What can I do to stop the chimney from sparking?

Good afternoon

Sparks are flying from the chimney in my bathhouse. The spark arrester doesn't help. I'm worried about fire safety because it sparks quite strongly, especially when the firebox door is open. The chimney is direct-flow, its diameter is 110 mm and its length is 4.5 meters. It is welded from a gas pipe. I cut this pipe into two parts and welded them to each other. I heat the stove with wood. A straight-through pipe is dangerous because of sparks, especially if it has a strong draft. You can really solve the problem if you make a smoke circulation that reduces the speed of smoke escaping into the chimney.

Also, probably, the doors of the firebox and ash pan do not close completely tightly and there is no gate. In this case, you need to consider some changes in the design of the furnace, and not the method of catching flying sparks. In addition, it is advisable to monitor the operation of the furnace.

In general, you should try to change the gas speed, but in such a way that the thrust is sufficient. Otherwise, you can simply get burned. Due to additional smoke circulation, the residence time of gases in the pipe can be increased somewhat.

It is difficult to talk about the problem if you do not have a drawing, but an additional smoke circulation device is preferable. In addition, it will allow you to obtain additional heat for the steam room, which now flies out into the chimney along with sparks and smoke.

Why does it smoke?

If the stove in the bathhouse smokes during initial use, the problem may directly be due to improper installation of the structure. We strongly recommend that you contact a specialist for help, since it will be quite difficult to find and fix the problem yourself.

In addition, there are other reasons why the stove in the bathhouse smokes. These include:

- First of all, strong winds can interfere with the exit of smoke from the chimney. In most cases, this is due to the fact that the pipe is located slightly below the ridge. The problem can be solved by making the pipe longer, or by installing a protective cap;

- Damage to the roof may also be the answer to the question - why does an iron stove smoke in a bathhouse? This is explained by the fact that if there is an attic flue, moisture enters it and seeps through damaged roof areas. This problem can be eliminated only by repairing these areas;

- An iron stove in a bathhouse smokes most often due to an excessively dirty chimney or foreign objects in it. Detecting this problem is as easy as shelling pears, since a clear sign is poor draft in the sauna stove. For example, very often birds build nests in chimney pipes, and debris and branches from nearby trees can get into an unprotected pipe. This problem can be solved quite simply; you just need to clean the chimney of soot, soot and foreign objects. As a tool, it is best to use a special flexible brush with nylon bristles;

- Among other things, smoke can be caused by too large a vent. This is explained by a large amount of cold air entering the hole, which subsequently heats up and pushes the smoke out.

The stove in the bathhouse is smoking - what to do? This is a rather serious problem that is easier and cheaper to prevent than to solve.

Attention! It is very important to properly design the stove and chimney to avoid smoke problems in the future.

When designing a chimney pipe, many people forget to take into account the height of the ridge, which is why the pipe does not reach its level.

Problems arise due to the fact that strong air currents form above the roof, preventing the smoke from fully escaping from the chimney.

That is why the following factors should be taken into account at the design stage:

- If the pipe is located at a distance of 1.5 meters from the ridge, then its height should exceed the level of the top of the roof by 50 cm;

- If the pipe is located at a distance of 1.5 to 3 meters, then it is permissible to install a pipe whose height is equal to the level of the ridge;

- If the chimney is located at a fairly significant distance, which exceeds 3 meters, then the pipe should be no lower than an angle of ten degrees from the ridge.

Main reasons

Special spark arresters easily cope with their functional purpose if the smoke exhaust system of the bathhouse is operating normally. If there is an error in the smoke turnover rate, sparks appear from under the chimney cap. They are particles of fuel that did not have time to burn.

A decrease in smoke turnover can cause the fire inside the firebox to die out. Excessive thrust, on the contrary, causes rapid combustion of the fuel, as well as its dispersion into individual elements. At the same time, a fairly strong air draft easily throws out burning particles, forming bunches of sparks. Any experiments with traction are extremely dangerous, so you should know what to do if sparking occurs.

ANSWER

When the pipe is straight-through and there is also a strong draft of sparks, sparks cannot be avoided. This is really dangerous, so we recommend that you think about creating a smoke circulation - smoke will fly into the chimney at a lower speed. There are several schemes, consult a specialist when choosing. In addition, check how tightly the doors of the firebox and vent close, and whether there is a damper. If the door fit is not tight enough, then you will have to make changes to the design of the stove; this will be much more effective than finding a method to catch sparks. Yes, and it is necessary to monitor the operation of the furnace.

