess moisture, a film is used. Most often it is laid on top of tires in several rows.

Arrangement on an additional basis is a good solution for large structures. For example, the length of a room is 5 by 5 meters. Then a crushed stone lining is used. Craftsmen know that work requires an open area.

Tool for work:

- file;

- shovel;

- ruler.

Builders use a shovel to prepare a construction site. The saw will allow you to work with tires if they do not lie in a row. The tool is also used for working with insulating materials.

The ruler will allow you to measure the required number of blanks. The material is preliminarily laid out and comparison takes place.

Concrete work on the foundation

The actual question is how to pour the foundation for a bathhouse with your own hands. For this, experts give recommendations:

— use of a protective cushion;

— adhesive mixtures;

— formation of formwork.

The instructions begin with simple rules for preparing the mixture. If a wooden panel is installed, it must withstand the maximum load. The mixture uses sand and cement in equal proportions. The prepared solution is poured after the adhesive additive is added.

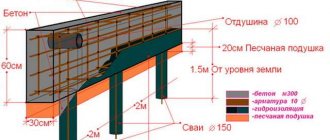

Reinforcement

The armored belt is made of thick reinforcement (>12 mm longitudinal and 6-8 mm transverse, vertical reinforcement). To work, you will need a grinder, wire for tying the armored belt, a welding machine, and a tape measure.

Reinforcement

The belt consists of longitudinal (four or more), transverse and vertical reinforcements. In this case, the entire structure must be 5 cm away from the formwork, soil and the top point of the foundation, and be reinforced in the corners of the building. The cross section of the armored belt is a rectangle or square.

The reinforcement is cut to the required length. Longitudinal and transverse rods are laid out on the ground and tied with wire at the points of contact. Welding the frame is not recommended, since the welded frame may lose its integrity when compacting the poured concrete or operating the constructed bathhouse.

The longitudinal rods are laid out and tied to each other with an overlap of about 30 cm.

Knitting longitudinal rods

The distance between the transverse and vertical rods should not exceed 50 cm. If the strip foundation is up to 120 cm wide, then it makes sense to make the frame not from two, but from three longitudinal reinforcement bars. If the foundation height is high, it is also worth increasing the number of longitudinal rods. The frame is also reinforced on top with U-shaped clamps, designed to increase the strength of the structure and reduce the risk of cracking of the strip base.

Clamps

At the corners of the bathhouse, the frame is additionally strengthened with reinforcement located at an angle of 45 degrees relative to the horizontal rods.

Corner reinforcement

Corner reinforcement

The finished connected frame is installed on plastic supports. To prevent movement during the pouring of concrete, plastic fasteners are inserted between the formwork and the reinforcement.

Strip foundation reinforcement

Reinforcement and laying of communications

Video - Knitting reinforcement with a hook

How to make a foundation - strip construction in practice

For example, it is worth considering the project of a 5 by 5 meter bathhouse. I'm interested in how to make the foundation correctly. In the case of a strip structure, the following work is carried out:

— marking points;

- trench;

— formation of formwork;

- filling.

The easiest way to make formwork is to use wooden boards. As for breeds, it is difficult to give a definite answer. The bathhouse is rigidly installed on the ceiling. Ruberoid is suitable for this. The step-by-step plan still begins with markings, since marks are placed at key points.

Also, in the case of the tape type, a square pattern is in demand. Builders first prepare raw materials for formwork. When one floor is used, the following material can be used:

- boards 2 meters;

— nails 100;

- corners;

- film.

The structure is assembled in several rows after the formation of the substrate. The depth of the trench should be no more than 0.1 meters. It is important to level the bottom of the site. You can use a regular shovel for this. Experts recommend not using sand pillows.

If the structure is larger than 5 by 5 meters, then you cannot do without it. The construction of insulation is the last thing builders deal with. The formation of the blind area comes to the fore. People have a desire to insulate the building so that the building is not subject to destruction.

Arrangement on an additional basis deserves attention when the soil is soft. For example, a builder does not have access to a vibrator to form the bottom. Then it’s worth laying out the film. Crushed stone backfills help with frequent downpours. The tape type always assumes that a person will lift the structure and strengthen it.

Crushed stone lining is also produced when using a structure whose length is more than 5 meters. The first step is to make a trench. The optimal width for it is 0.3 meters. Next, it is important to note that the open area was level. Differences are eliminated using a shovel.

