In order to maintain optimal temperature conditions and steam generation in the bathhouse during health procedures, comprehensive insulation of the building should be ensured.

If the insulation of the ceiling in the bathhouse is done correctly, the consumption of fuel material will be reduced, the heating time of the premises will be reduced and the internal microclimate will be preserved. In addition, insulating the ceiling base will solve another serious problem - preventing the formation of condensation.

Rules for insulating the walls and gable of an attic for a bathhouse

- We attach waterproofing film to the walls.

- We install a wooden frame from bars in increments of 0.4-0.6 cm around the window niches.

- We install a base beam at the bottom.

- We place a heat insulator in the space between the sheathing beams.

- We fix the vapor barrier membrane with an overlap and carefully glue the joints.

- We fill the sheathing with thin slats. It not only secures the vapor and heat insulation layers, but also creates an air ventilation gap.

- We install finishing material. Sheets of fiberboard or plasterboard are often used.

How else can you insulate a steam room?

You can hem the ceiling with a 50 mm unedged board. Narrow boards are attached to it from the outside for support, which are fixed to the wood grouse. For further cladding, tongue-and-groove aspen boards are used. It is attached with some gaps to narrow support boards.

In the attic, a vapor barrier membrane is first laid, on top of which sawdust mixed with clay is poured in a layer of 3 cm. Next, a 15 cm layer of basalt wool, density 125, is laid, and then a polyethylene film for protection from the wind. After this, the entire surface is covered with subfloor boards.

For bathhouses with log floors, a slightly different approach is used. To line the ceiling, a special sheathing is placed on the inside of the bathhouse. From the attic side, glassine is first laid and 20 cm of sand is poured. The owners add additional layers at their own discretion.

A detailed study of the insulation features of the steam room and other rooms in the bathhouse will help the owners of such structures to do everything right. Then a bathhouse built with your own hands will delight you with warmth, comfort and good steam. The options we have described can be modified and added at your discretion. We hope everything works out for the best for you.

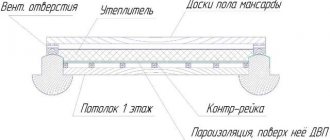

Insulation of a suspended ceiling

In order to insulate a suspended ceiling, you must perform the following steps:

- The boards are attached to the floor beams.

- Vapor barrier material in 2 layers is spread on the boards from the attic side. You can use roofing felt or glassine.

- Then the selected insulation is installed (read: “How to insulate the ceiling in a bathhouse correctly - do-it-yourself insulation options”).

- The insulation must be covered with waterproofing material. Polyethylene film is suitable for these purposes.

- The plank flooring is being laid. This will allow you to walk on the attic floor without damaging the insulation.

Types and properties of insulation

As the required temperature in the room increases, it becomes more difficult to construct a barrier to prevent heat loss. This problem can be solved by laying thermal insulation material in a multi-layer ceiling structure.

Thermal insulation allows you to eliminate the following types of heat leaks:

- heat loss through ceiling cracks;

- gradual movement of heat from heated objects to cold ones;

- warm air overcoming homogeneous barriers.

Mineral wool is a chaotically intertwined fiber; air voids are formed between them, which perform the function of retaining heat. This insulation on bathhouse ceilings is most often used. When wet, mineral wool loses its thermal insulation qualities. If the roof has insufficient protection against rainwater leaks, then it is recommended to lay waterproofing material on top of the insulation. There must be a thermal insulation gap between the layers of waterproofing and insulation.

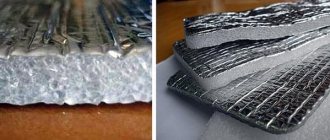

Also, the ceiling in the bathhouse can be insulated with foamed polypropylene. This material is very light and will not weigh down the ceiling structure. A material foiled on one side was developed especially for baths and saunas. In addition to the main function of insulation, it reflects the heat flow with the foil side. Acting on the principle of a mirror, this insulation material ensures faster heating of the steam room.

Expanded clay can also be used as insulation for the ceiling in a bathhouse. It is used in large baths. It is necessary to fill the expanded clay with a uniform layer equal to 30 cm. The material is relatively light, but, nevertheless, the weight of the ceiling structure will increase. This insulation material, like mineral wool, absorbs moisture well, so a waterproofing layer is also necessary.

Another option for insulating the ceiling in a bathhouse with your own hands is the so-called “folk” heat insulator.

In this case, insulation is carried out as follows:

- Soft clay is laid in a layer of 2 cm. It can be replaced with a mixture of chernozem and peat, wood shavings, which are filled with cement mortar, you can also mix clay with sawdust or sand.

- Sawdust or oak leaves are filled in (any other can be replaced).

- Dry soil is poured in a layer equal to 15 cm.

A bathhouse is a special place with high humidity and frequent temperature changes. Therefore, thermal insulation materials must have the following properties:

- resistance to moisture and temperature surges;

- resistance to mold;

- possibility of combination with finishing materials and floors;

- environmentally friendly, without evaporation of harmful compounds when the temperature rises;

- ability to retain heat;

- easy installation.