What to do

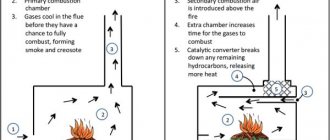

Problems associated with the emission of sparks are most often found in direct-flow type chimneys and relate to the design features of these types of pipes. In this case, the fire from the combustion chamber enters directly into the vertical chimney system. The presence of elbows, bends and horizontal sections in the pipe reduces the intensity of smoke circulation. For this reason, even significant sheaves of sparks, hitting corners and walls, become small and manage to burn out.

The disadvantage of a curved chimney system is the rapid and abundant accumulation of soot on the walls, so such modifications are not the best option for installation in bathhouses. The solution to the problem is to reduce the rate of smoke turnover inside the direct-flow pipeline, and regulate the draft using dampers, dampers or blower doors. At the same time, you can increase the duration of movement of smoke and sparks through the pipe by lengthening the chimney channel and installing a standard spark arrester.

How to paint iron

Bathhouse owners are constantly faced with rust.

Of course, it is best to make tanks and other stove components from stainless steel, but in the absence of such an opportunity, various paints and varnishes will come to the rescue.

So, how to paint a sauna stove? It is best to opt for heat-resistant silicone enamel.

Some of its varieties can withstand temperatures reaching 600-700 degrees.

Heat-resistant silicone enamel is completely unaffected by moisture and sudden temperature changes.

Therefore, if you want to protect the stove in your sauna from corrosion, heat-resistant silicone enamel will become an indispensable assistant in this matter!

Why do you need a spark arrester for a chimney for a bathhouse and is its absence dangerous?

The stove in the steam room is one of the main elements.

Operates, as a rule, on fuel made from solid materials. During construction, it is very important to ensure correct installation of both the stove and the entire chimney system. If installed incorrectly, there is a risk of carbon monoxide emissions and fire. To avoid deadly situations, you must first select the right spark arrestor for the chimney for the bathhouse and install it on the pipe in accordance with fire safety requirements.

Having certain knowledge, you can do the installation yourself. The misconception is that the spark arrester is not important and you can do without it. We must always remember that fire does not forgive mistakes. It is necessary to install a spark arresting device if there is a wooden roof, and there is an annual accumulation of dry leaves and poplar fluff on the roof.

The principle of operation of the damper

The question of choosing the size of a spark arrester for a chimney pipe is a purely individual question, since this parameter will depend on the size of the chimney itself. However, it is worth noting that most often this characteristic ranges from 80 to 550 mm. The size of the canopy for the device will depend on the size of the entire pipe.

If we talk about the principle of operation of this device, then it can be noted that it does not change in any way depending on the design, layout or dimensions of the structure. It is quite simple and looks like this:

- fuel burns in the heating system, forming combustion products that must be discharged outside through the pipe;

- when approaching the outlet, these substances will collide with the spark arrester and change their direction;

- right at the exit from the pipe, sparks will be caught by a spark arrester and extinguished in this element of the device.

The principle of operation is simple, but it is quite effective.

Spark arrestor value

Often, solid fuel is used to light sauna stoves. Sometimes there is a difference in the quality of the material, which leads to sparking. A spark is a hot particle that does not burn during kindling. With a stream of hot gases, it is directed up the chimney pipe and flies out. This phenomenon can lead to unpleasant consequences.

Sparks very often land on the roof or wooden elements of the building. The wind can blow them several meters around, which leads to the appearance of fires. Dry leaves, pine needles, grass, hay, surrounding structures, trees - all this can catch fire from one spark. To extinguish a hot particle, it is necessary to ensure its contact with elements and surfaces with a high level of thermal conductivity. This way, a red-hot spark will lose its thermal potential even as it moves through the chimney. In other words, it will simply go out.

To achieve premature weakening of the spark thermal potential, a spark arrester is installed on top of the pipe. This element allows you to catch sparks as they come out. A properly made and installed flame arrester reduces the risk of a fire in the bathhouse (sauna) and surrounding buildings.

Installing spark arresters has a number of advantages:

- Provides fire protection when flammable materials are located nearby.

- Prevents sparks from hitting the roof, especially if it is made of flammable materials and a large number of leaves accumulate on it.

- It closes the chimney pipe from precipitation, leaves, and birds, which often like to build nests in it.

- Helps reduce resistance, which eliminates reverse draft and increases the traction force of the chimney.

Making drying oil from sunflower oil at home

Caustic quicklime for whitewashing walls is converted into slaked lime before use, which is achieved by slaking it with water. Caustic lime is placed in the box designated for slaking and a sufficient amount of water is poured onto it, and slaking occurs, that is, strong absorption of water. At the same time, the lime becomes very hot, boils and emits a lot of thick steam;

If a lot of water is taken during slaking, then the lime will weaken its strength, and if not enough, then unslaked and, therefore, unusable pieces will remain in the lime. These are the main aspects of how to properly dilute lime for whitewashing walls; if you follow them, then preparing a working solution will not seem difficult.

