Sandwich chimneys have many advantages: lightness of construction, safety, aesthetic appearance. Why not try to assemble a sandwich chimney with your own hands? As practice shows, it is really quite simple. And everyone can build such a chimney like a construction set.

This work will require knowledge of the structure of the chimney and its installation - we discussed this material in detail in our article. We selected photos and diagrams describing the main elements of the chimney system, and provided step-by-step instructions for assembly and installation.

We also supplemented the material with useful tips for improving draft and a video demonstrating the process of installing a chimney in a country house.

Material from which pipes are made

For different heating devices and types of fuel, a different type of steel is selected. It must be highly alloyed and stainless, suitable for the manufacture of chemically resistant and fireproof chimneys.

In the construction of a chimney, one of the main characteristics is the steel grade as a criterion for long-term service and resistance to external negativity

When various substances burn, chemically active substances can accumulate in the chimney: sulfuric acid, sulfur, hydrochloric acid. In addition, the temperature during combustion of different fuels can vary greatly.

When heating with wood or gas, it does not rise above 450 °C; when burning coal, it can reach 700 °C. Metals react differently to these indicators. Therefore, when choosing a smoke exhaust system, pay attention to the main characteristic - the quality and properties of the steel.

Option #1 - stainless steel with alloying additives

The main grades of steel alloys that are used for the production of sandwich chimneys:

- Titanium stabilized stainless steel (AISI 321) . Used for wood burning equipment. Not resistant to corrosion in sulfur-containing environments. Permissible operating temperature is 600–800°C.

- Molybdenum stabilized stainless steel (AISI 316) . Installation of a sandwich chimney made of this grade of steel is carried out for heating installations that operate on wood, gas, or diesel fuel. The metal is acid-resistant and has increased resistance to corrosion and aggressive environments of various types.

- Heat-resistant steel (AISI 304) . The inclusion of chromium and nickel makes the steel insensitive to elevated temperatures and acidic environments. Used for the production of chimneys with high temperature exhaust gases - about 1000 °C. At temperatures of 600–800 °C, it is prone to loss of viscosity and ductility, which leads to embrittlement.

- The widely used grades AISI 409 and 430 are poorly resistant to high temperatures and acids. Most Chinese products and some domestic ones are made from these grades of steel.

It is impossible to check the steel grade visually. When purchasing, you can check the markings on the product itself or try to approximately determine the quality using a magnet.

Low quality material will attract a magnet, metal with added alloying additives will not.

When choosing pipes for a chimney, take an interest in their main characteristics. If you have doubts about the seller’s honesty, take a magnet with you - it will be attracted to steel products with insufficient proportions of alloying additives

Option #2 - ferrous metal for chimney pipes

The ferrous metal itself quickly wears out - it oxidizes and burns out. Therefore, special enamel is used to protect it. This increases resistance to acidic environments.

Enamel can serve for a long time at temperatures not exceeding 400 °C and can withstand short-term increases up to 750 °C.

The variety of shades of enameled pipes makes them quite popular

Enameled pipes are used to remove combustion products from heating columns, stoves, heating boilers, and fireplaces. Unlike steel ones, they can be painted in different colors. This allows you to select the right shades for the interior or facade of the house.

Option #3 - combined sandwich chimneys

To reduce the cost of production, enterprises try to use cheaper materials. If the inner pipe is made of expensive stainless steel, and the outer pipe is made of galvanized or enameled metal, then this has little effect on the service life of the product.

It’s worse if it’s the other way around: they use stainless steel on the outside, and hide cheap, low-quality material inside. With intensive use, such a pipe can last a year and fail, which will entail new costs for materials and installation.

Before purchasing, it is advisable to ask for the accompanying documents for the product to ensure the quality of the pipe you are purchasing. It is important that the internal element is made of high quality stainless steel

Between the two pipes of a sandwich chimney there is a layer of insulating material that retains heat inside and thereby maintains good draft. Basalt or ceramic wool is used as insulation - fibrous materials with the highest fire resistance class.