2 types: A - protection from condensation and wind from the outside; B - protects premises from emitted steam from the inside

Cheap for roof insulation. An earthen layer must be poured on top

Porous, clay material in the form of capsules of different densities. A wide layer is required for good insulation

Isolates moisture from the inside. Available in rolls, stapled to the entire ceiling

https://www.youtube.com/watch?v=xCCC_y1f810

Plates or rolls with foil coating on a fiberglass base

You can insulate the ceiling in a bathhouse inexpensively using sawdust, or purchase a higher-quality insulating agent.

The listed materials retain heat well in the room and at the same time regulate air exchange flows.

In saunas built with your own hands, there is usually an attic or attic space on top. This provides an additional layer of air and makes the room warmer. However, this will not be enough to keep the heat in the steam room. The ceiling of the bathhouse should be additionally insulated.

This is most conveniently done from inside the attic or attic. Insulation material is placed taking into account fire safety requirements

It is especially important to properly close the junction with the chimney

The distance between the pipe and the insulation must be at least 20 cm. To do this, a box of boards is built around it, and the inside is filled with fire-resistant material, such as expanded clay or mineral wool.

For any ceiling design, the insulating layer must be protected from moisture. For this purpose, a waterproofing film is used, as well as a membrane vapor barrier. This material allows steam to be removed from the insulation without letting moisture inside.

Why is insulation necessary?

Everyone knows from school physics that warm air rises. That is why the main amount of heat loss in a building occurs through the ceiling of the top floor or roof pie. When building a house, it is necessary to calculate not only based on the cost of materials, but also take into account further costs of operating a private house, which insulation will significantly reduce. So how to insulate an attic?

In order to properly insulate attic structures, you need to understand in which cases additional measures are required. When insulating with your own hands, all responsibility rests with the owner, so you need to carefully study the issue.

From inside or outside?

Different types of insulation for a brick bath serve different purposes. Thus, thermal insulation on the inside can significantly reduce fuel costs, helping to retain heat inside the room and eliminating the need to warm up the load-bearing structures of the building.

Insulation must be done not only from the walls, but also from the ceiling and floor. The floor is directly connected to the foundation, which has a huge heat capacity, and if you do not separate the inside of the bathhouse and the base using thermal insulating material, it will be very difficult to achieve a stable temperature in the steam room.

Hot air quickly rises to the ceiling, transferring energy. If the roof is not thermally insulated, then when it comes into contact with the roof and ceilings, it will cool down in a short time, and the heat obtained by burning fuel will be used to heat the external environment. Up to half of all thermal energy generated by heating equipment can be lost through the roof.

To ensure that a high temperature is maintained inside the building, it is necessary to create a closed thermal circuit, which will have to include walls, floor, and roof. This is the only way to significantly reduce energy leaks and reduce fuel costs for heating the bath.

If the creation of internal thermal insulation is aimed at increasing the efficiency of heat consumption, then insulating a brick bathhouse from the outside is necessary to protect the load-bearing structures from temperature changes and move the dew point outward, removing it from the thickness of the walls. This helps to increase the durability of materials by preventing steam condensation inside them, as well as freezing.

Doing double insulation is quite expensive, and given that the bathhouse will heat up only from time to time and the temperature inside, for most of the period of operation of the structure, will coincide with the temperature outside, shifting the dew point will not have a noticeable effect. Therefore, in order to save money, you can insulate the bathhouse only from the inside.

Specifics of internal and external insulation

In practice, it is easiest to insulate ceilings from the outside. It is also more effective than from the inside. Remember that internal insulation “steals” the height of the ceilings. For example, if you want to use mineral wool, then you will need at least 15 cm of space for sheathing, insulation and sheathing. If you use foam boards, you will only need 5 cm, but they can also play a significant role.

Internal insulation shifts the dew point. This means that condensation will form inside the room and settle on walls and other surfaces

And the last argument in favor of external insulation is that there are no problems with thermal insulation of the junctions of walls and ceilings. This is where mold can appear due to constant moisture condensation.

Details about external insulation

Such insulation can be called external only conditionally, since the insulation is located inside the attic. This option optimally solves the problem of heat loss. In this case, the materials that make up the insulation system are not subject to the aggressive effects of steam and hot air, and the danger of condensation formation both on the surface of the ceiling and between the layers of the thermal insulation system is eliminated.

External insulation of the bathhouse ceiling is carried out from the attic side

Before you begin insulating the ceiling from the outside, thoroughly clean the attic floor of debris and dirt. Inspect the ceiling structure for damage, carry out repair work if necessary and replace damaged elements.

Be sure to treat the base surfaces with a primer and antiseptic (if necessary, mastic) to protect them from the effects of fungus, mold and harmful insects.

There are several ways to insulate a bath ceiling.

Wet method

Pre-prepare the attic floor, which is the outer side of the ceiling, and fill it with the so-called warm mixture. You can purchase it ready-made in specialized stores or prepare it yourself. The components included in this mixture provide high thermal insulation properties:

- expanded clay;

- foam chips;

- wood waste – sawdust, wood chips, shavings;

- slag.

Begin installing the insulation by treating the junction areas. These are gables, rafter system, chimney. After the mixture has hardened, cover it with a moisture-proof material - mastic, special liquid, film coating.

If you use membrane sheets, take care to protect them from mechanical damage.

This kind of work is very easy to do yourself, this is its advantage. The disadvantages include the fact that if it is necessary to repair the floors, it is very difficult to carry out dismantling work.