As for the amount of water required to slak the lime, it is not always the same and depends on the composition and quality of the lime taken. That is why water is not poured into the lime immediately, but gradually until all the lime is quenched.

Lime produces a very common strong white paint on water for cheap brick and plaster work.

Lime destroys organic colors, but with earthy ones it gives durable tones.

Spar, light and heavy, serves as an admixture in paints to reduce their cost; it does not affect the color, but weakens the roofing ability. The surrogate, although commonly used, is dishonest.

How does the spark arrestor element of a chimney pipe work?

The spark arrester has a simple but effective design. It is a nozzle for a chimney, which has a mesh on the sides and a cone on top, providing reliable protection from foreign objects. The spark arrester is installed on any type of chimney. The operating principle of this device is quite simple:

- During the heating of the furnace, the solid fuel material burns. The result is smoke and gas. It is known from physics lessons that air masses rush upward along a free path. In the case of a bath, the formed substances pass through the chimney channel, trying to escape out. In this case, the smoke plumes may contain unburned combustion products, which, like sparks, lead to a fire.

- In the presence of a spark arrester, smoke with hot particles “rests” against the first and main barrier in the form of a protective cone.

- The sparks' direct passage into the air is closed. They head to the sides, where another obstacle in the form of a net awaits them. Hot particles under pressure seep through the cells, losing the accumulated thermal potential.

The whole principle of operation of a conventional spark arrestor consists of three simple steps that protect owners from fire. You can make such a device yourself without spending a lot of money.

How to improve draft through a chimney

Attention! Smoke in a bathhouse can lead to carbon monoxide poisoning, which is very dangerous for the human body.

It is thanks to it that the required amount of oxygen is supplied to maintain the fire, and also the combustion products are removed outside in a high-quality and timely manner.

If there is smoke in the bathhouse and fuel combustion has weakened, these are clear signs of deteriorating traction.

If your chimney structure was installed by turnkey repairmen, it is important to check the draft before the first fire. You can do this as follows:

- You need to bring a sheet of paper to the stove and observe - if it deviates towards the stove, then everything is in order;

- You can light a match in front of the stove and immediately extinguish it. If the smoke goes into the chimney channel, then everything is in order with the draft.

The main reason for poor draft in most cases is the so-called cold plug - a section of cold air in the pipe. Solving this issue is quite simple with the help of an ordinary burning newspaper. In addition, insulating the chimney pipe in the attic space will help cope with this problem.

Other common causes of worsening cravings include:

- The pipe is not high enough. The fact is that with a short chimney the difference in pressure at the inlet and outlet is negligible. It is best to place the chimney pipe near the ridge; in this case, the part of the pipe located outside will be minimal (remember, the chimney pipe must be at least 50 cm above the ridge;

- The chimney cross-section is insufficient;

- Blockage is the most common and simple cause. It can be recognized by a sharp and severe deterioration in traction, and this problem is solved by cleaning it with a special brush;

- Very often, the direction of the wind affects the draft in the chimney. To avoid this, a protective fungus should be installed on top of the chimney.

Main models

The elements of the chimney that ensure the elimination of hot incandescent particles are different. At home, as a rule, two types of spark arrestors are used:

- Stainless steel casing, which is a mesh structure. You can do it using improvised means.

- Deflector. In addition to extinguishing solid hot particles, it improves traction by redirecting the wind flow. Protects the stove device and bathhouse from a dangerous phenomenon - backdraft as a result of strong winds.

The damper in the form of a casing is the most popular, since its design is quite simple.

Holes are made in the pipe or a special nozzle in the form of a mesh is attached to it. The disadvantage of this design is the frequent revision of the spark arrester device. Perforated mesh quickly becomes clogged, as combustion products settle on their surface. The higher the degree of contamination, the less draft in the pipe. The spark arrestor, made in the form of a casing, is subject to frequent cleaning. On sale there are assembled casings for extinguishing sparks. Their advantage is their easy connection to the chimney pipe. More modern devices are spark arresting devices - deflectors. Externally they look more aesthetically pleasing. When using deflectors, the draft in the chimney is not reduced. Such absorbers are equipped with mesh and perforation. Their distinctive feature is the presence of narrowing points, which allow increasing traction inside the spark arresting element. Depending on the location of the narrow sector, there are various models of dampers, many of which are very similar in appearance to the casing, but are more aerodynamic. The disadvantage is that it gets dirty quickly and requires frequent cleaning, especially when using resinous logs as fuel.

