To increase the efficiency and benefits of the bathhouse, it must be properly insulated.

After all, high heat loss leads to the appearance of cold bridges, which not only reduces the overall temperature, but also causes the circulation of cold air, which can lead to a cold.

To insulate baths, various types of materials are used, including wood cutting waste (sawdust).

In this article we will cover:

- what is the difference between the thermal and steam conditions of a bathhouse and a house;

- how to insulate walls, floors and ceilings using sawdust;

- How does insulation with sawdust differ from insulation with other materials ?

How to insulate a ceiling with sawdust - thermal insulation options, instructions

One of the most important measures for thermal insulation of premises in a household is the insulation of the ceiling. At the same time, every property owner strives to use budgetary methods to reduce heat loss, among which the use of ordinary sawdust should be noted.

They are available at every woodworking enterprise in sufficient quantities. Sawdust for the ceiling can be purchased at a minimal price or even free. Their installation does not require a lot of time and effort, which means thermal insulation is easy to do yourself.

Recommendations and common mistakes

Often, insulation of ceilings and walls is performed without an additional layer of vapor barrier. As a result, a huge amount of water vapor penetrating through the ceiling from inside the bathhouse is absorbed by sawdust. During the cold season, condensation freezes and often flows through the ceiling into the bathhouse.

The second mistake is not preparing the sawdust deeply enough before laying the insulation on the bathhouse ceiling. As a result, the material decays and sometimes rots.

Advice! If you don’t want to bother with processing sawdust, you can replace it with more effective sunflower husks. It does not rot, does not cake and does not lose its properties, even if a vapor barrier has not been laid on the ceiling of the bathhouse.

The most effective material is considered to be birch bark or birch bark; it is laid on the ceiling with whole leaves, the outer part down, towards the inside of the bathhouse. Such insulation does not require any preparation at all and can last at least two decades.

Features of using sawdust for insulation

The materials used for thermal insulation are constantly being improved, and new, more modern products appear on the domestic market every year. Its cost regularly increases and the owners of a private house do not always have enough money to purchase insulation.

For this reason, the so-called “old-fashioned methods”, used for many years for thermal insulation of walls and roofs, are still popular and relevant. Ceiling insulation with sawdust has stood the test of time for many decades, while it is difficult to say what condition, for example, polyurethane foam will be in after a 20-year service life.

The main advantages of this method include:

- environmental cleanliness;

- hassle-free purchase of sawdust;

- symbolic cost;

- simple installation;

- long service life.

At the same time, savings in the case of using sawdust as ceiling insulation consists not only in reducing financial costs, but also in caring for nature, which helps improve the environmental situation and reduce home heating costs.

The process of insulating a home consists of several stages, including insulation of the ceiling, walls and floor. Moreover, each type of surface requires a special approach. When the ceiling surface is insulated, the material intended for this can be laid both externally and internally.

It is not difficult to verify the economic benefits of insulating a home with sawdust if you compare the costs of them with the cost of popular materials and the work involved in their installation. Thermal insulation using this wood material is practically free. In addition, you can agree with a woodworking company to deliver it to a specific address for a small fee.

Of course, as with the use of other thermal insulation materials, there are pros and cons to insulating the ceiling with sawdust. The disadvantages of this method include the fact that not all varieties of this type of wood waste are suitable for ensuring heat conservation in the house.

Differences between the thermal and steam conditions of a bathhouse and a home

Despite the fact that many perceive a bathhouse to be the same structure as a house, its insulation differs from the insulation of a house due to serious differences in thermal and steam conditions.

Read more about home insulation in the article Home insulation.

In a residential building, humidity rarely reaches dangerous levels leading to mold and rot. However, in the bathhouse the humidity exceeds this threshold many times over.

In addition, in a residential building you can install a ventilation system using a recuperator, this will allow you to constantly supply fresh heated air to the rooms. In a bathhouse, this method of ventilation is unacceptable.

After all, it is impossible to heat the air so much that it does not cool down the interior space of the steam room without intense heating from the stove, and the recuperator will only slightly raise its temperature.

Therefore, when using the bathhouse for its intended purpose, some of the excess moisture is absorbed into the walls, penetrating very deeply.

