Installing a chimney in a bathhouse from sandwich pipes is the most optimal option for a metal chimney. This light-weight and compact structure is almost irreplaceable in conditions where, in the original plan, there is no smoke exhaust device in the home.

It is not difficult to implement this installation idea. All you need is to fasten the main parts and auxiliary elements in the desired sequence.

In this case, you also need to take into account some of the nuances of this device. Without them, it will not be possible to correctly complete a solid and hermetically sealed structure. And such a structure would look like this:

Sandwich - structures formed from three layers received their name from the light suggestion of a famous resident of England. Chimneys in a bathhouse with this name are no exception.

A distinctive feature of these pipes is that an insulating layer is placed between the metal contour on the outside and the same contour in the middle. It is usually made from basalt materials.

Additional elements for installation:

- pipe equipped with inspection;

- clamps for crimping;

- brackets and other parts:

This kit helps ensure the proper functioning of the chimney system.

A sandwich chimney in a bathhouse has a number of advantages.

- The circuit inside the sandwich pipe tolerates heat to high temperatures and the influence of condensation well.

- During installation, the insulating material creates reliable protection for the external circuit from overheating.

- Structural features create obstacles for water to penetrate into the insulation.

- The required thrust limit is created, and the gases are discharged.

The circuit inside these materials is most often made of stainless steel, and this option is known to have high anti-corrosion properties. With savings as a goal, the outside contour is often made of less resistant galvanized material.

Thus, the consumer faces the problem of choosing a material: to prefer a long-lasting stainless steel or an option that allows some savings.

IMPORTANT! The material for the sandwich pipe inside is selected taking into account its ability to withstand high temperatures. And the product for the outer contour must be made of rigid material, otherwise its configuration cannot remain unchanged.

Also used during installation:

- Brackets on the wall to hold the building.

- An audit consisting of a window for cleaning, which also includes a stand.

- Adapter kit.

- Tees.

- Knees that make it possible to change the direction of the structure by 45 degrees or at a right angle.

- Clamps for fastening separate parts.

- Unloading platform. It allows you to accurately calculate the mass of a structure and remove the load from its base.

- To carry a chimney through the roof you will need a roof, a rosette and a comfrey.

Chimney design

Based on the type of structure location, one can distinguish street (external) and internal chimneys. The street chimney channel goes outside through the wall. Its advantages: simple installation and high degree of fire safety. At the same time, it consumes more fuel and requires insulation.

The channel of the internal structure goes out through the roof and, as a rule, has a strictly vertical configuration without horizontal sections. It has good traction, consumes less fuel and heats up the steam room and sauna as a whole faster. Among the disadvantages, I note more labor-intensive repair and installation, a lower degree of fire safety in contrast to the external channel.

Required Tools

After carrying out all the necessary calculations and deciding how to make a chimney pipe yourself, you need to prepare all the required elements. In addition to the list of parts of the sandwich system itself, you need to have on hand a list of the following items:

- clamps for tightening;

- support brackets;

- necessary hardware fasteners;

- heat-resistant sealant;

- grinder, metal scissors;

- spatula for sealant;

- roulette;

- square;

- screwdriver;

- drill and hammer;

- building level.

You also need a marker or construction pencil for marking. When assembling, the joints of the parts must be secured with clamps. The entire resulting structure is fixed vertically along the wall using brackets in increments of 1.5 to 2 meters.

Advantages and disadvantages of a sandwich chimney

The most common type of chimney for a bathhouse is sandwich pipes, which have a number of advantages:

- simple and easy installation, which you can even do yourself;

- high repairability due to standard parts;

- aesthetic appearance;

- high anti-corrosion ability;

- low heat transfer and low condensation due to the insulating layer;

- No soot is deposited on the inner surface of the sandwich pipe because this surface is smooth.

Despite their impressive track record of benefits, sandwiches also have their drawbacks:

- high cost compared to analogues;

- limited service life - up to 15 years;

- When heated, the joints may become depressurized due to metal expansion.

The materials from which it is made are of key importance for a sandwich pipe. The price, service life and safety depend on the filling.

Nuances requiring special attention

Of course, the manufacturer of the product is of great importance. However, a lot of fakes have appeared on the market. It is difficult for the average person to grasp all the subtleties, therefore, in order not to make mistakes, it is worth listening to the advice of professionals:

- Before going to the store, take a small magnet, wrap it in a thin cloth and put it in your pocket.

