Method of proper insulation

We insulate the ceiling in the bathhouse and you can protect it if you follow the method:

— the surface is initially processed;

— installation of insulation;

- use of film;

- protection from moisture.

The question arises of how to insulate the ceiling in a bathhouse from the inside. The method considers materials specifically for rooms with high humidity. If you are interested in how to insulate the ceiling in a bathhouse, first prepare a plan.

Layer 1 vapor barrier

Vapor barrier is a ceiling insulation for a bathhouse that protects against steam. Roll materials and sheets are used. The advantage lies in the fact that experts recommend both expensive and not so expensive products.

If you are interested in how you can insulate the ceiling in a bathhouse, you should consider the following vapor barrier:

- roofing felt;

— membranes;

- parchment. Insulation of the ceiling in a bathhouse with a cold roof is carried out using foil. Only it reliably repels steam and helps normalize the indoor microclimate.

The better the insulation of the ceiling in the bathhouse, the faster the owner will get rid of the fungus. There are new materials on the market that should also be considered.

Layer 2 thermal insulation

The second layer is always the insulation of the ceiling in the bathhouse, which serves as the basis for waterproofing. Thermofol and more are considered. If you are interested in the ceiling pie in the bathhouse, it includes plastic film.

It can be of high density, so it will be comfortable to work with. If you are wondering how to insulate the ceiling in a bathhouse, it is important to look for transparent films. The material can be stored for a long time; it is not afraid of high humidity. Insulation of the bathhouse ceiling can be done using laminate. The following brands are in demand:

- HDPE;

- LLDPE;

- LDPE.

The insulation is made on an adhesive basis, so read the instructions before use.

Layer 3 waterproofing

Thermal insulation of the bathhouse ceiling includes a layer of waterproofing. It provides complete protection of the building material. Suggestions for the consumer:

- rubber;

- membrane;

- synthetics.

If you are wondering how to insulate the ceiling in a bathhouse, it is important to take a closer look at synthetics. It can be in the form of slabs or rolls. Films and nets are suitable for baths. The most important thing is that they do not allow moisture to pass through.

Professionals are also concerned with the question of how to insulate the ceiling of a bathhouse and the best options. Experts consider not only synthetics, but also membranes. Main advantages:

- efficiency;

— versatility;

- do not affect the environment.

Insulating a bathhouse ceiling with a membrane is a good choice for builders. It is possible to measure the desired size and immediately cut the strips.

Mineral wool

When people are interested in how to insulate the ceiling in a bathhouse, they are sure to come across cotton wool. Insulation is provided by layers of slag. This material contains resins in small quantities.

Insulating the ceiling with steam wool means that the builder is ready to start processing it. Cutting material from a roll can be difficult. If you need insulation for a bathhouse on the ceiling yourself, it is better to choose another option.

The development of compositions from fiberglass and stone wool with increased biosolubility is considered widespread. Following classification, artificial vitreous fibers were developed and commercialized. The development and introduction of biosoluble fibers with increased content were taken into account in the new standards.

Precautionary principles are taken into account to further increase the safety margin. Traditional fibers are safe to use when recommended practices are followed. The regulations focus on fiber biopersistence, with half-life restrictions for fibers greater than 20 mm in length after inhalation or instillation.

The density of the fibers mainly depends on how much the fibers can be contained. It is believed that long fibers, which cannot be completely absorbed, are most active. Fibers that are too long to be completely absorbed are not only exposed to liquid.

In addition to possible exposure to the environment within, the microenvironment on the surface is porous. Long fibers dissolve and fragment into shorter fibers, and this is how heat is retained.

Expanded clay of various fractions

When asked how to insulate the ceiling of a bathhouse from the outside, expanded clay is often recommended to beginners. Indeed, this is an inexpensive material with a porous structure. If you are interested in insulating the ceiling of a bathhouse, expert advice, you should get down to business:

— use material without filler;

— it is allowed to apply decorative finishing on top;

— Expanded clay should be used with drainage.

Thus, this insulation for the ceiling in a bathhouse can be called universal.

Expanded clay is specified in international standards. They distinguish between materials for structural insulation and for masonry. The standard, among other things, provides for the use of expanded clay for any type of surface. However, the standards mentioned only take into account material of mineral origin.