Dry method

This option is considered the simplest. You just need to cover the surface of the attic with any bulk materials: slag, vermiculite, expanded clay, wood waste. Using wood waste means that you need to carefully treat the chimney junction areas with materials that are resistant to moisture.

Sawdust and expanded clay can be poured directly onto the base of the floor or between joists previously laid on the surface. The joists are needed to make it easier to later plan the laying of sheet material on top if you plan to lay it.

- The advantages of this method are its simplicity, low cost and the possibility of reusing the material. If the sawdust settles during operation, you can add expanded clay or any other “bulk”.

- Disadvantages: replenishment of material may be required very often. In addition, when repair work is required, you will have to try to clean the area to the desired condition.

Using this method, you can also insulate the bathhouse ceiling with mineral wool in slabs or rolls. If you use glass wool for insulation, then keep in mind that you need to provide yourself with personal protective equipment: gloves, overalls, goggles and a respirator or mask. In addition, mineral wool can be left open, but glass wool must be closed.

Mixed option

By combining dry and wet technology for installing thermal insulation, you will significantly expand the possibilities of using building materials.

Pre-level the surface, cover it with mineral wool or fill it with expanded clay. Make a moisture-proof screed on top. It can also be mounted on soft or loose insulating material.

When using this material, do not skimp on reinforcement, even if you do not plan to use the attic later.

Modern technologies

In modern construction technologies, fundamentally new materials are used for work:

- ecowool;

- polyurethane foam spraying;

- ceramic thermal insulation;

- polymer thermal insulation.

Experts consider the last two materials to be insufficiently effective.

Insulation materials in liquid form can be very demanding in terms of storage conditions. If they, for example, freeze, their thermal insulation properties will be lost.

To insulate the ceiling of a bathhouse using polyurethane foam spraying, you will need special equipment, so it is quite difficult to cope with such work on your own. In addition, the resulting monolithic structure will be inconvenient if repair work and dismantling are required.

Types of attics

When carrying out work, everything depends on the method of using the under-roof space. There are three of them:

- Cold attic. Such an attic is not heated, and air does not flow into it from the premises. In this case, the room temperature is assumed to be +5 degrees Celsius.

- Warm attic. The presence of a warm attic is typical for multi-apartment residential buildings. All ventilation ducts with heated air open into the attic space, increasing the temperature in the room.

- Attic. The under-roof space becomes a full-fledged living space and is heated like all the rooms of the house. In this case, we recommend that you read the article on attic insulation.

In a wooden or any other private house, it is correct to use the first or third option.

This is how you can transform your attic, turning it into a residential attic:

What materials should not be used

A bathhouse is a building with a specific purpose. The aggressive environment will not allow the use of any material for cladding. Cladding boards and panels made from pressed wood waste are not suitable for every room. The slightest moisture causes them to become deformed. Combustible materials cannot be used as insulation. Polystyrene foam and expanded polystyrene are only suitable for insulating the floor of a dressing room or washing room, but it is advisable to fill it with a concrete screed.

PET film and roofing felt are not used when lining the bathhouse. The material can be laid instead of waterproofing the ceiling on the side of the cold attic. However, it is better to cover the area above the steam room with a heat-resistant membrane.

Wooden lining that shows signs of mold should not be used for cladding. In a humid environment, the fungus will quickly spread throughout all structural elements. An unpleasant smell of rot will appear inside the bathhouse. The ceiling will quickly collapse.

With a cold roof or with an attic - what's the difference?

An attic is a floor in the attic space, i.e. the premises in use have an insulated roof and an existing floor, so it is more convenient to carry out repairs or installation of insufficient insulation from inside the bathhouse. And if the ceiling has a cold roof, then it is more convenient to install the heat-insulating “pie” from the outside, i.e. from the attic side.

If there is an attic floor, there is a problem with the penetrating temperature threshold from the steam room, from where a large amount of steam, warm and hot air rises and, accordingly, if it is not properly disposed of, it will accumulate in the attic space. Therefore, in order to insulate the ceiling in a bathhouse with a cold roof, you should carefully calculate the thickness of the ceiling insulation taking into account the loads and take care of better vapor and waterproofing.

There is an opinion that it is not necessary to insulate the ceiling in a bathhouse with an attic, but increasing the thermal insulation characteristics in it is more necessary than in an uninsulated attic space, where the heat penetrating outside does not encounter serious obstacles on its way.

The technology of the insulation process, the selection of thermal insulation material between the attic floor and the cold ceiling has few differences.

Vapor barrier

Is it possible to do without a vapor barrier in a bathhouse?

Of course not, if the tree is pathetic. If you don’t tend to spend money on wind and rot and your bathhouse is expensive, ceiling insulation and vapor barrier are something you can’t do without. Another thing is that there is a lot of debate about whether to use foil as a vapor barrier. But this is already a matter of faith. In fact, those who cope with similar work themselves can find their own answer - by steaming with and without foil. By the way, its advantages include high heat resistance, which means that if you install something else for vapor protection, then it will be with a temperature range corresponding to a specific bathhouse - Russian or Finnish. Find out more about foil and foil insulation.