It is very important that the moisture accumulated in the walls can escape not only inside the room, but also outside, leaving immediately into the atmosphere. For this reason, it is highly undesirable to build bathhouse walls from materials that do not allow moisture to pass through well, and you should not use insulation that prevents the free movement of water vapor.

Due to its ability to quickly absorb and release moisture without losing its thermal insulation properties, sawdust is the most suitable material for insulating a bathhouse.

Choosing the right sawdust

Medium-sized sawdust is best suited for insulating the ceiling in a private household. The fact is that it will be difficult to work with small wood waste, and coarse-grained material does not have a sufficient degree of thermal insulation.

The optimal insulation material is considered to be sawdust obtained as a result of sawing in carpentry production, since it has a low degree of humidity, does not require additional drying and does not begin to rot when used.

If round wood waste, which has natural moisture, is available, then before use it should be spread out under a canopy and thoroughly dried. You should not cover the sawdust, as it will then begin to rot.

Experts advise giving preference to waste from softwood processing. Since such material contains a lot of resinous substances, pests are afraid to settle in it. True, when deciding how to insulate a bathhouse ceiling with sawdust, it is better to use raw materials from deciduous trees.

Before installation, this type of insulation must rest for about a year. During this period, the level of sugars in sawdust decreases significantly, and it is they that contribute to the process of decay. It is necessary to pay attention to ensure that there are no foreign impurities in the insulation. It is advisable to sift the sawdust and remove large debris by hand.

Advantages of home insulation with clay

Obviously, insulating a house with clay has many positive aspects that you should know about. And the advantages are as follows:

- Cheapness. This material is significantly cheaper than analogues that are currently available on the market. Thus, if any problems arise with the clay insulation process, you can safely abandon this idea. Like clay, sawdust can be obtained with a minimum of effort. The main concerns lie in the arrangement of insulation, and this must be remembered.

- Light weight. Again, unlike its analogues, clay has a fairly modest weight. This, in turn, has a positive effect on the insulation process. Quite often, insulation materials are heavy, and this can negatively affect the condition of the ceiling. Accordingly, there should not be such problems with clay, but just in case, you still need to carry out some tests that will allow you to establish the strength of the ceiling.

- Fire safety. There is no doubt that clay is a material that certainly will not cause a fire or its spread. If you need to choose safe insulation, then clay is an ideal option. You should not pay attention to the presence of sawdust in this insulation, since they certainly do not pose any danger.

Well, I would like to repeat again that the process of arranging clay-based insulation is quite simple. In this case, we do not need to have any original devices, much less specialists who deal with such activities. Everything can be done by yourself. Of course, an assistant in this matter will not hurt.

Hemming of floor beams

Work related to how to insulate a ceiling in a private household with sawdust should begin with filing the ceiling; it is performed in a certain sequence:

- Prepare boards approximately 2.5-3 centimeters thick - this parameter depends on the distance between the beams. It is desirable that the lumber be tongue-and-groove or with a quarter, and certainly planed and dry, even if their cost is higher than unplaned edged products.

- On top of the assembled vapor barrier layer, boards are attached solidly with nails 10 centimeters deep or screwed with screws 5-6 centimeters long, 2 pieces at each fixation point. In this case, the nails are driven in at an angle relative to the wooden plane. It is necessary to ensure that the direction of the adjacent nails driven in does not coincide, and then the fastening will be strong and most reliable.

- Before starting installation work, boards and beams must be treated with special compounds - antiseptic and fire retardant. This will protect the wood material from fungus and various pests, and will also help reduce its flammability.

Planning work

Before you buy materials and take up tools, you should carefully plan your actions.

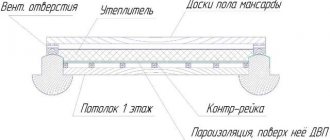

A clearer understanding of the matter will save you from annoying mistakes and the need to redo everything in the future. Wooden ceiling insulation scheme

The first question is: is it possible to insulate the ceiling in a bathhouse yourself? Or should we entrust this matter to a team of builders? The process of insulating the ceiling itself is not something complicated, so it is not difficult to do it yourself, even without much experience in repair and construction. The main thing is to carefully follow the technology and approach the matter responsibly.

The second question is: what exactly needs to be done? Insulating the ceiling in a cold bath consists of three stages:

- vapor barrier;

- thermal insulation;

- waterproofing.

