When going to a hot bathhouse to take a steam bath, we certainly put on a warm hat, although for a beginner it looks more than strange. But a hat is like a heat insulator that absorbs moisture and protects your head from overheating. Likewise, when building the bathhouse itself, the insulated ceiling is the most important part.

It is unacceptable to forget about this after insulating the floor and walls, for which different materials are used. In order for the bathhouse to retain heat well, it is necessary to correctly select the insulating material and method of thermal insulation of the ceiling, of course, taking into account the type of roof.

Insulation of the ceiling in a bathhouse with an attic

The attic room is the coldest in the bathhouse, because...

does not have a “thermal cushion”, so insulating the ceiling in a bathhouse with an attic is the most important task; with such a structural design, thermal insulation is used for both the second floor floor and the roof. After all, the excess heat from the bathhouse fully heats the attic room, and the heat-insulating layer prevents it from overheating. Conserving heat under the roofing material is also necessary. Both in winter and summer, you will be comfortable. Under the summer sun, the roof heats up, the outside heat combines with that coming from the steam room, and as a result, on a bath day you will get a scorching heat on the second floor.

How to insulate

The approximate “pie” of insulation from the inside of the steam room is as follows:

- lining;

- rail;

- foil taped with tape;

- rough board 150 x 20 mm;

- floor beam;

- glassine;

- expanded clay – 120 mm;

- Rockwool insulation – 50 mm;

- glassine;

- batten.

Look at the explanation of the above illustration of a bathhouse roof pie with an attic:

How to insulate

What thermal insulation material should I use? Yes, everything that is listed above, from time-tested, natural, natural insulation materials to ultra-modern ones (wood chips, shavings, sawdust, sand, expanded clay, mineral wool, basalt wool, ecowool). More information on insulation for baths here.

Heat leakage problems need to be solved comprehensively, and not just those discussed in this article. There are no trifles in organizing thermal insulation; window and door openings, walls, roof, ceiling, everything must be done correctly, in compliance with building codes and calculations taking into account your region. When constructing a bathhouse, or having problems with heat preservation in an already in use building, it is better to turn to professionals or get their qualified advice than to comprehend the science of construction by trial and error.

Structure of floors and roofs

The best results in the construction of bathhouses with attic floors were shown by a floor structure consisting of several main layers:

- On the side of the lower floor, a layer of foil or other vapor barrier with a reflective effect is laid

- Next, a layer of the selected insulation is laid

- Next will be another layer of vapor-waterproofing

- Next comes the flooring of the second floor.

Between the floor covering and the vapor barrier, you need to build a sheathing that will create a ventilation gap necessary for free air circulation.

The roof is assembled in a similar way. Only the outer sheathing under the outer covering is added. The most popular material for it is ordinary slate, since it practically does not heat up, or modern types of roofing coverings. Waterproofing is also added to the outside of the roof, which will prevent leaks into the room.

Work on creating a heat-saving layer must begin from the outside and gradually move inside the building. This means that you first need to install the outer roof covering from the material that was chosen, and then work inside, under the roof.

Important recommendations for insulating the ceiling in a bathhouse

Greetings, dear readers, the topic of today’s article is how to insulate the ceiling of a bathhouse and what is the best way to do it. In the last article we chose the optimal ceiling height, now let’s move directly to the construction and insulation of the bathhouse ceiling.

A little theory. We all know very well that warm air is lighter than cold air and rises to the ceiling. And imagine the situation - hot steam rose to the top, but the ceiling was cold. What will happen? That's right, condensation will form. You steam yourself with brooms in the bathhouse, and the rain drips on you :). Let's see how improper ceiling insulation and lack of vapor barrier can harm:

- Constant wetting of ceilings and, as a result, their premature destruction.

- The bath cools down very quickly; it is possible that in the cold season the steam room will not be able to warm up properly.

- Excessive consumption of firewood or electricity.

- There is a real danger of ceilings collapsing.

Correct ceiling insulation

In this article we will tell you how to avoid all these problems and properly insulate the ceiling. The whole process can be roughly divided into three key stages:

- Insulation of the steam room ceiling.

- Moisture insulation of the attic.

- Vapor barrier.

At this time, we, as builders, have a serious advantage over our ancestors - the modern construction market offers a wide range of different thermal insulation materials for every taste and budget. Let's look at the most popular thermal insulation materials.

How to change the shape of the attic when insulating?

