Material for production

You can consider the following options for yourself:

- Brickwork. It has been used for these purposes for a long time and is rightfully considered traditional. For many, this is a priority material, despite the complexity of execution. It is believed that laying out a stove yourself is much better than getting a ready-made one. This preference is due to the special warmth and atmosphere that lasts much longer. But do not forget that in this case a foundation is first laid, which is located separately from the foundation part of the bathhouse. Also, the dimensions of the structure and the furnace may not match. In this case, it is worth turning to projects with small-sized masonry. It is necessary to have certain experience in order not to cause harm to the health or life of people. Therefore, if you have doubts, it is better to turn to experienced professionals;

- Metal stoves are quite popular due to their compactness and ease of installation. In addition, its manufacture will be much easier, especially if you have experience in electric welding. You can use materials that seem intended for recycling. For example, you can make a sauna stove from a pipe, old car rims, unusable gas cylinders, old barrels, etc. For baths, steel stoves are usually used. The use of a cast iron stove for a bath is not always considered appropriate. Its positive qualities are the ability to maintain temperature for a longer time and good heat capacity. However, it is unstable to sudden changes in temperature and is quite fragile. Therefore, splashing cold water on hot metal is very risky, because the cast iron can crack. A steel stove cools down quite quickly after firing. This is its main drawback. This mainly occurs because the sheet thickness is insufficient;

- The combination of brick and metal is considered the most appropriate. In this case, a massive foundation is not needed, nor is sealing the joints during laying. The metal body is lined with brick. Building walls is quite simple. Such cladding can protect against a hot metal surface and serves as a good decoration for the bath interior, hiding the not very aesthetic appearance of the steel body.

What does it consist of?

Before you begin installation, you need to understand the purpose of all the elements so as not to make mistakes.

Foundation

Concrete base for the stove

A brick heater for a bathhouse needs a solid and strong foundation due to its mass.

It is laid out as follows:

- We dig a hole half a meter deep. Its remaining parameters should be 10 cm larger than those of the stove itself.

- Fill the gravel with a layer of twenty centimeters and compact it thoroughly.

- Pour a mushy thin layer of cement on top.

- We install formwork from boards.

- Inside, we mount reinforced rods vertically and horizontally and tie them together with soft wire.

- Mix a solution of gravel, sand and cement in proportions 5:2.5:1.

- Fill in the solution.

- After complete hardening, if necessary, you can raise the base to the level of the building’s foundation.

Advice: do not connect the stove foundation with the common one. They have different structures and can damage each other during the shrinkage process.

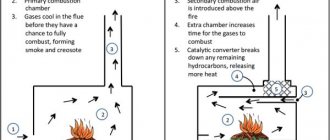

Firebox

Combustion chamber

This is a special compartment in which combustible materials are completely burned, producing heat. It is installed in the very center of the structure under the boiler. For greater productivity, a reed grille is required, located at the same level as the door.

Tip: the walls of the firebox must be made at an angle so that all fuel particles roll towards the grate.

Blower door

Patterned door

This seemingly insignificant and small part performs a very important function: it regulates the air supply to the combustion chamber through the ash pan.

- Excess air impairs the combustion process.

- The deficiency makes it uneven.

And only thanks to this damper it is possible to set the optimal inflow, which contributes to the full operation of the furnace.

Gate valve

Cast iron product

The price of this element is minimal compared to other stove components, but your health depends on its presence. Pushing back the chimney pipe valve of a sauna stove in time will save you from carbon monoxide poisoning.

Ash pan

Ash chamber

This part of the furnace is located under the grate with ash and serves to pour out combustion products of fuel materials and supply air to the firebox. Without an ash pan, the air flow simply would not have the opportunity to break through the fuel layer.

Stones

Ideal stones for a bath

The stones are placed on a grate under the chimney pipe for a sauna stove, which is made in two ways:

- Made from rods with a diameter of at least four centimeters.

- Made of bricks with gaps between them for the passage of smoke.

The instructions for calculating the amount of these elements are as follows: for one cubic meter you need about forty kilograms of stone.

Tip: It is recommended to choose round-shaped samples with a flat surface so that smoke and water can pass freely between them.

Energy

Basically, in practice, a wood-burning sauna stove is widely used. It is well-dried firewood that helps create a healthy atmosphere in the steam room, for which such a structure is being built.

There are other different models. For example, quite often preference is given to an electric sauna stove or its gas analogue.