What is an attic

This concept came to us from France, where back in 1630 in Paris, Monsieur Mansard initiated the use of attic space for residential and economic purposes. Obviously, there were such attempts before him, but this movement became widespread thanks to him, and the Parisian municipal authorities had a hand in this, since at that time there was a floor tax on property owners, and no money was taken from attics at all, like this The cunning Parisians gladly took advantage of the gap in the legislation.

Initially, the arrangement of the under-roof space was minimal, and the attic was intended to accommodate ordinary guests, and somewhat later, with the beginning of the era of industrialization and urbanization, to accommodate the low-skilled working class.

Today, regulatory documentation defines an attic as: “a floor in the attic space, the facade of which is completely or partially formed by the surface or surfaces of a sloping, broken or curved roof.”

For greater clarity, we will display the types of attic structures in the form of a table:

| Silhouette shape | Design features |

| Triangular | Has isosceles sides in the projection of the roof slope |

| Broken | The roof projection, in this case, has a steep slope in the lower part within 50 - 70 degrees, and a gentle slope in the upper part, with a slope of 15 to 30 degrees |

| Symmetric | Located across the entire width of the building |

| Asymmetrical | Designed on one side of its longitudinal axis |

Features of the arrangement of vapor barrier and waterproofing layers

The presence of a vapor barrier layer is not a whim, but a real necessity. Especially when it comes to rooms such as a bathhouse, where hot air is an integral part of using the room for its intended purpose. Rising in the form of steam, moisture can have a destructive effect on the insulation and contribute to the formation of mold and mildew on the wooden elements of the bathhouse frame.

Scheme of insulation and insulation of a bathhouse roof

In order to avoid problems that may arise as a result of moisture accumulation on the ceiling and walls, special films and coating materials are used, for example, anti-condensation membranes. When choosing a suitable material, it is advisable to purchase one that has a foil layer.

Helpful advice! During the installation of a vapor barrier film, it is very important to pay attention to its integrity. It is necessary to prevent the occurrence of gaps, as this will greatly affect the technical characteristics of the coating.

To ensure waterproofing, special films are used, which can be purchased at hardware stores. Sometimes the most ordinary polyethylene of sufficient density or cheap roofing felt is used.

To protect the bath frame from moisture, it is recommended to use a waterproofing membrane, which can be mounted in contact with the insulation without losing its properties

Insulation of the bathhouse ceiling with polypropylene foam

Foamed polypropylene, also called penofol, or foamed polyethylene - all these types of insulation materials are similar in structure, and they are installed in a similar way. The thermal insulators under consideration are very easy to install, but their thermal insulation performance is often insufficient. Because of this feature, polypropylene foam and similar materials are best used in combination with other types of insulation, for example, mineral wool.

Scheme of insulating the ceiling in a bathhouse with foamed polypropylene

- First of all, the surface to be insulated must be thoroughly cleaned of dust and dirt, and also free from existing irregularities. Then the base is coated with a primer, which promotes better adhesion of the materials to each other. After this, sheets of thermal insulation material are fixed to the surface. The most convenient method of fastening is to use a specific adhesive composition for penofol. The method for preparing the adhesive mixture may vary depending on the manufacturer; as a rule, it is indicated on the product label. The joints are sealed using metallized tape.

- The sheathing frame is mounted on the first insulating layer. The thickness of its slats should correspond to the thickness of the thermal insulation layer. The width of the insulation is the installation step. It is attached to anchors or self-tapping screws, which are selected according to the base material.

- The space between the slats is filled with a second layer of heat-insulating material. Mineral wool may be an ideal choice. Its slabs need to be laid flat in the cells of the sheathing; no additional fastening is required. It will be enough to secure the sheathing over this layer. The insulation needs protection against steam penetration. Vapor barrier sheets must be laid with an obligatory overlap of at least 10 centimeters both on the walls and on adjacent sheets, with the obligatory gluing of joints with tape for construction. You can secure the vapor barrier layer to the sheathing slats using a construction stapler with special staples or using small nails.

- The final stage is covering the ceiling with finishing material. For a bathhouse, OSB sheets or wooden lining are most often used. Insulation only with expanded polystyrene is justified only in regions with mild winters, where there is almost no frost. In other cases, it is advisable to use a combination of thermal insulation materials.

How it's done

If the installation of a ceiling in a bathhouse with a cold attic starts from scratch, that is, preliminary dismantling of old structures is not required, then the order of work will look like this:

- A vapor barrier film is attached to the load-bearing beams on the inside. This is possible with a hemmed ceiling construction, when the outer covering is hemmed from the inside of the building. With decked ceilings, the membrane is attached to the wooden deck on the attic side.

- Next, all joints of the film are taped with construction tape, even if it is overlapped.

- The next stage is assembling the sheathing from the inside of the bathhouse. This will create a ventilation gap and protect the film from damage. In deck structures this stage is skipped.

- Insulation is being installed. It should fit tightly to the membrane film. If the ceiling is suspended, then the heat insulator is placed between the joists or beams. In the case of flat ceilings, you will have to assemble a kind of lattice from boards equal in thickness to the layer of heat insulation being laid. Otherwise, it will be impossible to walk on the thermal insulation layer later.

- A layer of waterproofing film is attached on top of the laid insulation, all joints of which are also taped.