Expanded clay can be naturally occurring, made from natural materials, made from by-products of industrial processes, or from recycled raw materials or by-products of industrial processes.

The specification covers two main types of aggregates: aggregates obtained by expanding, granulating, or sintering products such as blast furnace slag, clay, diatomaceous earth, fly ash, shale, or slate; and aggregates obtained by processing natural materials such as pumice, slag or tuff. In addition, expanded clay consisting of the end products of combustion of coal or coke are listed in GOST 3400.

Polystyrene foam and polystyrene foam

Polystyrene foam is a special thermal insulation for the ceiling in a bathhouse, which consists of cells. When looking at the formula, there are different components used. The most interesting thing is that the ceiling cake in the steam room can contain phenol.

This component increases the mechanical strength of building materials. If you are interested in how to insulate the ceiling in a bathhouse, you should be interested in the number of additives.

Ketone leaves are considered common. Such insulation of the ceiling in the steam room solves a number of problems. The owners of the premises will definitely forget about condensation and high humidity. insulate the ceiling in a bathhouse with your own hands if you use polystyrene foam with film.

It is a thermoplastic material made from pre-foamed polystyrene beads that combines extremely light weight with versatile strength and thermal insulation. These characteristics have made polystyrene foam an excellent alternative to natural materials for construction projects that would otherwise be delayed or costly to implement. In particular, this technology has been successfully used in the industrial sector.

Ecowool

When renovating, I’m curious about the insulation for the bathhouse ceiling, which one to choose. Ecowool is a popular material. Peculiarities:

— lightness;

— ease of processing;

- low price.

If the question arises, what is the best way to insulate the ceiling of a bathhouse, you should take ordinary ecowool. Most often it is sold in a neutral gray color. the insulation of a bathhouse ceiling with your own hands if you prepare the base for the material.

Conclusion

In order to insulate the ceiling in a bathhouse, you can use different insulation materials and each owner makes their own choice. If you want to save money, you can choose, for example, expanded clay or clay with sawdust, but the installation process is more labor-intensive.

Using materials such as mineral wool or penoizol allows you to complete all the work much easier and faster, but be prepared for more significant costs.

How to insulate a bathhouse ceiling with your own hands

The insulation of the ceiling in the sauna is carried out according to the instructions:

- Preparation;

— first isolation;

— steam protection;

- water film.

If you are interested in how to insulate the ceiling in a bathhouse, you should follow the instructions sequentially. As you can see, it all starts with preparation. Insulating the ceiling in a bathhouse is possible using standard tools.

You often have to remove plaque from walls Processing of the material is possible using scissors. Under the floor, before starting work, you can see what material is used. Next, a decision is made whether to use new or old insulation. The main thing is to keep warm.

Insulation of floor-type ceilings

I am interested in how to properly insulate the ceiling of a bathhouse. If a deck-type structure is being considered, it is worth starting with the base. The ceiling insulation scheme in a bathhouse involves the construction of a frame. Next, you can use meshes or films. Curious about how to insulate the ceiling in a bathhouse from the inside.

Glass wool is suitable for this, although it is worth considering the size of the room. Many people are still considering roofing felt for flooring construction.

Insulation of a suspended ceiling

An interesting question is which insulation is better for the ceiling in a bathhouse. Many people use a false ceiling, so expanded clay is ideal. Insulation of the ceiling in a bathhouse with a cold roof follows the instructions. differences are taken into account , but it is always worth starting with preparation.

If you are curious which insulation is better, expanded clay can be compared with fire-resistant polystyrene foam. as additional material. However, to insulate the room only with polystyrene foam.

Extruded polystyrene foam begins as solid granules of polystyrene resin. The plastic pellets are produced from an extruder where they are melted and mixed with important additives to form a viscous liquid. A blowing agent is then injected to cause the plastic product to expand.

Under carefully controlled conditions of heat and pressure, the plastic mixture is forced through a die into the desired shape. The rigid foam is then cut to the dimensions of the final product and is usually recognized as boards. This continuous process creates a closed-cell structure that appears as a mass of uniform bubbles with common walls between them.

A continuous smooth film is also formed on top and bottom. The closed cell extruded polystyrene foam structure provides superior durability.