Basalt wool can withstand temperatures up to 600 °C, ceramic wool - up to 1000 °C. Both materials have good thermal insulation properties. A layer of insulation of 25-50 mm is used. For a chimney that is mounted outside, the larger it is, the better.

general characteristics

The structure, like a sandwich pipe, appeared on the building materials market relatively recently. Production technologies are constantly being improved. New types of materials are being produced that allow you to mount any system and give it the necessary qualities.

Installing a sandwich pipe with your own hands will save money on the family budget. The production of such chimneys is not very difficult. The presented designs can be made from materials that are available in hardware stores.

A sandwich pipe is a structure made of metal and insulation. For the latter, non-combustible materials are used, for example, basalt wool. The structure also includes two pipes of different diameters. Insulation is installed into the resulting cavity between them. It is thanks to the simplicity of such a pipe that you can assemble it yourself.

The influence of the type of fuel on the operation of the chimney

Below is a table that will help determine how to choose the right chimney for different types of heating equipment so that it works longer.

The user manual for each chimney device indicates the permissible temperature

When installing a sandwich chimney for gas equipment, you can get by with a cheaper design option. But for a Russian or sauna stove, it is better not to save money and choose a system whose quality is beyond doubt.

Flaws

The list of disadvantages of sandwich pipes is quite modest. The designs on sale are relatively expensive. This drawback does not matter for those owners who want to make such a chimney with their own hands.

It should also be noted that sandwich structures have not been used for more than 15 years. This is also a dubious flaw. The building materials market is constantly improving. If new, high-quality materials are used in the manufacture of pipes, they can last longer.

According to professional builders, the presented systems have a lot of advantages that overshadow the disadvantages. It is for this reason that many owners create sandwich pipes with their own hands. For a wooden bathhouse, the presented option is considered the best. It is also suitable for other types of materials.

Structural elements and their features

The variety of products allows us to perform complex tasks in the construction of sandwich chimneys.

Chimney manufacturers have developed more than twenty different elements to facilitate installation

The main design elements of the chimney duct are:

- Straight pipe sections. Sections with a diameter of 80-600 mm, up to 1 m long. The ideal chimney design is straight, but in practice this is difficult to achieve.

- Knees and tees. They are used if it is necessary to bring the chimney through the wall, to the outside of the building, or to bypass the structural elements of the house - beams, rafters. Sometimes, for turns (especially straight, 90°), tees with revision are used - they allow you to clean the chimney in hard-to-reach places. They are installed and reinforced with brackets so that they do not bear the weight of the structure above.

- Feedthrough pipe. It insulates the pipe from the interfloor partitions and serves as a fastening for the chimney.

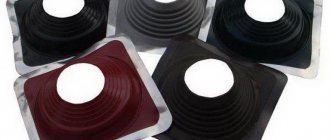

- Roofing cutting . It is a metal cone that is attached to the roof at a certain angle. Helps to pass the pipe through the roof without compromising its tightness and increasing fire safety. Instead, a special silicone seal can be used, which serves as better protection against leakage.

In addition to the above elements, there are also a lot of devices for installing a chimney made of sandwich pipes, as well as its further operation.

The chimney is secured with brackets every two meters. Fasteners for fixing clamps on the wall are selected in accordance with the material from which it is made

Manufacturing process

Creating such a structure is accessible to anyone with minimal construction skills. To make a sandwich system, you must have:

- metal pipe;

- galvanized steel sheets;

- stone wool.

The design of the device is a cylindrical product, which is covered on all sides with stone wool. The top of the structure is wrapped with galvanized sheets. In most cases, the outer shell of the chimney is prefabricated and consists of several parts. Therefore, the junction points of structural elements require increased attention.

Fixation of galvanized iron is carried out with special fleas, but you can also use ordinary screws. The fastening must be complete, that is, not only one sheet is fastened, but also all adjacent metal parts.

When making a sandwich chimney, each craftsman independently chooses the appropriate material. In this case, the brand of the fuel unit must be taken into account. For example, domestic hot water boilers maintain the temperature of the exhaust gases within 120 degrees. For such devices, mineral wool can be the thermal insulation material.