The result should be a kind of “layer cake”, the bottom layer of which is the ceiling covering, and above it, vapor barrier, thermal insulation and waterproofing are located sequentially from bottom to top. More details about why this is necessary and how to do it will be discussed below. Now it's time to think about the choice of materials.

Example of a ceiling insulation scheme

Ceiling insulation options

When insulating the ceiling with sawdust, you should be careful not to miss the cracks that are always present on the surfaces. To eliminate them, polyurethane foam is used.

There are several options for arranging thermal insulation of the ceiling using sawdust, both using pure wood raw materials and by adding additional additives to it, such as clay, lime, etc.

The most popular methods are:

- use of sawdust in its pure form;

- the use of additives - cement and lime;

- the use of additional components - clay and lime.

Insulation of walls with straw and clay

Today in the modern building materials market we have a wide selection of thermal insulation. Each of the materials has certain features and individual properties, as well as certain requirements for installation technology. But since we are looking for a more environmentally friendly and at the same time effective way to insulate a wooden house, we will focus on an old, but not forgotten method and consider insulating a wooden house with straw.

The popularity and relevance of insulating houses with clay is explained by the following advantages of this method of thermal insulation:

- The insulating clay mixture is easy to prepare and apply. To insulate a frame house with straw and clay, you do not need special construction skills; you can organize the entire process and bring it to its logical conclusion yourself. This insulation can be done with your own hands without any problems.

Low cost clay insulation. The comparative cost of clay insulation is significantly lower compared to synthetic materials. High thermal insulation performance. This is a fairly reliable way to insulate rooms. Can be used to insulate floors, ceilings, roofs, etc. Prepared in accordance with the technology, this composition is not attractive to rodents and insects. The environmental friendliness of this insulation is beyond doubt. All residues are of natural origin, which means they are not toxic.

The disadvantages of this method of thermal insulation include certain labor costs and duration of work.

Ceiling insulation only with sawdust

This method is simple and consists of several steps:

- Ceiling insulation made from sawdust is poured onto the floor of the attic in a layer of 15-20 centimeters and carefully leveled, often to the very level of the beams, but not compacted.

- Furnace ash is poured in one layer on top of the insulation. Now a vapor-permeable superdiffusion membrane is being used instead. Thanks to this coating, moisture is removed from the sawdust without hindrance, and this circumstance prevents the process of rotting. Such films are characterized by one-sided vapor permeability.

- If the attic space is planned to be used, then plank flooring must be secured along the beams. The boards are nailed so that there are small ventilation slots between them.

Insulating a cold attic with sawdust. Advantages of sawdust as insulation

Sawdust does not require large financial outlays to purchase. You can always get them at any sawmill for free, or you can prepare them yourself if you practice working with wood. High-quality sawdust has the property of retaining heat well. A thick layer of this natural material is not inferior in heat preservation to mineral wool.

Insulation of attic floors with sawdust

Sawdust is light in weight and does not create a load on the attic floor. Sawdust does not cause allergies, does not emit odors, and does not enter the respiratory tract or eyes like mineral wool fibers. They are easy to use. They do not create problems with transportation to the attic; they can be delivered there in small portions, which can be done by one person.

Sawdust insulation completely covers all non-standard places in the attic and gaps. It is convenient to level them and increase the thickness of the insulating layer as necessary. They dry well and quickly, while the volume of natural material does not decrease, and the quality of sawdust is not lost over time. For insulation, it is better to use small sawdust; their positive qualities are much higher than large wood shavings. Sawdust insulation is a time-tested method of insulating attic floors.

The disadvantage of using this type of insulation is the inability to further use the attic space. There is only one way out - lay a wooden board on top. Therefore, before you start insulating the floor, you need to think carefully about the future.

Creating ceiling insulation from sawdust

There is nothing particularly difficult about how to insulate a ceiling in a private house with sawdust. After completing the preparation of the ceiling surface, they begin laying thermal insulation in small layers, leveling and compacting each of them. The height of the insulation should be level with the top of the ceiling.

A thin layer of ash is poured on top of the mixture of sawdust and additives. It will protect the insulation from pests and fungus. A couple of weeks after completing the insulation of the ceiling with sawdust in a private house, when the mixture is completely dry, a vapor barrier layer is laid on top of it. It is necessary to prevent wood waste from becoming saturated with moisture present in the air.