- If the manager tells you that the pipe is made of high-quality stainless steel, just attach a magnet to it. Even the slightest attraction indicates that you are being deceived. The fabric prevents possible scratches.

- Be sure to make sure that the chimney is free of deformation, chips and dents.

- Pay attention to the thickness of the metal of the cylindrical product, which should be more than 0.5 mm. The durability of the entire structure depends on this parameter. The larger it is, the longer the service life will be.

- Each part must have an absolutely even shape. It is important that there are no traces of interruption in the welds.

- It is advisable to try to assemble several design parts directly in the store. All connections should be strong and without gaps. No consolidated movement of elements is allowed.

- Of course, everyone wants to save money, but this should not be done. It must be remembered that quality plays a major role, and price fades into the background.

What materials are they made from?

The sandwich pipe has 3 structural elements:

- External pipe. It can be made from various materials: stainless steel, copper, galvanized, steel.

- Inner pipe. It is carried out in a similar way to the outer pipe, but has a smaller diameter.

- The thermal insulation inter-pipe layer is made of cotton wool mineral heat insulator (basalt, stone wool, etc.).

I will dwell in more detail on the materials of the sauna pipe itself: it is this that determines the cost and operational capabilities of the sandwich chimney.

Steel

The steel sandwich is made of stainless alloy steel with high anti-corrosion ability. It is very technologically advanced and easily bends in different directions. It is light in weight, unlike, for example, a ceramic pipe. It can be equipped with cleaning hatches and spark-extinguishing grilles, which increase its safe operation. The optimal wall thickness is 1 mm. The pipe itself can be painted in any color, which allows you to decorate it organically.

Which is better: galvanized or stainless chimneys

Galvanization is cheaper than stainless steel, which is due to its lower ability to withstand mechanical damage. Even slight damage to the protective layer can lead to metal corrosion.

Some builders install a combined chimney to reduce costs and at the same time provide the necessary safety and reliability of the bathhouse pipe. Stainless steel is used to make a section in the steam room, where working conditions are more extreme. Galvanized pipe is used in the attic and outdoor areas.

With a combined installation, problems may arise with the joining of elements, so before reducing the budget for building a bathhouse, “measure” the consequences seven times!

Ceramic

Ceramic pipes have a number of advantages:

- High temperature resistance – up to 1200 °C.

- Eco-friendly: they are made from natural clay.

- Light weight in contrast to concrete and brick structures.

- Ease of use due to special ceramic modules, which are manufactured with cleaning doors.

The pipes themselves are compact three-layer modules 30 cm high. The inner layer is smooth, which promotes good traction and prevents combustion products from settling on it. They are easy to assemble into a solid and durable structure.

Glass

The main advantage of a glass pipe for a bath is its attractive and modern appearance. It is made of safety fire-resistant glass: when broken, it shatters into blunt fragments, which eliminates cuts. Glass pipes are durable, easy to clean, and resistant to temperature changes. Not everyone can install such a pipe, because its cost is much higher than chimneys made of sandwiches and other traditional materials.

I think that in the future they will become more affordable, but for now they are a designer luxury that can be abandoned in favor of budget options.

What material is best for a chimney in a bathhouse?

I have listed which pipes can be used to build a bathhouse. I dwelled on each type in detail, highlighting its pros and cons. Now let me clarify that it is not recommended for use in steam rooms.

These include concrete and asbestos-cement pipes: these structures do not comply with fire safety standards for premises with high-temperature operating conditions.

When choosing, take this recommendation into account; otherwise, decide for yourself according to your budget and aesthetic preferences.

Installation features

A sandwich chimney has a low fire hazard (the outer surface of the pipe rarely heats up to temperatures above 40°C), however, it is better to locate the smoke exhaust system at a safe distance from any wooden structures.

The height of the sandwich chimney above the roof surface directly depends on the location of the pipe exit relative to the ridge of the building:

- Removal by 1.5-3 meters. The upper edge of the chimney is mounted flush with the ridge.

- Removal less than 1.5 meters. The chimney should rise above the ridge by approximately 0.5 meters.

- Removal over 3 meters. The height is selected so that the angle between the roof ridge and the top point of the chimney is 10°.

We recommend that you familiarize yourself with: Types and characteristic features of plugs for profile pipes

Note! If the elevation above the roof surface is more than 2 meters, the chimney should be additionally secured with braces.

