- Design

- Metal

- Creating a Project

Building a bathhouse is a responsible undertaking. The pleasure and effect of the procedures performed in it directly depends on this. In this article we will look at step-by-step instructions in which the masters answer the question of how to properly make a good steam room in a bathhouse. It brings true pleasure only with proper organization, so we recommend entrusting the construction to professionals.

How to properly install the device, interior decoration and insulation

The safety and effectiveness of the procedures performed in the bath depends on the quality of the steam room. If you decide to entrust all the work to specialists, the device and the entire structure will be as concise as possible, and safety will be at the highest level.

Design requirements

The main rule is the development of the project. It must meet the following requirements:

- The key element is the firebox. You can't skimp on it.

- Before starting work, you need to find out the size of the oven and the number of people who can visit the steam room at the same time.

- All used space must be calculated as rationally as possible.

- The room should not be heated in vain.

Dimensions

The ideal ratio of steam room sizes is as follows: ceiling height – no more than 2.25 m, length – 2 m, width – 2.5 m. This room is designed for 3-4 guests. To be able to use the steam room at home, it is important to discuss the following questions with the installers before starting work:

- Do you need window openings?

- How do you plan to install the front door?

- What kind of ventilation system do you want to use?

- Where and how many benches will be located?

Doors and windows

According to standard designs, there are usually no window openings in steam rooms. However, if necessary, they can always be installed. The optimal window size is 0.5*0.5 m. Professionals most often use the latest generation double-glazed windows for maximum sound and heat insulation.

When installing doors, experts recommend making a high threshold (up to 35 cm) to reduce possible heat loss at the entrance. The door leaf itself should be comfortable and functional, without locks or latches. When choosing a material, it is better to give preference to glass or natural wood.

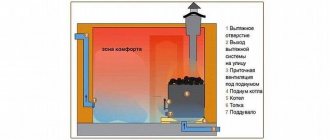

Exhaust ventilation system

As a preventive measure against mold, all kinds of fungi and reduction of humidity, it is necessary to take care of an effective exhaust ventilation system. This is done at the start of construction work at the site. Its main task is to bring clean air into the room and maintain optimal humidity in the room.

For ideal operation, it is better to choose supply and exhaust type ventilation, so that the supply channel is located near the firebox, and the exhaust is in the opposite part.

Video description

The video will demonstrate how to properly insulate the ceiling in a steam room:

Installation of doors and windows

It is better to avoid any plastic in the steam room. No matter how the manufacturer positions the harmlessness of its products, the danger of releasing harmful substances still remains. Especially with high heat. Therefore, the frames must be wooden. But have a modern airtight seal and double glazing. For maximum conservation of energy resources, triple is perfect.

You will have to spend extra money to install windows. Because the openings will have to be well insulated. It is better to install frosted glass instead of ordinary glass or apply a translucent film to it. This way you can easily get rid of the possibility of spying on the street.

The installation of a bathhouse inside always implies a separate and well-closing door to the steam room. This is a special element and is different from a regular sash. Firstly, the bath door is much lower and narrower in width. Secondly, the loot must be installed on the threshold.

Modern doors to a steam room made of glass Source vyborok.com

In modern baths you can see glass doors that are installed in the opening with a small gap at the bottom along the floor itself. Some experts will argue that a small heat loss in this case is not important. But the classic version of entering a steam room always has a threshold. Traditionally, it reaches up to 30 cm and you have to carefully step over it.

This design completely eliminates the occurrence of drafts and, as a result, reduces heat loss. And for ease of movement, the door must be equipped with reliable handles that do not allow you to get burned when touched. The door itself that allows entry into the steam room must be well insulated with heat-reflecting material.

Device Features

Step-by-step instructions for finishing a steam room, developed by the hands of masters, have many of their own nuances:

- First you need to correctly calculate the number of shelves needed. It is limited by the number of people who plan to relax in the steam room at the same time.

- For interior decoration and equipment, it is necessary to use high-quality materials that do not release resins under high temperatures. The ideal option is aspen.

- It is important to choose the right oven. It can be electric or made of brick, stone or metal.

- If space is limited, you can make a shower stall instead of a washing room.

Design

To avoid problems and unspecified questions during construction, it is important to correctly develop the design and plan of the steam room. All functional areas should be provided: dressing room, washing room and steam room.