The first difficulty that is usually encountered when insulating an attic is the shape of the room itself. After all, the geometry of the attic can be anything: triangular, broken, or with a steep slope of up to 70° or almost flat from 15°. In addition, during the insulation process, the following disadvantages will also come out:

- Sloped ceilings that will now be slightly lower.

- Noticeable loss of usable space.

- A technically complex insulation process, where it is important to choose the right hydro- and vapor barrier.

- Health risk if insulation was carried out incorrectly.

Can we handle it? Certainly! So what to do if, instead of an attic, you still only have an uninhabited attic, the pitched roofs of which go all the way to the floor? And why such angles, if the usable space, which is still of some use, is 1.50 meters maximum? The solution to this problem is very simple: build a frame from metal profile guides for drywall, and insulate along it. By the way, the further such a structure is from the cornice, the warmer the entire room will be.

If you don’t like the shape of the attic that we have now, then you can make a special frame, insulate it and sheathe it. It will be even warmer! Plasterboard profiles need to be attached in increments of 40 cm, onto hangers. At this stage of construction, carry out the electrical wiring. And upon completion of the insulation, attach the sheets of plasterboard to the finished frame:

Although many, we note, even like such niches - with ingenuity, they can also be used to save space in an already small attic.

By the way, the simplest frame can be made from timber with a moisture content of at least 12%. Additionally, before installation, treat it with antiseptics, and the structure will serve you for a long time. But even better is to make a frame from a metal profile (for example, a profile for drywall). Or combine both options:

The most important thing: build the frame so that the vertical lines are perfectly vertical and the horizontal lines are perfectly horizontal. Use a good building level for this, and don’t be lazy to constantly double-check everything. Otherwise, you can’t even imagine how much trouble you will have to adjust the insulation later.

Install vertical partitions with a profile pitch of up to 50 cm and no more, and horizontal partitions - as it is convenient for you. After installation and checking the level, take a control measurement of the diagonals - stretch the thread between the extreme points of the profile, and now apply it in a different diagonal direction. If the frame is not skewed, both distances should coincide. You don’t want to end up with a room with incorrect geometry, do you? Then you will be interested to know that in cinema the walls of a room are specially made at different angles and with a slightly distorted rectangularity in order to achieve the effect of an unkempt room.

Insulating the attic floor with foam plastic

The installation technology process is similar to insulating an attic floor with polystyrene foam.

The advantages of these materials:

- low cost;

- ease of operation;

- waterproof.

Among the disadvantages: flammability.

Technology for insulating attic floors with polystyrene foam or polystyrene foam

The process of installing rigid foam-based insulation is more than simple and can be done with your own hands. The work can be divided into two stages:

surface leveling. To ensure high-quality insulation, there should be no significant unevenness on the base floor. Such differences can be eliminated by screeding with sand-cement mortar.

The slabs are laid end-to-end or between beams. The presence of timber increases the strength of the floor.

Tip: carefully seal any seams, incl. joints with beams. When going around an obstacle, try to cut the holes as accurately as possible. A homogeneous thermal insulation layer retains heat better.

Insulation of the attic floor with polystyrene foam Rough coating

Polystyrene foam must be protected from destruction with film in an uninhabited attic. In a frequently used or residential attic, you need to move somehow, so it is better to install an OSB subfloor on top of polystyrene foam or expanded polystyrene or use a sand-cement screed.

Expert advice

For bath structures, the criterion of environmental friendliness of the insulation is important, so it is better to choose natural heat insulators that meet fire safety standards. Expanded clay, prepared sawdust-cement backfills, and vermiculite are well suited for thermal insulation. They can be installed independently, following installation technology.

When installing insulation, you need to build a protective steel box for the chimney pipe. Expanded clay can be poured into the box. It is necessary to ensure that wooden structures do not touch the chimney.

When insulating with mineral wool, it is better to choose multi-layer installation with overlapping of previous joints. This method will avoid heat leakage through the seams of the insulation. This will not affect the cost of the heat insulator, since it is sold in cubic meters. There is no need to exceed the thickness of the planned layer, but choose a thinner roll of cotton wool.

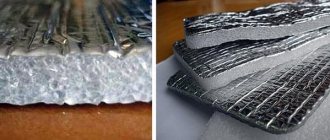

For bath buildings, foil materials are more relevant, since foil reflects infrared heat rays from the ceiling, improving the heating rate of the steam room. This reduces heating costs. The vapor barrier with foil is laid with the reflective side down. To fix the joints of vapor barrier films, foil tape is used. To form a sealed vapor barrier, the seams are overlapped by 10 cm and then secured.

