To ensure that the gate is closed all the time and does not require any effort, a special device is installed. Once upon a time it was a simple spring. It was attached with one edge to the frame of the gate, and the other to a pillar or wall of the house. But if the spring was tight, you had to “slip” through the gate or hold it from behind with your hand. Otherwise, you could have gotten the sirloin. Today, such “conveniences” no longer suit anyone. To keep the entrance closed, install a door closer on the gate. This is still the same spring, but with additions that allow you to adjust the speed at which the gate will close.

Advantages of door closers

The benefit of this mechanism is obvious - the closer will smoothly close a gate or door left open in the bustle. When driving a vehicle into a fenced area, there is no need to return to the gate to close it; the gate closer will do its job perfectly.

The positive side is that it prevents the gate from hitting the frame

Currently, frost-resistant door closers are a very popular product. Manufacturers offer a wide range of this device on the market. They can be used for gates, as well as installed on doors and gates.

An example of a closer with increased resistance to weather conditions

Basic Standards

When choosing a gate closer, each buyer is faced with technical characteristics. They are indicated by letters and numbers in the product code. It is necessary to understand their designation in order to make the right purchase:

- Class, it is designated by numbers from 1 to 7. It means a corresponding increase in inertia. It is calculated quite easily using a table; all you need to know is the weight and width of the gate.

- Reliability, an indicator from 1 to 3 determines the reliability and stability of operation.

- Use in different climates. For low temperatures, you should choose closers with the letter M, it means stable operation in cold weather.

- Corrosion resistance. It is best to choose 1, this means that the risk of rust is minimized.

When choosing specific parameters, it is best to round up the figures. This means that there will be a certain margin, and the device will not have to work at the limit of its capabilities. Thanks to this, you can count on greater durability.

| Closer force in accordance with European Standards | Door width, mm. | Test door weight, kg. |

| EN1 | up to 750 | 20 |

| EN2 | 850 | 40 |

| EN3 | 950 | 60 |

| EN4 | 1100 | 80 |

| EN5 | 1250 | 100 |

| EN6 | 1400 | 120 |

| EN7 | 1600 | 160 |

Advantages and disadvantages

Pneumatic closers have the following advantages:

- operation does not depend on weather conditions;

- do not require additional effort;

- easy installation;

- a long period of open state does not carry the risk of the closer breaking;

- can withstand heavy loads, and therefore can be used for heavy gates.

The main disadvantages are the unaesthetic appearance and the importance of correct installation. Most often, problems with the operation of a pneumatic closer occur due to improper installation. In connection with this circumstance, it is recommended to entrust the installation to trusted specialists. Many people also include the cost of the device as a disadvantage. But the durability of its use completely pays for the price.

Closers perform the following functions:

- regulate the speed of door closing;

- attract the door in case of loose slamming;

- If necessary, fix the door in the open position.

Depending on the place of installation, closers are:

- overhead – mounted on sashes, frames or door hinges;

- floor - installed before installing the doors;

- hidden.

Door closers should be selected based on the following parameters:

- compliance with the weight of the door (gate, gate);

- frost resistance (relevant for outdoor mechanisms);

- functioning resource;

- warranty service.

Installation nuances

Even before purchasing a door closer, you need to find out the main installation nuances. In most cases, you can easily handle this mechanism with your own hands. It is necessary to prepare tools and fasteners. In most cases, self-tapping screws and a screwdriver will be enough.

The main point is careful preparation for installation. You should choose the right size door closer, focusing on the weight and area of the gate leaf, then take measurements and mark its future location. It depends on the type of mechanism. For spring ones, the best place will be in the middle part of the canvas, and for hydraulic and pneumatic ones - in the top. Additionally, you need to focus on the angle at which the model will allow you to open the gate; it can be from 90 to 180 degrees. Then it will be enough to just secure two parts separately, one of which will be on the support, and the second on the canvas itself, after which you can connect both parts and begin operation.

Among modern door closer models, everyone can choose exactly the one that suits them in all respects.

Device installation

If you decide to install a pneumatic door closer yourself, follow the recommendations below.

- Choose a device that matches the weight and dimensions of your door and buy it.

- Select the type of installation.

- Based on the installation diagram, mark the fastening points.

- Drill holes of the required depth in the required places on the jamb and door leaf.

- Attach the mechanism with self-tapping screws.

- Connect the lever parts with the screw provided in the kit.