Products are available in a variety of compressive strengths to suit different application needs. Due to its physical properties, this strength is not dependent on the use of cladding materials or laminates, which can sometimes be compromised during installation.

However, extruded polystyrene cladding products are available to add additional strength if specified for a specific application. Extruded polystyrene plastic also comes in a wide range of sizes and is up to 102mm thick, allowing it to be used in many applications.

Insulation of panel ceiling

If we consider the panel construction, it is interesting how to properly insulate the ceiling in a bathhouse. Experts in this case only talk about ecowool. In fact, insulation for a bathhouse on the ceiling is suitable due to its low weight and low thermal conductivity.

Where to order or buy

Insulation of the bathhouse ceiling is an important component of construction. Therefore, companies separately indicate ceiling insulation in the list of services provided.

Some craftsmen prefer to carry out thermal insulation work themselves. for them there is a section with companies offering insulation.

Ceiling, Ceiling insulation in the bathhouse · 03/17/2019 · 0

Types and design features

Among builders, the question that comes first is how to insulate the ceiling in a bathhouse, because there are a huge variety of designs:

- flooring;

- tiled;

- mounted.

If you are interested in how to insulate the ceiling in a bathhouse, it is simply important to look at the design. The flooring option is not practical for applying insulation.

If you evaluate the tiled type, it requires additional supports, so slats are installed. A false ceiling is the simplest, and any insulation is acceptable.

Flat ceiling

You can insulate the ceiling in a bathhouse with your own hands, if it is on a floor, if you immediately make a frame. Many people recommend a membrane, but it only works well in small spaces.

Thus, the question remains of how to insulate the bathhouse ceiling from the outside. The correct answer is roofing felt. This is an excellent insulation for the ceiling in a bathhouse with a similar design.

False ceilings

Insulation of the ceiling in the steam room of a hemmed-type bathhouse is easy with foam plastic. Professional builders understand that they will have to use several layers. The sauna ceiling sandwich works well in small and large spaces.

The steam throughput is also taken into account. Such thermal insulation shows good results.

Panel ceiling

If a panel bath is being considered, the ceiling insulation can be done with cotton wool. The material is extremely flexible, suitable for beginners. The question naturally arises of how to insulate the ceiling of a bathhouse in the attic.

In the case of cotton wool, it is easy to cut pieces and place them on the surface. If you are interested in how to insulate the ceiling in a bathhouse with your own hands, mineral options have greater moisture-repellent power.

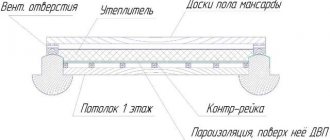

Installation of thermal insulation

To achieve the main goal - accumulation and “saving” of steam, you need to make 2 layers of PIP and 1 additional layer for thermal insulation. This measure will make the room warmer and more comfortable.

Experts advise placing layers perpendicularly. This arrangement will increase the strength of the entire structure and help avoid severe deformation. If you use mineral wool and clay, the process will take place in several steps:

- take an unedged board (5 cm) and attach it to the bottom of the beams;

- to support the filing, we fix the flooring along all the bases;

- tongue and groove slats made of aspen are attached to them (taking into account the gap for ventilation);

- We lay vapor barrier material on the outside of the roof;

- spread mineral wool 15 cm wide over the laid mixture;

- then we lay polypropylene film;

- We place boards on top of the resulting structure; this is the future floor of the attic.

If everything is done correctly, the end result should be an excellent steam room. All the steam will remain inside for a long time, and the steam room will not cool down for a long time.

How to insulate concrete floors

When we insulate a room with a concrete floor, we have to use special materials. Slag wool is suitable in almost all cases. At the initial stage, the question will be how to insulate the ceiling in a bathhouse. When using slag wool, it is important to prepare the base. The ceiling in the bathhouse is leveled from the inside, cells are formed. Next, you will have to make a blind area so that the insulation holds. Small or large sheets can be placed in the bath

Dry insulation method

If you are interested in how to properly insulate the ceiling in a bathhouse, you should consider the dry method. In this case, an air gap is used. Next, the question arises of how to insulate the bathhouse ceiling. Cotton wool and expanded clay are suitable for the dry method. The insulation for the bathhouse ceiling can be rolled or sheet.

