When building a bathhouse, you can use any material, but you absolutely cannot do without a stove. There are several stove options, but not a single modern electric model can replace a traditional heater.

DIY sauna heater

The stove-heater can be of two types:

- metal;

- brick.

Everyone must choose which one is better on their own, since there is no clear answer to this question. The only important thing is that the design, made by yourself, will fully comply with the requirements and wishes of the owner.

Brick stoves for saunas

Before considering the pros and cons of each option, let’s find out what a sauna stove should be like.

Technical requirements

A stove-heater is the main element of a Russian bath.

A heater for a bath performs several functions. It warms up the steam room, maintains the room temperature and ensures that the correct steam is produced. In order for a furnace to perform these tasks, its design and installation method must satisfy a number of stringent requirements.

- Maximum efficiency – the heater does not work for long. Therefore, it is more important to warm up the room as quickly as possible than to maintain the temperature for a long time.

- In the furnace, the ash collection section should be located at a distance from the floor of at least 18 cm.

- The furnace body can also be metal. But in this case, there is a protective screen made of fire-resistant materials around it. It is more profitable to immediately build a brick oven.

- A brick casing does not replace stones for generating steam. It is important not just to evaporate the water, but to first spray it into very small particles. This requires flat stones, and with a special surface.

- Install the sauna stove at a distance of 55 cm from the wall. If the body is protected by a stone box, the distance is reduced. In addition, it is allowed to install a wood-burning stove built between the steam room and the dressing room. In this design, the doors of the firebox and ash pan are located on the side of the dressing room, which allows it to be heated from the outside.

- The steam room is finished only with wood, and this material is flammable. To prevent fire, the floor around the heater is protected with asbestos or mineralite sheets. The wall is also protected in the same way.

The stove can be combined with a water heating tank.

Types of heaters

Heater stoves are precisely designed to produce steam. If there are people who think that a heater is just a stone stove, but this is not entirely true.

The name of the heater comes from the design of this stove. Essentially, a sauna heater is a container filled with stones. When the oven operates, they heat up, and steam is generated from the water that gets on them.

Usually, like all stoves, a sauna heater is made of brick. But, in principle, a sauna heater can also be made of metal. The advantage of ready-made metal structures is the speed of their installation. You just need to choose and buy a stove, and then install it in the required location of the bath.

Another important factor why many people prefer a metal heater is its relatively small dimensions and the absence of the need to build a foundation for the stove.

Types of sauna stoves

Types of stoves for saunas

Heaters in a wooden sauna are classified according to a variety of criteria. For example, there are models of constant and periodic combustion. The first ones produce rather hard steam, since here the stones, even on a flat surface, do not heat up above +350 C. The intermittent combustion model only heats the steam room. Here the stones are heated not only by heating, but also by the passage of hot gas through the grate. At the base of the stone slide, the temperature can reach 1100 C, so the steam here is soft - finely dispersed and does not make breathing difficult.

By material

The body of the device is made of two main materials: metal alloy and brick.

Metal heater

Metal alloy – special heat-resistant steels and cast iron. Such designs are attractive due to their low weight, compactness with very high efficiency, and rapid heating - a medium-sized steam room is heated in 1 hour. In addition, iron stoves can be beautifully and unusually designed.

However, such a project has a lot of disadvantages. The metal quickly gives off heat, but does not retain it: the stove cools instantly, and the temperature in the room jumps sharply. The case gets very hot, which poses a danger to the wood-trimmed room. Most often, the heater has to be surrounded by a protective screen and its design becomes unimportant.

A self-made iron stove according to a ready-made drawing is the most budget option. But its effectiveness is low.

Heater made of heat-resistant bricks

Heater made of heat-resistant bricks warms up the room more slowly - up to 6 hours, but maintains the temperature in the steam room for at least 2 hours after the end of the fire. The stone heats up less, so the risk of fire is much lower. A brick oven can heat a room with an area of more than 30 m². Its durability is much higher than its iron counterpart.

The disadvantages include the large weight: you will have to build your own foundation for the stove. Its installation is complex, requires experience, and it is more difficult to care for. And the size of the heater is quite considerable.

If a metal stove is sealed with a brick barrier, the overall dimensions are comparable to a brick heater.

By fuel type

Gas stove-heater

The stove in the steam room is classified according to the type of fuel:

- wood - the most popular, since the cost of firewood is the lowest;

- coal - less common, since coal gives a higher temperature and it turns out to be much more difficult to control the heating of the room;

- gas - this can be installed only with special permission;

- electric – more often found in home saunas and is attractive due to its high fire safety, but is expensive to maintain.