View this post on Instagram

Posted by Svaimaster (@svaimaster64)

Filling trenches and installing a plinth

After the cushion has been prepared and reinforcement has been carried out, it will be necessary to begin pouring concrete into the trench. This procedure must be carried out in 1 step, so it is worth calculating your strength and preparing a concrete mixer in advance or ordering ready-made concrete in advance.

When pouring, it is worth remembering that if you are building a bathhouse measuring 5x6, you will need 16 tons of concrete. After it goes completely into the trench, the mixture will have to be compacted until a layer of so-called “concrete milk” appears on the surface of the concrete. This procedure will need to be carried out in order for the air to escape from the mass.

After the underground part of the foundation has hardened, it will be possible to proceed to the design of the base. This structural element of the bathhouse is made of stone, brick, or by pouring concrete into formwork made from boards. After this procedure, it will be necessary to bring the finished foundation to zero. For this purpose, its level is measured in diagonally located corners.

During the measurement, “plus” or “minus” marks are applied to the foundation, depending on the detected deviations. Later they are eliminated by adding concrete to these points. As for the horizontality of this line, it is established using a building level. In addition, small unevenness can also be eliminated using plaster. When this is completed, it will be necessary to waterproof the foundation, and then proceed to the construction of the walls of your future bathhouse.

Foundation: what will the walls be made of?

Novice builders are wondering how to properly mark the foundation. Before doing this, you should pay attention to the material of the walls.

Options to choose from:

- timber;

- brick;

- foam block.

Before making the formwork, it is worth calculating the load. The material is weighed differently, the coverage area is taken into account. The formwork for the base can be recessed into the ground or, conversely, raised. The optimal height for the structure is 0.2 meters. For the foundation of the bathhouse, you can prepare additional supports as needed.

From a log frame

I'm interested in how to make a foundation with your own hands. If the walls are made of timber, you should not expect a heavy load. The maximum protrusion for the structure is 0.2 meters.

You can install a ceiling on the foundation. Ruberoid is best suited for these purposes. When pouring a bathhouse, the supports and side racks are checked.

Brick foundation

The builders are planning to install a brick bathhouse, so they are interested in how to make the foundation correctly. Experts show calculations and talk about the need to install a columnar structure.

To construct wooden formwork, you can prepare boards 2 meters long. Bars are installed in the corners for strengthening. Strip-type foundations are also suitable, but the indentation should be no more than 0.2 meters.

Foundation with foam blocks

When a structure is made from foam blocks, it is interesting how to calculate the load. The strip foundation option eliminates all questions. Advantages:

- small height;

- Can be done on any type of soil.

To calculate the basis, you need to know the dimensions of the structure. The interval between supports is no more than 0.3 meters. Marking can be done using inserted rods.

Basis for a frame bath

There is a frame structure, so it is interesting how to mark the foundation. Experts give the following advice:

- use of tape base;

— use of high grade concrete;

— make the ceiling from roofing felt.

The correct foundation is level. Builders plan in advance where subsidence may occur. Calculation of the foundation for a frame structure assumes that the interval between the posts will not be more than 0.2 meters.

What is needed to mark the foundation

In order to do everything efficiently, with your own hands, quickly and correctly, you will need:

- 10m tape measure;

- laser marker (level, water level);

- screwdrivers, plumb lines, hammers and hatchets;

- hacksaw;

- reliable cords, it is possible to use fishing line;

- fittings;

- when creating body kits: wooden beam 10x10 cm, board 4x15 cm, screws and nails;

- construction site with suitable soil.

The bathhouse will last the longest on soils that are not prone to subsidence, landslides or heaving. Therefore, peat, silt, clay and fine sand are not the best option, as they will require additional hardening with coarse sand in a layer of up to 25 cm.

How to calculate the basis

The main question is how to mark it correctly. The following factors are taken into account:

- type of overlap;

— indentation from the ground;

— length of the structure.

When a bathhouse is built, the foundation is made according to building codes. The maximum distance from the ground should be no more than 0.2 meters. Next, the spacing between supports is taken into account. A simple foundation for a bathhouse is placed based on the type:

- ribbon;

- pillar;

- piles;

- plate.

Scheme for calculating the basis of the tape type

On forums, builders are interested in how to make a base for a bathhouse. In the case of a strip structure, the following standards are established:

— indentation up to 0.2 meters;

— maximum length 4 meters.

The construction of the foundation begins with the formation of a pillow. Formwork is placed on the trench. After this, the foundation of the bathhouse will be able to withstand heavy loads.

