Materials used in the construction of roofs and arrangement of premises with non-standard temperature and humidity operating conditions are endowed by manufacturers with special properties. They not only easily resist the attacks of steam-saturated hot air, but also create a “thermos” effect, due to which energy consumption for heating is greatly reduced.

These specific products include foil vapor barrier, the installation of which allows you to solve a lot of important problems in the construction of building structures.

Principle of operation

Foil materials are a complex product with a layered structure. The base here is polypropylene fabric, fiberglass, and lavsan. These are components that are resistant to explosive effects, biological and chemical aggression.

The use of a durable non-woven or woven polymer base allows you to create a reliable base for metal foil, which itself cannot boast of particular strength. At the same time, flexibility convenient for installation is maintained. This composition eliminates the possibility of fungal colonies settling and rotting.

Vapor barrier materials on the working side are backed with metallized film. The positive qualities of both aluminum foil and the polymer base are preserved. Vapor barrier with foil copes with three tasks at once:

- Insulation from precipitation and steam. The foil material protects the wall insulation system or roofing pie from steam penetration.

- Reflection of thermal radiation. The metal coating serves as a kind of reflector; it interrupts the flow of heat waves, redirecting the stopped heat within the house.

- Protection from ultraviolet rays and wind. Vapor barrier films are a durable barrier against wind. In the summer, they are able to reflect the sun's rays from the roof if they are installed with the working side facing outwards.

Pasting aerated concrete

Aerated concrete is a material with thermal conductivity identical to natural wood. Despite the fact that it is a mineral material, aerated concrete floats in water. It is suitable for a bath, but subject to careful protection from water. It must be remembered that it actively absorbs moisture. Its resistance to moisture is much lower than that of wood.

On the other hand, getting wet does not lead to the destruction of the aerated block, but it is very undesirable.

The method for attaching foil in a block bath should take this into account.

Invest in thorough waterproofing and do it according to all the rules.

Only in this case will the aerated concrete bathhouse serve you for a long time and be fireproof.

The use of foil in an aerated concrete bath is desirable not so much because of insulation, but because of its excellent vapor barrier properties.

In terms of technology, all the methods for making foil in a bathhouse made of aerated concrete do not differ from the standard ones described in detail in this article.

Foil should not be installed directly on aerated concrete walls. A layer of insulation must be laid. Exactly the same wooden grids with cells and insulating boards are used here.

Methods of application

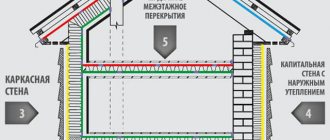

The structure of foil vapor barrier materials has significantly expanded the scope of application. Now they are actively used in insulated roofs , they are often placed on the inside of the roof pie, and in the south they are usually mounted above the insulation. If the house has an unfurnished attic, then foil protection is installed along with waterproofing.

They are often used as a substrate for floor coverings and underfloor heating systems, and for insulating frame wall structures. A foil vapor barrier is also installed in the form of a screen that reflects heat flows from any heating units.

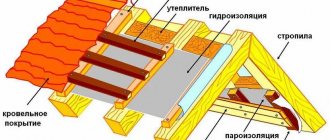

The system must be installed correctly so that the foil materials can perform their reflex function. Between the ceiling of the steam room, the walls, the inner lining of the attic and the metal covering, you should always leave a non-ventilated air gap, the thickness of which should not be less than 2 cm.

If the material is used as a heat-reflecting screen for an attic or flat roof, then a ventilated gap of 3 cm is left . Here, everything that is reflected from the foil can easily be discharged onto the street along with the penetrated steam and condensate.

The necessary gaps are formed by installing a sheathing made of a metal profile or bar. The laths are installed taking into account the type of roofing, the calculated load on the structure, and the slope of the slopes is also taken into account.

Arrangement of thermal protection of walls and ceilings

Insulating the walls and ceiling of a bathhouse from the inside is similar to how it is done in other rooms, but special attention should be paid to the reliability of laying the vapor barrier layer.

Stage one - creating the sheathing. The procedure for how to insulate the ceiling in a bathhouse from the inside suggests that the distance from the sheathing to the base of the wall or ceiling needs to be made slightly greater than the thickness of the material for thermal insulation.

When using galvanized profiles, this gap is adjusted using hangers, and the block is nailed down using a backing, which can be a piece of block. Galvanized hangers are also used for wooden sheathing.