Protecting the wall from overheating

During operation of a sauna stove, its surface temperature can reach 400 degrees and above.

In addition, it emits infrared rays, heating the walls of the room, especially those closest to it.

If the wall decoration is made of wood, then its constant overheating can lead to charring and fire.

To prevent this, special fire-retardant compounds are used, and for greater reliability, a protective screen is installed for the stove in the bathhouse. The most popular materials for its manufacture :

- Metal. Insulation of walls in a bathhouse from the stove is most often done using a metal screen. They are mainly frontal or lateral. Metal screens significantly reduce the temperature impact on the walls;

- Brick. Brick protective screens can both reduce radiation from the stove in the bathhouse and protect walls from prolonged exposure to high temperatures. Brick for sauna stoves has been used for a long time because it takes a long time to heat up, then gives off soft heat to the room, cooling down for a long time;

- Stainless steel sheets. This material is used to cover both the furnace and surrounding elements. If a stainless steel sheet is thoroughly polished, its mirror surface will reflect harmful infrared radiation.

Distinctive properties

When installing a spark arrester on the chimney of a bathhouse, you need to know what main features this device has:

- Installation of spark arresters is advisable only in bathhouses heated by solid fuel stoves. The view doesn't matter.

- A mesh is installed along the side surfaces of the device. The cell size is no more than five millimeters. With large opening areas, there is a possibility of hot particles leaking through the trap. It is also impractical to make them too small, as the mesh will quickly become dirty. The passage of smoke is obstructed, which can lead to the accumulation of caustic vapors inside the steam room.

- Installation of a spark arrestor is mandatory if there is a roof made of flammable materials.

- Installation of the device is required when the chimney is located in a straight direction. The condition applies to baths and saunas.

- Installed to protect the chimney from nesting birds and foreign debris.

- The catcher mesh undergoes frequent cleaning, since all particles that were not burned during the combustion process settle on it. The spark arrestor requires especially careful care when using resinous logs as fuel.

All of the listed distinctive properties of spark arresters characterize this device as one of the main elements responsible for fire safety.

Do it yourself or order a device?

Custom spark arresters are a fairly common option. If you trust the contractor, you can count on a good service life and complete serviceability. But this does not always happen, especially if the manufacturer decides to save on material.

If you decide to make your own spark arrester, it may take you longer. At the same time, you will be able to fully control the process, from the selection and acquisition of materials to design nuances.

Tips for choosing

When choosing, you should pay attention to the dimensions of the pipeline, the type of construction and the quality of the material. The diameter of the devices is usually 80-550 mm

The dimensions of the canopies depend on the dimensions of the tubular structures that are placed on the chimney.

The process of making a device with your own hands

You can make a simple spark arrestor with your own hands. Before you start creating a device for a chimney, you need to prepare all the necessary tools and materials:

- Stainless steel sheet with a thickness of 0.5 to 1 centimeter.

- Rigid mesh made of durable metal.

- Rivets are preferably made of steel.

- Scissors for cutting metal.

- Welding device.

- Angle grinder.

The sequence of operations is as follows:

- Measure the chimney opening.

- Make a preliminary sketch of the future spark arrester, taking into account all the components.

- Cut out mock-ups of the parts that make up the device from cardboard.

- Attach cardboard templates to a sheet of metal and carefully cut out analogs. In this case, dimensional accuracy must be observed.

- The mesh can be made from metal rods with a thickness of one to six millimeters. The possibility of using a finished product is acceptable.

- Connect all existing joints by welding. Clean them with a grinder.

- Secure all parts with strong rivets. The best option is made of steel.

- Install the spark arrester on the chimney pipe. Secure it carefully so that it does not blow away in a strong gust of wind.

- If desired, a deflector can be attached to the spark arrester.

- Using special scissors, cut out a visor from a metal sheet, which is subsequently bent at the desired angle. Secure all folds with rivets.

- Fasten the manufactured cone and the base of the device together. For fixation it is advisable to use steel rivets.

Racks

Another important detail is the racks, which allow you to connect all the components into one structure. They can be made from metal rods, or they can be made from sheet steel. The width of the stand is 15 mm. To increase strength, they are made in three layers. This must be taken into account when cutting a workpiece from steel.

The length of the workpiece will depend on the design features, but do not forget to provide for the possibility of fastening: reserve space for 1-2 rivets on each side of the rack.

When all the parts are made, begin assembling the spark absorber.

- Stands are attached vertically to the pipe or “glass”. For this operation you will need 1 or 2 rivets.

- A mesh cylinder is inserted between the posts. The cylinder should fit into the “glass” with emphasis on the rivet heads. It should be of such a height that when the structure is fully assembled it will rest against the cone of the “umbrella”.

