Black stove project for a bathhouse. In this article I will introduce you to my stove project. It is made using modern technologies for constructing furnaces, but the principle of operation of the furnace is the same as hundreds of years ago.

Stove projects for black saunas

You can order any stove design for your bathhouse from me. Stove designs for gray saunas or Russian steam baths are in great demand. A gray heater stove is a brick stove where the stones are heated directly by smoke, but the smoke no longer comes out into the steam room, but into the chimney.

Such stove designs serve to create the steam atmosphere and conditions of a Russian steam bath. This will be written about in another article on the FireplaceTeplo blog.

I suggest you visit my group on VK. Subscribe to news, ask questions, join the ranks!

Black oven project

In a black-style heater, wood, when burned, heats the stones located directly above the hearth. The smoke, passing through the stones, fills the bathhouse and heats the walls and ceiling of the bathhouse, after which it leaves the steam room. Such a sauna heats up faster than a gray or white sauna, where the smoke exits into the chimney. The soot on the stones burns completely, but remains on the ceiling and walls, painting the walls and ceiling black. This is where the name comes from.

Fans of such a bath claim that it is the most beneficial for health. No other bath can compare with the aroma and spirit of such a bath. The frame of a black-style bathhouse does not rot for a long time, since it is deeply disinfected directly with smoke, which contains a natural antiseptic.

It is believed that such a bath heals. In modern times, when hundreds of models of iron stoves are on sale, the demand for a black sauna will return again.

You can order a black-style sauna stove project by calling the phone number listed on the “contacts” page. We can also carry out the laying of a stove for a sauna in black style. If you have questions about this design, please email.

Visit the blog page FireplaceHeat How to heat water in a black sauna. This is the answer to the question in the comments to this publication: “Why is there a pipe in a smoke bath?”

How to drown

The stove is heated with the doors, windows and portholes open - a small window above the fireplace through which smoke comes out. To take a steam bath, they heat it for several hours in a row, until the stones glow crimson. They use, as before, more birch, but in general, they heat it with whatever is necessary, placing birch logs only on the last stash.

Panorama of a functioning black bathhouse in one of the villages (described above)

After the last portion of firewood has burned, the corners are raked out and taken away. Those remaining in the hearth are poured. Open the doors and windows and ventilate, waiting until the smoke disappears and the fumes settle. Then they add water to the hot stones so that the steam squeezes out the remains of the burning, and wash the shelves from the settled soot (all with the doors open). Then close the doors/windows and wait for half an hour until the bathhouse heats up. You can take a steam bath.

Just be careful with the soot. It doesn't wash well. These are the impressions of someone who was used to taking a steam bath in a white bath, and then, having decided to try exotic things, went to take a steam bath in a black way. His review is below.

I heard enough about the delights of a black bath, so I went to a friend’s grandmother to take a steam bath. He heated it, when the stones got hot, he went in. Although this is said loudly. Almost crawled. With my height 190, the height of the door is 125. In general, I climbed. I couldn’t see anything in the smoke; I almost turned inside out from coughing. It turned out that we needed to remove the coals and wash the shelves. While I was doing all this, all my hands were covered in soot.

Further more. While I was sitting and warming up, everything was fine. It smelled like it was scorched, burnt, smoked. But you can consider it a highlight (smoked). OK. Then I decided to take a steam bath with a broom. As he waved, he scooped up a fair amount of soot from the ceiling. I became a tiger man, pink striped. I tried to wash myself on the spot. Can't be scrubbed off with soap or shampoo.

I decided to go to the garden in a barrel. Grandma worked there. When she saw me, she began to cross herself and mutter “holy, holy, holy,” and tried to poke me with a shovel. It didn’t hit well - it’s very old. Then she admitted it and asked for forgiveness.

I rubbed and rubbed, neither with sand nor with herbs, but it didn’t help. High quality carbon black. As a result, I washed myself with a simple powder from my grandmother’s supplies. The one who existed even before Asya or Dusya (whatever her name was). Then it itched mercilessly for a week, but at least it became uniformly pink, without black stripes. And one more thing: I smelled smoke for another three days. Despite the abundance of water procedures with all possible and impossible means, including laundry detergent.

Description of design

The design of a black sauna stove can be divided into several parts:

- Foundation. For the construction of this furnace, it is advisable to use a good cast reinforced concrete foundation. The stove is heavy and requires a reliable base.