- Adjust the length of the lever: its position must be perpendicular to the closed door.

Next, you should adjust the closer mechanism, in particular, the speed and power of closing the door. For this purpose, the device has two adjusting screws.

Diagram and video of proper installation

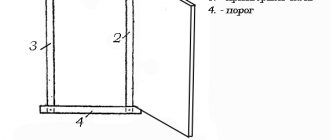

Let us describe the process of installing the top closer. All stages are clearly presented in the subtitle picture:

- Select the door opening angle according to the dimensions from the instructions, mark four holes in the door or jamb for the closer body and two holes for the mounting shoe. Drill the holes.

- Fix the closer body to the door or jamb with four screws or screws (on a metal surface) so that the adjustment screws are on the hinge side.

- Remove the threaded rod and mounting shoe from the main arm and install it on the jamb or door.

- Install the main lever on the rotary axis of the closer and secure it with screw No. 1 .

- When adjusting the length of the rod , make sure that it is installed perpendicular to the door when connecting to the main lever and secure them with the No. 2 .

- Place the decorative cap on the opposite part of the rotary axis of the closer.

Principle of operation

Today there are many samples on the market that have fundamental differences in their design, but the principle of operation of any of them is the same.

When opening the gate, the applied force is transferred to the mechanism of the device. The most common mechanism has a metal spring and piston. It moves along the wicket, the spring is compressed, and the created pressure generates energy directed back to the original movement of the mechanism.

Door mechanism design

When the opening force ceases to act, the energy of the compressed spring begins to return the piston, and therefore the entire gate, to its original position. Due to the fact that the cylinder with the piston contains compressed air and oil, the gate moves smoothly and evenly when closing. There are models with the ability to adjust the piston stroke, which allows you to adjust the speed of closing the gate.

Speed control

Features of choice

- The choice of door closer is made based on the dimensions and weight of the door. The larger of these parameters is taken as the basis. There are 7 classes of closers. For massive and wide canvases, a powerful, high-class device is required. The simplest mechanisms can withstand a weight of 20 kg and are suitable for sashes up to 750 mm wide. Class 7 products are designed for doors weighing 160 kg.

- An important factor is the operating temperature. Hydraulic and hydromechanical devices are used for indoor installation. A special frost-resistant mechanism is required for street and entrance doors.

- If the door height is up to 2.5 m and there is additional load, for example, from strong wind, you should choose closers for a metal door of a larger size and power.

- The manufacturer's marking on the box indicates the maximum loads, but the closer can also be installed on lighter door structures.

- It is worth paying attention to the presence of additional functions that will make operation comfortable. These include braking and closing delay, range of slamming speed control, the ability to fix an open door, maximum swing angle of the leaf, wind brake, coordination of the operation of the leaves for double doors.

- Each product has its own resource, which is calculated by the number of complete closing-opening cycles. This parameter is related to the intensity of use of the door and the level of traffic in the room. For a public institution and a private home, the load is noticeably different.

- A vandalism-resistant model should be installed on external doors, for example, at the entrance or at the gate.

- The operating temperature range depends on the category of oil used. Moreover, one model can be produced with different oils depending on the country of delivery.

- The selected door closer size must comply with the manufacturer's recommendations.

Mechanism repair

In the event of a major breakdown of a mechanism, it is more profitable to purchase a new one than to bother with repairing a damaged one. These devices usually do not allow for replacement of parts. But if the problem is minor, you may be able to fix it yourself.

In winter, the housing may be damaged. In this situation, first assess the extent of the breakdown. If the crack is small, seal it with sealant. If the damage is extensive, repair is impossible; only replacement will help. Installation and maintenance of the door closer does not require much experience of a technician.

When adjustment is necessary

In most cases, setting up and adjusting the closer can be done with your own hands. The initial adjustment of the mechanism is performed immediately after installation. Preventative inspections and elimination of minor faults are carried out 2-3 times a year.

How to adjust the door closer? The condition of the lubricating fluid is affected by the state of the environment. Structural parts are subject to constant thermal expansion and contraction. In winter, the oil thickens and the door speed slows down. In summer, the structure heats up and the doors close very quickly. Therefore, the main procedures are carried out during the changing seasons.

Adjustments are made during scheduled maintenance. During the setup process, the optimal parameters are established. With constant temperature fluctuations, the closers are adjusted more often - once every three to four months.