- If the racks are mounted vertically, then greater strength can be ensured by attaching a metal mesh to them. For fastening, use 1 rivet for each rack.

- Install an “umbrella”. The mounting sections of the racks are bent so that they fit tightly onto the inside of the cone. Through holes are drilled, rivets are installed and finally fixed.

Installation is complete. The device can be mounted on a pipe and you no longer have to worry about sparks flying from the chimney.

Chimney with spark arrestor and protection plate

When assembling, if possible, you can use welding instead of rivets. Welding joints must be cleaned using a grinder. We recommend studying the drawings of a chimney weather vane for further independent production.

Spark arrestor as a decorative element

Creation of a deflector type spark arrester

Deflector designs are more effective compared to mesh models of spark arrestors. The Tsaga deflector with an apron that captures hot, incandescent particles is very popular. To create it you need:

- Cut out a cardboard template of the proposed design. You will need it when cutting metal.

- Measure the diametrical size of the chimney pipe.

- The inside of the spark arrester is a pipe with a diameter larger than the chimney. If the required workpiece is not available, it must be made from a stainless steel sheet.

- Roll out the upper edge of the sleeve being created, since its diametrical size should exceed the lower one.

- Make a casing shell from a piece of pipe. Using metal plates, attach it to the sleeve.

- At a six-centimeter distance below the casing, attach an apron whose diameter exceeds the casing. Otherwise, the spark arrester will be ineffective. In appearance, the part resembles a curved plate, which serves as the main component responsible for catching hot particles.

- It is necessary to make special holes in the apron through which accumulated water will subsequently drain.

- Attach the cover over the top casing side using rivets. For them, drill the required number of holes in the right places in advance.

- Attach the created spark arresting device to the pipe. It is imperative to check the strength of the structure so that it can withstand strong gusts of wind.

- Additional strength and durability can be provided by attaching several rolled stiffeners.

Lead and zinc white

The most important of them are lead and zinc white. In terms of chemical composition, lead white is a basic carbon dioxide salt. Pure white is called solid and is marked No. 0. White with an admixture of barite sulfate (heavy spar) is called graded and is marked No. 1, No. 2 and No. 3. The last two grades sometimes contain up to 40% heavy spar.

When painting with oil, the primer is usually filled with lead white and then covered with zinc.

In terms of its chemical composition, zinc white is zinc oxide. In trade, the highest grade of zinc white is called Schnweiss and is marked No. 0; zincweiss - No. 1.

From lower grades and a by-product of the production of zinc white, zinc gray paint is obtained.

Additional options for protecting your sauna from hot particles

In addition to installing a spark arrestor, there are several other options for protecting the bath:

- The simplest and most common method is to weld the chimney pipe tightly. A large number of holes are drilled in the upper part to allow smoke and gas to escape. This method is also suitable for a pipe installed on an existing one.

- The second option to protect the building and surrounding buildings from fire as a result of a falling spark is to weld a metal mesh at the end of the chimney pipe. The disadvantage of this design is rapid contamination, leading to weakening of traction. Frequent replacement with a new mesh will be required.

- To prevent return draft as a result of strong winds, a deflector is installed on the chimney pipe.

- When building a chimney, the structure is often made with bends. Hot particles ejected from the furnace are extinguished along the way, without reaching the top of the pipe. In addition to extinguishing hot particles, a chimney with elbows provides the steam room with additional heat.

All of the above methods have a simple design, so you can create them yourself, using improvised means, without spending a lot of money. All of them are effective and fully provide protection for the bathhouse roof and surrounding buildings from dangerous fires resulting from the ingress of a hot particle. You can install a spark arrester of any type in a short time, but the effect will be significant.

How to improve draft through a chimney

It is thanks to it that the required amount of oxygen is supplied to maintain the fire, and also the combustion products are removed outside in a high-quality and timely manner.

If there is smoke in the bathhouse and fuel combustion has weakened, these are clear signs of deteriorating traction.

If your chimney structure was installed by turnkey repairmen, it is important to check the draft before the first fire. You can do this as follows:

- You need to bring a sheet of paper to the stove and observe - if it deviates towards the stove, then everything is in order;

- You can light a match in front of the stove and immediately extinguish it. If the smoke goes into the chimney channel, then everything is in order with the draft.

The main reason for poor draft in most cases is the so-called cold plug - a section of cold air in the pipe. Solving this issue is quite simple with the help of an ordinary burning newspaper. In addition, insulating the chimney pipe in the attic space will help cope with this problem.