An example of calculating a foundation with pillars

The foundation for a bathhouse can be of a columnar type. This means that you need to look at the standards:

— the interval between supports is 0.3 meters;

— maximum offset 0.4 meters.

Next, builders are interested in how to fill a bathhouse. The use of ready-made mixtures will help in this matter.

Scheme for calculating a foundation with piles

The pile foundation for the bathhouse is made according to the following standards:

— pillow height 0.1 meters;

— the interval between piles is 0.2 meters.

The pile foundation for a bathhouse can be located at different heights from the ground. Experts recommend paying attention to the terrain. Also interested in the foundation, step-by-step instructions, which will be discussed later.

Scheme for calculating a foundation with a slab

The tiled structure is ideal for a bathhouse, but the following standards are important:

- formwork required;

— maximum rise 0.2 meters.

Interested in DIY foundation, video. From the materials on the Internet, you can understand that the design standards were established for a reason.

Final activities after pouring concrete

Proper maintenance of concrete protects the finished foundation from cracking.

To do this, maintain constant humidity of the array in the following ways:

- regularly moisten the belt surface;

- cover the concrete with polyethylene after saturation with moisture.

Compliance with these requirements ensures the normal course of the hydration process. A month after pouring, when the monolith gains strength, carry out further work on building the bathhouse.

How to properly mark the foundation

The simplest foundation for a bathhouse, for example, is the strip type. To make markings, you should follow the plan:

— tool preparation;

— setting labels;

- clearing the site.

The foundation for the bathhouse will be made according to the standards, if there is an interval between the supports. Experts know that the permissible deviation is no more than 0.2 meters. To prevent the foundation for the bathhouse from collapsing in the future, reinforcing mixtures are used for exterior finishing.

Preparation and marking of the site

In order to correctly carry out the marking, it is necessary to first prepare a project and calculate the foundation of the future bathhouse. You will use it to mark the walls.

Marking the corners of the walls is done by driving in pegs at the required points.

After this, you need to install four more pegs with precision. It is necessary to check the accuracy of the diagonals of the external walls of the bathhouse. If everything is correct, then we move on to marking the external walls of the bathhouse.

We stretch the rope from one peg to another, at the level of the future foundation. For greater reliability, you need to use a level.

Waterproofing the bathhouse foundation

For example, consider the foundation for a 3x3 bathhouse. Roofing felt is used as waterproofing. Such a basis for a bath, photos can often be found on the Internet. Builders can use additional mixtures for waterproofing.

Nuances for specific types of foundation:

- plate;

- ribbon;

- piles or pillars.

The foundation is decisive in the use of waterproofing material. Bitumen-rubber mastic is a good option for anyone. Optimal application surfaces are concrete, cement. In this case, good tenacity is ensured.

If brick or stone bases are considered, lightweight versions are used. Buyers should pay attention to the expiration date. When wooden or metal ones are used, there will be no problems with adhesion.

Ceramics and asphalt can also be used on the site. In this case, the isolation completely works. The fact is that reinforced concrete and metal structures provide tenacity and rigidity. When it starts to rain, there is no risk of surface deformation.

Lightweight versions differ in solvent content. You can check with the manufacturer for the exact percentage. The smaller it is, the better. Other bath protection products:

— hydrobelt;

- mastic foundation.

Builders understand that modern waterproofing material is emerging. It significantly surpasses the previously considered options in properties. There is a tape-type mastic that is considered appropriate for a bath.

It is suitable for protecting building structures, so builders are ready to take it in large quantities. The price per roll is no more than 600 rubles. The raw material protects against capillary moisture. The user will not have any problems with installation since the material is easy to cut.

The second point is the quality composition; the packaging indicates that the hydrobelt is made of high-quality polyvinyl chloride (PVC). For a bathhouse, it is important that the material is suitable for protecting wall structures. Installation can be done in one or several balls.

Provides protection against capillary penetration of moisture. Some may also be interested in paying attention to the following properties:

— rigidity of the tape base;

— always ready for installation;

- easy to roll out the roll.

Insulation is considered elastic and flexible. When applied with one ball, you can be sure that in bad weather it will remain in place. The third point is that no lubrication is required. People use bitumen mastic to avoid problems with moisture. When treated with bitumen and resins, the effect of comprehensive protection is achieved.

Characteristics:

— strength from 200 N;

— roll length 50 cm.