Significant temperature fluctuations destroy the mechanism, causing breakdowns and damage. At the first sign of malfunction, the device is checked. Oil leaks are eliminated and worn parts are replaced.

Important! In case of complex malfunctions, knowing how the closer is adjusted will not help solve the problem. In such cases, the device is returned for repair or replaced with a new one.

The frequency of scheduled maintenance is influenced by the service life of the equipment (old equipment breaks down more often), frequency of use, and the average value of constant loads.

Varieties

Currently, consumers are increasingly buying door closers. Although the operating principle of all mechanisms is the same, today there are many varieties of these devices.

Depending on the type, their price can vary significantly. In order for the buyer to choose the most suitable model, it will be useful to become familiar with their main types.

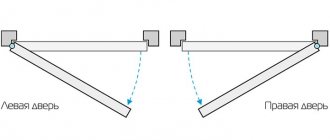

Installation on the door depending on the opening direction

All closers are usually divided into three types:

- Hydraulic.

- Pneumatic.

- Electrical.

We invite you to familiarize yourself with: Do-it-yourself metal tile repair

Hydraulic

Closers with a hydraulic mechanism are the most common devices today. Their work is based on the movement of the piston and the compression of the spring. They consist of two parts, one for the gate, the other for its frame. This type can work with any variety of hinges.

Diagram of the hydraulic mechanism

To install a hydraulic closer, no special knowledge or skills are required; it can be done by one person without assistance.

Pneumatic

One of the newest types of design is an outdoor frost-resistant door closer with a pneumatic mechanism.

Its operating principle is also based on the movement of the piston in the cylinder, but such models do not have a spring. When the valves open, air is compressed on one side of the piston, and a vacuum is formed on the other. The compressed air pressure returns the open gate to its original position.

The principle of operation of a device with pneumatics

Door closers of this design have many advantages:

- They remain operational in a wide temperature range, as a rule, from −50°C to 50°C, with ice and heavy snow cover.

- The working components of the device are made of high-quality stainless steel, so the device is not susceptible to corrosion.

- The sealing elements are made of wear-resistant polyurethane, which minimizes the effects of friction and allows the device to remain mobile for a long time without maintenance.

- They have a wide opening angle of up to 160°, making them the most convenient in places of construction, repairs, and large groups of people.

- Such door closers can be installed regardless of the side of the gate opening.

- The device can be placed in a vertical or horizontal position. That is why they can be used not only to equip gates, doors, gates, but also furniture in production.

The idea of installing pneumatics on a gate

Electrical

Electric closers are one of the most complex in their design and installation method. Their design can be without a top crossbar. The complexity of this design is due to the presence of functions that are not found in any other types of door closers.

Electrical mechanism installation option

These functions include:

- Safety of use (the closer will not close the gate if there is a small child or animal in the opening).

- Smooth not only closing, but also opening of the gate.

- Maximum quiet operation.

- Automatic opening and closing using a separate button or control panel.

- The presence of a large number of options and settings in itself allows you to select the device that best suits the client’s needs.

- Possibility of temporarily disabling the door closer functions without dismantling the device itself.

- Aesthetic appearance.

Schematic representation of an electric gate closer

Find out what options there are by type of installation

- Top or overhead . A common option. The housing is mounted on the inside of the door from above, and the lever or rod is attached to the horizontal strip of the jamb.

- Floor-standing . Installed in a recess on the floor. Almost invisible. Designed mainly for thin glass doors.

- Framed or hidden . They are placed inside the door structure, where they are inserted during the production process.

There is also a classification according to the method of work :

- Mechanical.

- Electrical.

You should choose spare parts from the same manufacturers that manufactured the main mechanism. Common accessory elements include linkage rods, mounting plates, retainers open ( FOP ) and sliding channels.

Adviсe

It is better to fix the closer on the street door from the inside. This will protect it from the negative effects of natural factors. If such an installation is not possible, purchase reinforced frost-resistant models and install them in a place convenient for you.

If the door opens towards itself, the device is mounted in the upper part of the sash on the side of the door hinges. If “from yourself,” then the closer lever is attached to the sash, and the mechanism itself is attached to the jamb.

You will learn more about pneumatic closers in the following video.

The device and functions of a door closer for closing doors

A gear and rack based closer consists of the following elements:

- Lever rod . Provides coupling between the mechanism drive and the door.

- Spring block . It contains a spring that serves as the main “engine”.