Things are completely different when it comes to homemade fireplaces or solid fuel boilers. The heating temperature in such systems can reach 800 degrees. In this case, you simply cannot do without stone wool. As a substitute, you can use a basalt analogue. To avoid rapid burning of the inner pipe, it must have a thick wall.

Stainless steel is considered the ideal material for a sandwich pipe. It has certain properties that allow such a system to be used for many years. Moreover, the inner surface of the stainless pipe always remains smooth. Gases escaping through this product do not affect its walls, which in turn increases the efficiency of the chimney itself.

When joining thermal insulation from the long side, some problems may arise. The fastening should be carried out with an overlap, having previously made an undercut equal to half the thickness of the pipe wall, with an additional overlap of approximately 10 cm to create an even geometry.

Let's make a small comparison. A high-quality sandwich structure 10 m long can be purchased for RUR 20,000. An ordinary metal pipe costs 6,000 rubles. The price of insulation does not exceed 2,125 rubles. For galvanized sheets you will have to pay 2,500 rubles. The total amount is 10,625 rubles. In this case, you get a 50% savings. Of course, unforeseen expenses are also possible, so we’ll add another 6,000 rubles. But it's still quite profitable.

In other words, 4,000 rub. left in your pocket, and a metal pipe with a wall thickness of 3.6 mm is always better than a stainless steel structure of 0.5 mm. From the above calculation it is clear that before you start building a smoke channel, it is worth considering what it is best to make it from.

How to choose the required chimney diameter?

The diameter of the chimney pipe is selected based on the boiler power data.

For low-power heating installations with less than 3.5 kW, pipes with a diameter of 8 cm are used, for boilers with values no more than 5.2 kW, pipes with a diameter of 9.5 cm are used, and over 5.2 kW - 11 cm. Narrowing of the chimney is not allowed, but widening, on the contrary, can be carried out.

Another indicator that affects the diameter of the chimney is the thickness of the insulating layer. It can be 25-100 mm. The larger it is, the better it exhibits its properties, but its cost also increases. The thickness of the metal itself used to produce pipes can be up to one millimeter.

If it is necessary to build on, replace or modernize any section of the chimney, the consumer may find himself in a difficult situation. Elements from different brands are not able to provide a sealed joint.

When purchasing missing parts, it is better to find (order) components of the same brand as the rest of the structure.

Main dimensions of pipe products

It is important to remember that the dimensions of the sandwich pipe for the chimney depend on the diameter of the boiler pipe outlet.

During installation, the product is mounted on it, so the cross-section of the sandwich pipe must necessarily exceed the outlet pipe. Today, sandwiches for chimneys with a cross-sectional size of 0.5 and 1 m are more in demand, but they also come with diameters ranging from 110-300 mm. In the range of pipe sizes for chimney design there are other options, but much less frequently.

Today, chimney sandwiches with a cross-sectional size of 0.5 and 1 m are more in demand, but they also come with diameters ranging from 110-300 mm. In the range of pipe sizes for chimney structures, there are other options, but much less frequently.

Pipe connecting elements have angles:

- 90°C - for corners and tees;

- 135̊ C - only for tees.

The thickness of the inner wall is 0.5-1 mm, and the outer wall is 0.7 mm. The thickness of the internal thermal insulation layer ranges from 2.5-6 cm, and the outer diameter of the sandwich structure is 200-430 mm.

Installation of a sandwich system for smoke removal

Before installing the structure, you must carefully read the technical documentation and safety regulations.

It is imperative to take all measures to prevent fire during operation of the chimney.

Before purchasing, it is necessary to calculate all materials, taking into account the specific layout of the house

Step #1 - assembly of chimney pipe elements

Installation of the structure always starts from the bottom up. Sandwich chimneys must not be connected directly to a heating device.

A sandwich chimney element is never connected to the heating device - a single-wall pipe or adapter is installed first

First, install a special adapter or a single-wall steel pipe half a meter long.

If it is planned to lead the pipe directly into the wall, then install a horizontal outlet with a slight slope of 2°.