Vapor barrier material, usually polyethylene film, is attached to the floor beams using a mounting stapler. The result of the work done will be a thermal insulation layer covered on both sides with a vapor barrier.

What tools and materials will be needed

To create insulation for the ceiling of a bathhouse, you will need a fairly impressive arsenal:

- A container for soaking clay, a bayonet shovel with cut sides or a spade. The clay will have to be beaten several times to achieve more or less tolerable plasticity;

- Metal tank for processing sawdust with a heating device;

- If lime or disinfectants are used, then a container will be required for additional reagents;

- Construction trowel;

- Plastering rule;

- Tamping is manual;

- Maklovitz brush;

- Carpentry tools – saw or jigsaw, chisel, hammer, nails.

The materials you will need to purchase are fatty clay, table salt, disinfectants, sawdust, possibly slaked lime, laundry soap, plastic film and wooden slats.

For your information! When forming a layer of insulation on the ceiling of the bathhouse, you will also need several boards, 25-40 mm thick, or sheets of plywood. They will be used to assemble a platform on which you can move, or formwork for insulating the walls of the bathhouse.

What sawdust is best to use for insulating a bath?

For the ceiling, it is best to use pine or birch shavings. Aspen, linden, fruit and hardwood species are used less frequently due to the relatively high scarcity of the material. Poplar sawdust can be used together with clay to make block insulation. In this case, the molded bricks, like adobe, are dried in the sun and then fired until the sawdust burns out completely. The results are light and durable blocks with huge pores, reminiscent of shell rock. It can be used to insulate residential premises, but it is not suitable for a bathhouse.

To insulate walls, it is better to use sawdust from hardwood, oak or larch. Due to the high speed of the cutting tool, the chips are small, so chopped straw is often added to the batch to prevent the insulation from cracking.

Bathroom ceiling insulation options

Nuances of insulating ceilings in a wooden house

There are a number of nuances regarding how to insulate a ceiling with sawdust in a wooden house. Thermal insulation of floors in this case can only be done from the top side, if the raw materials are not pressed into slabs or mixed with clay.

When using sawdust to insulate wooden floors, you need to make sure that they are dry. Such chips, unlike wet ones, will crunch and crumble when squeezed into a lump by hand.

All cracks on the wooden surface are filled with polyurethane foam. Sheets of cardboard are laid on the ceiling and nailed with a stapler. Then, when insulating the ceiling in a wooden house, the first layer about 10 centimeters thick is filled with sawdust. Larger shavings are also suitable for this. After completing the installation, the sawdust must be compacted by walking on it.

Next, a second layer of the same thickness as the first is poured onto the compacted material. Fine sawdust is used for it. They are compacted again.

Choosing material

When purchasing a construction gasket, take into account the technical properties of the raw materials and look at the integrity and quality of the block itself. There are a number of mandatory and additional criteria.

Photo from the site Stroiplaneta.com.ua

The first include:

- environmental friendliness;

- high moisture resistance;

- thermal conductivity;

- the presence of antifungal and antibacterial impregnations;

- ability to withstand loads without deformation;

- durability.

These requirements apply to most building materials for aquazones. But consider other characteristics:

- compatibility with other finishing elements;

- water-repellent properties;

- compliance with sanitary standards and fire safety regulations.

The thermal conductivity index affects which layer the sheet will be laid. Correct insulation of the ceiling in a bathhouse with a cold roof with your own hands depends on taking into account the ergonomic properties of the gasket.

Photo from the site Ural-him.ru

The origin of the material is especially important:

- organic;

- synthetic.

Each of them has its own advantages and disadvantages. Folk remedies, mostly of natural origin, will help to insulate the ceiling on top of the bathhouse. Their main advantage is safety during use.

Article on the topic: How to properly make a fence from corrugated sheets with a strip foundation

Photo from the site M.prom.inforico.ua

Thermal insulation of bath ceiling

When insulating a bathhouse, the ceiling surface is sheathed with wide boards. To install the chimney, a ceiling cut is performed. Components can be purchased ready-made in a store or made by yourself. In the second case, a circle is cut out in the middle of a stainless steel sheet that completely covers the hole for laying the chimney.