The safest type of steam room is a wood-burning stove.

Selection principles

The stove is mounted between the steam room and the dressing room.

The criteria are as follows:

- power - determined by the size of the steam room and the number of users;

- material – today chromium steel is considered the best option, as it reduces the burning of oxygen;

- type of firebox - elongated, that is, the stove is mounted between the steam room and the dressing room, and ordinary closed;

- type of heater - plane, mesh next to the body, screen around the body and part of the chimney;

- the duration of operation with one filling is determined by the design features of the furnace;

- warming up speed - a “hot” stove warms up rooms in a couple of hours, but quickly cools down, a “cold” stove maintains the temperature.

Other criteria are also important, such as the presence of a water heater, protective devices that prevent carbon monoxide from entering the room, operating modes, design and ease of kindling.

Requirements for heater stoves

Sometimes, such an important device as a sauna heater is subject to increased and even contradictory requirements. Everyone wants a stone stove to take up as little space as possible in the bathhouse. Another wish is a low price, quick warm-up and economical fuel consumption.

First of all, you need to decide what fuel the stone sauna stove will use. An electric or wood-burning oven can be used. Wood-burning stoves for heating a house or cottage are not the most rational choice, but wood-burning stoves for a sauna are an excellent choice. First of all, wood stoves are an economical option. Secondly, a wood stove not only produces heat, but creates a specific aroma in the steam room.

But an electric sauna stove, although quite convenient, is not particularly economical. Therefore, an electric stove is installed if it is not possible to install a wood stove.

However, an electric stove also has advantages, since you will not need to worry about having a supply of firewood. In addition, the electric heater is compact and suitable for a small sauna. The most important advantage is that an electric stove does not require a chimney.

Metal heaters: advantages and disadvantages

What's better? Traditional brick heater or metal stove? It is impossible to answer this question unequivocally; you will need to look for the best option for a specific bathhouse built on the backyard of a house or cottage. But we will give you some tips to help you choose one or another oven option.

First of all, we will consider all the advantages and disadvantages of metal stoves.

Main advantages:

- Compact sizes.

- Quite light weight. As a rule, the weight of such stoves starts from 50 kg.

- Fast warm-up. You can use the heater after 1 hour.

- Multifunctionality.

- A wealth of varied designs

The disadvantages include:

- Uneven heat distribution.

- Fire hazard.

- Fast cooling.

- Stoves of this type are suitable for small rooms, no more than 25 m³, so if you plan to make a spacious bathhouse with a swimming pool on the site near your house or dacha, then it is better to choose a different stove option.

Brick heater

It is worth noting that many connoisseurs of the Russian bath believe that a stone stove for a bath is the best option. What are the advantages of a brick stove over its metal counterparts?

Main advantages:

- Soft and uniform heating of the steam room.

- Long-term heat retention.

- Ideal fire safety.

- Possibility of heating a large area, more than 25 m³.

- Easy to use.

- High reliability and durability.

Like any other, a brick stove is not without its drawbacks:

- Heavy weight.

- Requires installation of a foundation.

- Occupies a large area.

- Long warm-up, from 3 to 5 hours.

- Inconvenient to clean after use.

If you decide to install a brick heater in a bathhouse on the garden plot of your house or cottage, we will help you build it as profitable and convenient as possible.

Of course, a structure of this type requires the availability of appropriate construction skills. But if the master took part in the construction of a house or cottage, then a heater for a bathhouse can easily be made with his own hands.

Popular models and prices

Cast iron stoves are rarely installed due to their heavy weight.

The choice of stoves on the market is huge. However, for a bathhouse it is preferable to purchase models from domestic manufacturers, since their products are adapted to existing conditions.

- Harvia produces both regular floor-standing models, as well as wall-mounted and corner models. The main material is high-strength steel. The body is coated with special fire-resistant paint. Models cost from 14 thousand rubles.

- Helo - most models are made of stainless steel, which guarantees a long service life; a characteristic feature is a heat-resistant glass insert that allows you to observe the flame. The cost of electric heaters starts from 40 thousand rubles.

- "Termofor" - produces heaters for the Russian steam room mode. Offers a huge selection of models of different power and design. Heat-resistant chrome-plated steel is used for the firebox. Models cost from 23 to 45 thousand rubles.