The sequence for attaching the profile is as follows:

- A UD guide profile is fixed along the perimeter of the walls or ceiling, observing a 60-centimeter step. It is mounted to timber or logs with self-tapping screws, and to brick or concrete walls - with screws and plastic dowels.

- The axes of the CD profiles are marked, taking into account that the gap between them should allow the laying of heat insulation slabs without trimming. Then the hangers are attached to the wall, observing a step of 60-80 centimeters.

- To install and fix CD profiles to the hangers, use metal screws 9 millimeters long. The free edges of the hangers need to be folded.

Stage two - installation of insulation. Basalt wool in slabs is placed between the bars (profiles). The insulation of a ventilated façade or loggias is carried out in the same way. The work must be done in a respirator (gauze bandage) and special glasses. The fact is that the small fibers of this material are volatile and, when they get on the human mucosa, they greatly irritate it.

Stage three – installation of steam and waterproofing. Strips of material are fixed horizontally from bottom to top, maintaining a 5-centimeter overlap. The foil side of the insulation should be facing inside the room.

The method of fixing the vapor barrier depends on the material from which the sheathing is made. So, before you insulate the steam room in a log bath, you need to stock up on a construction stapler. If there is a galvanized profile, the strips are secured with double-sided aluminum tape.

To create a high-quality vapor barrier, the insulation not only needs to be fixed, all existing joints must be taped with the same tape. Then moisture will not be able to penetrate the insulation.

Stage four – clapboard covering. To make the room cozy and beautiful after completion of insulation, it is necessary to finish the walls.

First, prepare the tools and materials necessary for the work, including:

- circular saw or electric jigsaw;

- drill - screwdriver;

- rasp (required when adjusting and processing the edge of the lining);

- construction square (necessary for marking boards);

- level and plumb line (they are in demand when checking verticals and horizontals);

- metal clamps for fixing wooden lining;

- copper or galvanized screws, which are needed for fastening the clamps to the bars;

- metal screws;

- wooden baseboards for finishing corners.

When carrying out work, you need to consider a number of points:

The end boards in each row of the lining should be fastened with screws through and through, and their caps will be covered by the baseboard. All other boards will be held in place by clamps.

The above-described procedure for carrying out work allows you to both insulate an old bathhouse from the inside and a completely new building. Thermal protection of a bath structure is a very important stage, since the efficiency of the steam room depends on its quality. The main thing in the work is to take into account the slightest nuances and then the result will exceed expectations.

Benefits of use

Insulating materials, where water-repellent material is combined with foil, have many advantages, which is why they are in high demand among craftsmen. These include:

- Minimum thickness. Laying does not affect the thickness of the roof pie. If materials with anti-condensation properties are used, then it is not necessary to install a distance gap.

- Lightness. This installation will not affect the weight of the structure. Therefore, there will be no need to carry out additional actions to strengthen the foundation.

- Flexibility. Installation is easy, even if you have to lay the material on complex forms. You can easily go around concave and convex corners, various rounded surfaces.

- Environmental Safety. Vapor barrier films are made from materials that are not harmful to human health or the environment.

- Manufacturability. The sheets are easy to cut with regular scissors, or you can use a construction knife.

- Zero porosity. Vapor barrier does not absorb moisture. Long-term use, even in a damp room, will not cause the foil to rot.

- Multifunctionality. The same film can be used to protect several adjacent structures, creating a continuous sealed barrier.

Izolon - pros and cons

Izolon is made on the basis of foamed polyethylene. It has different thicknesses and outer coating. Foil-coated isolon is suitable for baths. The material acts as a waterproofing agent. Additionally, it reflects heat from the walls. The material is not afraid of large temperature changes -85 to +125 °C.

Flexible isolon is easier to install on the walls of a bathhouse with your own hands.

The texture of the material is different and can be flexible or hard, cross-linked (from several layers), homogeneous.

To insulate a bath, you can use any option. Foiled on two or one side will be more effective in a steam room, and unstitched for a rest room or dressing room.

Thanks to its small thickness of 50–100 mm, the insulation will not steal the space of the bathhouse, such as mineral wool or polystyrene foam. But in terms of thermal insulation characteristics, 100 mm thick isolon is equal to a 200 mm layer of mineral wool.

The main advantages of insulating a bathhouse with isola include the following characteristics:

- Heat loss in the steam room is reduced by 90% due to the reflective properties of the foil;

- the area of the steam room is reduced minimally (2–5 cm);

- You can insulate the walls and ceiling with your own hands without additional skills;

- the material is not afraid of moisture;

- not subject to corrosion;

- resistant to sudden temperature changes;

- non-toxic, does not emit harmful substances when heated;

- low price for the material.