On roofs made of flammable materials, fire safety standards require the installation of an additional unit - a spark arrester. This element is a fine metal mesh that easily allows smoke to pass through, but traps a significant portion of sparks. The spark arrester is mounted on the chimney head.

Professionals recommend not installing a sandwich in the steam room, preferring a regular single-wall steel pipe. Such a pipe will heat up much more than a sandwich, acting as an additional source of heating and allowing you to obtain the required temperature in the steam room much faster.

Buy or make it yourself

Buying a chimney for a bathhouse is easier than making it correctly yourself. But simpler does not mean better, especially if you have the necessary skill, free time and a desire to save money. With the right approach, making a good design will not be difficult. You can use a compromise option: make some elements yourself, and buy some complex components.

approximate price

How much a pipe for a bathhouse costs depends on the number of offers in a particular region of the country, what size the bathhouse itself is, etc.

I collected average market prices so that preliminary calculations could be made.

Completion of installation work

Upon completion of installation, it is necessary to free the pipes from the protective film. The result should be a sealed chimney (all seams must be sealed) with a total length of 5-6 meters. It is necessary to use heat-resistant compounds that can withstand up to 1000 degrees Celsius as a sealant.

Application is carried out as follows:

- on internal pipes - from the outside of the upper pipe;

- on external pipes - from the inside;

- at the transition between single- and double-wall pipes - externally along the entire circumference;

- For other joints of a single-wall pipe, it is also necessary to process the joint around the circumference.

Upon completion of work, the system must be tested to ensure that the hottest areas are suitable for regular operation in this mode. You can make chimney maintenance and cleaning easier by installing a removable inspection section or door on the chimney.

Bottom line

The article describes in detail the procedure for installing a chimney using sandwich pipes. If the basic installation sequence is followed correctly, the result can be a high-quality and safe system. You can always entrust the work to professionals who will take responsibility for all stages - from purchasing the necessary materials to installing the chimney and putting it into operation.

Basic requirements for a chimney in a bathhouse

The chimney is subject to increased fire safety requirements, because it gets very hot and can cause a fire in the bathhouse. To avoid negative consequences, during assembly and operation you must adhere to simple but important rules:

- 250 mm from the pipe is the permissible distance for placing flammable objects.

- The walls near the stove must be made of fire-resistant materials: fireclay bricks, sheet steel, etc.

- It is not recommended to sprinkle the channel with bulk materials so as not to disturb the air cooling of the structure.

- To prevent fire from sparks, the edge of the pipe must be at the required distance from the roof.

Parameters influencing pipe selection

When deciding on a pipe, you should consider the following parameters:

- internal section;

- chimney height.

These nuances should be considered at the design stage. It is better if the drawing is completed by a qualified person.

The internal cross-section should be equal to the cross-section of the furnace inlet channel. To calculate the required length of the chimney, you must also follow certain rules.

The above parameters are equally important when creating a chimney with sufficient draft.

How to make a chimney in a bathhouse with your own hands: step-by-step instructions

The easiest way to assemble a bath channel is from sandwiches. When assembling, there are several nuances that are worth considering so as not to get into trouble:

- Docking of modules must take place in visible areas and is strictly prohibited during ceiling or roof penetrations.

- The optimal size of the horizontal section is up to 100 cm in length, otherwise traction may deteriorate significantly.

Following these two simple rules will help you avoid thousands of negative consequences.

Required tools and materials

To assemble a sandwich structure for a bathhouse, you will need the following materials:

- sandwich modules according to the project (drawing);

- elements for the arrangement of cutting in the interfloor slab and roof passage;

- cotton wool mineral thermal insulation;

- if the sandwich channel for a bath has a complex configuration and horizontal sections, then various adapters will be needed;

- fasteners (screws, ties);

- sealant for sealing joints;

- head.

For high-quality installation you will also need a set of tools. A standard list should include:

- jigsaw;

- drill and screwdriver, or an electric screwdriver;

- skeleton gun for sealant;

- set of chisels;

- level and tape measure at least 5 m, otherwise there will be inconvenience and loss of time during measurements;

- metal scissors.

Design, drawings and diagrams

At the design stage, it is worth considering several common truths:

- The height of the chimney structure to ensure normal operation is at least 450 cm.

- The distance from the edge of the channel to the plane of the roof slope is at least 50 cm.

- The channel must be equipped with a valve (gate, valve) to regulate draft.