- "Hephaestus" - offers cast iron models for baths with the highest efficiency - up to 90%. The stoves are very economical and provide light steam. Minimum cost from 50 thousand rubles.

Cast iron stoves are installed much less frequently. Despite the fact that this design retains heat for a long time, it is very heavy.

Advantages and disadvantages

The advantages of a brick sauna stove include:

- the ability to accumulate and release heat for a long time;

- uniform and stable heating of the room;

- attractive and neat appearance

- comfort and ease of use.

The disadvantages of a brick kiln are:

- stationary installation option, inability to move the oven even a few centimeters;

- large weight and size, the need to create your own base (foundation);

- heating the room takes longer than when using metal stoves;

- If used incorrectly, there is a risk of carbon monoxide poisoning.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

The advantages and disadvantages of brick kilns have been known for a long time. Users prefer brick baths for uniform and stable heating, safety and ease of use.

If you accidentally touch it, it is more difficult to get a severe burn on a brick oven than when you touch it on the hot body of a metal structure. In addition, the cooling of a brick structure takes much longer - the bathhouse maintains operating mode for several hours.

Foundation for a brick stove-heater

Foundation for a brick stove-heater

For a brick or cast iron stove weighing more than 700 kg, you need to make your own foundation. The foundation is selected based on the weight of the structure and the nature of the soil.

Rubble concrete foundation

This option is built for a small heater. You can use not only rubble stone, but also brick. The step-by-step instructions are simple.

- They dig a pit, the dimensions of which around the perimeter are 15–20 cm larger than the dimensions of the stove.

- A sand cushion is placed on the bottom and waterproofed. Formwork boards are placed on the walls.

- Lays out layers of rubble stone and fills the voids with crushed stone. The thickness of the layer does not exceed 15–20 cm. Fill the rubble with a thin layer of cement.

- After the solution has hardened, a second layer of stone is laid out. The cement mortar is applied again. The operation is repeated until the pit is filled.

The fragment is not brought to the edge of the formwork by 7–8 mm. Cover it on top with roofing felt and fill it with bitumen.

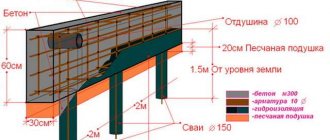

Foundation slab on piles

Foundation slab on piles

The pile foundation is installed on bulk and marshy soils. Steel or concrete rods are used for piles.

Step by step guide:

- Holes for piles are drilled in the corners of the site. A layer of sand and crushed stone 15–20 cm thick is compacted onto the bottom.

- Roll up a roll of roofing felt and insert it into the recess.

- Piles are driven into the ground.

- Formwork is constructed, reinforced and poured with concrete. The thickness of the slab is at least 20 cm.

Using the same technology, foundations are built on columnar foundations.

Monolithic foundation

Such a solid foundation is installed for the bodies of heavy furnaces. Making a foundation is not difficult, but more materials will be required.

- Dig a pit according to the dimensions of the furnace plus 15 cm around the perimeter. Fill in 15 cm of sand and compact the bottom.

- The pit is covered with expanded clay and covered with film or roofing felt.

- They make formwork. Reinforcement made of rods 10 mm thick, connected with steel wire, is placed inside.

- Fill the pit with concrete and compact it with a vibrator.

The concrete takes about 3 weeks to dry. At this time, the surface of the foundation must be moistened with water and covered with film.

Foundation arrangement

In order for the stove to last as long as possible, you need to make a reliable foundation for it. If you plan to build a structure weighing more than 700 kg, then the foundation for the bathhouse and the stove should be different, and they should be located at a distance. Also, the foundation for a heater for a brick bath needs to be built at a depth that is below the freezing level of the soil.

We follow the step-by-step production of the foundation

The algorithm for producing a foundation for a heater is as follows:

- A pit is dug up to 700 mm in depth, and around the perimeter it should be about a third larger so that formwork can be installed and the gap filled with sand.

- A sand cushion 150 mm thick is made at the bottom, then the sand is filled with water to compact it. As moisture is absorbed, it will settle, and you will need to top it up so that the required thickness remains the same.

- After the water is completely absorbed, a stone layer or a layer of broken brick is laid on top of the sand, then compacted. If there are gaps between the stones, they are tightly filled with sand and water. This layer should be up to 250 mm.

- If the sand does not settle, you can lay out a layer of crushed stone and then compact it.