- The last stage of assembling the structure will be laying the flooring on the attic side or ladders on which you can walk.

The interior decoration of a bath involves the creation of a decorative covering attached to the sheathing inside the premises. Everyone is free to choose the material that suits them, and therefore there is no point in considering this point in detail - all coatings have their own characteristics and are installed differently.

Insulation of attic walls

Laying thermal insulation on main walls from the inside of the house is not recommended, but is not prohibited. If external insulation cannot be carried out for objective reasons, then the internal thermal insulation must be covered from the side of the room with a reliable and continuous layer of vapor barrier.

The second option for vertical “cold” enclosing surfaces of the attic is frame walls on studs. Structurally, they do not differ from the external walls of a frame house, except that they do not need external finishing, since the roof protects the cladding from the effects of precipitation, wind and solar ultraviolet radiation.

According to the definition of SP 23-101-2004, these are single-layer walls, which are thin-sheet cladding on a wooden frame with insulation in the middle. For such walls, the dew point is located inside the insulation, so a vapor barrier is required on the inner surface of the heat-insulating layer, and the outer fence must be vapor-permeable and allow moisture to evaporate.

Multilayer construction

Properly executed insulation technology consists of several layers and is a so-called insulation pie, where the materials are arranged in the following order:

- waterproofing (membrane film);

- basalt insulation;

- protective foil.

The thickness of the thermal insulation layer averages from 20 centimeters and depends on the type of roof (presence of an attic), the functional purpose of the room and the climate in the region in which the building is erected.

As a rule, in a steam room these parameters are increased and two layers of membrane film are laid in front of the insulation sheets, which will increase the concentration of steam inside the bath.

Is the ceiling different in a Russian bathhouse and a sauna?

If you are not a big fan of tradition, ready to fork out money in order to make a kind of flattened dome or tent in the steam room - a form that is most suitable for preserving the properties of a good steam cake - then we can say that the ceiling in a Russian bath can be exactly the same like in a sauna.

However, one circumstance is still worth keeping in mind - this is the excessive (compared to Finnish) humidity of a Russian bath. By feeding water into a closed heater, you force it to evaporate in the form of superheated steam, which immediately rises up

Therefore, in a Russian bath, more attention should be paid to protecting the material of the finished ceiling itself and the layers following it from the action of this steam

In particular, you can use oil or oil wax impregnation, which will protect the wood from moisture penetration. And don’t forget about high-quality vapor barrier, which itself should be located at some distance from the finish, so as not only to delay the passage of moisture, but also to be able to evaporate it. This is achieved due to the thickness of the sheathing slats.

The ventilation in the sauna should be so well thought out, and the humidity there is no more than 15%, so you no longer have to worry about dampening the ceiling and ceiling. It would be good, however, if the ventilation in the Russian steam room was also at the same level. So that everything dries quickly after the procedures. But we have a whole section about ventilation, we recommend you take a look at it.

Natural insulation for baths

The features of these materials lie, first of all, in their environmental friendliness and ability to “breathe”. In past times, Russian baths were insulated exclusively with the help of natural components. But don’t think too much, this is an easy and quick answer to the question of which insulation is best to insulate a bathhouse. Natural thermal insulation has both positive and negative characteristics.

Advantages

Thermal insulation products of natural origin have the following advantages:

- environmental cleanliness;

- harmless to human health;

- long service life;

- low thermal conductivity.

Flaws

Reference: the main disadvantages of natural materials include their properties acquired due to organic origin.

They are:

- flammability. Almost all natural materials burn well. To increase fire resistance, special substances can be added to the composition, but in this case the material loses its environmental properties;

- allergenicity. Some types of thermal insulators can cause allergies;

- gyroscopicity. Most natural materials have a high moisture absorption capacity. This can cause the material to rot if it gets wet.

- possibility of damage by rodents and insects.

Which ones are used to build baths?

Natural materials have long been used as inter-crown insulation for baths. Moss, tow, felt, and hemp were laid between the logs. Red moss, used for internal caulking, is well suited for a timber structure. Among the modern options used for inter-crown insulation, jute fibers can be distinguished, which are also devoid of any “chemicals”.

Attic insulation technology

Any cold attic of a private house is insulated in 2 stages:

- Stage 1: arrangement of the ceiling and floor of the room.

- Stage 2: insulation of the rafter system.

How to insulate a ceiling along beams

We will consider insulation with mineral wool, but these instructions are also suitable for bulk insulation, only the thickness of the backfill is approximately 2 times greater.

- STEP 1. The base of the ceiling of the lower room is hemmed first, it is also the subfloor of the attic.

- STEP 2. A layer of vapor barrier is laid on the beams and subfloor. The membrane rolls are rolled out across the beams and overlapped. The canvas is stapled, and the joints can be taped with double-sided tape.

- STEP 3. Mineral wool mats or slabs are laid in the space between the beams.

A ventilation gap of 50 mm is left between the insulation and the attic floor

- STEP 4. Lay another layer of vapor barrier on top. This membrane is nailed to the beams with a counter-batten. The vapor barrier should sag slightly between the beams.

- STEP 5. A floorboard is placed onto the counter-batten. If you plan to install laminate, then instead of boards you can sew plywood or OSB with a thickness of 10 mm or more.