View this post on Instagram

Publication from HOUSE▪️BANI▪️FURNITURE (@dom_bani)

If frame

The frame structure is a sandwich made of (for example) boards, OSB or just boards on both sides and insulation inside. Of course, stiffening ribs are added to this - a frame, as well as steam and moisture protection, but the main thing is that insulation is already present. And if the thickness is good, then you can simply cover the OSB with a vapor barrier, fill the sheathing slats and cover the walls in the bathhouse with clapboard.

If it turns out that there is not enough insulation, then additional insulation can be done, and then everything will be the same. Before covering the steam room in the bathhouse with clapboard, you can cover the walls and ceiling with foil as a vapor barrier.

Selection of material for waterproofing and vapor barrier

Insulation for the ceiling in a bathhouse can be selected only by price, but in the case of waterproofing, additional factors are taken into account:

— thickness;

- security.

I wonder how to insulate the ceiling of a bathhouse from the attic side. For vapor barrier, the following factors remain important:

— density;

— porosity;

— thickness. Insulating the ceiling of a bathhouse is often accompanied by mistakes that are repeated by beginners. They take different insulation materials and try to install them without preparation. This method of insulation is incorrect and entails unnecessary waste. The vapor barrier layers must be combined. A large amount of material does not solve the problem. In the case of foam plastic, attention is always paid to the joints. The layer of boards is not an obstacle to priming and further preparation of the base. Next, you can work on expanded clay or move on to cotton wool.

Insulation is the cheapest thing you can install in a room to make it as comfortable as possible at the lowest cost. Fiberglass or cellulose, and in some cases rigid materials, will actually save a lot of money on heating costs.

But this is not the main thing in saving heat; It is important to have a vapor barrier wherever there is insulation. Continuing the rule, the vapor barrier should extend to the heated part of the room, and not to the street.

Most of the insulation has a paper base. A vapor barrier prevents air loss from indoors to outdoors, thereby saving heat and making insulation more effective. It also prevents water vapor from escaping.

Traditional methods

from the attic side , so the problem needs a solution. If funds are limited, folk ceiling insulation will help. For this, ordinary shavings are used. It is curious how to insulate the ceiling in a bathhouse so that the sawdust holds on. In fact, ordinary clay is saved. The bathhouse may lose its interesting appearance, but it really works. Such advice naturally does not come from professional builders. It is worth understanding that new materials are being invented roofing Ceilings, of course, need protection. In the case of a bathhouse, we always choose a decent material.

Insulated ceilings require maintenance in any case . If places with cracks appear, you will have to change your choice.

Lining a wooden bathhouse with clapboard inside: is it necessary?

The first reaction of those who learn about the owner’s decision to line the inside of a wooden bathhouse with clapboard is, of course, surprise - was it worth spending money on expensive wood if you then cover it, like in a cinder block bathhouse, with clapboard?

But here, as in the story with the Roman and his shoes - “who of you knows where they are too tight for me?” Therefore, we will proceed from the fact that, without any particular reason, the owner of a wooden bathhouse will not hide its advantages under a layer of lining.

What reason could force him to do this? First of all, the thickness of the log house or timber is insufficient. If the calculation was wrong, then it’s time to dig, or not to dig – it will still be cold. And if so, then you need to insulate yourself. When you have insulated, you need to think about finishing, and the most common one is lining.

It also happens that you want to make a thermos in a steam room - cover it with foil. And if you do this, then the foil goes into the bathhouse under the lining. Insulation may or may not be done, the main thing is to separate the foil from other materials by air space - this is both a ventilation gap and a condition for the heat-reflecting screen to work, because metal conducts heat very well, while air conducts heat very poorly.

That is, in order to sheathe the inside of a bathhouse with foil and clapboard, you need to make a lath (on top of the insulation or directly on the wall), fasten the foil to the lathing, fill the slats again, now with counter-lattens, and install the clapboard on it.

Log house inside

Of course, before you start covering the log house, you should caulk it thoroughly or otherwise eliminate all heat leakage points.