The first also serves as a relaxation room. As mentioned earlier, the second zone can be replaced with a shower stall. If the area and conditions allow, it is possible to allocate a separate room for washing. When developing a steam room project, it is important to determine the size of the stove so that it matches the dimensions of the entire steam room. A proportion comes in handy here: 1 kW of heat energy is used to heat 1 cubic meter of room volume. If we talk about area, then for one soaring person you need to allocate 0.7 square meters. m. Do not forget that insulation will take a few centimeters on each side, take this into account when planning.

If you decide to abandon window openings, you need to pay special attention to artificial lighting.

To insulate the structure, specialists use lining, specialized blocks for wall cladding, etc.

Preparing to build a sauna

When planning the construction of a steam room, you need to decide what size it will be. There should be 0.7 m2 per person in the sauna.

The steam room should not be cramped or very spacious. In the first option it will be uncomfortable, and in the other it will be quite cool, because it is difficult to heat a large room. It is preferable to create a steam room measuring 2x2.4 meters. But it is not allowed to deviate from ordinary decisions.

Sauna size designation

To a certain extent, the width of the steam room depends on the way a person is positioned on the shelf. If it is planned that a person relaxing in a bathhouse will sit on a platform, then the room is made miniature.

When it is decided to steam while lying down, more space is required to create a steam room. In this situation, the best width is considered to be equal to the height of the tallest person in the family, plus another 20 cm.

The dimensions of the shelf and bath are selected taking into account the position in which it is comfortable to steam

The height of the steam room can be from 2.2 to 2.4 meters. It is determined based on the height of the tallest visitor to the bathhouse. When entering the steam room, this person should not touch the ceiling with his head.

Oven: which one to choose and where to install it

The main element of the steam room arrangement is the stove. The modern market offers 3 types of this equipment.

Metal

Characterized by small size and high performance, it can quickly heat the required area. The heating device requires a minimum of time to heat up and cool down. However, touching its heated surface is extremely dangerous. For this reason, when choosing this equipment, it is necessary to provide reliable fencing to prevent accidents.

Brick

Installed exclusively on a pre-prepared foundation. The dimensions directly depend on the characteristics of the steam room. Disadvantages:

- difficulty in choosing a good stove installation specialist, and as a result the high cost of services;

- mandatory presence of a foundation due to the large mass of the furnace;

- long time for construction;

- slow heating.

Its advantage is long cooling, the formation of light and fine steam, which is ideal for a Russian steam room, safety (even if you accidentally touch it, there will be no burn), and the absence of infrared radiation. Based on this, a brick oven can be installed close to the shelves for long-term heat generation.

Electric

Its main advantage is the absence of hassle with kindling firewood. But it is important to consider that these heating devices are effective only for small rooms, they cool down quickly, and their cost is high. Any faults in electrical insulation can lead to serious problems and short circuits. For this reason, when choosing electric furnaces, you need to carefully check the quality of the electrical wiring.

Stone

Soapstone is a popular and in-demand material today. It is characterized by a high degree of strength, therefore it is durable. The main advantage of this material is uniform and gradual heating of the room. The stove itself is not cheap, but it allows you to significantly save on fuel: after heating for an hour, the heat will remain throughout the day. In addition, such steam has healing properties and can improve your health.

Insulation system inside

It is organized by a specialist in several stages based on the developed project. High-quality performance of these works allows you to reduce heat loss and minimize fuel consumption. First, installers insulate the ceiling, then the walls and floor.

Stages:

- The surface is thoroughly cleaned, all dust and dirt are removed. After this, a sheathing consisting of bars measuring 5*5 cm is installed. A level is used for checking.

- Material is applied to the wooden frame for reliable waterproofing.

- The insulation is being installed. The ceiling is treated with two layers, the walls with one.

- A vapor barrier is being installed. This can be aluminum foil, fixed to the wood sheathing using a construction stapler and staples. The joints are carefully processed with aluminum tape.

- A sheathing with insulation and vapor barrier material is installed on the walls, then protection is laid for the wooden lining, which acts as a decorative covering. To finish the floor, you can choose floor tiles or porcelain stoneware.

- At the last stage, existing holes, cracks, seams, etc. are sealed. For this, silicone or sealant is used.

Briefly about the main thing

Particular attention should be paid to insulating the steam room from the inside. You need to start with the layout of the steam room, choosing the cladding option and insulation material.

Mineral wool is considered the best insulation; for the floor it is preferable to use expanded clay. Aluminum foil is used as a vapor barrier.

It is necessary to approach the process with great responsibility. Therefore, it’s up to you to decide how to make a steam room yourself or with the help of professionals.

Ratings 0

Installation of shelves and oven

The next answer to the question of how to build a steam room concerns the firebox. It is performed in the corner closest to the front door. According to current standards, the distance between the heating device and the walls must be at least 33 cm. Previously, we have already become acquainted with the types of modern fireboxes on the market.