- Passage units in the floors and roof of the bathhouse must be thermally insulated.

- The simpler the configuration (the course of the pipe for the bath), the cheaper and more convenient it is!

There are also folk life hacks. For example, paint the outer surface of the pipe with white or light paint to easily detect leaks through which smoke is coming.

Before assembly, it is important to make a drawing or diagram. Below are two diagrams of a chimney made from sandwiches, which can also be used for a bathhouse.

Diagram of the external (external) channel

Internal channel diagram

Methods for connecting modular elements in a chimney

Sandwich modules can be connected in two ways:

- "By the smoke." This connection prevents smoke and carbon monoxide from entering the room. The lower module is inserted into the upper one so that the edge of the lower one is higher than the edge of the upper one, as shown in the right figure.

- "By condensate." This option prevents condensate from entering the heat insulator of the sandwich pipe. To do this, the upper module is inserted into the lower one so that the edge of the upper one is inserted below the edge of the lower one, as shown in the left figure.

Assembly order

Before installing the sandwich pipe in the bathhouse, passages in the ceiling and roof are prepared. If the cutting of the ceiling-passage assembly (CPU) should be done immediately, then it is better to make a hole in the roof with the sandwich pipe directly approaching it. This way you can prevent the premises from getting wet during rain, as well as unnecessary work on closing the hole itself.

After installing the PPU, you can begin assembling the sandwich line:

- To accelerate heating of the steam room, a steel pipe is immediately installed, and the sandwich is installed closer to the ceiling at a distance of 20–30 cm

- You should not join modules in passage units, otherwise to repair them you will need to disassemble the polyurethane foam or the passage in the roof.

- It is better to install sandwiches for a bathhouse “in the smoke” to protect the health of steamers.

- The joints of the modules are sealed with heat-resistant sealant.

- The roof hole is closed with a flash master with a silicone lining, which seals the roof hole.

Light weight and simple joining of sandwich pipes allow two craftsmen to install them in a short time. You can even assemble a sandwich pipe for a bathhouse yourself, but it is better to call a competent friend or acquaintance to avoid amateurish mistakes.

Chimney passage through a wooden interfloor ceiling

The ceiling-passage assembly (CPU) in wooden floors should be carried out in accordance with SNiP, which sets out the following rules:

- The PPU sleeve is made of non-flammable material, see SNIP for the classification of materials.

- The cutting (the passage of the pipe through the ceiling) is made of fire-resistant materials (basalt wool, etc.).

- The cutting for wooden floors is made with a width of 50 cm.

- The cross-section of the sleeve must be wider than the diameter of the channel to ensure convenient installation.

- You should not use a rigid groove connection with an overlap to prevent channel bending.

- The setback (distance between the pipe and the adjacent wall) for wooden walls is 26–50 cm.

Compliance with these simple rules will ensure the safe operation of the bathhouse chimney and the health of bathhouse attendants and steamers.

Chimney passage through a roof with a roof made of combustible materials

The channel through the roof is carried out as follows:

- Marking and cutting of the roof is done in such a way that there is at least 130 mm from the outer layer of the pipe to the edge of the roof.

- If the roof is insulated, then under-roof and top plates are installed, and the space itself is filled with a heat insulator.

- If the roof is cold, then it is enough to install a flash master.

- The outer cover or flash master at the junction with the roof is coated with bitumen sealant.

Output through the ceiling

Installation of a chimney in a bathhouse through the ceiling is carried out as follows.

For the exit, a special unit is installed in the ceiling covering, which creates reliable fastening and high fire safety: Despite the fact that such a pipe is a two-layer structure with non-flammable thermal insulation in the middle, to increase the level of safety, a hole is made in the ceiling opening for the chimney installation of a small pipe, which is 15-20 cm in diameter larger than the diameter of the chimney.

From the bottom, such a hole is sealed with a steel sheet. The part that ends up in the attic is filled with non-combustible material. To do this you can take:

- basalt wool;

- sand;

- expanded clay

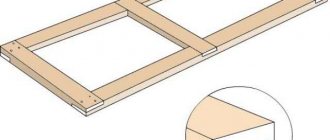

A large-volume rolled pipe range for insulating a sandwich chimney can be replaced with a box made of non-combustible materials:

A sandwich - a smoke exhaust - is passed into the box, and the empty space is also filled with non-flammable material:

The video provided details how such work is carried out.