Polish-made bitumen mastics remain in demand. It has high strength and there are no problems with selecting a roll of the required length. This is important for non-standard designs. If the country of origin Poland is indicated on the packaging, the bitumen content will not exceed the norm.

It has already been proven that the product has an average temperature of use. That is, mastic can be applied when the temperature outside is not lower than + 5 ° C. The optimal layer thickness is 1 mm. Some are experimenting with additional powders, but research in this area is lacking.

UV stability of the material is ensured for 3 months. This is quite enough to unpack the roll and calmly apply it to the ceiling.

General principles

It is not clear how to make the formwork, since it is important to think about waterproofing. The stores offer different types of primers:

— rubber base;

- synthetic material;

- combined options.

When calculations for a bathhouse have been made, builders must consider the consumption of waterproofing material. To do this, it is better to look at the manufacturer's recommendations.

Nuances for specific types of foundation

If previously the question was how to calculate the foundation, now the issue of waterproofing is relevant. When different types of construction are considered, discrepancies emerge. Before calculating the base for the bathhouse, it is worth providing a sufficient amount of insulation material.

Slab

Now the question is how to make the foundation. The tiled option requires waterproofing measures. Ruberoid is well suited for this, but the sheets will have to be prepared to avoid problems with cracks.

For this purpose, a heating method is used. Using resin it is possible to remove even small holes.

Ribbon

Beginners ask how to mark the foundation. In terms of waterproofing, roofing felt sheets are suitable, but the type of ceiling is taken into account. If the racks are made at small intervals, then the waterproofing material should not sag.

The construction of the foundation is accompanied by constant problems. The sheets may come apart and need to be glued. When the material shrinks, the tightness of the ceiling is broken.

Pile or columnar

The columnar foundation of the bathhouse is not like the others. Roofing felt is not suitable as waterproofing for such structures. Builders use liquid mixtures.

If the sheet is pulled over the pillars, after a while it will begin to sag. The problem is made worse by the fact that the insulation is broken after every rain.

Under the stove

Many have figured out how to properly make a base for a bathhouse, but waterproofing under the stove requires a special approach. Expert advice:

— use of multilayer flooring;

— treating the area with anti-corrosion agents.

Such a bathhouse and foundation will last a long time if the work is carried out in stages.

View this post on Instagram

Publication from Individual Construction (@topbuild_dom)

So which foundation should you choose?

If our bathhouse is light, made of timber, then it would be preferable (and cheaper) to have a columnar foundation or a screw one. If the bathhouse is made of stone, then the classic tape. However, the tape can be recessed (below the freezing depth) and shallow-recessed (MZFL). The area of its sole is also important, which depends on the bearing capacity of the soil (i.e., how much it can sag depending on the pressure per sq. cm).

Note: to determine the width of the foundation depending on the bearing capacity of the soil and the weight of the bathhouse, you can use an online calculator, for example on the website kalk.pro. At the same time, we must not forget that the width of the foundation in any case should not be less than the width of the walls.

READ How to properly glue decorative stone to a wall

If the choice is made on a strip foundation, then, as already mentioned, its arrangement largely depends on the groundwater level and the type of soil. If the factors are favorable (low groundwater level and low soil heaving), it is enough to make a shallow strip foundation - i.e. a trench with a depth of about 50-70 cm is dug. Half of this trench is filled with non-heaving material, and the rest with concrete of a grade not lower than M250, with reinforcement.

Types of foundations (click to enlarge): strip (traditional), columnar, screw, monolithic slab

Note: if you choose fiberglass reinforcement, look at its quality; there should also be no kinks on it. Unwind carefully, it is very elastic. In general, the passions and disputes associated with this fitting do not subside and will apparently continue for a long time. After reading all the disputes and arguments of various experts, analyzing and weighing, I came to the conclusion that it is not scary to use it in the foundation, and I use it myself, but it should not be thin (as some write that thinner fiberglass reinforcement replaces thicker metal one) , and preferably (not necessarily), even vice versa, 2 mm thicker than the calculated metal reinforcement.

It is worth mentioning this type of foundation, which, it seems to me, is undeservedly enjoying little popularity - a monolithic slab. This foundation is not afraid of high groundwater level, as well as heaving soils and their weak bearing capacity. So, when heaving, it simply “floats” without collapsing (if the technology is followed - concrete of a grade not lower than M300, good reinforcement, thickness from 15 cm, and in some cases, when the bathhouse is light, 10 cm is enough), and its area is sufficient for any bearing capacity of the soil. In addition, we immediately receive a finished subfloor, and, if desired, a warm one - i.e. water heated floor pipes are immediately laid, although for a bath this may not be entirely appropriate, because we are still actively drowning it. However, the floor still needs to be insulated - i.e. 10-15 cm of expanded polystyrene should be present after the waterproofing layer.