- Fire cutting. It consists of a brick wall, built on the same foundation along with the stove. The fire wall is located at some distance from the wooden wall. The gap is needed so that when the frame shrinks, the wall does not deform or crack. It is known from experience that the log house does not settle evenly. The displacement of logs occurs not only rectilinearly along the vertical axis, but also its displacement occurs along the horizontal axis. The gap is also necessary for drying the wall.

- The body of the stove in black consists of: An outer frame. It is made of brick.

- Internal fireproof part. Accordingly, it is made of refractory brick. Laying must be done using a fire-resistant mixture. The inside of the furnace is indented from the outside to reduce the temperature load on the lining. The gap prevents the destruction of the outer finish of the stove. Also, thanks to the gap between the housings, the outer cladding does not overheat. Bondage from a corner for fire-resistant masonry is required. The stone attachment only loads the internal masonry. The stones are in a metal basket.

Manufacturing examples

Having decided to make a sauna stove on your own, you need to approach the matter thoroughly.

Firstly, choose a project that is best suited for the bathhouse, and secondly, make drawings to make it easier to build. There are many options for sauna stoves, so anyone can create their own version, taking into account some basics. Here are some examples of homemade projects.

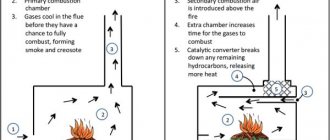

Metal with a tightly closing heater

This option is possible for a steam room measuring 2 by 3 and 2.3 meters high. The material, namely metal, is taken as a sheet, three millimeters thick. The air supply goes to the top of the firebox. A metal plate is welded to the back wall of such a firebox, and air is supplied into the hole between the wall of the firebox and this plate using tubes. This helps cool the back wall and push hot air up where the flue gases are concentrated. When mixed, the substances ignite. Thanks to this, the stones are heated to high temperatures, although much less firewood is used.

For a compact steam room

It is not difficult to build such a stove. To build it you will need a metal sheet up to five millimeters thick. If you take a thinner sheet, the stove will quickly burn out. Its dimensions are 90 cm in length, 80 cm in height and 60 cm in width. To create a chimney, a piece of pipe with a diameter of 11.5 cm is suitable. At the bottom there should be an ash pit with a door; between this part of the stove and the firebox, cast iron grates and heaters are placed to remove waste remaining after combustion. To do this, one third of the back wall of the heater is welded with a strong sheet of metal, where a chimney pipe is welded in the center, lowered down 10-12 centimeters.

The top of the oven is covered with a metal lid up to one millimeter thick. It is this that prevents the stones from cooling down and also prevents waste and ash from entering the steam room. The lid opens only when needed, namely before going to the bathhouse.

Simple heater

This is the best homemade stove, which is suitable for both a sauna and a simple bathhouse. The high temperature is reached in about an hour and a half. During this time, the 50 liters of water needed for swimming can boil. Such a stove has not one chimney, but two. The first is suitable for heating the room. The second is for the release of carbon monoxide and acrid smoke. The structure consists of sheets of iron 3-4 millimeters thick, but the firebox itself is made later. It is made of metal up to 6 millimeters thick. The kit also includes a small and large valve and two metal grilles.

The heater is made of steel up to three millimeters, which is attached to the “neck” of the firebox itself. Two pipes are placed on top, to which flanges with the necessary holes are welded for fixing the outlet pipe and for attaching the elbow.

With brickwork

In this option, double technology is used, that is, brickwork plus a metal body. Steel up to two millimeters is suitable here, and the brick must be heat-resistant.

First, a base is made to which the legs necessary for the stability of the structure are welded. Then they lay out a row of bricks. The remaining rows are built near the half-brick firebox. Install a grate and a grate for stones. It is also necessary to install a window for the valve, where the heat will be retained after the end of the fire. The last two rows are made solid, leaving only a place with a window for the chimney.

Having finished laying the brick and waiting for it to harden, you can begin welding the metal body, which plays the role of a case. It is necessary to cut out the metal for the ash pan and windows for loading. A door is installed, always with a seal. The metal base is complemented by a cold handle.

The last thing to weld is the lid with the hole for the chimney. When the stove is installed in the place allocated for it, you can lay the stones. Their bookmark plays an important role. After all, work efficiency also depends on this. It is better to take stones that are round in shape and of different sizes, from approximately 50 to 100 kilograms.

Having examined the types and designs of homemade sauna stoves, we can say with confidence that making one yourself is a completely doable job if you take into account all safety requirements when installing it. This will save money for the family, and the stove itself will become the property and pride of the owner.

In the next video you will see how to make a sauna stove from a pipe with your own hands.