- Formwork is made from boards 40 mm thick, it is firmly fixed in the pit and a reinforcement frame is installed. There should be a distance of 50 mm between it and the formwork walls.

- The next layer is a wooden beam or steel reinforcement that needs to be compacted. The top layer is brought to the edges of the formwork, and the screed must be level. The poured liquid concrete is left for several days.

- When the layer hardens, the formwork is removed, and the concrete is covered on top with 2 layers of fused tar and the void between the walls is filled with concrete-based soil and sand.

In this video you will learn how to install a sauna stove:

Upon completion, such an area should be covered with polyethylene and left for a week. Only after this can bricks be laid.

Materials and tools

Fireclay refractory brick

To build a brick heater you will need:

- refractory brick - preferably fireclay, for laying out the firebox;

- facing for the body;

- steel chimney of the required diameter;

- doors for the firebox and ash pan, cast iron grate;

- clay mortar for masonry;

- trowel, hammer;

- level, slope, tape measure.

You will also need waterproofing material, mesh or steel sheet under the stones.

Precautionary measures

In order not to endanger the life and health of people during operation, you must follow all recommended fire safety measures. When installing a stove in a bathhouse, you need to remember the following nuances:

- the foundation for the furnace must be as strong and stable as possible;

- it is imperative to equip the chimney in such a way that those surfaces that come into contact with it do not overheat;

- When placing the stove in a bathhouse, care must be taken to ensure that all surfaces are reliably protected from overheating during lighting.

An important condition is the correct organization of insulation.

Brickwork around the sauna stove is a must. But simply using masonry is not enough. It is also necessary to purchase tin.

DIY making

Arrangement of the heater stove

Laying a heater stove in a bathhouse differs little from the construction of a regular one. It is important to carefully follow the order and act according to the developed scheme.

- The foundation is waterproofed: 2 sheets of roofing material are laid, overlapping by 10 cm. Bitumen is not needed.

- The first row is always solid. The bricks are fixed with masonry mortar.

- On the 2nd and 3rd rows, an ash tray and a channel for air exchange are laid.

- From 4 to 6, the internal walls of the firebox are laid out from fireclay bricks, grates are installed and doors are mounted. For sashes, hinges are placed in the masonry.

- At 8 and 9, supports for the mesh heater are installed. For this purpose, sections of profiles or T-beams are used.

- From 13 to 15, inspection holes and steam outlet holes are formed.

- During laying, each odd row is checked for level to ensure horizontal alignment. Every 2-3 rows, wire is placed in the seams to strengthen the structure.

It is recommended to lay the brick out dry and only then lay it on the mortar.

All fittings are installed simultaneously with the masonry. It is recommended to use asbestos cord for winding the doors.

Water container

Water tank for the chimney

There are 2 water heater options in the bathhouse.

- Tank on the chimney - since the steel pipe will heat up to +500 C. The water in the tank also heats up very quickly. In this case, heat is not lost from the escaping heated gases, and the chimney itself functions longer, as it transfers excess heat to the water.

- Wall-mounted – installed on the wall inside the steam room. The tank is heated by the heater body, and the water is transferred through pipes to the washing area. Less economical model.

It is not advisable to install a hanging tank in a sauna, since this will allow water vapor to enter the room.

Characteristic features of brick products

A brick structure for a bathhouse is considered a good solution. It has a number of undoubted advantages. Among them:

- the generated heat is retained for a long time;

- fire safety is ensured;

- the sauna space is heated evenly;

- it is possible to warm up a bath with a large area;

- the stove is easy to use;

- combustion products and stones do not come into contact with each other.

In this video you will learn how to make a stove-heater:

But a heater for a brick sauna also has its drawbacks: it needs to be heated in advance, and difficulties may arise in arranging the foundation. In addition, it is important to choose the right place to place it.

Possible mistakes

It is recommended to choose basalt stone for the heater.

The heater in the bathhouse will function for a long time and correctly if you follow certain recommendations when arranging it.

- For laying the body, it is better to use red clay bricks. Only fireclay is suitable for the firebox; replacement is not allowed.

- It is important to choose the correct consistency of clay mortar for masonry. If it is too dry and liquid, the masonry will crumble; if it is too greasy, the joints will be loose.

- Not every stone is suitable for a heater. Choose basalt, soapstone, and andesite.

- The stones are selected to be relatively flat in shape and placed in a vertical position. When placed horizontally, heat is distributed unevenly.