The adapter is designed to connect different sections of the chimney system - single-wall and sandwich pipes

The section of uninsulated pipe can be short or long if greater heat transfer is expected. Walls and structures located near it must be protected with a screen or casing.

They install it “smoke-wise”, that is, they put it on top of the heating device pipe and additionally protect the joint with a heat-resistant sealant.

Assembly “by condensation” prevents drops of moisture from penetrating into the insulation system, which significantly reduces its insulating properties

The chimney sandwich element can be connected to the heating device through an adapter - a double-circuit pipe, the lower part of which is installed “for smoke”, and the upper part “for condensate”.

All subsequent pipes will be installed “on condensate”, which will prevent its seepage and protect against damage to the thermal insulation layer.

All joints are secured with couplings. A clamp is installed near each joint to secure the system to the wall.

To prevent lateral movement of the structure, wall brackets are used every two meters, and support brackets are used for tees. The system is attached to the wall using consoles or support platforms every five meters.

Step #2 - passing ceilings and walls

Even the fact that sandwich chimneys have an insulating layer does not mean that their surface cannot heat up quite strongly. Therefore, it is prohibited to place them without additional insulation near flammable materials (wood, plastic, etc.).

The joints of sandwich pipes for chimneys during their installation and operation should not coincide with the passage in the ceiling or wall.

The free space between the ceiling and the pipe is filled with non-flammable and non-flammable basalt wool

The diameter of the hole in the wall or ceiling is cut 250 mm larger than the diameter of the outer pipe.

Make it round or rectangular. Heat-resistant material is placed in the free space, which is hidden with decorative plates.

The passage unit is heat-resistant, it prevents deformation of the chimney when the building structure moves - shrinkage, moisture and temperature deformation

To pass through the ceiling and, especially, through flammable materials, a special passage unit is also used. An air gap is left between the outer contour and the inner surface of the assembly.

When passing through a ceiling or wall made of a slightly flammable material, you can use an unloading platform instead of a passage unit. It will act as an additional support.

Step #3 - passing the system through the roof

When the chimney pipe is brought out through the roof, its tightness is broken. To strengthen the pipe, isolate it from flammable elements of the roof and eliminate the possibility of leaks in the roofing, special devices are used: conical roofs, silicone seals.

These parts have standardized slope angles; they are selected taking into account the roof parameters.

Silicone sealant - Master Flash greatly simplifies the work and helps create reliable protection against leaks

When placing the pipe, it is calculated so that the distance to flammable materials is at least 37 cm. To protect against water getting under the roof, an apron is installed on top of the roof. Its edges go under the roofing.

Step #4 - placing the structure above the roof

The height of the chimney pipe depends on the distance between the base of the pipe and the ridge, but not less than half a meter above the ridge, 1.2 m above the surface of a flat roof or 2 m with a combined roof. If the head of the ridge is one and a half to three meters away, then it should be placed above or opposite the ridge.

If the distance is 3 m or more, then it is permissible to place the head no lower than the line that is formed if you draw a horizontal line from the ridge and measure down an angle of 10°.

If the pipe head is mounted lower than required, backdraft may occur in the system.

If there is a nearby building, the top of the chimney pipe should rise above its roof by one and a half meters or higher.

A pipe of this size must be further strengthened with guy wires.

When planning the design of the chimney, take into account the type of roof and the location of neighboring buildings. The pipe should not get into the support zone, which will negatively affect the formation of draft

If flammable material was used to cover the roof, a spark arrester is placed in the chimney. The chimney design is completed by a cone-shaped head. Sometimes it is protected with a fungus or a deflector or other devices.

Required components

The standard list includes:

- Boiler adapter. The initial section of the pipe. Responds to the required rotation during installation. Suitable for assembly in the direction of condensation.

- Starter sandwich. With its help, a transition is made from a single-wall to a sandwich (double-wall) structure.

- The gates are rotary. A valve or damper with several holes. The damper blocks the flow of carbon monoxide.

- Crimp clamps. Fasteners for tensioning are made of steel. Fix the chimney system in a stationary state and do not allow it to come into contact with the stove.

