The internal insulation of baths, saunas and hammams has features unique to these objects. In addition to energy saving, “climate” cladding should provide:

- rapid heating of the room;

- thermal inertia (slow cooling after stopping the furnace fire);

- high level of vapor barrier.

Today, foil insulation for a bathhouse is considered necessary, and in some cases, a sufficient element to ensure the above conditions. To understand why this material is a generally accepted standard, it is necessary to consider the physics of heat transfer processes in a steam room.

The principle of a thermos for thermal insulation of a bath

During operation of the furnace, up to 80% of the heat is transferred by infrared radiation; up to 20% - due to the thermal conductivity of air, surfaces and objects located in the steam room; up to 7% - due to convection (mixing layers of air). That is why the role of the infrared screen is becoming in demand. This is what foil for the bath does, which is produced by industry in the form of a single-layer material, or as part of a two- or three-layer sandwich.

What does heat reflection do?

The use of flexible cladding with a glossy aluminum layer allows you to heat the steam room faster and retain heat longer. Foil for bath insulation acts as a mirror, reflecting the intense infrared radiation of the stove arches back into the room. Skeptics believe that this is only possible in one case: if you do not cover the foil with casing. They are wrong. The lining reduces the percentage of reflected heat rays, but when heated from the back side of the foil, the lining becomes a much less thermally conductive material. The design of the thermos thus changes, but the overall energy effect remains the same.

Illustration of the principle of heat reflection from foil material using the example of Alucraft products

What ensures that the cooling of the bath slows down? After all, the foil does not affect the thermal conductivity of walls located outside of it. In this case, other physical laws apply. The heat reflector promotes more uniform heating of air, surfaces and objects in the room. Heat transfer works from more heated bodies to less heated ones. By reducing the temperature difference, we thereby reduce heat transfer.

Why is foil glued to the insulation layer?

If the heat-reflecting material is placed without direct contact with the thermal insulator, then an air layer is formed behind the infrared mirror, heated by heat transfer through the foil. This layer will transfer heat towards the street. Therefore, no matter what kind of bathhouse you are going to equip - chopped, brick or with concrete walls - there is no point in using foil without insulation.

As an analogue, we can consider the operation of a thermos: the inner surface of the glass flask plays the role of a thermal mirror, and the vacuum between its walls is the thermal insulating layer. The difference with the arrangement of baths is that instead of a vacuum, the mirror is in contact with a thermal insulator glued to it.

Insulation of a log bath

Another question is whether an additional layer of insulating material is needed? In log houses, it is enough to use thin bath insulation with aluminum foil. foil sandwich. Log baths do not require any other insulation, except for inter-crown gaskets and caulking of seams. Infrared mirror technology is economically feasible in any steam room, but stone walls require thorough thermal insulation using wool or slab materials, the effect of which cannot be replaced by foil-based coatings.

Coating methods

In the construction of any bathhouse, as a rule, the installation method using thick beams or durable boards is especially popular. They serve as supports, and sometimes the ceiling is laid on top directly on the wall frame. Installing a ceiling in your bathhouse begins with how you choose the installation method.

Bathhouse construction process

There is no need to explain that the ceiling is erected only after the finishing work in the construction of the roof, otherwise the unfavorable environment will harm the thermal insulation, reduce its effectiveness and lead to the walls slowly sealing, and the growth of fungus will begin, which is very difficult to fight.

Types of ceiling coverings

The installation of a ceiling in a bathhouse traditionally involves laying a base, which is made up of internal boards. Edged or unedged ceiling boards, which are usually covered with clapboard, are widely used.

Between the floor beams, a layer of protection against moisture and heat preservation is laid on the internal boards. Steam and waterproofing should not have any gaps, joints should be sealed tightly, and boards should be of good quality, without knots. A tight fit of the board and additional overlap will create favorable conditions and protect against the formation of water.

There are several ways to lay a ceiling:

- Hemmed, for large-sized baths;

- Floor-mounted, for small structures;

- Panel, as an alternative to the first two.

false ceiling

The insulation for a false ceiling is usually mineral wool, which has a high level of absorption and drip absorption. It is covered with waterproofing and sheathed with boards on the outside.

If your bathhouse has a superstructure in the form of an attic, you don’t have to worry about the safety of bath accessories and their drying - mineral wool, as high-quality insulation, promotes rapid absorption of moisture and is ideal for such conditions. Cotton wool is produced in the form of pressed slabs and is easy to install.

The floor ceiling does not require external cladding, since it is usually covered with thermal insulation material. This method is not suitable if the bathhouse has an attic. Any manipulations with the attic floor can damage the thermal insulation of the bathhouse.

A more complex flooring option is a panel ceiling. Despite the difficulty of covering, the ceiling is very economical if you decide to go with this option.

It has undeniable advantages:

- It is a prefabricated structure made of load-bearing beams;

- Vapor and waterproofing is installed in the structure box and, if desired, it is insulated with mineral wool;

- The ceiling can be made outside the walls of the bathhouse.