The thickness of the installed layer of a specific heat insulator is calculated based on climatic conditions and the thermal conductivity coefficient of the material.

The greater the temperature difference between the environment and the heated steam room, the faster the hot air tends to leave the room. Proper sealing of all cracks, gaps and technological openings will prevent rapid heat loss. A monolithic thermal insulation layer with a sealed reflective vapor barrier will significantly reduce heat loss.

How and with what to insulate a bathhouse, see the following video.

Combined insulation technology

In addition to the usual combined attic insulation, where two types of insulation are used to combine their qualities, we also want to tell you how to insulate an attic in a more cunning way - with additional heating.

One of the most atypical ways to heat an attic is to install an infrared heater directly on the pitched walls. The thin film is easily installed under the skin and releases valuable thermal energy. This, in turn, heats the objects in the room, and they also give off additional heat.

Infrared floor heating is based on the well-known principle of heating through current. The current flows through the resistive foil and generates heat up to 45C, which is emitted by infrared invisible rays 9.5 microns long. This warmth is comfortable, and the temperature difference between the floor and ceiling is only 1-3C.

A modern film infrared ceiling heater works for only 15 minutes every hour. A fairly economical option in which the air itself does not heat up, and therefore the heat does not escape through the ridge.

Installing infrared film is also simple and safe, as you can see from the step-by-step photos:

Just keep in mind that each manufacturer has its own subtleties of installing such films, for which you must read the attached instructions. But the principle is the same: spread it out, secure it and connect it.

The use of bulk insulation in a house with a cold roof

How to properly insulate a ceiling under a cold roof if you have access to free or cheap natural raw materials such as pine needles or peat, or have excess expanded clay or sawdust left over from production or construction? Of course, you should take advantage of this life bonus. Despite the fact that these options are outdated and require very large backfill thicknesses, nothing prevents you from using this method when it comes to a cold attic.

Ceiling insulation with expanded clay

In this case, even if the profile of the floor beams is not enough to form “pockets” 30–40 cm deep, they can be expanded with wooden planks. After all, reducing the space in the non-residential under-roof space does not affect anything.

It is necessary to lay a layer of vapor barrier film under the backfill, but it is not recommended to cover it with anything on top. It is better to ensure high-quality roof waterproofing. The backfill must be well ventilated.

Important points

With any method of laying insulation, it is important to understand that under the attic floor there is a steam room and all adjacent rooms. This means that at the second level a greenhouse effect is possible. This must be avoided at all costs, as steam will quickly render the entire structure unusable.

To do this, you need to take care of high-quality hydro and vapor barrier of the ceiling between levels. Ventilation will also be of utmost importance. The comfort of being inside and the service life of the building depend on how well the entire building is ventilated. Moreover, it is necessary to provide ventilation not only in the attic, but also in the bath complex itself.

Ceiling

If a ceiling is installed in the attic, then it is a classic wooden ceiling, in which the top tie acts as load-bearing beams. It is the tightening line that “cuts off” the small cold attic above the attic.

The insulation of a wooden floor has the following scheme:

- hem the rough ceiling;

- mineral wool is laid between the beams;

- if the mats are not laminated (covered with film), then fiberglass is spread over them, protecting the insulation from weathering;

- from the inside, a vapor barrier is attached to the false ceiling in a continuous layer, which is fixed around the perimeter with self-adhesive vapor-proof tape;

- install lathing for interior decoration.

There is no need to waterproof the ceiling insulation. According to the standards, this is a mandatory measure to cover the entire cold attic. Moreover, it must be carried out to a width of at least one meter from the outer wall - it is in this area that condensation can accumulate, flowing down to the eaves along the waterproofing of the roof covering.

The need for vapor barrier

Whatever the structure, laying a layer of vapor barrier for the ceiling in the wooden ceiling of the bathhouse is a mandatory element of insulation. It is laid before installing the insulation layer. As a vapor barrier in bathhouses without an attic, wax paper, aluminum foil or thick cardboard impregnated with drying oil are used.

In buildings with an attic or attic, similar materials are allowed to be used. However, in practice, wooden floors are most often coated with clay, with a layer of 2 cm.