How to insulate a reinforced concrete floor

Theoretically, reinforced concrete slabs can also be insulated with mineral wool or bulk materials, but then you will have to put wooden blocks (joists) on the concrete and arrange the floor according to the beam scheme described above.

The technology consists of 5 stages:

- STEP 1. Putty the seams between the reinforced concrete slabs;

- STEP 2. Cover the concrete with Penetron waterproofing or something similar.

- STEP 3. Lay EPS in 1 or 2 layers.

- STEP 4. Lay technical polyethylene.

- STEP 5. If you plan to screed, then lay down the reinforcing mesh and pour the solution along the beacons. You can lay 2 layers of any durable board material spaced apart and fasten them together (OSB, plywood, DSP, etc.)

EPS can easily withstand reinforced or prefabricated screed

How to insulate an attic ceiling

In a private house, the ceiling of the attic is usually a rafter system. Insulating rafters is somewhat similar to insulating an attic floor along beams.

The differences are small, but they still exist:

- On top, across the rafters, a vapor-permeable windproof membrane is sewn.

- The wind protection is nailed to the rafters with a counter-batten (thickness from 50 mm).

- A sheathing or decking is nailed on top of the counter-batten under the final roofing covering.

- Insulation is inserted from below, between the rafters.

- A vapor barrier is placed on top of the insulation along the rafters; a ventilation gap is not needed here.

- Next comes the counter-batten and the base for finishing the attic.

In cold regions, the rafter system is insulated in 2 layers

Main types of attic roofs

- Cold - for their installation, a sheathing is stuffed onto the rafters, taking into account the roofing covering, roofing material is attached to it, insulation is carried out along the ceiling, laying thermal insulation on it, which is covered with a vapor barrier on the room side, and a waterproofing membrane on the attic side;

- insulated - for exploited under-roof spaces - attics, additional elements are added to the previous components: insulation, vapor barrier, waterproofing, counter-lattice - timber with a section of 40 x 40, 50 x 50, 60 x 60 mm, placed on the rafters along their length. A waterproofing material is laid on the beam, protecting the insulation and roof from external moisture, then the sheathing is laid on which the roofing covering is attached. The spaces between the rafters are filled with appropriate insulation, and from the attic side it is covered with a vapor barrier layer.

Types of bathhouse ceiling insulation:

- outside - more convenient to use, most effective for a ceiling located under an uninsulated roof, the insulation is laid out on the attic floor and covered with a rough or finished floor;

- from the inside – it prolongs the durability of the material, there are no temperature changes, but you will have to “steal” a few centimeters of the height of the bathhouse, a frame is mounted on the ceiling, after fixing the first layer of vapor barrier, and insulation is placed in it, then the vapor barrier is again and the ceiling covering is attached.

Insulation technology

In order for bath procedures to be comfortable, it is necessary to follow the bathhouse roof insulation technology:

- A vapor barrier layer is installed. To do this, you need to purchase special materials. The vapor barrier is attached between the beams. Foil tape is glued to the knocks.

- A sheathing is nailed on top of the vapor barrier. As a rule, the distance between the sheathing bars is 60 cm. However, the dimensions of the selected insulation should be taken into account.

- The insulation is laid or filled in, and there should be no free space left. The thickness of the layer depends on the climatic conditions of the area where the bathhouse is located. Thermal insulation characteristics are directly dependent on the thickness of the layer, that is, the thicker it is, the better the thermal insulation. But there is no need to make the layer excessively thick. In most cases, 15-20 cm is sufficient.

- The cracks should be filled with foam.

- Thermal film or polyethylene is spread over the thermal insulation. A waterproofing layer is required; if it is missing, the insulation will quickly become unusable. The film is fixed using a construction stapler.

- The ceiling is sheathed with finishing material. The best option is eurolining, but you can also use regular boards.

Here is a general plan of action for insulating the roof of a bathhouse. The insulation technology can be changed depending on the type of ceiling structure.

Finishing and roughing: materials

Let's briefly go over the materials that are suitable for finishing and rough ceilings in a bathhouse.

Lumber differs in wood species, grades (quality), and type. If these are boards, then they can be edged or unedged, the latter being the result of the initial cutting of the trunk, without trimming the ends.

Regarding varieties, just in case, we suggest not using conifers above the steam room, but in other rooms conifers are quite suitable.

Pine is practically the cheapest type of wood. And its characteristics are suitable for all parts of the ceiling - for beams, and for boards, and for lining.

As for the grade, we should proceed from the fact that second grade wood may not only have many knots, but also be infected with a fungus (blue fungus, for example). For a rough ceiling in a bathhouse, both grade A and grade B would be suitable, but B with caution. Still, the evenness of the rough base will affect the evenness of the finish.

ADVICE! It is advisable to treat all wood that will not encounter high temperatures in the steam room with ready-made antiseptics. This will extend its service life. Additionally: boric acid protects against mold; bleach eliminates its variety, called “blue acid.”

Also, a completely unedged board is suitable for rough coating, which is used solely for the purpose of reducing costs; it has no other advantages at this stage.

The finished ceiling is made from wood of a higher grade - highest or A. Moreover, the type of lumber can be either edged or unedged. However, the quality of the surface finish of the finishing boards must be very high.