Despite the large number of advantages, isolon has a number of disadvantages:

- afraid of mechanical damage;

- The joints must be glued, otherwise cold bridges will appear.

The disadvantages are mainly associated with improper installation of insulation in the bathhouse or the use of low-quality material. To avoid troubles, buy insulation from well-known brands in large shopping centers. Installation should be carried out according to the instructions.

When choosing a material for insulation, it is worth choosing a roll type, although the manufacturer also offers a block type. It is easier to work with a roll in a small room.

Installation technology

Most often, vapor barrier materials with foil are used to equip a cold attic and a warm attic. In the first case, the insulation system must be installed along the ceiling, in the second - along the slopes.

To install a vapor barrier correctly , you need to adhere to generally accepted construction rules:

- The vapor barrier of the slopes should be a continuous barrier that prevents the penetration of moisture. To do this, the canvases need to be sealed together with regular tape.

- Strips of vapor barrier material are usually laid strictly horizontally. The first panel is fixed at the ridge girder, the second is placed on top to cover the edge of the installed panel on the side of the room that is being finished.

- The canvas spreads from the attic side onto the wooden floor in strips, extending onto the walls along with vertical ceilings of 20 cm each. It turns out to be a kind of pallet with sides.

- Then the material is rolled out as if the roll was formed by the manufacturer himself. The installation side is indicated on the vapor barrier - it cannot be changed at your discretion.

- On pitched roofs, the material is stapled to the rafters from the inside. If they are fixed with a block, then a counter-lattice must be placed on top under further cladding.

- If you need to put a vapor barrier in a system with open rafters, then it is placed along the outer ribs, then rigid slab insulation is installed. The fabric is secured with a stapler.

- If you are installing a ceiling on the ceiling side, then you need to buy self-adhesive materials.

It is worth noting that accessories for foil insulation must be selected from the same manufacturer as the material. Of course, you can find universal tape on sale that is suitable for joining materials of any kind, but in the case of foil structures, you need to remember about tightness. Therefore, here it is better not to experiment with options for adhesive tape for gluing, but to take it from the same company that produces the foil sheets themselves.

Covering installation

To ensure the most effective and high-quality coating and ensure a comfortable stay in the steam room, you should follow a number of tips when laying the material.

When laying foil materials in steam rooms of non-commercial baths and saunas, it is sufficient to use rolled or kraft foil with a thickness of at least 3 mm. For large steam rooms, foil on a mineral or basalt base is suitable. When locating a bathhouse inside a house or in a basement, it is important to take into account central heating and the location of its sources, if possible using it for additional heating of the steam room air. Before starting work, it is necessary to provide for the removal of condensate by making a small withdrawal of the canvas from the ceiling to the walls, as well as from the walls to the floor. To do this, the foil material is laid with an overlap of 15-20 cm and taped with foil tape.

The installation process of foil occurs in several stages; the most convenient to use are rolls or sheets 60 cm or 1.2 m wide

The installation process of foil occurs in several stages; the most convenient to use are rolls or sheets 60 cm or 1.2 m wide.

- The walls of the steam room need to be lathed with beams with a cross-section of 5x5 cm. The distance between adjacent planks depends on the width of the material. For rolls of 600 and 1200 mm it is 60 cm, for foil materials with a width of 1000 mm and 1500 mm - 50 cm. The bars are fastened with self-tapping screws of a suitable length.

- A layer of mineral insulation is laid between the slats so that it does not protrude beyond the level of the beams.

- A foil material is fixed on top of the insulation layer with the obligatory placement of a reflective layer inside the steam room. The joints of adjacent canvases or sheets can be glued with metal tape, but it should be remembered that under the influence of high temperatures the glue can soften and the panels will separate, breaking the tightness. It is best to fix the foil with staples or nails, nailing them directly onto the beams. If the width is large, the foil material is fixed not only at the edges, but also in the middle.

- The laid foil is sewn up with clapboard, leaving a one and a half centimeter air pocket, the main function of which is to reduce the thermal conductivity properties of the foil layer and to maximize the reflection of all the rays that hit the foil back into the steam room. An air pocket will allow you to create a sheathing for the lining. Choose planks 10-20 mm thick and fix them with self-tapping screws.