For some craftsmen, it is more convenient to make a stove that operates using liquid fuel (diesel). In this case, the combustion part that supplies diesel fuel is moved outside the bathhouse to the street.

However, wood-burning sauna stoves are rightfully considered the most popular and convenient.

Optimal oven dimensions

For anyone who installs a stove on their own, the most important parameter is its size for a specific room, namely the length of the sauna stove.

In order to determine it, it is necessary to carry out special calculations based on the following parameters:

- The ratio of the stove to the total area of the room to be heated. This is one in fifty (seventy);

- The combustion hole should be one in two or two in three deep;

- The combustion volume should be related to the chimney section as one to ten.

Metal models used in Russian baths can be from four hundred to six hundred and eighty centimeters long.

For brickwork, the usual length is either 89 by 102cm or 102 by 129cm.

Performance characteristics, pros and cons

The product has 3 structural parts (from bottom to top):

- Blower, chamber for loading fuel (firewood, wood briquettes).

- Container for laying out stones with a lid. The lid has a hole for steam to escape.

- Tank for heating water.

Among the advantages of metal devices:

- fire safety;

- long service life;

- compact dimensions;

- light weight compared to a heater;

- no carbon monoxide is produced.

Among the disadvantages, users highlight rapid cooling, so the stove will have to be constantly kept burning.

To solve this problem, manufacturers have created two types of stoves:

Hot. Suitable for occasional use. The mechanism quickly heats up to 100 degrees

The room warms up at an accelerated rate. When choosing, it is important to pay attention to the thickness, quality of the metal and seams. Thin sheet steel at this heating temperature will begin to deform.

Cold Used in buildings where it is necessary to provide constant heating

The metal heats up gradually and over a long period of time, so the risk of burns is minimal. The temperature in the oven is adjustable. The maximum mark is 50 degrees. There are several chambers for combustion of fuel. Thickened steel sheets should be used as raw materials for manufacturing, and the firebox should be made of cast iron.

To correctly calculate the consumption of stones, take into account the area of the steam room and the presence of thermal insulation. Average consumption is 20–40 kg per 1 cubic meter

m of premises. The more stones there are, the easier it is to generate steam.

As for the volume of the firebox, it is made about half as large as a similar one in a heater.

Water tank

The type of sauna stove with a water tank can be:

- electrical;

- gas;

- wood-burning

The purpose of the water tank is always the same - to allow you to swim after the bath procedure.

In a sauna with a brick stove, you can use a wide variety of fuels. This ensures ideal heating of the entire room. A well-constructed design largely eliminates the presence of heavy vapors in the steam room.

Therefore, the wish “enjoy your steam” will correspond to reality. This type of design works exclusively with flow-through heaters, so the opportunity to “add steam” will only present itself when the fuel has completely burned.

When the stove in the bathhouse is used no more than once a week, it should be warmed up after drying. What is a purlin firebox used for? If this is not done, cracks may appear from the inside.

Cast iron stoves are not manufactured independently. But you can supplement them with the necessary element - a water tank. It is usually leaned not against the wall of the firebox, but against the wall of the stove itself.

Steel stoves are quite simply made by welding. To do this, you can invite an experienced welder or do the manufacturing yourself.

The main thing is that the material for the stove is of appropriate quality. For example, iron for boilers is considered the best. Its thickness varies from five to ten millimeters.

Strong heating of metal elements can be “softened” by brick shielding. In this case, only the heater should go into the steam room. This arrangement of the stove will help create more comfortable conditions for taking a “bath”.

The only problem is this. In such cases, the steam room will not be able to receive all the heat entirely. Some of it will be lost on the street.

Design options

Regardless of the format, sauna stoves are made from pipes 530 mm or larger, but the maximum recommended cross-section is 600 mm. This diameter is considered optimal for high-quality heating of the steam room without excessive fuel consumption.

In addition to this, other materials will be required:

- sheet steel for the manufacture of end walls, lintels;

- chimney pipe with a diameter of 100-150 mm;

- ready-made or cut-out doors for the firebox and ash pan;

- hinges for doors;

- stainless steel tank;

- reinforcement bars for grates or finished cast iron grates;

- steel corners and strips.

The thickness of the sheets should be approximately the same as the thickness of the pipe walls Source prom.st

A specific list of required materials and their quantities is determined from the drawing of the selected or independently invented design. For beginners and people far from this area, it is better to use ready-made, proven diagrams so that the stove made from a pipe is guaranteed to be reliable, safe and efficient, with an optimal volumetric ratio of the heater and firebox.