Oven dimensions

The overall size of the stove for a black sauna with fireproof cuts is 180 cm x 155 cm. The stove occupies 2.8 m2 of the area of the steam room. The height of the fire wall is 23 rows. This is approximately 165 cm, since one row of masonry is below the level of the finished floor of the bathhouse.

The size of the furnace body itself: the height of the masonry is 12 rows. This corresponds to approximately 90 cm. The width of the stove on the firebox side is 5 bricks. This is about 130 cm. The depth of the oven is 4 bricks = 103 cm.

Overall dimensions of the stove for a black sauna

What are the benefits and harms of a steam room?

The positive effect of the Japanese bath on the body has been scientifically proven. Useful properties of the steam room:

- improvement of breathing, blood microcirculation;

- skin rejuvenation;

- cleansing the body of waste and toxins;

- normalization of liver and kidney function;

- removing excess fluid from the body;

- removal of edema;

- acceleration of metabolic processes.

- strengthening the immune system;

- getting rid of excess weight;

- elimination of joint pain.

Since high temperatures affect the body when staying in a Japanese bath, you cannot visit it if you have some diseases. It is recommended that you visit your doctor in advance to get recommendations.

Weight of the stove and stones for a black sauna

To build a foundation, you will need data such as: weight of the stove; The weight of the fire wall is 1450 kg. The weight of the furnace body is approximately 945 kg. The weight of the fireclay part of the furnace (this is the firebox) is 760 kg. The weight of part of the fire-resistant wall made of fireclay is 300 kg. The total weight of the stove with the fire wall is 3,455 kg.

To this you need to add a heat-accumulating nozzle made of stones. The weight of the stones was 450 kg + lintels made of sh-96 brick - 26 kg. 6 such bricks were used in the oven. We get the total weight of the stove and stones for the black bath - 4,000 kg. Even at the stage of designing a stove-heater for a black bath, you can calculate the weight of the structure for foundation calculations.

The only competitor to a black-style sauna stove is a heat-intensive brick stove with smoke exiting through a chimney. The so-called gray bath. According to the steam room conditions, such stoves are the lot of connoisseurs of real Russian steam. Order a project for a brick sauna stove “Russian steam” (sauna in gray) and drawings of a heater stove for a Russian steam bath.

The stove is designed to burn dry wood. You can find out how to prepare and dry firewood on the page of the same name by following the link.

Advantages

A bathhouse that is not equipped with a chimney has always been loved. Previously, people only went to such steam rooms. Despite its simple design and ancient origin, the traditional old Russian steam room has many advantages:

- To build a black steam room, you do not need to spend a lot of time and money.

- The absence of a chimney also increases savings, since the heat does not escape beyond the walls of the bathhouse, which means the cost of firewood will be lower.

- All structural elements are heated simultaneously.

- When birch and aspen firewood burns, hydrocarbon substances and phytoncides are released, which have an antiseptic effect. Therefore, the room is sterile, like an operating room.

- High temperature and smoke help destroy fungus and various insects that can grow in wood. A protective shell is formed around each log, which increases their service life.

- Natural hydrocarbons can improve the functioning of the respiratory system and cleanse the skin. The Russian black bath made it possible to stop the plague epidemic that consumed Europe.

- The air inside the bathhouse is not too dry, since a large number of stones and hot walls contribute to the uniform distribution of heat.

- Smoke completely destroys harmful and fetid odors, which makes your stay comfortable and enjoyable.

Inside view

Fire prevention measures

The bathhouse is installed at a fire safety distance from neighbors' houses. This must be taken into account in advance. We also must not forget about fire extinguishing measures. A fire shield and fire extinguishers must be installed at a certain distance from the bathhouse.

It doesn't hurt to be able to use a fire hydrant either. Elements of the bath that are not in contact with humans can be treated with fire retardants. Fire retardants are substances that protect wood from ignition and spontaneous combustion. These are rafters, wooden roofing, wooden elements of the attic space.

Some more photos in the gallery.

View from the entrance

Stove façade in black

Smoke stove

I installed a stove in such a bathhouse. If you are interested in making such a log bathhouse, please email or call. I will help you contact the master.

Photo of a log bathhouse “black style”

Preparing and cleaning furnace equipment

Before you start heating the stove, you need to prepare the combustion chamber. To do this you should:

Use a scoop to clean the ash chamber. Remove soot and remaining ash from the grate. Prepare logs. They should be stored in a firewood rack, which can be placed in the dressing room. Carefully inspect the heater

Rinse it with water if there are no stones inside. Fill the boiler with water if there is not enough water. Attention should also be paid to the presence of traction. To do this, you need to open the valve on the chimney, the combustion chamber door, and the ash pan.