After this, the issue of additional insulation is resolved. If it is necessary, then a complete thermal insulation “pie” is installed; if not, then it is enough to do as described above: make a lath, foil, counter-lattice in the steam room and sheathe the inside of the bathhouse frame with clapboard.

SAWDUST and cement or clay what to choose

Sawdust in the attic will be useful to retain heat. The ceiling pie can be covered with clay or cement, and it is important to choose something . , the ceiling insulation scheme looks effective .

It has the best viscosity and is superior in ease of application. However, lovers of traditional methods know the best way to insulate the ceiling. Naturally, we are talking about clay, although its superiority over cement at least in some respects has not been proven.

The characteristics of clay minerals that can be used as insulation materials are often discussed. For builders, the chemical composition and structural features of various types of artificial and natural clays are described.

Chemical structures are often considered complex because of their unfamiliar names, which are sometimes taken from the regions where they originate, although structurally only minor differences actually exist. Now in many countries the adsorption and aggregation properties of typical dyes in clays are compared.

The quality depends on the type and amount of metallic elements present in the clay, the amount of water adsorbed, and the structure of the organic matter. All of these factors are discussed in relation to insulation.

What can't be used in a steam room?

It is unacceptable to decorate the walls of the steam room with coniferous species (spruce, pine). The reasons for this are as follows:

- when the walls are very hot, touching them can become unexpected and quite unpleasant;

- drops of released resins can get on the skin and burn it.

It is not recommended to use hardwoods such as oak and walnut. This is explained by their high heat capacity, which leads to the accumulation and retention of heat on their surface.

In a steam room, the walls of which are covered with clapboard made of oak or walnut, it is usually difficult to breathe. In addition, if you accidentally touch them, you can burn your skin.

You should not cover the walls in the steam room with chemical materials: varnish, stain and other similar compounds.

This is due to the harmful effects of chemicals on the human body at very high temperatures.

Required thickness for each type of insulation

Insulation works if the thickness of each layer is taken into account. The first layer can be in the range from 3 to 6 mm. Next comes the vapor barrier, and the expert claims a thickness of 4-6 mm.

The outer side may be thickened, but much depends on the material. The steam room includes waterproofing and it is worth making the right choice. The optimal thickness for it is 6-8 mm. Thus, the features of insulation for a bathhouse. Common methods and tools are reviewed. The advantages and disadvantages of individual materials are taken into account.

Panel

Panel ceilings are made from pre-prepared wooden panels. Each shield is assembled according to a specific template:

- two bars are laid on a flat surface at a distance of 50 cm from each other, the front edges of which are aligned using a lath;

- boards are nailed on top using nails so that their edges protrude 5 cm beyond the edges of the bars (heat-insulating materials will be placed in these gaps when installing the ceiling);

- When the boards are attached, the panel is turned over and its inner surface is covered with a vapor barrier material, which is secured using thin slats.

All these operations are performed outside the bathhouse, so you will need help to move the workpieces to the roof for ceiling installation.

Transport and stowage

To prevent the panels from becoming deformed during transportation, they are secured with two jibs, which are later removed.

When installing panels on beams, a sealant must be placed (usually jute is used for this). There should be at least 10 cm between the edge of the panel and the outer edge of the wall - this distance will allow you to install the rafters at the desired angle without cutting.

After all the panels are laid, begin laying the thermal insulation. When using fibrous thermal insulation material, the width of its web should be slightly larger than the distance between the panel beams. If polystyrene foam is used for insulation, its sheets are cut exactly to the size of the distance between the bars.

Waterproofing is laid on top of the thermal insulation layer. It is placed on the heat insulator, but in no case on the beams of the floor panels.

To prevent heat from escaping through the joints between the panels, a heat-saving sealant is placed between them - felt with a polyethylene gasket.

After laying the insulation and waterproofing, they begin to install the flooring from the boards. To do this, a board, the length of which is equal to the total width of all ceiling panels, is attached to the panel bars with self-tapping screws or blind screws. Several short boards are then attached to the beams of each panel. The entire structure is again secured with a long board. So, alternating several short and one long boards, a continuous covering is formed. The joints of short boards are covered with an overhead strip.

Panel ceilings are quite difficult to install and you cannot do without help during their installation. But you can save on their installation by using remnants and trimmings of various lumber left over after construction.