Heaters made of metal or powered by electricity can be purchased at the store.

To make boards, craftsmen use slats made of oak or aspen. When connecting, it is important to leave a small gap between them. This is necessary for the removal of water and the entry of air. The dimensions and number of shelves depend on the number of steamers and the size of the room itself. Optimal shelves are 1.8 m long and 0.6 m wide.

Lighting

Most often, bathhouse owners prefer to abandon natural light. For this reason, the organization of artificial lighting is of particular importance. When arranging a steam room, the required number of light sources must be provided. The lamps themselves should not distract from the procedures or irritate the eyes. The optimal points for their location are above the door and above the shelves.

The lighting fixtures used can be recessed or overhead. During their installation, it is important to properly insulate the light bulbs and wires. For this purpose, to protect against overheating, the former are placed in sealed cases, and the latter in plastic boxes. The switch must be made outside.

How to properly make a steam room in a bathhouse

So, we move on to step-by-step instructions according to which experienced installers perform all the work.

Creating a Project

As we have already said, a well-developed plan with all dimensions and descriptions of stages is half the success of a started enterprise. The illustration shows the optimal dimensions:

For each window it is necessary to provide thermal and waterproofing. When choosing a double-glazed window, it is better not to save money and purchase an option with high performance. Well, don’t forget about the ventilation system. After developing a diagram, a drawing of the steam room and a detailed plan, you can already begin implementation based on them.

Insulation

Fuel consumption directly depends on the organization of thermal insulation. The worse the insulation of the floor, walls and ceiling, the more resources are needed to raise the temperature and warm up, so we are sure that the master will do a better job of it. So, the ceiling is insulated first. It can be lined with foam plastic boards. At the same time, they are temporarily fixed to the ceiling and then sheathed with specialized plywood that is resistant to moisture. It can be replaced with any other material that you like best. Insulation is carried out between the beams; here it is important to ensure that the thickness of the slabs is at least 100 mm. A vapor barrier is made on top, and under the tiles the surface is covered with a polyethylene film.

After the ceiling is insulated, specialists begin to work on the walls. Here it is important to correctly assemble the frame, for which a square beam of 0.5 by 0.5 m is used. The step size should be such that sheets of insulating material are placed between the beams. For walls, you can limit yourself to a thickness of 5 cm.

For reliable sealing and protection, installers treat the joints with aluminum tape. And for wall insulation, other materials are used, for example, mineral wool. Otherwise, the process is similar: a polyethylene film or other substance with water-repellent properties must be laid on the base.

Some experts believe that the floor covering should not be insulated. However, if you plan to install a steam room in an area with a harsh climate, it is better not to give up thermal insulation and use wooden flooring or ceramic masonry for it.

Choosing the type of wood for making benches and deck chairs

To determine suitable raw materials, consider the following:

- The use of softwood lumber is contraindicated. Otherwise, when heated, resin begins to release, which sticks to the body.

- The wood must be resistant to conditions of high humidity, constant temperature changes, and have high-quality antiseptic protection. Otherwise, the shelves will rot and quickly become deformed.

- There should be no chips, burrs or other defects on the surface.

- Low thermal conductivity of the material is necessary so that the benches do not heat up and this does not cause discomfort for vacationers.

Let's look at the properties of the most popular breeds that are suitable for shelving in a Russian bathhouse.

Aspen

Very popular among residents of the private sector due to the availability of raw materials and low price.

Other benefits of aspen include:

- resistant to moisture;

- does not rot;

- does not deform;

- has healing properties;

- cleans the air of bacteria and germs;

- does not require maintenance.

It is generally accepted that products made from aspen restore strength, give vigor, and act as a neutralizer of negative energy.

From constant exposure to moisture, aspen can change its shade to grayish.

Thermal aspen

Thermal aspen is wood that has been treated with high temperatures (over 200 degrees) and steam.

Resulting in:

- The humidity of the raw materials has decreased.

- Essential oils evaporated from the structure, which means the material became more resistant to fire.

- Density has increased. Therefore, thermoaspen absorbs less moisture.

Thermal aspen does not swell, does not rot, and lasts a long time. This material is considered a reliable decorative option for finishing bath rooms. Thermal aspen shelves and furniture look very beautiful.

Disadvantages: fragility and high price.

Larch

It is characterized by increased resistance to moisture. Has a strong solid structure. It is chosen for the manufacture of furniture, decoration in saunas, open verandas and gazebos.