Light a match or splinter and bring it to the door. If the flame rushes towards the combustion chamber, there is draft. If the flame does not move, you should check the chimney.

The last stage is preparing the ignition medium. More often, newsprint or birch bark is used. You can buy a special liquid composition for ignition.

It is prohibited to use gasoline for kindling.

Log house for black-style sauna

The black bathhouse in which the stove was built according to my design has internal dimensions of 262 cm x 462 cm. The area in terms of the steam room is 12 m2. The ceiling height is 190 cm. We get a volume of about 23 m3. The plan of the steam room shows that the heater is located on the right in the corner of the room. On the left are shelves and a cold water tap. Water heating is provided for supplying the stones, for washing and for steaming brooms. This will be discussed in another article on the FireplaceTeplo blog.

Black sauna plan

In addition to designing stoves, we perform the following bath maintenance work:

- Repair of the sauna stove structure in gray

- Repair of sauna stoves in black style

- Replacing stones in sauna stoves of any design

- Cleaning chimneys and channels in batch sauna stoves

- Roof washing (hydrodynamic pressure cleaning of the roof) from moss and other fouling (phone number of the technician on the “Contacts” page)

You can get acquainted with what is included in the design of a black-style sauna stove

Advantages

A bathhouse that is not equipped with a chimney has always been loved. Previously, people only went to such steam rooms. Despite its simple design and ancient origin, the traditional old Russian steam room has many advantages:

- To build a black steam room, you do not need to spend a lot of time and money.

- The absence of a chimney also increases savings, since the heat does not escape beyond the walls of the bathhouse, which means the cost of firewood will be lower.

- All structural elements are heated simultaneously.

- When birch and aspen firewood burns, hydrocarbon substances and phytoncides are released, which have an antiseptic effect. Therefore, the room is sterile, like an operating room.

- High temperature and smoke help destroy fungus and various insects that can grow in wood. A protective shell is formed around each log, which increases their service life.

- Natural hydrocarbons can improve the functioning of the respiratory system and cleanse the skin. The Russian black bath made it possible to stop the plague epidemic that consumed Europe.

- The air inside the bathhouse is not too dry, since a large number of stones and hot walls contribute to the uniform distribution of heat.

- Smoke completely destroys harmful and fetid odors, which makes your stay comfortable and enjoyable.

Inside view

Let's summarize

Now that you know the features and benefits of a black sauna, you can start building a sauna with your own hands. It is not difficult and inexpensive, relative to modern analogues. If you want to improve your health, then you won’t find a better place than the “black” sauna. Even in the old days, women gave birth in such a bathhouse.

Isn’t this an indicator of reliability and safety for the health of an adult and even a child?! High temperature, a herbal broom and cold water will make your vacation simply unforgettable, especially since one kindling of the sauna is enough for several visits. Using the tips and recommendations presented in this article, you can, without much difficulty, build with your own hands a place in which, perhaps, your grandchildren and great-grandchildren will rest, remember you with a smile and be proud.

Masonry

The masonry process is very painstaking and complex. There are a large number of subtleties and nuances here, understanding some of which comes only with experience. Therefore, to make this work easier for you, this section contains several videos that tell you step by step and show how to lay row by row.

As an example, consider the manufacture of an open small stove-heater. The size of such a stove is 102x62 cm. It is capable of heating a steam room with a tank, while the tank itself is located separately. It uses an interesting water heating system - an open siphon. So, a pipe is welded into the tank at a slight angle, which is sealed at the end. It should be under an open fire in the firebox. As soon as the water in the pipe boils, it rises into the tank, and cold water comes in its place.

The diagram below shows an example of a stove with an open heater:

Diagram of an open heater

And also a diagram of the arrangement of the firebox of an open heater:

Firebox order

Below in the diagram is the order of laying bricks for the stove:

Brick laying order

If you want to make a closed stove, keep in mind that this is much more difficult to implement. There are many nuances that must be taken into account when laying it. It is quite difficult to describe the entire technological process, so we suggest you watch an introductory video. The peculiarity of such a furnace is that the reservoir for stones is lined with fireclay bricks:

Video about making a closed stove:

It is worth noting that upon completion of the masonry, drying should be 10 days. At the same time, drafts are unacceptable. Only after this time can the first fire be fired.