For the finished ceiling, lining, tongue-and-groove floorboards, and polished regular edged and unedged boards are used. The choice is up to the owner.

The thickness of the roughing board is 25 mm. Finishing - depends on the selected material.

Selection of insulation technology

They say that a correctly asked question contains 50% of the answer. Knowing the physics of the processes occurring in the cold under-roof space, it is possible to identify the most important criteria for choosing thermal insulation and evaluate all technologies based on them. The attic in buildings of this type is traditionally designed taking into account the possibility of cold ventilation. In both summer and winter, air flows are directed upward.

Ventilation of an uninsulated attic

To support this movement, two natural outlets are provided: for the flow between the tiles and the waterproofing, the joint between the membranes opens under the ridge of the roof, and for the heat rising from the ceiling, dormer windows are provided. Our ancestors experimentally found out that it is impossible to hermetically seal a space that is not heated. Excess moisture should evaporate freely from all house structures.

It is worth noting that all traditional building materials have two characteristic properties: high vapor permeability and increased capillary activity. The latter means that moisture moves inside the structure in a certain direction due to surface tension forces. However, since then, many materials have appeared that are completely different in physical properties from clay, brick and wood. It is logical that the issue of insulation can be resolved differently for them.

So, in order to figure out how to properly insulate a ceiling under a cold roof, let’s consider the basic technologies from the point of view of vapor permeability and capillary activity:

Ceiling insulation with sawdust

- Vapor-permeable backfills. From sawdust, peat, pine needles, sand, straw, used for centuries - to expanded clay granulate, which appeared in the 20th century and more modern ecowool

- Vapor-permeable fiber materials.

- Slab heat insulators with low or zero moisture saturation. These are expanded polystyrene (foam plastic and EPS), as well as slab foam glass.

- Hydrophobic seamless (solid) insulation. These include sprayed polyurethane foam.

Taking into account the design features of ceilings is equally important for any insulation technology. The force elements that take up bending loads are:

- Wooden beams. In the vast majority of low-rise private residential buildings.

- Concrete plates. In second place in popularity after wooden beams.

- Steel trusses. Used relatively rarely. However, due to the development of modular construction from thin-walled profiles, the popularity of this flooring option is growing.

In the case of beams and trusses, the thermal insulation layer can be located in one of four possible positions: from inside the room on the false ceiling, from the attic side on the flooring, between the beams (trusses) on top of the false ceiling, or between them, but below the flooring.

Ceiling insulation technology

Regardless of the material chosen for the construction of the bathhouse, the design of its upper ceiling is almost the same. The load-bearing base is made up of beams resting on the upper rims of timber or logs or on the mauerlat of brick or panel buildings. The timber used for the construction of the beam floor is usually treated with an antiseptic before installation. But, if the fungus protection procedure has not been carried out in advance, the wood should be treated before laying layers of thermal insulation. Particular care must be taken at the junction of building materials with different technical characteristics. In such tandems as brick-wood, foam concrete-wood, wood-metal.

- On the side of the bathhouses, the ceiling is hemmed with boards, nailed from below to the beams.

- Rolling boards are knocked together, which are two rows of low-grade boards perpendicular to each other.

It is necessary to draw a diagram and, according to it, calculate the dimensions and configuration of each of the shields. After manufacturing, the shields must be numbered so as not to get confused during installation.

- Knocked together “boxes” also need to be protected from rot and bacteria with antiseptic impregnation.

- A vapor barrier material is stapled to the bottom and inner walls of the pallet-like panel.

- The panels are lifted up without insulation, starting with those that will be mounted last.

- Having raised all the elements to the top, they are arranged according to the markings. The lower plane of the replaced shield must coincide with the lower plane of the beam.

- After placement, the boxes are filled with thermal insulation material. It is also necessary to insulate the gaps between the panels and beams.

- The entire structure is covered with boards on top in a direction perpendicular to the direction of the beams.

Instead of boards, you can use fiberboard, homemade slabs made of cement mortar with sawdust. The finished ceiling must be treated with a fire retardant; in the area of the chimney, all wooden elements are sheathed with asbestos sheets.

Thermal insulation for steam room

This is a separate topic, since the upper plane of the steam room should not only not let through, but also promote the accumulation of steam in the ceiling area. It is recommended to lay two layers of vapor barrier material over the steam rooms and supplement the insulation for the bathhouse ceiling with layers of thermal insulation.

Design by Sosnin and Bukharkin

- The beams are hemmed with tongue-and-groove boards 2.5 cm thick. They need to be covered in two layers with drying oil, which, according to the developers, should make the lumber moisture-resistant.

- A low-grade board with gaps of approximately 3 cm is nailed on top of the beams in the transverse direction. This is the so-called moisture gap.

- Roofing felt is laid on boards laid with gaps, or polyethylene film can be used. It’s great if the owner doesn’t skimp on reinforced foil.

- Fill up with a 20-centimeter layer of slag or sand.

Why do this?

The main rooms in a Russian bath are the steam room and the dressing room. The steam room maintains a high level of temperature and steam. Heated moist air tends to escape through gaps in the ceiling and walls. It is impossible to make a sealed steam room out of wood. The majority of heat loss occurs through the ceiling as hot air rises. To reduce the outflow of heat, insulation is installed. The thermal insulation material will act as a barrier and protect the steam room from rapid cooling. Insulating the steam room will reduce heat loss.