Test ignition is carried out after the masonry has completely dried, it lasts no more than 5 minutes. For 3 days, the procedure is repeated several times a day. Only after this do they begin to fully heat the steam room.

Stage one. Preparing the container

First, we determine the dimensions of the container that will be used to heat the water. To do this, you need to find out what the maximum number of people will take a steam bath at the same time. And the calculation should be as follows: per person there should be about 8-10 liters of heated water.

Note! It is preferable to use an open type container for this.

This involves slight evaporation of the liquid, but we get several advantages:

- freedom of access;

- the ability to remove residual water in winter and maintain the internal surface;

- In addition, we will be able to clean the inside of the container from scale and dry it.

Such a boiler can be purchased at a specialized store, or you can make it yourself. Well, let's start building!

Step-by-step description of the work

It is easier to complete any work if it has been previously divided into stages.

But in the case of laying out the oven, this is a necessity, since the sequence plays an important role and cannot be violated.

- Having laid out the first row, you need to check the vertical and make an ash pan.

- The blower should be fixed at the level of the third row.

- At the level of the 5th row, you need to install steel corners on which the grate will be fixed.

- Now you can start laying the firebox.

- Having expanded its area, you need to make holes that are necessary for secondary air supply.

- After laying the outer brick, the firebox doors must be completely closed.

- We install a partition for the chimney and mount the tank, after which we close the firebox.

- All that remains is to lay out the compartment for the stones and the chimney.

Remember that after finishing the work you must wait until the oven is completely dry. Only after this can you start using it.

Ways to increase furnace efficiency

Increased equipment efficiency, economical fuel consumption is possible with complete combustion.

When the firewood is on top of the grates, the primary air passes from below through the grate from the ash pit. This air promotes the oxidation of fuel, releasing water vapor and carbon dioxide. As soon as the temperature of the wood increases, flammable gases begin to be released. They burn out in the space directly above the fuel and come into contact with coke elements, forming carbon monoxide.

To increase the efficiency of the stove, it is necessary to ensure the combustion of combustible gases in the firebox. To do this, secondary (additional) air is passed through the holes in the firebox door.

If this is not done, there will be underburning of the wood and increased deposition of soot on top of the stones. The consequence is that heat transfer decreases and the risk of fire increases due to the large amount of soot in the pipes.

At the beginning and at the end of the firebox, excess air enters the firebox. The intensity of wood burning decreases. Heat leaves through the chimney along with flue gases. To reduce heat loss, it is better to close the dampers on the chimney.

Other ways to increase efficiency include:

- Increase in the volume of stones.

- Increasing the heated surface area.

- Reducing the thickness of the walls of the structure (material – metal).

It is necessary to take into account the direct relationship between the size of the firebox and fuel consumption. The larger the volume of the firebox, the greater the fuel consumption. At the same time, the heat transfer of the furnace also increases.

How to choose a heater for a bath

Choosing a heater stove is always an individual undertaking. It is impossible to recommend one model or another here, since all baths have a different set of needs.

When purchasing a heater stove, you should pay attention to its parameters:

power . It is not necessary to consider it in kilowatts. Usually they indicate what size rooms this model is intended for;

size and weight of the heater . The larger it is, the more uniform the heating. However, if the total weight of the stove and stones exceeds 700 kg, you will have to make your own foundation;

fuel type This is an important point, since the efficiency of the furnace and the amount of upcoming costs depend on it;

presence and location of a water tank;

the presence of additional functions (remote firebox, length of firewood, etc.).

When going to the store, you need to check the dimensions of your bath and specify all the necessary data. This will help you consider the characteristics of the models in detail and choose the most suitable option.

Features of the firebox and ash pan

During the construction of the stove, it is important to correctly determine the size of the combustion zone, taking into account various nuances. Be sure to take into account the need to install a collector for heating water and the type of fuel used.

The depth of the firebox is determined individually. If this size is 80 cm, then 55 cm of this is used for loading standard length firewood, and 25 cm is used for the water heating system. The width of the combustion zone can be 40 cm, and the height – 35 cm. A firebox of such dimensions allows you to load 8-10 standard logs at a time.

Fuel combustion products are removed from the sauna stove through the ash pan. The blower also allows you to collect ash. In addition, air necessary for the combustion process enters the combustion zone through them. To regulate the rate of fuel combustion, an ash pan or a special valve is used. If it is necessary to quickly heat the bath rooms, it is recommended to completely open the air passage.