Arranging a steam room with your own hands

If you wish, you can make ofuro with your own hands in a spare room in a private house or a separate building.

It is easier to build a Japanese bathhouse than a Russian or Finnish one, but each stage of construction has certain features.

Materials and tools

To build an ofuro you need to prepare:

- cedar or oak boards;

- natural stone or ceramic tiles;

- fasteners;

- stainless steel hoops;

- wood-burning metal stove;

- miter saw;

- set of chisels, hammer;

- screwdriver, drill;

- grinding machine;

- shovels, concrete mixer.

It is prohibited to install plastic parts in a Japanese bath. This material will deform when exposed to high temperatures and release harmful toxins.

Stages of work

A hot tub on the street near the house

The process of building a Japanese bath:

- Construction of a pile or strip foundation.

- Construction of walls, construction of rafter system.

- Covering the rafters with roofing, assembling the subfloor, ceiling, sewing gables, anemones.

- Installation of windows, doors, communications.

- Furnace placement, interior decoration. For cladding it is better to use lining made of larch, alder or linden.

Barrel assembly:

- Cut oak or cedar boards into separate pieces according to the required dimensions.

- Attach them together using waterproof wood glue. Attach the bottom to the barrel.

- Place 2 metal hoops on top of the finished product.

- Secure benches inside the barrel and install a thermometer.

- Drill a hole closer to the bottom of the container and install a drain valve.

- Separately assemble wooden steps for the container.

You can assemble a lid that will cover the barrel when it is idle (for example, when visitors are resting, drinking tea or relaxing after a massage).

It will prevent the water from cooling quickly and protects the container from debris.

On sale you can find designs with built-in pumps, automatic water drainage, liquid filtration systems, and hanging tables for tea.

Features of further arrangement of the Japanese bath:

- If you have space and building materials, you can assemble a container for sawdust. After each procedure, the filler must be replaced with new ones, which can cause a number of purchasing difficulties.

- The surrounding decoration should be decorated in a traditional Japanese style, for example, by placing massive vases with plant branches. You can hang pictures on the walls. Pillows should be laid out in the rest room and a corner for incense should be equipped.

- The windows need to be covered with wooden slats.

Inside such rooms, calm tones should prevail.

Treatment

A wooden barrel will be constantly exposed to the destructive effects of moisture and temperature changes. To protect it and make it more durable, you need to use special antiseptics for wood. They will make it resistant to temperature changes.

Creation of sand-clay composition

After preparing the base, the next step is mixing clay and sand. It would seem that why exactly such a composition is needed if there is cement, but the answer is obvious - the cement mortar is completely unable to withstand exposure to high temperatures. That is why all designs of a brick heater stove for a bathhouse require a sand-clay composition.

The best clay for laying a stove in a bathhouse can be obtained at a depth of about half a meter. Naturally, the material must be thoroughly cleaned and soaked for several days before use. For soaking, you can make a small groove next to the bath. It is necessary to prepare not only clay, but also sand - it must be cleaned of various impurities and thoroughly sifted so that there is no debris in the masonry joints.

The clay is kneaded directly in front of the slave. Experienced stove makers use a special “oar” for these purposes, which is perfect for these purposes. Next, water is added to the clay, and it all mixes well until it becomes sour cream. Moistened sand is added to the clay mixed with water.

To determine the quality of the resulting solution, a dry and clean stick is lowered into it, and the result is determined by the following criteria:

- If a layer of mixture less than 1 mm thick has stuck to the stick, you need to add clay;

- If the thickness of the adhering layer exceeds 3 mm, sand is added;

- If 2 mm of the mixture adheres to the stick, then the solution is suitable for use.

Safety precautions

Safety regulations:

- Damaged ovens must not be used.

- It is necessary to regularly clean the chimney to prevent smoke from entering the bathhouse.

- It is prohibited to use chemicals or liquid fuel for kindling. Compositions for igniting stoves are allowed for use.

- Firewood cannot be stored or dried close to the walls of the stove.

- There should be a sheet of metal under the ash hole to protect the floor from coals falling out.

- Do not leave the oven door open during combustion.

- Bathrooms should have proper ventilation.

- After each fire, you need to clean out soot and ash from the combustion chamber and ash drawer.

- You cannot fill the firebox to the very top.

The following cannot be used to light stoves:

- painted boards;

- old clothes, rags;

- plastic products, rubber;

- rotten, rotten logs.

Garbage not only clogs the firebox and chimney faster, but also emits a pungent, unpleasant odor.