On the building materials market you can find several vapor barrier options:

- Thick polyethylene film is used quite rarely, as it contributes to the greenhouse effect. In this regard, when installing it, it is important to leave technological gaps for condensate evaporation.

- A special polyethylene vapor barrier film with pile to retain condensation.

- All kinds of vapor barrier membranes.

The need for a vapor barrier layer is due to the fact that it allows you to protect the insulation for the bathhouse ceiling from the accumulation of moisture contained in the warm air. This is important, since moisture will gradually lead to a decrease in the thermal insulation qualities of the material, shorten its service life and increase the load on the walls as a result of an increase in the mass of the ceiling.

Insulation of a suspended ceiling

Here, it is not the flooring itself that is laid on the upper part of the wall, but support beams made from wooden beams or boards spliced together. And the ceiling and floor of the attic are laid on the beams below and above. At the same time, layers of steam, hydro and thermal insulation are laid in the space between them.

Scheme of insulation of a false ceiling

The process of insulating a ceiling with a similar design depends on what material you use. For mineral wool this happens as follows.

- On the roof side, a layer of waterproofing material is laid on the beams and secured using a furniture stapler. To protect from moisture, installation should be carried out with an overlap of 10-15 centimeters.

- Next, plywood or wooden boards are laid on top of the waterproofing. Since the false ceiling is quite strong, the resulting space under the roof can be used as an attic or attic.

- Mineral wool should be placed in the free space between the beams. Its thickness for middle latitudes should be approximately 150-180 mm, and for areas with severe frosts - 200-250 mm. If in a layer of thermal insulation material there are joints between sheets of mineral wool, then the next layer should overlap them.

- A vapor barrier film is attached to the floor beams from below. In this case, it is desirable that its edges bend and overlap the upper part of the walls. Also make sure that when laying the material there is no damage or tearing.

- Wooden slats are attached on top of the vapor barrier perpendicular to the beams.

- The final stage is laying the lining, nailed or screwed to the slats with self-tapping screws.

Video - We insulate the ceiling in a bathhouse with a cold roof using mineral wool

The process of insulating the shed ceiling of a bathhouse with a cold roof looks a little different when expanded clay or a cement-sawdust mixture is used. Let's present this in the form of step-by-step instructions.

Ceiling insulation scheme with expanded clay

- A rough flooring made of boards is laid on the floor beams below. The gaps between them must be treated with sealant or coated with a mixture of clay (or concrete) and sawdust.

- A vapor barrier film is laid on the flooring both from the steam room side and from the roof side, and not only the boardwalk should be covered, but also the beams themselves.

- Expanded clay is poured into the resulting boxes or ecowool is laid.

- Roofing felt or other waterproofing material is laid over the insulation overlapping and secured to the beams using a construction stapler.

- Boards or plywood are laid over the waterproofing to form the attic floor.

- The lining is laid underneath on the rough boards.

Insulation of a false ceiling with expanded clay

If you use a mixture of clay and sawdust to insulate the ceiling, then it is advisable to put a layer of mineral wool on top of the frozen mixture or fill it with expanded clay - this will improve the thermal insulation performance.

Main types of attic roofs

- Cold - for their installation, a sheathing is stuffed onto the rafters, taking into account the roofing covering, roofing material is attached to it, insulation is carried out along the ceiling, laying thermal insulation on it, which is covered with a vapor barrier on the room side, and a waterproofing membrane on the attic side;

- insulated - for exploited under-roof spaces - attics, additional elements are added to the previous components: insulation, vapor barrier, waterproofing, counter-lattice - timber with a section of 40 x 40, 50 x 50, 60 x 60 mm, placed on the rafters along their length. A waterproofing material is laid on the beam, protecting the insulation and roof from external moisture, then the sheathing is laid on which the roofing covering is attached. The spaces between the rafters are filled with appropriate insulation, and from the attic side it is covered with a vapor barrier layer.

Types of bathhouse ceiling insulation:

- outside - more convenient to use, most effective for a ceiling located under an uninsulated roof, the insulation is laid out on the attic floor and covered with a rough or finished floor;

- from the inside – it prolongs the durability of the material, there are no temperature changes, but you will have to “steal” a few centimeters of the height of the bathhouse, a frame is mounted on the ceiling, after fixing the first layer of vapor barrier, and insulation is placed in it, then the vapor barrier is again and the ceiling covering is attached.