Alder (black alder)

Alder is the optimal raw material for making steam room benches yourself.

Its advantages:

- high strength;

- low thermal conductivity;

- durability;

- wear resistance;

- does not deform;

- does not change color even after years;

- perfectly tolerates temperature changes and constant humidity.

More expensive than linden. The structure is uniform.

To contrast the colors in the steam room, you can assemble racks of light and black alder.

Linden

Linden is often used to decorate steam rooms. It has a pleasant aroma that has a relaxing effect on a person.

Among the advantages of raw materials:

- it is convenient to handle;

- a light weight;

- ease of installation;

- smooth surface;

- even over the years it does not lose its attractiveness;

- tolerates temperature changes and humidity well.

For homemade shelves, it is recommended to take thoroughly dried linden, otherwise the structures will begin to darken.

Linden is more expensive than alder, but in terms of quality and properties these species are almost equal.

Poplar

It is distinguished by soft and easy-to-work wood. Solid poplar has a light brown, sometimes white tone. Light in weight.

In terms of resistance to moisture and temperature changes, it is inferior to other breeds.

It is customary to make furniture and carved decorative elements from poplar.

Maple

The main advantage of maple is its strength. Products made from this raw material are difficult to break or damage, they do not crack.

Other advantages:

- long service life;

- ease of processing;

- affordable price;

- resistance to moisture, wear;

- homogeneous structure.

Examples of maple with a beautiful texture are the “sugar” and “bird’s eye” types.

Abacha (abashi, abash)

Abash has gained wide popularity in recent years for finishing and making furniture for baths and saunas.

This is the name of African oak. It differs from other breeds in a lot of advantages:

- The raw material tolerates temperature changes well.

- Due to its strength, it can withstand heavy weight loads.

- Looks beautiful.

- Lasts a long time.

- Does not rot, does not crack.

- When heated, abash emits a pleasant odor, which has a positive effect on the human respiratory system.

- Wood without knots. It is easy to handle. The surface is smooth.

- Even over time it does not lose its original appearance.

In the absence of high-quality ventilation in the steam room, the abash begins to darken in places. This is expensive material.

But benches made from budget alder or linden will look no worse and last a long time.

Floor installation

It is important to choose the right material so that it is not afraid of humidity and temperature changes. Natural aspen is perfect for this. In addition to excellent performance characteristics, it has a pleasant appearance and is easy to process.

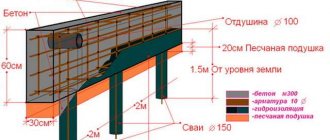

Installers assemble the underground according to the scheme presented below:

An alternative material for flooring is ceramic masonry. The tiles are easy to use, easy to clean and easy to maintain.

What to consider when choosing a heating device

Each type described above has characteristic advantages and disadvantages. Metal furnaces cool down quickly after stopping operation and require serious protective measures and fencing. Brick ones must be laid on a separate foundation. Electric furnaces are distinguished by the absence of a chimney and easy installation, however, they require a special approach and compliance with all precautions.

Choosing a device depends on individual preferences, the size of the room and the desired result. In any case, you can always consult a professional and ask for help with your choice.

Making shelves right

Previously, we talked about the design of a steam room in a bathhouse, and now we will look at how many levels there should be, their sizes, quantity and on what factors they depend. The best option is 3 shelves located at a distance of 30-40 cm from each other. But it is quite acceptable to limit ourselves to two. If the area of the room is small, to rationally use the space, you can make them retractable and add as needed.

When installing, the professional first determines the shape, and then assembles the frame at an angle or straight. Next, wooden panels are laid on the surface. There must be a gap of 1 cm between the panel boards. For their production, you need to use aspen or linden.

Steam room design ideas

In fact, almost all steam rooms look the same. All of them are made from natural wooden materials, perform the same functions and have similar internal contents.

The main difference between steam rooms consists of different positions of shelves, their configurations, types of lighting, parameters, design and design of the heater stove. Ideas for designing a steam room in a bathhouse are presented in the photo.

Only a steam room in a traditional log house can boast the most plausible design. This is a classic version of a Russian bathhouse, made of logs, without decoration, with rough benches and a brick stove.

A wooden steam room with plank walls and sun loungers made of linden or cedar, with a brick or metal heater, has a more modern look. Stylish lighting, birch brooms, wooden buckets and ladles are used as decoration.

At your own discretion, you can arrange and fill the steam room with whatever you want. The decor of the log panel will give the steam room a modern, Art Nouveau style. LED lighting and original lamps will make the design more exotic.