Sometimes the order of arrangement of materials can be changed - a layer of foil is stuffed onto the insulation layer placed between the sheathing bars, staples or nails, which is fixed on top with thin slats placed strictly on top of the sheathing with self-tapping screws of sufficient length.

In some cases, wooden sheathing can be placed on top of the insulation layer, laying foil over the entire area of the walls, including. and on the uneven bars. Then it is impractical to leave air pockets, and the lining is fixed directly on the sheathing. But, as practice shows, purchasing combined heat-insulating materials with a layer of foil is not only more economically profitable, but also significantly simplifies the entire installation process.

Video - How to properly decorate a steam room in a bathhouse

Arranging steam rooms using foil materials allows you to save 25-30% on heating raw materials for stoves, as well as extend the service life of the structure, preventing the development of fungi, mold and microorganisms harmful to humans.

Leading foil products

To install a ceiling or attic, you need to select a suitable and reliable vapor barrier film. Therefore, you should first find out what proven and popular product options are available on the construction markets.

Energy saving film DELTA®-REFLEX

These products have proven themselves well in roof construction and have an impeccable reputation among roofers. The reflective coating on the working side is created by spraying. Then a polyester film is applied over it, which protects the aluminum layer from shedding and damage. The reflection coefficient of this product is about 50%.

At sub-zero temperatures , the film does not lose its flexibility; it is used to provide protection against steam from inside and outside the house. Can be used in different rooms with high humidity. If you find a version of a similar film, but where the word PLUS is added to the marking, then there will be a self-adhesive tape along the edge of such films - it makes the work of installers much easier, which is why it is what is most often purchased, despite the high cost of the product.

Reflective material “Izospan FD”

In terms of price, this is a more humane option, but it is also less resistant to the realities of adversity. This is a two-layer composition made of polypropylene fabric, with an aluminum coating applied on top.

In terms of strength indicators, it is inferior to the first option, but is able to outperform in terms of energy-saving characteristics: the coefficient of thermal reflection is about 90% . It usually attracts installers with its affordable price; in addition, these products are easy to find in many hardware stores. It is worth noting that in the technical data sheet of the film, a separate line indicates the temperature range, which ranges from -60 to +80 degrees.

"ARMOFOL® type A" super durable

This vapor barrier is made on the basis of a durable fiberglass mesh. The scope of application is exactly the same as the two previous options. But the operating temperature range is more extended. The material works flawlessly at temperatures of -60 degrees (Delta has a threshold of -40). And in the plus segment the limit reaches +150 degrees.

Armofol is used both in new construction and for restoration work during the repair of basement and basement structures, roofs, swimming pools, saunas, bathrooms, steam Russian baths. In terms of thermal reflection, the coefficient reaches 97%; due to this indicator, the material is also purchased very often.

Information about the use of foil vapor barrier film for construction is needed by both professional roofers and independent craftsmen. Properly installed material guarantees that your favorite property will be equipped for a long period of use. Therefore, such repair work must be approached with full responsibility: starting from the selection of popular options for foil films and ending with their installation.

Why do you need a vapor barrier for a bathhouse ceiling?

Vapor barrier of ceiling and walls in the bathhouse

Since no one has yet canceled the laws of physics, it means that everything in this world remains as before.

Everyone knows from school courses that heat always rushes upward. For a steam room in a bathhouse, this is doubly true. If the vapor and thermal barriers do not work well, then all heat and moisture losses will pass through the ceiling.

And if the ceiling is insulated with mineral insulation (rolled basalt wool, slab mineral heat insulators), what will happen to them? Simply, insulation saturated with moisture will stop working.

There will be practically no effect from its use. You can safely begin to dismantle it and completely replace the insulating layer. This is a thankless job, so it is better not to make gross mistakes during the construction of baths and saunas.

Here is the second negative point, if the vapor barrier of the bathhouse ceiling is not done correctly.

All wooden structures, such as floor beams, rough ceilings, and roof elements, will be subject to premature rotting. High temperature and high humidity have a beneficial effect only on humans, but for wood this is considered an aggressive environment. Repair of the roof and ceiling is definitely guaranteed.

Installing a vapor barrier using a furniture stapler

I recently witnessed a neighbor redoing all the ceilings in a newly built bathhouse. The builders, trying to deliver the project on time, simply did not vaporize the ceiling in the steam room. All the expensive URSA roll insulation had to be thrown away.

Literally after 3-4 times of using the steam room, it became so saturated with moisture that water simply dripped from the ceiling. It’s good that all the work to correct this gross mistake was done almost immediately, and the tree did not have time to suffer much. The situation is unpleasant - money and time are wasted.