Next, the edges of the cutout in the ceiling are sealed with basalt wool, and strips of metal are stuffed on top of it. The chimney is secured with guide strips so that it can move freely due to thermal expansion. A plate is screwed from below and the resulting passage is thermally insulated.

Insulation of the ceiling in the bathhouse is carried out in the following sequence:

- In the attic room, a vapor barrier is laid with an overlap of 10-15 centimeters with a bend on walls of a similar size.

- The mixture for the sawdust ceiling, prepared in accordance with one of the previously described recipes, is laid in layers, each time, well leveling the insulation and compacting it. If the bathhouse is planned to be used only in summer, then the thickness of the thermal insulation layer can be 5 centimeters, and when in winter, then at least 15 centimeters will be required.

- After finishing laying the insulation, you need to wait until it dries. If cracks have formed on the surface, they are sealed with the same composition. To keep their quantity to a minimum, salt is added to the mixture before installation at the rate of 5 - 6 tablespoons per 10 liters of water.

- It sometimes takes up to a month for the insulation with sawdust to dry. Then a thin layer of lime is poured over the mixture and a vapor barrier is laid. Next, the surface is covered with boards, if desired.

When using a mixture of sawdust and gypsum for thermal insulation, it should be applied in thin layers. When performing work, you must not forget that the gypsum composition dries quickly. By the way, both methods of insulation can be used when working with horizontal and vertical surfaces.

Source of the article: https://pod-potol.com/remont-i-ukhod/teploizolyatsiya/kak-sdelat-uteplenie-potolka-opilkami-varianty-teploizolyatsii-instruktsii.html

How to insulate a steam room?

These operations are in many ways similar to the same actions in ordinary houses, so we will provide links to articles where you can find useful information, as well as the main differences.

After all, it is necessary not only to know what and how to do, but also to understand why it is right.

This will help to find the most suitable solution in certain conditions when the measures recommended in the article are not applicable either due to the design of the wall, or due to the unavailability of the material or the impossibility of performing certain work.

You will find more detailed information about sawdust-based insulating compounds, as well as binders, here.

Insulation of a bathhouse ceiling with sawdust, clay, cement

Due to the high air humidity in the bathhouse, the ceiling must be equipped with a vapor barrier rather than a hydro barrier .

Otherwise, condensation will constantly form and they will quickly lose their thermal efficiency and then begin to disintegrate.

can be used as a vapor barrier :

- roofing felt;

- glassine;

- kraft paper;

- cellophane;

- polyethylene;

- aluminum foil.

The vapor barrier film is laid between the ceiling boards and the insulation, and the film should extend onto the walls.

If your budget allows, then it is better to make a vapor barrier from aluminum foil; it will not only protect the insulation from moisture, but will also increase its thermal insulation properties .

After all, the foil reflects infrared rays, due to which part of the thermal energy returns to the steam room and participates in heating the air.

In addition, you need to use a mixture of sawdust with lime and clay, because other binders are not suitable for insulating the ceiling of a bathhouse.

During washing, part of the moisture, despite the vapor barrier, will pass to the insulation and settle on sawdust in the form of ash , so the lower edge of the insulating layer will often be damp.

PVA will not allow sawdust to effectively absorb moisture, so the dampness will transfer to the ceiling boards, causing them to quickly rot and require replacement.

Cement and gypsum are afraid of high humidity, so they will deteriorate, and after them the wood will begin to disintegrate.

Clay is devoid of these disadvantages, therefore, after washing is completed, the moisture will be evenly distributed throughout the entire insulating layer and will begin to evaporate, exiting through the attic.

In addition to binding individual sawdust, clay also acts as an element that accelerates the spread of moisture throughout the entire insulating mass; in addition, after the loss of excess moisture, the clay will again bind the sawdust together.

The minimum thickness of the insulating layer is 10 cm, the optimal is 20–25 cm. In addition, it is necessary to establish high-quality ventilation of the roof, otherwise the moisture rising from below will not be able to effectively escape into the atmosphere.

When planning to insulate the ceiling of a bathhouse, you must understand that this work can only be effectively done from above, that is, from the attic or upper floor.

After all, when insulating from below, it is impossible to create a normal vapor barrier, so the sawdust will become saturated with a large amount of moisture, which will damage not only them, but also the ceiling lining.