The role of steam and the mechanism of its formation

The specificity of the microclimate formation within buildings operated in our latitudes is directly related to intense steam formation. The climate dictates the need to maintain a higher temperature indoors compared to outdoors. Our heating season is longer than the part of the year that does not require an increase in temperature parameters in homes.

Along with temperature indicators, an increase in the absolute level of humidity is also noted. This happens because warm air is able to hold more water vapor than cold air. The lower the temperature of the air mass, the less moisture it can contain.

According to substantiated statements of physicists, a cubic meter of air with t° = +20°C at one hundred percent absolute humidity contains about 17.3 g of vaporous water. At the same moment, a similar one hundred percent humidity is noted if an outdoor thermometer, for example, records t° = -10°C, and the relative humidity is only 2.3 g.

The fact is that the density of cold air is much higher than the same indicator, but with a higher temperature. It is clear that when the air mass cools, it has to part with excess steam, which it can no longer contain. This water is released in the form of condensate, which settles on building structures during cooling.

We are all very familiar with the phenomenon of the release of excess water from a cooling air mass. Let us remember the fogs characteristic of the early morning that comes after a cool night in the hot summer. True, humid air does not cause such serious damage to nature that it threatens building systems and materials.

Most building materials cannot withstand the effects of condensation settled on surfaces:

- A fungus grows on damp wood, rendering parts of the supporting structures unusable.

- Pockets of rust appear on metal elements, even if they have invisible microscopic scratches.

- Damp insulation loses its insulating qualities, which is why the rooms do not retain heat, feel cold and have an unpleasant musty smell.

In addition to condensation, which is formed due to the difference in temperature inside and outside the building, building systems and materials are affected by an abundant flow of household fumes. They are secreted by plants, animals, and hosts during the process of respiration. Steam is generated when performing hygiene procedures, cooking, washing, cleaning, etc.

The evaporations released during vital activity rush to where the saturation of the air mass with them is less. Steam constantly moves in the air to where there is little of it and the thermometer readings are lower. This explains its desire to penetrate outside through enclosing structures and ventilation systems.

The process of flow itself is called diffusion. Evaporation predominantly diffuses through building systems, and not the air itself, which is easier to pass through leaks in the fit of windows and doors to frames, ventilation devices, open vents, etc.

The predominant part of the evaporation leaks out through the ceilings, roofing structures and the upper part of the walls, because warm air, together with the moisture present with it, always moves upward. These are the ones that need to be equipped with a vapor barrier, as they are the elements of the building most exposed to moisture.

Insulation and insulation materials

In order to properly insulate the roof, you need to decide on the following questions:

- What insulation to use? This will depend on what materials your bathhouse is made of. Insulation can be done with felt or moss, bulk or foamed modern materials.

- What type of insulation? Here the choice will depend on the design features of the roofing pie. There are two options - insulation from the inside and outside. As a rule, the first option is preferable. But if this cannot be done, then use the second one.

The materials used to insulate the roof of the bathhouse must meet certain requirements:

- resistance to high temperatures;

- moisture repellency;

- resistance to mold and rot;

- resistance to deformation;

- environmental friendliness;

Soft materials can be used as insulation. We are talking about traditional natural fluff, felt, and moss. They are used for wooden buildings. The advantages of such materials are that they are environmentally friendly. But they have serious disadvantages - they can rot and over time turn into a home for insects.

The next category of insulation is natural bulk. These include clay and earth. They are suitable for buildings made of wood and brick. Again, their advantage is that they are environmentally friendly. But the disadvantages lie in the complexity of the work. Long and labor-intensive insulation with clay is complicated by the need to use straw as an additional material when working.

Among modern materials for insulation we can name liquid ones - suspensions in the form of foamed granules. They can be used on any buildings.

But the most popular is still the use of harmless and cheap polystyrene foam, ecowool and backfill. These materials are suitable for both wooden and brick baths.

Roof insulation scheme

The use of polystyrene and other slab foam insulation is possible provided that the brand used is not flammable and does not contain fire retardants.

The boards used to line the ceiling can also act as insulation. And their ability to retain heat directly depends on the thickness of the material.

Based on the type of insulation, there are two methods:

- From the inside, when the ceiling of the steam room and dressing room is insulated.

- Outside, when roof slopes are insulated. This option is not suitable if you have an unheated attic, because condensation may occur, which will destroy the wood.

If the bathhouse has an attic floor, then the ceiling along with the slopes is insulated. This is done to provide a good rest room.