Mineral wool

Types of insulators based on aluminum foil

In addition to considerations related to the physics of heat transfer and infrared reflection, the choice of substrate type is related to the ease of installation and mechanical strength of the two-layer material. The foil is easily torn during installation, which requires additional time to seal the gaps with special tape. When paired with a backing, the material becomes much more reliable, which makes it easier to attach it with a stapler to the wooden battens of the sheathing.

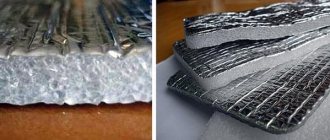

Foil insulation for baths

As a strengthening and/or thermal insulation layer, the following is industrially glued onto the foil:

- Mineral wool. The material is produced in rolls with a thickness of 5 - 100 mm. However, not every foiled cotton wool is suitable for arranging baths. In order to increase hydrophobic properties, mineral fibers are impregnated with special compounds that are unsafe for human health when the material is heated. Only insulation without these impregnations should be used with a direct indication of its purpose in the name. For example, "ISOVER Sauna" or "ROCKWOOL Sauna Butts".

- Kraft paper. The main commercial names of the material are “Kraft foil”, “Foil paper”, “Alucraft” and “Isolar”. In Izolar, a third element is added to the aluminum layer and paper - a polyethylene film, which increases strength and serves as a waterproofing layer for the paper layer. The thickness of kraft paper is in the range of 0.3 - 1.0 mm.

- Foamed polyethylene (FPE). The most popular material in the group of foil insulation. Produced under the names "Folgoizol", "Folgoizolon" in rolls with a thickness of 2 - 10 mm and plates (20 - 110 mm). Rolled foil insulation is usually used to equip baths and saunas in log houses without additional thermal insulation. It is produced in large quantities and has good installation and performance qualities combined with a reasonable price.

- Fiberglass mesh. As an infrared screen, a three-layer material “Folar” is sometimes used, containing a reinforcing layer of mesh with a cell of 4x4 mm. The original purpose of the folar is vapor barrier.

We insulate the joints with special tape

A separate group of materials includes PIR slabs, which are formed from high-strength polyurethane foam (PPU) and lined on both sides with aluminum foil. This thermal insulator is available in thicknesses from 30 to 250 mm. It makes sense to use PIR slabs with a thickness of 80 - 120 mm for insulating saunas, baths and hammams in buildings with walls made of brick or concrete. In this case, the slabs play the role of both the main insulation and a layer intended for infrared reflection and vapor barrier. Despite the high price, this material justifies itself on objects intended for long-term use.

Useful video

In the video we will see a typical mistake when installing vapor barrier:

You won’t find a clear answer: which vapor barrier is better and which vapor barrier to choose for a bathhouse. It all depends on the correct installation: you can buy expensive foil, but not get the desired effect if you install it incorrectly; and, conversely, proper vapor barrier with cheap natural materials will perfectly protect the structure from rotting.

(2 ratings, average: 4.50 out of 5) Loading…

Bath ceiling vapor barrier

Hello, dear readers! Today we’ll talk about one important factor, without which your steam room will not have the necessary thermal characteristics...

A truly good bath should not only look beautiful, but also have properties specific to it. One of these properties is the rapid injection and retention of heat indoors.

Properly performed vapor barrier of a bathhouse ceiling solves not only this important problem, but also a number of others.

Which ones? - you ask. More on this below...

Features of installation of foil insulation

If work is carried out in a log house, then, as a rule, foil insulation is used. The material can be attached directly to logs (beams) using a stapler with the aluminum side facing the inside of the room. Depending on the thickness of the cladding, butt or overlap joints are used. The joints are taped with metallized tape.

Air gap between foil and lining

To drain condensate, it is planned to release foil material from the ceiling to the wall, and from the wall to the floor. Slats with a thickness of at least 3 cm are attached on top of the foil insulation. They perform two functions: they serve as a lathing for the finishing cladding and form an air gap between the foil and the lining. The gap is important in order to exclude direct heat transfer from the lining through the aluminum layer.

The arrangement of baths in rooms with brick or concrete walls has a single, but very significant difference from work in log houses: contact of foil material with the load-bearing wall is strictly unacceptable. First, the main insulation is carried out with heat insulators of sufficient thickness. Then the foil material is installed. The gap between the foil plane and the finishing lining must be observed.

Another important note for all types of baths and saunas equipped on the principle of a thermos using foil: such rooms must have high-quality ventilation.

Being a 100% vapor barrier, aluminum promotes the formation of condensation. Only intensive air exchange between bathing sessions can promote the natural evaporation of accumulated moisture.