The ceiling can be insulated from the attic side or from below. The technology of thermal insulation works includes the construction of a multilayer structure. The result of high-quality ceiling insulation will be a reduction in heating costs and an increase in the time of maintaining comfortable heat in the room.

Requirements for insulating material for a bath

The operating conditions of the bathhouse differ from other premises. High temperatures and humidity require a special approach to the selection of building materials. This applies no less to thermal insulation.

Since bath procedures are used for healing, the evaporation of harmful substances should be excluded. In different rooms of the bathhouse, the requirements for insulation differ. The most extreme conditions are created in the steam room, where the temperature can reach 160 °C.

If insulation is done from the inside, different materials may be used in different rooms. When insulating the ceiling from above (from the attic side), it is wiser to use one insulation material. The material must have the following properties:

- low thermal conductivity;

- moisture resistance;

- resistance to high temperatures;

- no harmful fumes when heated;

- resistance to rotting and fungal growth;

- durability.

The safety of the material must be confirmed by a sanitary and hygienic certificate.

Properly selected materials are the key to a successful result

In the old fashioned way, wood materials are used to work on bath rooms. Dried wood, such as conifer, is best for working on the outer box. In turn, for use for interior decoration, it is better to choose materials from deciduous trees.

Structures made of boards fit tightly to each other, which is why they provide good heat retention, however, special attention should be paid to the resin content, since it is the low resin content that is the key to success in this situation

This is explained by the fact that wood with this indicator has low thermal conductivity, good sound insulation and, last but not least, a long service life.

This is explained by the fact that wood with this indicator has low thermal conductivity, good sound insulation and, no less important, a long service life. In this regard, pine species are not recommended for cladding the ceiling in a steam room with your own hands, because the resin content of conifers is at a fairly high level

In this regard, pine species are not recommended for covering the ceiling in a steam room with your own hands, because the resin content of conifers is at a fairly high level.

According to some reports, at high temperatures, the resin is released and is a source of burns, which is why coniferous species are rarely used for interior decoration of steam rooms.

However, not everything is so scary. Many knowledgeable people finish the inside of the steam room with pine needles and remain satisfied for many years. Here the developer should rely solely on personal preferences. Do-it-yourself ceiling in the steam room, step-by-step instructions:

Important! Under no circumstances should fiberboard, chipboard, or plywood be used for the interior lining of the steam room, since they are made using toxic adhesives that are harmful to health. In many European countries, the use of such materials for the construction of residential buildings is prohibited!

Installation

Now we get to the step-by-step instructions. However, it is worth noting that no instruction will be complete enough to reveal all the nuances of the work ahead, so it remains advisable that the builder have at least basic experience with tools and construction in general.

Construction instructions, installation step by step

Grazing

Take all necessary measurements. If you are working in a log house, draw a line along the level where the deck boards will lie. If you have walls made of a different material, check the horizontality of the mauerlat or strapping beam. If it deviates from the horizontal, prepare the necessary tabs.

Boards can be very different - edged, unedged, tongue and groove. But whatever they are, they need to be cut taking into account the approach to the wall of at least 5 cm (more is possible).

In the ceiling crown, as we said above, you need to cut out a “shelf” on which the boards will lie. To do this, you can use an ax or chainsaw. “Shelves” are cut out on two opposite walls only.

The boards are laid out on the mauerlat in the same way, only there is no need to make a ledge.

Fastening can be done with self-tapping screws or nails.

Then bars or boards placed on the end are laid out on top - all this across the length of the flooring board. From below they are attached through and through with self-tapping screws. This is a necessary measure to ensure that the boards do not “play” in the future.

Next, we cut and lay the vapor barrier, securing it to the base with a stapler.

We lay the selected insulation on the vapor barrier.

We cover everything with waterproofing (some do not cover it).

From below, we adhere to the chosen design solution - either we leave the existing one as a finished ceiling, or we fill unedged boards with a shift, or we make a sheathing and cover everything with clapboard.

In the steam room, of course, some owners will stuff the bottom with foil, put the sheathing on top of it and cover it with clapboard. This is done to reflect infrared radiation back into the steam room.

Hemmed

As agreed, we believe that we already have the ceiling beams. We take measurements and set the horizontal lines exactly to the level on the wall. We stretch the construction threads.

We fill the cranial beams in accordance with the horizontal lines (this is one of the options, there are others). The skull beam provides a ledge on which the boards will rest between the beams.

We cut the boards and lay them in the transverse direction of the beams on the skull beam. Secure with self-tapping screws or nails.

On top, without covering the beams, we lay a vapor barrier. This means that the upper section of the beam remains open, the vapor barrier fills only the formed “containers”. This is necessary so that the wood of the beam can release moisture.

We lay insulation on the vapor barrier secured with a stapler.

We cover it with waterproofing (vapor barrier does not breathe, but hydro - breathes, releases steam from the insulation).

On top of the beams, either a subfloor or a finished floor is laid.

The bottom trim remains. Here too it depends only on the design decision. See a similar point on the floor ceiling above.

You will find a step-by-step guide on how to make a steam room ceiling in a bathhouse with your own hands on this page.