If you have an attic floor, it is important to properly organize the vapor barrier of the floor. This will avoid increased humidity in the room.

The ceiling can be insulated:

- in a flat way. It involves laying thick boards on the top rims of the log house.

- in a hemming manner. In this case, the boards are fastened from below to the floor beams.

First, briefly about what ceiling insulation provides

- Economical operation. Fast heating, due to reduced heat loss through the roof, allows you to reduce energy consumption (wood, coal, electricity, gas, etc.);

- Comfort for steamers. The absence of condensation that “pleasantly cools” people’s backs and the musty smell resulting from dampness;

- Durability of the structure. Prevents excess moisture, preventing the creation of a convenient bacteriological environment for the appearance of fungus, mold and wood rot.

Enough arguments? Then let's get down to business, and please pay attention to the next paragraph...

What types of ceilings are there in a bathhouse? Here are the main types - hemmed / floor / panel. Each option has its own design features. But the insulation process is almost the same. We will not consider this, since we have a different topic now.

So, materials. There are two main types of insulation for baths, which we roughly divide into natural (“old-fashioned”) and artificial (including those made on a natural basis with the addition of artificial substances).

Device depending on the type of attic

Everything in a bathhouse should be profitable.

If the roof is not insulated, then it will be a so-called “cold roof”, which has its own advantages and disadvantages. But if, on the contrary, you invest in insulating the roof itself, then it would be strange if the second floor of the bathhouse did not become a residential or at least equipped utility room. ATTENTION! When choosing a ceiling in a bathhouse, its design will depend primarily on whether people will walk on it from above and place heavy things on it.

In a bathhouse with a cold attic

The fact that you have the same temperature under the roof as outside significantly affects the desire to climb into the attic, say, in winter. And if it is also low, then the only benefit of this room is its participation in the ventilation of the entire building, as well as the possibility of storing small items of brooms and buckets that did not have a place below.

And if there’s nothing special to do upstairs, then what’s the point of investing in a more expensive version of the ceiling? Therefore, usually the installation of a ceiling in a bathhouse with a cold attic comes down to a flooring scheme.

Below we will describe all the layers of the floor ceiling in the bathhouse. However, this does not mean at all that you have been ordered the option of installing a hemmed ceiling.

IMPORTANT! If the distance between opposite walls is more than 2.5 meters, you will simply have to make beams and a hemming option.

Therefore, if desired or necessary, the hemmed option is just as appropriate in a cold attic as the flooring option.

With an attic or warm attic

But the rule does not work in the opposite direction.

WARNING! A flat ceiling is completely contraindicated in bathhouses with a residential second floor or a warm attic.

The reason is easy to guess - it simply cannot withstand the weight of furniture and people. Intellectually, of course, it is worth making calculations, but even without them it is clear that a long board, which has support points only at the ends, cannot be compared with beams that have more rigidity.

Thus, here you can only do a hemmed version, period.

Exterior works

A prerequisite is that the house is insulated in warm and dry weather. It all starts with an inspection of the surface. Next, all wooden components need to be treated with an antiseptic, and metal ones with an anticorrosive agent. It is also necessary to thoroughly dry damp areas. If the tree is damaged by insects, it is replaced.

In a log house, the rafter system is made of wooden beams. So the waterproofing film is glued directly to these joists, after which the lathing is created and the roof is installed. Insulation from the inside occurs by laying the material between the rafters with its fixation on top of the vapor barrier, as well as finishing with plasterboard. There is no need to compact fiber-type insulation - you need to cut out pieces of material with a small allowance and insert them between the rafters. If a soft roof is to be installed, then OSB boards or moisture-resistant plywood are laid directly on the sheathing, after which the roof is created.

Schematic diagram of a vapor barrier

We have already said that steam spontaneously moves to where the air is less saturated with moisture and, as a rule, has a lower temperature. In accordance with our climatic realities, the flow of evaporation passes through building structures and is directed into the environment. This is exactly what happens for most of the year. Only on hot summer days, which, unfortunately, are few and far between, can vapors from outside rush indoors.

The vapor barrier is arranged in full accordance with the prevailing direction of the diffusing steam flow. It is installed very first on the inside of pies of all types of enclosing structures, including roofs. Those. First, on the side of the premises there is a film that protects the insulation and the roofing pie as a whole from steam, then other components come.