To pour concrete, you need to build formwork (although some are poured directly into the ground), as a rule, this is done from boards, although other materials can be used - plywood, EPS, etc. The foundation must be raised above ground level by at least 20 cm - but it also depends on the region, if the winters are snowy and the snowdrifts are high, the base should be raised higher so that the wall block or beam resting on the foundation does not come into contact with snow/moisture. The height of the plinth also depends on the type of floor - whether it will be floors on the ground, or wooden floors on joists where communications are laid underground - all this should be taken into account when designing a bathhouse.

When preparing a site for a bathhouse, it should be taken into account that it should have a slight slope to the west, south or east. This will allow melt and rainwater to drain and prevent flooding of the foundations for the bathhouse.

So, we have considered the basic principles and parameters for arranging foundations. Now let's look at a specific example of building a foundation.

Marking for the foundation

Insulation of the base of the bath

There is debate online about how to mark the foundation. It is clear that polystyrene foam can be used as insulation. This is not an expensive material; installation occurs in sheets. Dowels can be used as fastening.

Other options for insulation:

— waterproofing membrane;

- foam glass.

The waterproofing membrane is used for vertical installation. In the case of a bathhouse, you can use a simple option without powders. Craftsmen note that the material provides mechanical protection for waterproofing.

When installing, there are subtleties in cutting sheets. It is important to start with the long edge so that there are no folds. Among other things, the waterproofing membrane ensures constant ventilation of the wall. Some people are interested in using the material together with a lining.

The studded side should be on top. The maximum depth of formation is 4 meters. Professional builders understand that most errors occur when installing horizontally. The concrete surface is treated with a primer before use.

Thus providing a barrier. It plays an important role in ultraviolet radiation. Additionally important is protection against the evaporation of radon and methane gases. When choosing materials, builders give preference to the German manufacturer, since the packaging claims a high class.

When it's needed

Beginners consider how to make a foundation. The question specifically about insulation remains relevant. It must be installed if minimum temperatures drop to -10 degrees. The type of construction is also taken into account. For example, the basis for a bath has been calculated and the columnar option has been selected. It will definitely have to be insulated, since the structure is blown from below.

Preparatory activities

Carry out work to prepare the construction site, guided by the following recommendations:

- Before laying the foundation for a bathhouse under construction, clear the site. Remove turf, remove rocks and debris, and level out uneven surfaces.

- Mark the building, starting from the corner located on the outside of the future bathhouse. Refer to the pre-designed drawing.

To complete the markup you will need:

- wooden pegs;

- long rope;

- building level;

- roulette;

- a protractor or a standard triangle made from planks with a right angle.

This area should have a slight slope in any direction

Marking is performed in the following sequence:

- Drive in the pegs according to the sketch of the bathhouse.

- Pull and secure the cord.

- Check for right angles by comparing dimensions diagonally. Equal diagonals indicate the presence of a rectangular contour.

- Mark the internal walls of the building.

Now you can begin excavation work, which involves excavating the soil 15-20 centimeters deeper than the depth of the trench, recess for pillars or solid foundation. The width of the base should exceed the dimensions of the building by 5 cm on each side, and for soft soils - by 10 cm.

Plan the bottom of the pit using a level, ensuring that the walls are perpendicular. Add sand or a sand-gravel mixture 20 cm thick to the bottom, moisten and compact thoroughly.

Calculation of the foundation slab

It comes down to determining the thickness of the structure:

- First, it is assigned taking into account the protective layer of concrete below 2-5 cm and above 3-7 cm, as well as the distance between the rows of reinforcing mesh 10 cm.

- Stiffening ribs are designed under walls and heavy equipment.

- The laying depth should not be less than 40 cm.

- For timber and log cabins, the slab has the shape of a bowl.

- The width of the slab should be 30 cm larger than the overall dimensions of the bath.

As a rule, for small loads, a detailed calculation of the foundation is not carried out. A slab 10-20 cm thick with double reinforcement with mesh with a cell of 20x20 cm and a rod diameter of 8-16 mm is capable of supporting the weight of buildings over a very wide range.