- Hydraulic cylinder . A sealed cavity filled with working fluid. Responsible for the speed and force of closing the door.

- Gear drive . Charges the spring through a system of gears and moves the linkage in the opposite direction.

- Adjustment screws . Necessary for adjusting device function parameters.

Spring models do not have a hydraulic cylinder. This is outdated technology. The cam mechanisms are complemented by a shaft with a heart-shaped cam, which acts as a closing speed regulator.

In addition to products with the main function of smoothly closing doors, there are accessories that can solve auxiliary tasks:

- Damping . Balancing the door opening speed if it is affected by a sharp gust of wind or human muscle force.

- Fixing the open position . Secures an open door to allow cargo to be carried through the entrance area.

- Closing delay . Allows the closer to operate only after some time, usually 30 seconds.

- Dokhlop . Acceleration or deceleration of the door movement approximately 15 ° before “meeting” the lock in the box.

There are mechanisms on the market without linkage . For them, the role of a connector is performed by a bar sliding in a profiled channel. The modification is more aesthetically pleasing and resistant to vandals: it is difficult to break.

What to pay special attention to when buying a door closer

Choosing a street closer for a gate or wicket is not the most difficult task, but you should still take into account some features. Otherwise, the purchased device may not work properly or may break after working for a very short period of time.

Installation and configuration instructions

The main parameters that deserve attention are:

- power is the main parameter of the closer. A device with low power will fail very quickly if it is attached to a large, massive gate. If a powerful closer ends up on a light, small gate, then there is a high probability of it breaking, the hinges coming off, and the locking device failing;

- the presence of a latch is necessary in order to leave the gate open for a while. This is required when furniture and other things are brought through the passage, and a large number of people pass through. In this case, the absence of a latch will lead to inconvenience and increased wear of the closer mechanism.

Methods of placing mechanisms

Some owners, instead of a latch, place supports from improvised means under the gate. In this case, there is a risk of creating excessive stress in the cylinder, which will also shorten the life of the closer.

Adjusting the door closer during operation

A device that is installed and adjusted correctly guarantees flawless operation for a long time. However, the oil inside the mechanism reacts differently to changing weather conditions, which means the spring will compress differently. The characteristics of the system change after cold weather and manifest themselves differently in the summer heat. These are standard indicators, and you can adjust the door closer yourself without calling a specialist. The main thing is to do it in time and take into account some nuances:

- study the door closer instructions in detail, carefully following each step described;

- turn screw No. 1 counterclockwise ½ turn to adjust the reach;

- screw No. 2, turned ¼ turn clockwise, determines the opening speed;

- screw No. 3 (side) determines the force of movement of the sash.

Reasons for adjustment

As a result of prolonged use, any mechanism loses its original characteristics. Likewise, the closer, deviating from the settings, can close the sash very slowly or with a roar. Repairing the closer, carried out on time, and adjusting its mechanism will allow you to avoid more serious problems in the future. The reasons for adjusting the operation of the device may be the following events.

- Preventative checks of the entire system must be performed 1-2 times a year.

- In anticipation of low winter or high summer temperatures, prevention is mandatory. When temperatures fall or rise, the oil filler changes its properties, and the movement of the canvas slows down in winter. In the summer heat, the filler composition, on the contrary, liquefies and causes acceleration and impacts of the sash against the frame. Problems can be avoided by timely adjustment of the mechanism.

- When malfunctions occur, adjustments to the operation of the mechanism are especially necessary. If malfunctions are noticed, the damage should be inspected and repaired.

Tips: how to loosen a door closer

When users do not like the installed settings, the operation of the device is adjusted further. The closer can be adjusted using screws. If the door moves with difficulty, and considerable effort must be made, the screws should be loosened, and the door will work easily and smoothly. Fully loosening the screw allows you to keep the blade open when necessary.

Requirements for operation

Along with selecting the right model, an important factor influencing the life of the device is its correct operation. Increased attention should be paid to the correct installation of the gate. The gate closer must be proportional to the weight and dimensions of the door.

To avoid frequent breakdowns, it is prohibited:

- Open and close gates unnecessarily many times;

- Apply force to the gate to close it faster;

- Use improvised objects instead of a retainer.

Correct hinge connection plays a decisive role in proper operation

Here are all the most basic requirements, the fulfillment of which will allow the device to serve the period specified by the manufacturer.