All materials used in roof construction have some degree of vapor permeability. It can vary from zero or thousandths of one to 3000 mg/m². This characteristic tells about the ability of the material to pass a specific volume of moisture per day. To form a barrier against moisture suspended in the air, options with the lowest vapor permeability are chosen.

The main principle of constructing a roofing pie is that on the side of the room there is material with the lowest vapor permeability:

- With zero vapor permeability values, the film will not allow household fumes to penetrate into the thickness of the roofing pie at all. Condensation formed there due to the difference in temperature on the outer and inner sides of the roof is evaporated in such cases through vents or accumulates on the waterproofing, after which it flows into the gutter.

- With permeability values other than zero, a certain amount of vapor penetrates into the roofing pie. In this case, there is a need for effective moisture removal. To remove steam, an under-roof ventilation system is installed, and dormer windows are constructed to ventilate non-residential attics and attics.

Any of the steam protection options installed on the side of the premises must make it difficult for water suspended in the air to seep into the roofing pie. However, if it does penetrate, the structure should be arranged in such a way that complete moisture removal is guaranteed. This means that the layers following the vapor barrier should allow it to pass through freely.

Therefore, when constructing roofs, the order of the layers, determined by the vapor permeability indicators, must be observed. The first of them should allow the least amount of water to pass through, followed by those with the highest ability. The specified arrangement of protective layers at the same time prevents the passage of cold air flows from the outside into the building.

Which to choose?

Insulation in the form of shavings or sawdust is considered the oldest material. In areas where woodworking production is highly developed, this material is very cheap. It is perfect for creating a layer of insulation on top of a wooden floor. A significant disadvantage of this type of insulation is its high flammability.

There are three types of mineral wool in the construction industry: stone, slag and glass. Stone wool is obtained from rocks with the addition of clay, limestone and formaldehyde.

A significant disadvantage of this material is that it contains harmful substances. When heated, they turn into phenols and enter the air. Balsat wool is considered safer; it contains much less harmful substances.

Slag wool is obtained from the use of blast furnace slag and other waste from the metallurgical industry. Due to its average thermal conductivity and ability to absorb large amounts of moisture, it is not suitable for insulating a cold ceiling.

The obvious disadvantage is that if particles of the material get on the skin or mucous membranes of a person, it can cause harm to health. In this case, experts advise using gloves and special protective equipment when working with this type of insulation.

A clear advantage of wool as home insulation is its ease of transportation and installation. This is possible due to its low weight. Cotton wool has low flammability and can only sinter at high temperatures

It is important for owners of country houses and cottages to know that glass wool is not the most favorite material for insects, various rodents and mold to live in.

Polyethylene foam is foamed PVC, on which a layer of foil is applied. The manufacturer produces this insulation in rolls up to one meter wide. You can also insulate the ceiling using polystyrene foam

But it is important to know that in this case additional installation of suspended structures will be required. In a private home it is also good to use polystyrene foam

It fits tightly and, due to its good density, is often used in the attic as a base for further putty.

Expanded clay is also very popular. It is better if it is made of light alloy clay. Due to this, the material is light and has a fairly porous structure. The production of modern insulation allows you to choose foam products. Many builders consider isover as insulation. This material is similar in many characteristics to mineral wool. But it is more elastic and resistant to stress.

Another worthy option is penofol. Its distinctive feature is its ability to reflect thermal radiation. This material is well suited as insulation inside and outside the house. With this method it is quite possible to insulate the entire country house, and not just the ceiling.

Don't forget about polyurethane foam. It is a convenient and good quality material that meets all the necessary characteristics as insulation. It is a polyurethane foam that only needs to be sprayed on to get the desired result. It not only insulates, but also helps to soundproof the room.

An excellent option in this case would be to use expanded clay. This material is fire resistant and perfectly protects against moisture.

Vapor-permeable insulation is often used inside the apartment. In the process of repair work, the master uses special materials that fill the entire ceiling area. After this, you can begin finishing work using drywall.

How to choose and implement a two-story bathhouse project

Making baths based on ready-made solutions is a very popular service on the market. At the same time, owners of land plots can be completely sure that, when ordering the construction of a building with 2 floors, they will receive a bathhouse project made of timber or logs that will meet all safety standards and norms. In this case, you can get not only significant time savings, but also a high-quality result, backed by a guarantee.

Construction companies usually include as standard:

- log house (or box);

- foundation base;

- partitions;

- roofing;

- door and window structures.