Other common causes of worsening cravings include:

- The pipe is not high enough. The fact is that with a short chimney the difference in pressure at the inlet and outlet is negligible. It is best to place the chimney pipe near the ridge; in this case, the part of the pipe located outside will be minimal (remember, the chimney pipe must be at least 50 cm above the ridge;

- The chimney cross-section is insufficient;

- Blockage is the most common and simple cause. It can be recognized by a sharp and severe deterioration in traction, and this problem is solved by cleaning it with a special brush;

- Very often, the direction of the wind affects the draft in the chimney. To avoid this, a protective fungus should be installed on top of the chimney.

Sparks from a sauna pipe: what to do

The spark arrester does its job as long as the sauna chimney is functioning properly. Violation of the smoke circulation rate leads to sparks flying from under the hood. The first step is to figure out where they come from. Sparks are small particles of fuel that have not had time to burn in the firebox. With normal draft, they have time to burn out in the stove, and some of them smolder inside the pipe on the way to the exit from the chimney.

As the smoke flow decreases, the fire in the firebox goes out. If the craving is higher than normal, the opposite effect occurs. The fuel flares up quickly and crumbles into particles, which do not all have time to burn. A strong draft of air flow picks up these particles along with the smoke and throws them out through the pipe into the street in the form of a bunch of sparks.

The problem of sparks escaping is inherent in a direct-flow pipe, which is the only drawback of this chimney design. The fire from the firebox immediately enters the vertical pipe. If the chimney channel of a bathhouse has elbows, bends, or horizontal sections, the smoke circulation weakens. Even with strong draft, sparks hit the pipe walls at turns, scatter into smaller parts and manage to burn out before they fly out. However, curved chimneys become clogged with soot faster. For a bathhouse with knees, a pipe is not the best option.

The problem is solved by reducing the smoke circulation rate of the direct-flow pipe. The draft is regulated by dampers, dampers, and the blower door. If positive results cannot be achieved, increase the residence time of smoke and sparks in the chimney by increasing the length of the chimney channel. After the draft is normalized, the spark arrester catches the rarely emitted sparks.

Reducing the smoke circulation below the norm leads to the contamination of the bath with carbon monoxide, which is deadly to humans.

The structure and principle of operation of the spark arrester

The spark arrester device of different models has distinctive design elements. The appearance varies. The common feature is the presence of a housing, a spark-extinguishing element made of steel mesh or sheet, as well as a cover that delays the emission of sparks.

All models of spark arresters work on the same principle:

- After the sauna stove is ignited, hot combustion products are formed inside the firebox, consisting of gas, smoke, air, and small particles of unburned fuel. The draft air flow directs them through the chimney of the bathhouse to the street.

- At the top of the pipe, hot air collides with the tip. The smoke escapes unhindered into the atmosphere, and particles of burning fuel strike the extinguishing element made of mesh or sheet metal, the housing, or the deflector cover.

- A burning spark hitting a metal element loses its heat capacity and quickly dies out.

The spark arrester most often traps large fuel particles. Small sparks sometimes slip through. If sparks fly strongly from the sauna pipe, you need to reduce the draft by closing the dampers. Another reason could be burnout of the spark-extinguishing mesh.

Spark arrestor models

Models of spark arresters differ in design, method of catching and extinguishing sparks, and auxiliary capabilities. Conventionally, the elements are divided into the following groups:

- Dynamic models deposit burning particles using gravity. From contact with a cold deflector and a mesh of heat-absorbing metal, the spark loses energy.

- Filtration models extinguish sparks and purify gases passing through the mesh partitions of the filter. Such a spark arrestor is rarely used for a bath. More often it is found on the exhaust pipe of a car, tractor, or combine.

- Liquid seals are a special type of spark arrestor. Combustion products pass through water, where 100% of sparks are extinguished and soot settles. Cold air without a burning smell comes out of the chimney outside.

How to properly heat a brick sauna stove with wood

It is recommended to heat the stove often and little by little. A rare and long fire does not do her any good. Therefore, it is best to burn a couple of full loads of firewood in one firebox.

Firewood should burn with full fire, and new ones can be added only after the previous stack has burned out by more than half.

The blower valve should be kept in the normal open position. It is not recommended to add firewood one log at a time. Otherwise, the chimney can quickly become covered with soot, and draft problems will arise.

One of the important questions is how long to heat the stove so that it does not overheat. Depending on the type of fuel, the stove should be heated for 1.5-2 hours in the morning and evening. There is no need to allow it to overheat. The temperature of its walls should not exceed 70-80 °C. The hotter the oven gets, the more heat will escape outside.

Signs of an overheated oven include:

- Due to the high heating temperature, it is impossible to touch the side surface of the stove with your palm. Typically, the temperature of external stones, with the exception of stones around the firebox, does not exceed 85 ° C;

- hot cast iron parts. In this case, their temperature will exceed 600°C. To avoid this, you need to clean out the ash. Burning can be accelerated by choosing the right firewood.

