Insulating a bathhouse with expanded clay is one of the methods for reducing heat loss during the operation of a bathhouse complex. The main heat leakage occurs from the bathhouse through the walls, floors and ceiling. The greatest contribution to heat loss comes from poorly insulated floors and ceilings.

To prevent heat losses, it is necessary to carry out work during the construction of the bathhouse to ensure high-quality thermal insulation of the premises of the bathhouse complex from the external environment.

For this purpose, you can use various materials that serve as good heat insulators. It can be:

- stone and mineral wool;

- ecowool;

- expanded polystyrene;

- expanded clay;

- wood sawdust.

One of the most popular materials used for insulation work is expanded clay, which is used most often in areas where there is a decrease in air temperature in winter below 350C.

Insulating the floor and ceiling in a bathhouse with expanded clay has a large number of advantages due to its properties.

The use of expanded clay to insulate the ceiling of a bathhouse, according to reviews from owners of suburban areas, makes it possible to carry out thermal insulation of the room efficiently and without large financial costs in order to prevent heat loss . In addition to heat-insulating properties, this expanded clay has excellent sound-proofing properties.

Types of expanded clay for insulation

Expanded clay, if used as a building material for insulation, has many advantages. According to its physical parameters, expanded clay is a porous and fairly lightweight building material that does not create large loads on the ceiling plane.

Externally, expanded clay looks like round granules. The raw material for the manufacture of heat insulators is clay, which is subjected to high-temperature firing. The use of natural raw materials in the production process guarantees the highest possible purity of the finished product.

Insulation can be found on the market in two varieties:

- expanded clay sand;

- expanded clay gravel.

Expanded clay sand is used in the form of aggregate in the preparation of mortars. The size of the main fraction included in this type of building material can vary in the range from 0.14 to 5 mm. This variety is used as a filler for mixtures and as backfill for ceiling insulation when forming a layer up to 50 mm thick.

Expanded clay gravel is a type of building material, the main fraction of which has a size ranging from 5 to 40 mm. This variety is used to insulate the floors, walls and ceilings of the premises of the bathhouse complex.

Technology

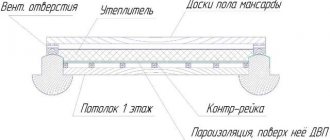

How to insulate a bathhouse ceiling with expanded clay? The technology for insulating the ceiling in a bathhouse with expanded clay is of medium complexity. In principle, anyone who does not have any construction skills can handle it. The insulation is installed from the attic side. First you need to put a layer of vapor barrier material. It will also perform the function of waterproofing.

The current construction market offers a huge variety of options for vapor barriers . These can be modern materials such as Izospan or analogues. You can take regular plastic film, roofing felt and aluminum foil. However, experts do not recommend roofing felt. When exposed to very high temperatures, it gets wet. In addition, roofing felt may catch fire.

The chimney pipe and rafter beams are also laid with a vapor barrier . The vapor barrier should be fixed higher than the height of the expanded clay layer. Vapor barrier film or membrane sheets are secured with a regular construction stapler or masking tape.

The expanded clay layer is not laid out immediately. First, lay a layer of crushed clay .

The expanded clay layer should be at least 12-15 cm. For better thermal insulation, material of two fractions is used, which are called expanded clay sand and expanded clay gravel. This will increase the density of the layer and reduce future subsidence of the granules.

And this article talks about how to make a fence from a chain-link mesh.

Advantages and disadvantages of expanded clay

When comparing expanded clay with other insulation materials, the following advantages of this insulation can be highlighted:

- Not biodegradable during use. Over time, most of the heat insulators used for thermal insulation of bathhouses undergo decomposition, which provokes the release of substances harmful to human health from their composition into the air. Expanded clay, despite its service life, does not emit harmful chemicals and does not deteriorate its thermal insulation characteristics.

- The insulation does not attract rodents, which allows it to be used for an almost unlimited time.

- Insulating the ceiling in a bathhouse using expanded clay guarantees high fire-resistant qualities of the ceiling, high sound insulation characteristics and increased resistance to water vapor.

- The insulation has high frost resistance. This building material can withstand up to 25 cycles of complete freezing followed by thawing without loss of thermal insulation properties.

In addition, expanded clay is characterized by low heat transfer rates, which range from 0.07 to 0.16 W/m, which makes it possible to use it as an effective insulation for a bathhouse.

Additionally, one more significant advantage of this building material should be noted - low cost, which contributes to the popularization of expanded clay as a thermal insulation material for bath complexes.