Turnkey two-story bathhouse projects and prices for their implementation depend on the dimensions of the structure and the material chosen for construction.

A bathhouse with an attic made of timber is one of the inexpensive popular solutions

When choosing the size of a future building, it is necessary to take into account the following nuances:

- type of placement of the bathhouse on the site (a separate structure or an extension to a residential building);

- the total area of the land plot and the amount of free space;

- the number of people who will visit the bathhouse;

- the thickness of interior partitions and walls;

- type of insulation and finishing material;

- internal layout and its features.

Characteristics of projects and prices of two-story bathhouses made of timber and logs

Almost any materials are suitable for building a bathhouse, but timber and logs are considered the most popular. To decide which option is more acceptable, you need to compare the characteristics of each of them.

Comparative characteristics of materials for bathhouse construction:

| Criterion | Projects of two-story baths made of timber | Projects of two-story log baths |

| Material price, rub./m³ | Unplaned (5000) | Unrooted (5000) |

| Profiled (10000) | ||

| Dried (10000) | Rounded (10000) | |

| Glued (25000) | ||

| Installation features | Construction duration is from 2 to 6 weeks, the ability to do the work yourself | Construction duration is from 2 to 8 weeks, work is carried out by specialists, commissioning in 6 months. |

| Ecological cleanliness | Environmental friendliness (with the exception of laminated veneer lumber, when purchasing it you should check the characteristics of the adhesive composition) | Environmentally friendly material |

| Shrinkage rate | Glued – 2% | 15% |

| Profiled – 5% | ||

| Unplaned – 10% | ||

| Features of finishing work | Caulking of walls is necessary only in cases where untreated timber is used; profiled material does not require this | The walls need caulking and sanding |

| Decorative properties | Modern appearance, large selection of designs | The authenticity of traditional Russian steam rooms |

| Cost of building a bathhouse 6x6 m, rub. | 409000 (63 m²) | 463000 (64m²) |

For the construction of a modern bathhouse, it is advisable to use timber. There are several varieties of this material on the market, each of which has its own advantages and disadvantages, properties and technical characteristics.

For example, planed timber can have a cross-sectional size in the range of 150-200 mm. Its cross-section can be square or rectangular. This option is considered the most budget-friendly, but in terms of performance characteristics it is significantly inferior to other types of timber. The profiled material is characterized by geometric clarity of shapes and sizes, due to which the construction of a bathhouse is greatly simplified and accelerated. The section size ranges from 100 to 150 mm.

Glued laminated timber is considered the highest quality material option. Projects created on the basis of this raw material have the highest cost. Today, owners of summer cottages with limited space can even afford the luxury of building a comfortable bathhouse. This became possible thanks to a modern approach to building design. The main thing is to competently approach the choice of layout and building material.

Why is this necessary?

A person in a steam room often encountered such a phenomenon as condensation. It is formed when hot steam rises and drops of water appear in the room.

It doesn’t matter whether the steam room is built into the room or is a separate structure, it is necessary to insulate it. The only question is how and to what extent

If it is built into the room, excess heat can go into the house. Therefore a thermal camera is required.

Wooden parts of the structure are most exposed to the aggressive effects of high temperatures and moisture. Therefore, the coating must be of high quality to ensure an “impeccable” microclimate in the steam room.

To make wood last longer, it is impregnated with various compounds (additives - fire retardants). They increase durability. This safety measure is justified, because the temperature in the steam room reaches 100°C. However, chemical anti-mold coatings will produce toxic fumes at high temperatures.

The main “ally” of wooden coverings is insulation, which should retain hot steam indoors and prevent the development of rot. It protects the wood from condensation, prevents wood from rotting and extends its service life.

Proper insulation of the ceiling in a bathhouse or steam room with your own hands involves observing the following points:

- Steam must accumulate and remain indoors.

- The inside of the roof must be protected from high humidity.

- It is necessary to prevent the occurrence and accumulation of condensation both in the steam room itself and in the ceilings under the lining in the walls and ceiling.

Methods

First of all, it is worth deciding what method will be used for insulation. There are two main options:

Both methods have the right to life and are not without drawbacks. The second option can generally only be used when the entire structure is being built. The insulating layer is laid in the walls and ceilings of the attic during the construction of the entire bathhouse. Afterwards, this method will not work.

The internal method of laying insulation is available at any time. Even if the bathhouse was still used as a one-story building, and it was only now decided to make the attic floor habitable.