Interior wall decoration

The method of insulating the walls of a bathhouse and a house directly depends on their design .

For more information about insulating the walls of a house, read the article Insulating walls.

The main difference is that in the absence of a high-quality ventilation system that can quickly ventilate the room after washing is completed, the walls must be protected with a vapor barrier from the inside.

First of all, this applies to houses made of logs, timber or boards, including frame ones. Indeed, due to high humidity and poor ventilation, the wood becomes heavily filled with water and swells so much that damage to the structure is possible.

In brick baths, poor ventilation leads to rapid destruction of the inner surface of the walls, which is why they begin to crumble.

High humidity does the least harm to concrete walls, but after a few years they begin to slowly collapse, crumbling from the inside.

Therefore, it is necessary first of all to organize ventilation , which would create air circulation covering the entire room.

are especially effective in bathhouses, because they allow you to quickly ventilate the steam room and remove excess moisture.

However, vapor barrier cannot completely protect walls from high humidity, so nothing on the outside should prevent the evaporation of liquid and its release into the atmosphere.

Because of this, the walls of bathhouses cannot be insulated with foam plastic, polyurethane and other similar materials.

And the use of mineral wool will not give the expected effect, because it is afraid of even a slight increase in humidity.

compositions based on sawdust, lime and clay/cement as a binder as insulation for walls

It is undesirable to use PVA and gypsum as a binder, because glue transmits water vapor much worse, and gypsum is afraid of even a slight increase in humidity. In all other respects, the insulation of bathhouse walls is carried out in the same way as in ordinary houses.

Thermal and waterproofing of the floor

about the main methods of floor insulation here, so further we will only talk about the differences that arise when working in a bathhouse.

The main problem that arises when insulating a bathhouse floor is very high humidity.

Therefore, it is necessary to exclude any contact of the insulating material and water. This can be done in two ways:

- creating a waterproofing screed;

- adding liquid glass to the insulating solution.

A waterproofing screed is preferable if the base can easily withstand additional weight.

Therefore, this method is most often used on concrete floors.

However, it can also be used on wooden floors, but only in small rooms , because the load-bearing capacity of wood is much lower than that of reinforced concrete.

If the subfloor is made of wood, then you can insulate it with a composition containing liquid glass, and also cover it with a thin layer of waterproofing.

It is advisable to use liquid glass as a waterproofing material, because bitumen waterproofing is resistant to high temperatures . You can also use polymer waterproofing materials based on polyurethane and rubber.

If the most effective insulation is required, then a mixture of sawdust and lime is used, and clay or PVA is used as a binder.

After the insulating mixture has hardened, it is left for some time (depending on the type of binder, clay - for a month, PVA for two days), after which it is covered with a vapor barrier (cellophane/polyethylene film or aluminum foil).

Then a layer of waterproofing is poured and only after that the boards are laid. Moreover, the subfloor is laid on such a base without fastening, so it is advisable to use a tongue and groove board. If the floor is covered with tiles, then a 10 cm thick screed is poured over the vapor barrier.

Types and features of vapor barrier

It does not matter what kind of bathhouse is being built - a Russian wood-burning one or a sauna. The room is maintained at high temperature and humidity. In order to maintain a unique microclimate and avoid the formation of condensation, additional waterproofing of the ceiling in the bathhouse is necessary. Among the wide variety, how to choose a vapor barrier for a bathhouse ceiling and which one is better? Additional protection is only necessary if bulk insulation or mineral wool is used. Foam and polystyrene do not require insulation. because They are not at all afraid of moisture.

Types of vapor barrier:

Bath film for the ceiling. The simplest material, the texture can be smooth to the touch or rough. A more expensive modification may have reinforcement.

- Membrane. Special woven material that does not allow water to pass through and prevents the formation of condensation;

- Foil. The best option for insulating a bath room, because in addition to vapor barrier properties, it retains heat well;

- Izospan. A special combination of different materials that has excellent vapor barrier properties.

Izospan for bath ceilings is one of the most popular materials today. The base is kraft paper with a foil layer of lavsan applied. Can be used at elevated temperatures, including in a steam room. The presence of foil in its composition allows it to additionally reflect heat. Izospan retains heat well and prevents the steam room from cooling quickly.

Important! The vapor barrier must be placed hermetically, otherwise heat will escape even through a small gap.