The main requirements for materials and raw materials: insulation for a bathhouse on the ceiling, which is better and more reliable

When the entire structure has already been built, and all systems have been well thought out, it is worthwhile to take up insulation, especially if you plan to use the bathhouse throughout the year, regardless of the season. Moreover, in the sultry summer and cold winter, this will be equally useful and simple if all the calculations for insulation are correctly made, especially the ceiling, from where the lion's share of the heat from inside the room can be ventilated. To begin with, before you figure out how you can insulate the ceiling in a bathhouse, you need to understand that this material must meet special requirements, otherwise it’s simply not worth taking it, it will be wasted funds, and now is not the time to risk your own money.

Important

It is worth understanding that, first and foremost, the insulation in a bathhouse on the ceiling, the builders forum is replete with similar statements from real professionals, must be moisture resistant, since all the hot steam first rises. Moreover, you should not hope that vulnerable material that absorbs water can be reliably hidden under a vapor barrier. It will, of course, help a little, but such an insulator can still become unusable and completely lose its properties in just a couple of years, due to the regular appearance of condensation, which is inevitable with temperature changes.

- Also, the insulation for a bathhouse on the ceiling must be completely harmless and not dangerous to human health and life. That is, it should not release toxins, aldehydes, or other dangerous substances, even under the influence of high temperatures that will regularly occur in the bathhouse.

- Fire safety is another important factor that insulation for the ceiling in a bathhouse must have, and which one is better under this criterion, they will help you figure it out, for example, in a store.

- We should not forget about sudden changes in temperature, which the thermal insulation indoors must withstand without much reaction, and over a long period of several years.

- Biological and chemical inertness, as well as resistance to the development of various microorganisms, fungi and other “living creatures” of the material for bath insulation is also extremely important.

Among other things, I would like to definitely note that the heat-insulating layer must be sufficiently tight and elastic, but such that, for example, it itself will not sag over time. Therefore, in order not to be too tormented by the question of which insulation to choose for the ceiling of a bathhouse, it is worth purchasing one that is relatively inexpensive, but in terms of performance and properties is at its best. Moreover, it is worth understanding that this can be done using natural materials, or you can choose synthetic ones, which also “work” quite well.

Insulation of a wooden base

Layout of an insulated wooden floor on joists

A wooden floor in a bathhouse can be based either on a strip foundation or on screw piles. But from a technological point of view, the thermal insulation process will be the same in both cases. High-quality heat and waterproofing will be needed directly in the washing room, as well as in the steam room. How to cover a wooden floor on screw piles with sheets of foam plastic and other thermal insulators?

- first of all, the bars are mounted on the sides of the support piles;

- the beams are attached to the lower edges of the beams on both sides;

- screws or nails are used to fix the cranial beam;

- wooden boards are laid between the support piles;

- then they install the waterproofing film with their own hands;

- and only after that the heat insulator is fixed without gaps.

Important! Before making thermal and waterproofing on screw piles, the ceiling is inspected: rotten logs are replaced, and deformed ones are reinforced with wooden blocks.

Insulation of the concrete base

Construction of a cake with an insulated cement screed

Insulation of a concrete floor in a bathhouse is usually done using penoplex, expanded clay, glass bottles or foil materials. When covering the base with your own hands, you can also use mineral wool, but only of high density. What is the technology for installing insulation?

- first level the base using a screed;

- after the screed has hardened, a waterproofing film is installed;

- for waterproofing, either polyethylene film or roofing felt is used;

- lay the sheets overlapping with a margin of 15-20 cm;

- the joints are coated with bitumen mastic;

- then install the reinforcing mesh and fill it with new solution;

- After this, the base is sheathed with a heat insulator.

To finish the ceiling in this case, experts recommend using hydrophobic materials such as penoplex, polystyrene or basalt wool. The process of installing insulation in a sauna is described in more detail in the video clip.

Insulation of the base on screw piles

Wooden bathhouses at dachas are often built on screw piles, so the technology for covering the base is practically no different from finishing the lag covering:

- To begin with, the heads of the screw piles are tied using support beams;

- The grillage mounted on the joists is additionally waterproofed to prevent rotting;

- I use bitumen mastic or roofing felt as a waterproofing agent;

- Then, on screw piles, inside the grillage, logs are installed that will serve as a rough foundation for the floor;

- A cranial beam is attached to the lower part of the log, after which it is sheathed with boards;

- At the final stage, the floors on screw piles are sheathed with a heat insulator (foil insulation, mineral wool, penoplex).

In the video clip, experts talk about the advantages and features of hydro- and thermal insulation of floors on screw piles.

Walls

Insulation of walls begins with the installation of wooden frame racks. is installed in the resulting cells tightly, spaced apart, without any gaps, to prevent the occurrence of “cold bridges”. To achieve greater effect, it is recommended to lay the slabs in two layers with the joints overlapping as much as possible.

Vapor barrier

Protection of cotton wool from moisture is carried out using a vapor barrier. To achieve the required effect, the barrier must be continuous.

The rolls are rolled out over the entire surface of the walls with an overlap of 10 - 15 cm. You should start from the bottom. The first roll is rolled out close to the floor with a slight overlap on it.

The vapor barrier is attached to the frame elements using a construction stapler. The joints are sealed with metallized aluminum tape.