The use of expanded clay in construction work

Expanded clay is used for the preparation of dry mixtures used in the insulation of foundations, walls and ceilings during the construction of various buildings, including buildings of bathhouse complexes.

Using a layer of expanded clay-based heat insulator, which has a thickness of 100 to 150 mm, can reduce heat loss by 70%. The insulation is ideal for filling hard-to-reach cavities in which it is impossible to install other heat-insulating building materials. It is capable of creating a very high-quality heat-insulating layer that will perform its functions for a long time and prevent heat loss.

In some cases, a mixture of expanded clay and polystyrene foam can be used to insulate the roof of a bathhouse. This mixture isolates the room from the external environment much more effectively than in the case of using mineral wool. A mixture of expanded clay and polystyrene can significantly reduce thermal energy losses and save on fuel consumption when heating the bath complex.

When purchasing building materials for insulation, it is necessary to take into account the degree of shrinkage, the coefficient of which is 1.15. 1 m3 contains about 20 bags of expanded clay. Possessing a high degree of fire resistance, this type of insulation does not change its stability when sudden temperature changes occur. Easily able to tolerate both severe frost and high temperatures. Very often the material is used as insulation in areas with harsh climatic conditions.

In order to properly insulate the bathhouse premises, care should be taken to insulate not only the ceiling, but also the floor of the premises.

A good effect from the use of expanded clay is felt when using a layer of insulation of at least 100 mm.

Features of using expanded clay when insulating the ceiling of a bath room

When insulating the ceiling of a bathhouse using expanded clay, the characteristics of the building material should be taken into account. It is not recommended to insulate with expanded clay if there is no attic space above the ceiling, since this material is capable of absorbing moisture. In the absence of an attic space, this may negatively affect the thermal insulation properties of the material. In addition, the moisture absorbed by the material contributes to the weighting of the material, which increases the load exerted by the insulation on the floors of the premises of the bathhouse complex.

In order to avoid such a situation when installing an expanded clay insulation layer, additional waterproofing should be laid, which will prevent moisture from penetrating from the air to the insulation layer. A layer of insulation should be placed on top of a layer of expanded clay.

Making a layer of insulation using expanded clay is quite simple, since during the installation process it is not necessary to adjust the elements and carry out fastening work. During the work, it should be remembered that expanded clay, like any other bulk material, is capable of generating a large amount of dust when working with it. For this reason, it is recommended not to pour this building material onto bare boardwalks. To prevent dusting, it is recommended to lay expanded clay on a prepared substrate.

Before using expanded clay as the main insulating building material for the ceiling, the feasibility and effectiveness of using expanded clay should be analyzed. This is required due to the fact that the effectiveness of the material appears only with a layer thickness of over 100 mm.

To ensure high-quality thermal insulation, in some cases it may be necessary to form an insulating layer from 200 to 400 mm. Before forming a layer of insulation in the thickness of the floor, you will need to lay a layer of hydro- and vapor barrier between the floor boards and the layer of heat-insulating material.

Features of floor insulation in a bathhouse using expanded clay

Insulating the floor in a bathhouse with expanded clay with your own hands can be done with ease if you follow a certain sequence of operations and follow the insulation technology. Regarding the arrangement of thermal insulation of the flooring in the premises of the bath complex, you should worry about it at the stage of construction or repair work. When installing insulation and calculating its quantity, you should also calculate the maximum permissible load on the floor.

When carrying out floor insulation work, the following instructions should be followed:

- A bitumen-based waterproofing material is spread, the material is applied taking into account the overlap of the strips on each other at a distance of 10 cm and on the walls by 15 cm.

- Beacons are attached that will show the thickness of the layer and its evenness.

- Before filling the material between the floor joists, they should be treated with an antiseptic special compound.

- Expanded clay is backfilled with a layer equal to 150-200 mm. For better thermal insulation of the floor, it is recommended to use a mixture of different fractions of insulation material for backfilling.

- After backfilling, the layer is filled with cement laitance to bond the granules together.

- After the milk has set, a reinforcing mesh is installed to provide additional rigidity.

- A cement-sand screed is poured over the layer of insulation and reinforcing mesh, which must have a thickness of at least 30 mm.

- After the screed has completely hardened, the waterproofing material should be laid and secured.

- After installing the waterproofing, the finished floor is installed.

When laying and insulating the floor of a bathhouse on the ground, the insulation layer must be at least 350mm. This indicator should be taken into account at the design stage of the facility, since the insulation layer will inevitably lead to a rise in the floor level.