- PPU (ceiling-passage unit) with mineralite. Used in cases where the pipe will pass through the ceiling or roof. The composition includes fireproof insulating material, followed by a layer of air and space for fastening a layer of thermal insulation.

- Tees at 45, 90 degrees. Change the direction of exit of flue gases.

- Cap or head. Performs the function of an umbrella, protecting the internal cavity of the chimney from precipitation.

- Sandwich sections. Straight, 3-4 pieces. Length from 25 to 100 cm.

- Brackets, screws. They will connect the structural parts.

- Knees at 90, 45 degrees. Allows you to mount the chimney at the desired angle.

- End caps.

- Various adapters, condensate collectors.

- Support platform. Distributes the load evenly.

- Window for cleaning the chimney.

The list of elements is incomplete, since each heating system has its own characteristics. There are options for direct smoke channels with condensate drainage and stands.

The assembly of double-walled pipes is based on the method of socket-profile joining or, in popular parlance, “tongue and groove”.

What to do to improve traction?

The principle of operation of the chimney is based on the creation of draft - the ventilation effect that occurs due to the temperature difference in the middle and outside of the duct.

The density of warm air in the chimney system is less than that of cold air outside and this leads to a pressure difference. Due to this difference, cold air enters the stove, and hot air rises through the chimney and goes outside.

Reasons for poor removal of combustion products

A simple way to determine the presence or absence of draft is to visually assess the presence of smoke in the room or identify the problem by the color of the fire.

Orange shades indicate insufficient draft, white flames and a hum in the chimney indicate excessive draft. Sometimes cravings may change direction for a short time.

Common causes of reverse or poor draft are a high obstruction and a low-lying chimney

Without taking into account a chimney that is not cleaned in time and is clogged, the reasons why backdraft occurs in it are the following:

- incorrect calculation of the ratio of boiler power and pipe parameters;

- unfavorable weather conditions - fog, rain, heat, strong wind;

- a large number of narrow sections and turns in the chimney design;

- high location of the ridge in relation to the head of the chimney or nearby tall buildings;

For the formation of normal draft, a lack of supply air and insufficient ventilation in the house is extremely undesirable.

How to prevent problems with traction?

Here are some recommendations on how to assemble a sandwich chimney so that the heating device does not become a source of soot and soot in the house:

- the height of the structure must be equal to or greater than five meters;

- it is preferable to build a straight chimney - without bends and turns;

- turns (no more than three) are made at an angle of 45°;

- An almost horizontal section of the chimney can extend from the boiler (with a slope of 2°), but not more than one meter.

If during the operation of the chimney problems are discovered with smoke removal, they resort to installing special devices that increase draft.

It could be:

- Deflector. It works on the principle of reducing pressure as air passes around obstacles. It works effectively in windy weather, but in calm weather it can, on the contrary, hinder the removal of smoke.

- Stabilizer . It is an additional element that has the shape of an umbrella and is placed on top of the pipe. From below, air enters through the open area, increasing traction.

- Rotary turbine . It works using the force of the wind: rotating in one direction, it creates a vacuum of air above the channel. It is not effective in calm weather.

All these devices are not a panacea, especially if the chimney is not initially designed correctly.

The deflector may interfere with the removal of combustion products in calm weather

Final stage

The sandwich pipe must be installed correctly with your own hands. It should be noted that the distance of the entire chimney should be a total of 5-6 m. The distance is measured from the head to the grate. All joints will need to be sealed with sealant. Also, the space between the two pipes from above must be treated with the presented product. The insulated circle should not remain open.

Pipes are treated both indoors and outdoors. You should also seal the joints on the outside of the chimney. Moreover, after starting the system, all connections must be carefully checked. If there are leaks, the joints are once again treated with a sealant that can withstand heating temperatures of up to 1000 ºC.

Having learned how to assemble a sandwich pipe with your own hands, you can create a chimney yourself in accordance with building codes. At the same time, it will be possible to save money on the family budget and install a strong, durable system that will not need to be restored for many years.