To heat up the stove faster, it is recommended to increase the burning speed of the wood by choosing the right size. Obviously, the burning rate is affected not by the volume, but by the surface area of the log being burned. Thin logs burn faster than thick ones, without having time to warm up the stove.

How to make a spark arrestor for a pipe in a bathhouse

It is easier to bend a spark arrestor for a bathhouse in the form of a casing from sheet metal and mesh. The design has no moving elements and is simply put on the pipe. A diagram with dimensions will help you cut out the fragments correctly.

Selection of model and materials

When choosing a model of a cap for the chimney pipe of a bathhouse, you should once again carefully think about its effectiveness. A conventional casing is simple, but it only catches sparks and is not able to improve traction. It is better to equip the bath pipe with a deflector. Which option to choose is up to the owner of the bathhouse to decide.

Before production begins, the material is purchased. For any spark arrestor you will need sheet steel. Galvanized is suitable, but stainless steel is better. You also need a mesh with small cells.

Tools for assembling a steel structure you will need:

- metal scissors;

- hammer;

- electric drill;

- chisel;

- pliers;

- rivet gun.

In order not to make mistakes with the calculations, a prototype is first made from paper - an exact copy of the spark arrester. You will need the following materials and tools:

- thick elastic cardboard;

- office stapler;

- paper scissors;

- pencil;

- ruler;

- compass.

If the choice fell on a head with a deflector, in addition to the outer thickness of the bath chimney, measure the diameter of the pipe from the inside. They put their dimensions on the sheet with the drawing.

They think in advance about how to fix the steel elements of the spark arrestor. The best option is rivets. In the absence of a riveter, the fragments are connected by welding. The ability to weld thin metal is important here. If you burn a hole in the housing, sparks will burst out.

The effectiveness and long service life of a spark arrestor depends on the quality of the material. Stainless steel sheets and mesh are used with a thickness of about 1 mm. Thick metal is difficult to work with.

The mesh can be perforated sheet steel. In any case, material with holes of 4-5 mm is suitable. Sparks will freely escape through large cells. Small cells will clog faster, and in addition, draft through the pipe will worsen.

Making a spark arrester prototype

After removing the internal and external diameters of the bath pipe, we begin making a paper prototype. Elements of the drawing are transferred to cardboard. At the joining points, leave an allowance of about 2 cm. The width of the seam should be enough for the hole for the rivet.

The lined fragments of the head are cut out of cardboard. It must be elastic, otherwise creases will appear when bent. Temporarily the parts are connected with a stationery stapler. The finished prototype of the spark arrester should be life-size and put on the bathhouse pipe.

If the template is satisfactory in all respects, it is disassembled. The paper clips are carefully unbent at the joints, removed, the fragments of the head are straightened, placed on stainless steel, and outlined with a marker. A pencil will not work for marking, as it is hard to see on the steel.

Assembling the product yourself

After transferring individual parts of the cardboard spark arrestor prototype, the fragments are cut out of metal. Usually this is an umbrella, strips of different sizes, a rectangle of mesh for a cylinder. The spark arrestor body, which will be attached to the chimney, is easier to cut from the finished pipe. However, it is difficult to find a suitable stainless steel blank with the required diameter. The pipe is bent independently from a rectangular sheet of steel, the joints are connected with rivets.

Further work is based on assembling all elements into a single structure. If, instead of a riveter, the joining is performed by welding, the width of the allowance is made less than 2 cm. Welded seams are cultivated by grinding with a grinder.

The sequence and specifics of assembling a homemade spark arrestor for a bathhouse depends on the model. The usual model of the casing is assembled without gaps. Sparks flying out of the bathhouse pipe must hit obstacles on their way. In the second option, a deflector is first made. A skirt is formed from a stainless steel sheet. The detail resembles a saucer with curved edges. Holes are drilled on the lower part of the upper glass of the spark arrestor and the skirt is secured with rivets.

If making a spark arrestor turns out to be difficult, there is an option to improve the bathhouse pipe. The method depends on the chimney material. The metal pipe of the bathhouse is closed from above with a plug. The upper part, about 20 cm wide, is perforated with a drill with a diameter of 5 mm. If the bathhouse pipe is brick, it is simply covered with a mesh on top. The spark arrester turns out to be primitive, but it will stop some of the flying sparks.

Installing and securing the device

When the spark arrester is ready, all that remains is to climb onto the roof of the bathhouse and install it. The head is placed on the pipe. To prevent it from being blown away by the wind, fix it. The lower part of the head is pressed to the round pipe of the bath with a clamp. The method is reliable and convenient. It is always easy to release the clamp to remove the spark arrestor for cleaning.