Tags: closer, gate, pneumatic, hand, own

« Previous entry

Limitations in adjusting the closer

In order not to damage the mechanism of the device, it is necessary to observe some restrictions:

- You cannot turn the screw more than two turns from the starting point, or oil loss will occur, all this will negatively affect the performance of the mechanism;

- During installation, distortions should not be allowed, otherwise the product will quickly become unusable;

- When the door is not fully open, you should not prop it up with foreign objects; you must use a special function;

- It is not allowed to place heavy objects on the door leaf, otherwise this may lead to a skew of the constructed diagonal.

Compliance with these rules will allow you to regulate the closer in a quality and timely manner, extending its service life using all its functionality.

Kinds

In the modern door hardware market, door closers are presented in a wide range. Models are classified according to a number of criteria, the most determining of which is the method of transmitting torque. Based on this feature, there are two types of devices.

Lever Models

In such devices, torque is transmitted by a folding lever. This is the most common and budget type of mechanism, providing reliable and durable articulated rods. The only drawback of knee devices is the low level of protection against vandals and not a very aesthetic appearance, and if the latter point can still be accepted, then the likelihood of intentional damage to the device is an acute problem and sometimes forces one to abandon the use of these simple and proven mechanisms in favor of more secure models .

With sliding channel

This type of device is less susceptible to attacks by vandals, which allows it to be used more often in public places and various types of institutions. The transmission of force in such devices is carried out by means of a sliding rod, the lever of which moves along the channel. Due to the absence of angular structures, the models are more aesthetically pleasing and, unlike the previous type, do not have vulnerable protruding elements. In addition, the channel can be easily equipped with an elastic limiter that controls the opening of the door leaf.

An equally important feature by which closers are divided is the location of their installation. According to this criterion, four categories of closers are distinguished.

Upper

Devices with this method of placement belong to the largest group and are widely used in residential premises, public buildings and production workshops. Installation of the working housing is carried out on the door itself or above it and depends on the design of the door system and the model of the device. The devices can have both a gear and a cam design, and operate on both a sliding and lever rod. The advantages of overhead door closers are their wide consumer availability and simple installation. The disadvantages include the need to make holes in the door or wall, visual clutter of the door leaf and the risk of ruining the design of the room.

Floor-standing

Such models are completely invisible, which is due to the absence of levers that force the axis to move. In fact, the door leaf is located directly on the axis itself, which, in turn, imposes certain restrictions on the scope of their use: such closers can be installed on doors whose weight does not exceed 300 kg. The devices are widely used on plastic and wooden internal doors installed in cinemas and shopping centers.

Hidden

These devices are intended for installation on door systems, where the visual presence of the device should be as minimal as possible. Hidden models, in turn, are divided into two types: models with sliding rods and closing loops. The first ones in their design are not much different from their overhead counterparts, but they are miniature in size and are located in a door niche or in a door frame striker. The advantages of built-in devices include high strength of the mechanism and long service life. Among the disadvantages are the need to violate the integrity of the door and frame during installation, as well as the impossibility of operation in door systems that are too heavy and oversized.

Closer hinges are made in the form of a miniature device, the entire mechanism of which is located inside the door hinge body. The main advantage of the devices is that there is no need to chisel or drill out the door, which allows the models to be widely used on glass sheets. The closer is mounted according to the principle of a regular door hinge and is absolutely invisible during visual inspection. The disadvantages include the inability to use on heavy dimensional systems, as well as the requirement to comply with installation rules.

The door must be hung using a building level, otherwise it will be difficult for the door closer to operate the skewed structure. Closer hinges are widely used on indoor doors and have proven themselves to be a very convenient device in homes where there are small children. In addition, door closers are well suited for doors equipped with magnetic and electric locks, due to the absence of the need to overcome the resistance of the latch and seal.

Specialized devices

This category of door closers includes models for sliding and sliding interior systems, as well as sliding doors. In their design, the devices resemble rod-type furniture closers, but differ from them in size and the initial force created. Installation of devices can be done either in a box or in a canvas, and consists of forming holes of the required diameter at the ends of the box or door and then placing the device in them.

Manufacturers and reviews

The ranking of door closer manufacturers is as follows: the German companies Dorma and Boda deservedly occupy the first and second places. Enterprises specialize in the production of models with sliding traction, which are very popular and are much better bought than knee models. Following the German companies are the Italian Cisa and Cobra, offering consumers traditional lever and hidden floor devices. Next comes the Korean KDC, which uses German components and produces anti-corrosion models for outdoor installation, and the Finnish Abloy closes the top six.