Operation of chimney sandwich systems

After installing the chimney, you should conduct a test fire to check the tightness of the joints and make sure that the adjacent structures and materials do not heat up.

When using the system for the first time, light smoke and a specific smell may appear from the heating of oil residues, sealant, and dust on the surface of the pipes.

Proper operation involves timely removal of soot. When cleaning, do not use any detergents. A review of the best cleaning products and methods is discussed in our other article.

It is better if it is carried out by an organization that has a special license giving the right to carry out this type of work.

Preparation

Do-it-yourself installation of a sandwich pipe is carried out using a certain technology. It includes several stages. First you need to make a drawing. To do this, take appropriate measurements and think through the necessary details.

After creating a plan, you can purchase the required amount of materials. You should also prepare all the tools necessary for the work. Next, the structure is assembled and installed on the roof.

To manufacture such a system, you will need to purchase a sheet for the inner part of the pipe made of stainless steel, thermal insulation and an outer sheet for the pipe, which can be made of galvanized steel, brass or copper. The choice of materials must be given special attention. The functionality and durability of the chimney will depend on this.

Conclusions and useful video on the topic

More information on how to correctly assemble a reliable chimney from modular sandwich pipes can be viewed in the video:

Independent installation of a chimney from sandwich pipes will require the user to study some of the nuances and subtleties. But by doing the job correctly, you can be confident in the safety of your family and yourself.

Do you have experience assembling a chimney from sandwich labor? Did you install such a chimney yourself? Share your experience with novice home craftsmen - write in the comments block what difficulties you encountered during installation, how long you have been using it and how you care for your chimney.

Fire safety

To avoid a fire hazard, it is necessary to install the flue gas exhaust device so that it does not touch the wall or ceiling. Sandwich pipes must be in special boxes that limit them from touching other materials.

To ensure greater safety, closed hollow structures are equipped with basalt wool. Quite often, a self-installed chimney is separated from the ceiling by a small metal sheet. Steel becomes a kind of radiator, heating the surrounding air.

Joints

Great attention should be paid to the junction of the chimney and wooden blocks. Indoors, the area where the wooden elements and the pipe meet at the top is one of the most important points. According to accepted standards, there should be 38 - 40 cm from the internal element of the chimney to the wooden elements. The entire gap is filled with a non-flammable substance. If it is impossible to create additional space, then it should be further increased. Sometimes the gap can be reduced to 24-28 cm; this can only be done if the wooden blocks themselves are protected. Wood blocks such as:

- logs;

- lathing;

- rafters

protected using galvanized sheet metal.

Joint of a stainless steel chimney with a wooden wall

An additional layer of asbestos sheet with a thickness of 5 to 10 mm is made. Galvanization prevents the spread of open fire; it regulates the uniform distribution of infrared radiation coming from the pipe. For comparison, if the chimney is made of steel, then the distance to wooden structures increases to half a meter (this is the minimum).

Layout

What is important in the layout of the chimney is the absence of joints and contact with other blocks. The chimney is directly mounted into a metal pipe; it is made in the form of a box. An important parameter is thickness; it should exceed the thickness of the ceiling by no more than eight centimeters. The smoke removal system is important; it should be calculated when designing the facility. Pipe connections are also an essential element to be aware of. There are two types of layout:

- by smoke;

- by condensate.

When installing “by smoke”, the lower part of the pipe is installed in the element of the upper elbow. With this combination, hot gases, without encountering any obstacles, move upward unhindered along the inner surface of the pipe. In the second joining option, the internal element is installed in the lower part. With this arrangement, all condensate flows down. Typically, all chimneys (taking into account the appearance of condensation) are mounted on innovative gas units. The outgoing temperature of the outgoing products does not exceed 200 degrees Celsius.

As an example, we can mention: in furnaces that are made of metal sheets (“potbelly stoves”) the combustion temperature is about 300 degrees Celsius, moisture is released already at one hundred degrees. When the device heats up, steam is formed, it settles on the internal chambers, drops are formed, which then roll down into a special collection. It is most rational to install a chimney of “sandwich” structures taking into account the appearance of abundant condensation.