Laying technology

The principle of floor insulation with expanded clay is to arrange a heat-insulating layer into a prepared frame. First, a rigid base is prepared. If the material is poured directly onto the ground, it must be compacted well. Lay a row of waterproofing.

The next stage is the assembly of the frame, consisting of ordinary wide slats, reinforced with transverse bars.

In the case of a large insulation perimeter, it is recommended to divide the structure into several fragments.

The last thing is pouring the expanded clay mixture and fixing the fastening boards to the frame.

If the work is carried out under a screed, then the filled expanded clay is filled with a cement composition.

Features of insulating the walls of a bathhouse complex using expanded clay

Using bulk materials for insulation, you can only insulate walls that are built from brick or stone. The process of carrying out operations to insulate walls with expanded clay should be thought through before the start of construction work.

Insulation of the walls of a bathhouse built of brick or stone using expanded clay should be carried out in the following sequence:

- The first outer wall, half a brick thick, is being erected.

- At a distance from it, a second wall of the same thickness is erected from the inside. The distance between the walls should be 350mm.

- During the construction process, jumpers are installed between the walls every 100 mm.

- The space between the two walls is filled with expanded clay, the layers of which should be no more than 200-400 mm. The filled expanded clay is thoroughly compacted.

- Each layer is watered with a cement mixture to ensure adhesion between the individual elements of the building material.

- The process is repeated in stages until the very top of the building.

Insulating walls with expanded clay is used in very rare cases, since the technology for carrying out the work requires a lot of time and money. In addition, the use of such technology for insulating the walls of a bathhouse complex leads to an increase in the load on the foundation of the building, which, in turn, requires the construction of a reinforced foundation. The implementation of such a foundation also requires significant labor costs and financial investments. It should also be noted that when using this method of insulating a bathhouse building, the installation of high-quality hydro- and vapor barrier of the walls will be required.

Baths made of expanded clay concrete blocks reviews

Reviews from owners about the construction of bathhouses made of expanded clay concrete blocks are not unanimous. There are pros and cons. Every owner dreams of getting not just a “box”, but a real masterpiece. Depending on the type of building (residential, industrial, warehouse), building materials are selected. If you are planning a bathhouse, expanded clay concrete is an excellent choice, but for a house, block structures are not the best alternative option.

- Oleg (Yaroslavl): I always dreamed of building a bathhouse on my site. When I approached the issue seriously, I was at a loss at the variety of alternatives on the construction market. A friend advised me to pay attention to expanded clay concrete blocks; according to him, they are not only affordable, but also high-quality building materials. This was my first independent construction. Despite various opinions about the material, I, like many other self-taught people, chose expanded clay concrete blocks for my bathhouse.

- Alex (Voronezh): My wife and I practically live at the dacha, the plot allows us to build a bathhouse, so we didn’t think twice about it, but began to develop a project and come up with a layout. When it came to choosing the material, and, of course, calculating the cost, I was confused. I started reading forums, consulted with professionals who build turnkey bathhouses and, despite numerous excuses, still decided to use expanded clay block. After all, I am the happy owner of a luxurious home bath.

- Vadim (Samara): My granddaughter is an athlete, so she needs regular baths. I am against public steam rooms, I prefer to have my own, but since my granddaughter needs it, I decided to build one. I calculated the cost, it’s not a cheap pleasure, but expanded clay concrete for building a bathhouse is not only a budget-friendly, but also a completely worthy alternative. When I talked about my idea at work, it turned out that there were more bathhouses built from expanded clay concrete blocks than I could have imagined. This gave me even more confidence and confidence in the right choice. We built a bathhouse with the whole family and don’t regret it, the reviews about the expanded clay block are only the most positive.

- Volodya (Krasnodar): My grandmother left me a plot; I’m not a gardener, so I won’t grow anything. Instead, I decided to slightly modernize my inheritance; there is a residential building there, and I decided to build a bathhouse so that I can often come and relax with friends. I chose blocks to build quickly. There were good reviews about foam blocks, but the cost did not please me, then I found out that a bathhouse made from expanded clay concrete blocks is no worse, and the price is much lower. My steam room is ready, I see only advantages for myself, I recommend it to everyone!

Despite negative reviews from builders and specialists about expanded clay concrete blocks, more and more self-taught people are using this material in home construction of baths. A small one-story house, a modest garage or a country bathhouse are the most popular objects made from budget building materials.

Generalization: advantages and disadvantages of expanded clay concrete baths. In what cases should you use expanded clay concrete block to build a bathhouse?

When choosing expanded clay block for a bathhouse, you should be prepared for its features. In addition, despite all the advantages, the material has its disadvantages.