Products from this company are equipped with independent valves that ensure smooth operation and ensure tight closure. In addition, models from Finland are equipped with a very precise control system, which responds very responsively to the slightest change in settings. Buyers consider the only drawback of foreign models to be quite high cost. Thus, the price of especially powerful models designed to control heavy steel doors can reach 38 thousand rubles.

Russian-made models are also popular and in demand on the domestic market. Devices from well-known and Nikiret are in no way inferior to imported analogues in terms of their performance characteristics, have many positive reviews and are sold well not only in Russia, but also in neighboring countries. Consumers note the high adaptability of the devices to Siberian frosts and the ability to use the devices in almost all regions of the country. In addition, Russian door closers are much cheaper than their European counterparts, which makes them even more popular and in demand.

Operating principle

If you are interested in how closers work, you should know that the design is based on a spring, but auxiliary elements are also provided. It accumulates mechanical energy by contracting. When a person releases the sash, the spring straightens. In addition, front door closers operate smoothly. This possibility is provided thanks to the hydraulic system.

To ensure that the spring straightens smoothly, an oil shock absorber is used. The design includes a system of special valves, thanks to which oil flows from chamber to chamber. In this way, the speed of operation of the installed closer is regulated, and at the same time the speed of movement of the web. Due to a sufficient level of viscosity, the mechanism also ensures silent operation.

Internal structure

Device nodes:

- traction - connects the door and the door closer, with the help of this element the force that a person applies to the door when trying to open it is transmitted;

- rotary axis;

- a cylindrical piston connected to a spring - the unit is driven by a gear, which, in turn, depends on the position of the rotary axis;

- oil valves containing a viscous liquid, which ensures smooth movement of the structure;

- adjusting screw - allows you to set the spring compression power;

- a screw responsible for limiting the opening of the sash.

The operating principle of a door closer is based on the interaction of two main components: a piston with a spring and a valve system. The remaining elements are auxiliary in the circuit and help ensure correct adjustment of the mechanism. Screws are used to control the operation of the closer. Without these elements, the sash will close too slowly or, conversely, quickly, and will also create a noise effect. The design of the door closer, in particular the lever arm and the housing, can be different; on the basis of this, the design is divided into groups.

Upper

Another name is hinged or overhead. Installed on the top of the door frame. One part of the structure is attached to the frame, the other part is attached to the door leaf.

There are varieties in this class that differ in the method of transmitting force:

- Lever mechanism. The force of the compressed spring is transmitted to a system of two iron levers. This design is reliable. It has two drawbacks: it looks unattractive when closed due to protruding levers; the entire structure is not resistant to intentional breakdown.

- Parallel traction. The device is similar to the lever type, but the lever layout contains an additional bracket. In the closed position, the levers are parallel to the door leaf. The result is a design that is hardly noticeable.

- Sliding channel. The force is transmitted to a sliding rod, one end of which is rigidly fixed, and the other moves in a closed channel. This option has no protruding parts, which makes it unnoticeable and resistant to damage.

Floor-standing

They are attached to the floor and partially recessed into it. There are options that differ little from the upper models, only fixed at the bottom. But the most widespread are leverless designs with a lower loop attached to the axis of the closer. Floor-type mechanisms are usually installed for glass sashes that open in both directions. In rooms with increased aesthetic requirements, the floor option is indispensable.

Hidden

These are lever-type mechanisms with a body completely recessed inside the door leaf. Only the lever attached to the frame protrudes outward. Doors with a thickness of at least the size of the body being installed and having a cavity inside are suitable for their installation. They are low-power, therefore they are not able to cover heavy structures.

Features of operation and maintenance of door closers

Proper use and periodic maintenance will increase the service life of the mechanism. The appearance of foreign objects or defects in the door structure will interfere with the effective movement of the leaf, so it is necessary to remove unnecessary things from the path of opening the leaf. To prevent rapid wear and tear, it is prohibited to leave a door equipped with a closer installed in residential premises open for a long time.

Seasonal temperature changes affect the viscosity of the oil poured into the body of the closer, so it is necessary to adjust the mechanisms twice a year and lubricate the rotating and rubbing elements. A broken door closer cannot be repaired, so the device must be replaced. The breakdown is revealed by leaking oil, the cessation of holding the door, and the futility of attempts to correct the fault by adjustment.