To fix it to a rectangular pipe, use a homemade rim with brackets. Another fixation option involves the use of rivets. The head is held securely on the pipe. However, if maintenance is necessary, the rivets will have to be cut off with a grinder, which is extremely inconvenient. The last option is to weld a spark arrestor to a metal sauna pipe. Bad idea. For maintenance, you will have to cut the head off the pipe with a grinder each time.

More information about making a deflector for a bath pipe can be found in the video:

Maintenance of spark arresting systems

Like any simple mechanism, the spark arrester requires routine maintenance, which consists of the following:

- Inspection of the integrity of the entire structure. At least once a year.

- Cleaning the main components and assemblies from soot and other deposits. Twice a year.

- Unscheduled inspection and cleaning. For example, in areas with an abundance of common poplar, the fluff of this tree is able to clog the spark arrester mesh to a dense fiber state. In addition to deteriorating traction, such a nozzle is also a fire hazard. Such work must be carried out as an objective need arises and is not regulated by specific deadlines.

Systems made of ferrous metal under conditions of different temperature loads and condensation formation have a tendency to increased corrosion, which predetermines closer service attention to them than in relation to systems made of stainless steel. https://www.youtube.com/embed/mcL0zx_1jLg

https://youtube.com/watch?v=mcL0zx_1jLg

Cementin is a cheaper product

The high cost of painting drying oil prompted us to find means to replace it with a cheaper product.

After numerous experiments based on studying the properties of oils, as well as drugs offered abroad, it was possible to prepare a composition called cementin, the merits of which have been fully determined over the past decades.

Cementin is a liquid with the consistency of ordinary painting varnish, light fawn in color, which makes it convenient for priming under different colors of oil and adhesive paints on wood, brick, cement, plaster, and also as an independent paint for inexpensive household paints. It is especially recommended for priming fresh (new) wood, such as facades, roofs, fences and other wooden structures.

For cheap work, a single coat of oil paint is usually sufficient to obtain a smooth and shiny surface.

« Previous entry

What oils and drying oils are suitable for wood?

Most paints are diluted in oil, which can be of mineral, vegetable or animal origin. Mineral oils include petroleum, rock wax, etc.

In painting, oil and drying oil for wood are used exclusively of plant origin, extracted from the seeds of various plants and mainly flaxseed. You can find out which ones are suitable further in the article.

Vegetable oils are very diverse in their composition and are commercially available in solid (Japanese wax), thick (coconut oil) and liquid (linseed oil).

All vegetable oils when left in air for a long time oxidize, thicken and turn bitter.

Liquid and lubricating oils have the property of being viscous, harden and are able to form a beautiful elastic, rubber-like mass.

The second: wood, olive, almond, rapeseed, rapeseed, mustard, beech, castor, etc.

Flaxseed oil is extracted by pressing flaxseeds. Cold pressing produces the best type of oil with a pleasant smell and light yellow color, which makes it possible to eat it.

In oil mills, however, cold pressing is considered unprofitable due to the relatively low yield of oil and is replaced by hot pressing, and the resulting product will be darker in color with a strong odor. This unrefined oil is used almost exclusively for the preparation of drying oil (boiled oil).

As for the quality of the oil, it depends on the method of preparation and the quality of the seed from which it is prepared.

Since linseed oil is a rather valuable product, it is often mixed with various impurities that spoil its quality. The most common contaminant found in flaxseed oil is mineral oil. Such drying oil usually dries poorly and becomes tacky. If you look at it through the light, you will get a bluish tint, which, however, is not always noticeable, because recently they have begun to use well-refined mineral oil (colorless) as a mixture.

Of all vegetable oils, linseed oil is the most widely used in painting, representing the best product for preparing linseed oil.

Poppy oil is obtained from poppy seeds by pressing at ordinary temperatures, or by heating. In the first case, the oil will have a light color, a pleasant taste, and therefore such oil is usually used as food. In the second, the dark color and bitter taste due to the abundance of impurities make such oil suitable only for technical use, such as, for example, in the preparation of expensive dyes. This oil is rarely used for ordinary painting work.

Sunflower oil is extracted from sunflower seeds, which grow almost everywhere in Russia and are especially sown in Little Russia, the southern provinces and the Caucasus. The color of the oil is golden yellow, when fresh it has a pleasant taste and smell and is readily consumed. Sunflower oil is mainly used for preparing light drying oils and for diluting white and light paints. It dries much slower than linen. If prepared improperly, such drying oil becomes sticky and acquires a red tint.