The reverse side of ceiling insulation

On the opposite side of the insulation, that is, on the floor of the attic, it is also worth insulating between the beams. The laws of physics are such that heat tends to rise, so a decent layer of thermal insulation and vapor barrier is appropriate in this area. Various types of insulation are laid between the beams, and then covered again with waterproofing. What can be used for insulation? Everything: from soil to mineral wool. For a steam room, a good option would be to lay a layer of clay (3 cm), and put mineral insulation on top. Clay complete with foil will no longer allow mineral wool or foam glass to reach temperatures that can cause the release of harmful substances. For the rest, you can use slag, black soil, peat or mixtures thereof. If you decide to use earth as insulation, it is better to burn it so that the microorganisms present in its composition do not play a cruel joke on you. What you should not take to insulate the ceiling is tyrasa, sawdust and other flammable materials.

Laying a vapor barrier in a steam room

The quality and duration of the main bath procedure depends on the correct device for vapor barrier of the steam room ceiling.

A certain amount of steam is instantly formed, which effectively warms the body of people in the steam room through the skin.

But the steam tends to rise up to the ceiling and go out.

If this happens, you have to heat the heater again and again to create steam.

That is, you have to light the stove again and again.

To perform this procedure as rarely as possible, you should place a barrier in front of the steam so that it does not go outside, but remains inside, in the steam room.

To do this, an additional layer is laid in the ceiling between the hemmed material and the insulation - a vapor barrier.

It prevents steam from escaping and protects the insulation from moisture getting into it.

Creating a vapor barrier in a steam room is associated with a number of problems.

The fact is that quite often the air temperature in the steam room rises to 100 degrees or even more.

And polyethylene film in most cases is not designed for such temperatures.

It begins to shrink sharply and fails very quickly.

It simply bursts.

Therefore, the film should be left for vapor barrier in other rooms of the bath, where the air temperature is much lower.

And in the steam room for vapor barrier, you should use modern materials that have a foil coating on one side.

For example, stizol.

This material can simultaneously perform two functions: vapor barrier and insulation.

Stizol successfully withstands both large amounts of moisture and high temperatures.

This is an ideal material for vapor barrier of the ceiling in a steam room.

Vapor barriers such as foamed polypropylene are also gaining popularity.

This material is laminated with foil and not only does not allow steam to pass through, but also reflects high temperature back into the steam room.

Video about vapor barrier of a steam room ceiling in a bathhouse:

Performing a vapor barrier is not difficult.

The main thing is to be careful not to damage the material.

What else to read on the topic?

Recommendations

Recommendations:

- The foil layer must be located inside the bath rooms.

- To secure the material, you can use a construction stapler or nails.

- A gap must be left between the decorative sheathing and the reflective layer for ventilation.

- The sheets should be connected with aluminum tape.

When purchasing, it is better to take 1-2 more rolls so as not to have to go to the hardware store again if the material is damaged.

In order for the heat to escape from the steam room more slowly, you need to properly insulate the walls, ceiling and floor. To do this, it is recommended to use foil, which will effectively reflect thermal radiation. To secure it, you don’t need to have practical skills, just follow some rules.

Insulation goals and material requirements

Diagram of an insulated wooden floor in a bathhouse

Why do you need insulation in a steam room? The main purpose of using thermal insulation materials is to retain radiant energy indoors. Thanks to shielding, you can not only save on heating the bath, but also maintain the required temperature in it for a long time. What properties should thermal materials have?

Due to the special operating conditions in the steam room, the following requirements are imposed on thermal insulation coatings:

- Thermal performance indicators. The coating should not deteriorate under the influence of high temperatures and affect the specific properties of finishing materials;

- Strength. The strength characteristics of thermal insulation must remain unchanged, regardless of the humidity and temperature conditions inside the room;

- Condensation accumulation. The insulation should prevent the accumulation of condensation, as this can lead to the development of mold and mildew in the steam room;

- Moisture absorption. Materials must be as non-hygroscopic and moisture-resistant as possible;

- Safety. The safety of using thermal insulation must be confirmed by quality certificates;

- Practicality. The coating should be easy to install, providing good shielding with minimal heat loss.

When choosing the appropriate type of insulation with your own hands, you should definitely take into account the above criteria. Otherwise, you will not be able to achieve the desired temperature in the steam room or you will have to heat it all the time to maintain the necessary microclimate.