For internal walls and ceilings, a number of civil and industrial buildings, in most cases the following is necessary: • expansion couplings for passage through the wall - to level out the temperature expansion of the pipelines themselves; • fire protection couplings - to provide protection against flame penetration into adjacent rooms during a fire. All these requirements are provided by the sleeve and couplings for the passage of pipes through the walls.

Features of the passage of pipelines through building structures

An incorrectly installed pipeline creates a potential danger of an emergency. Inside the building structure there are a large number of different utility networks. Communications of different materials and strength can pass through the same building elements. The technology for running a pipeline through building structures depends on their type and the material of its components. The latter can be made of copper, steel or various plastics.

How to hammer a bell

During repair work, reconstruction or expansion of the drainage system, it often becomes necessary to connect different lines. Before caulking a sewer pipe, it is often necessary to disassemble an old, defective connection. It is extremely difficult to hammer out a bell that has become overgrown with monolithic layers over many years. The main problem is the danger of destroying the socket of an entire pipe or tee. If this happens, you will have to disassemble and replace the entire riser or horizontal pipeline.

Before caulking out an old cast-iron sewer, it is necessary to clean the connecting element and remove all foreign objects and deposits. As a rule, various temporary patches of paint, additional layers of mortar, and other materials are applied over the standard connection. All such areas must be completely removed.

After this, it is necessary to determine what material the insulating seal is made of, since it is much easier to caulk a cast iron sewer with cement than with sulfur. If cement mortar is used, the process of disassembling the joint will be easier. However, if pouring with plumbing sulfur was used, the procedure will be complicated. The material will have to be heated with a gas torch or blowtorch, since it will not be possible to simply break and remove particles from the gap - sulfur has high strength and viscosity. You will have to work in a gas mask, since toxic gases will be released when heated.

Procedure

In order to caulk a cast iron sewer, you must first remove the cement or sulfur filling (1/3 of the depth of the socket), and then remove the hemp strand (2/3 of the depth)

The first stage requires caution and accuracy. There is a high risk of breaking the socket of a tee or other receiving element

First they use a chisel, then a screwdriver with a long thin blade. With gentle blows of a hammer, the screwdriver is immersed in the gap, breaking off small pieces of the seal.

Many sources recommend first tapping the socket around the circumference with a hammer, and then checking to see if the pipeline has become loose. This is useless advice, since it is impossible to caulk cast iron sewers in this way. Until the top layer of cement or sulfur is removed, the pipe will not be able to swing. In addition, hammer blows can break the socket, which will significantly increase the amount of work.

When the hard plug is removed, the joint will gain mobility. They move it a little to the side, pick up the rope and pull it out, swinging the pipe to the sides to facilitate the process. After this, the bell will be completely freed, the connecting element can be easily removed.

How to ensure maximum service life of building structures and pipelines?

There are a number of recommendations: • According to SNiP standards, non-insulated units should not have direct contact with building structures; • Before the horizontal outlet, protection is provided with a cement layer of several centimeters; • Use sleeves (cases) in places where pipelines cross; • To increase sound insulation properties, an elastic material is used, which is placed in the gap between the outer diameter of the pipe and the inner diameter of the case; • Sleeve waterproofing can only be used for slabs; • During installation, uneven shrinkage of the foundation is taken into account: gaps are sealed with mastic or sealants. Moreover, the internal diameter of the case must exceed the diameter of the pipe by 2 cm; • Copper components are also placed in cases, and the border with the building structure is treated with cement, in wooden houses - with asbestos; • Changes due to temperature changes are compensated by means of sliding supports, which must be taken into account during the creation of the project. At the exit, install a fitting (tee, elbow) to prevent it from being removed from the wall.

Pros and cons of installing an external chimney

A chimney located in the wall, of course, is more familiar to our eyes and does not attract the attention of others. But at the same time, it also has its shortcomings, which are more than covered by the external hood.

- Installing an attached external chimney significantly increases the fire safety of the room. After all, everyone knows that over time, soot deposits accumulate in the pipe, which, when heated at high temperatures, can flare up no worse than gasoline. At the same time, during its combustion, temperatures arise that only ceramics can withstand. Therefore, an external chimney is the safest in this regard.

- Minimizing possible smoke. With the correct design of a chimney of this type, the part of its outlet channel located inside the room is negligible, and therefore the probability of exhaust gases entering the room tends to zero.

- Possibility of arrangement without disturbing the roof covering and installation in an already finished building (I know from practice that not many people want to “make holes” in the roof).

- Simple increase in traction due to free choice of pipe height.

Certain disadvantages of this design include only the need for the correct choice of fasteners for its reliable fixation, the likelihood of strong windage when rising to a great height and a possible violation of the general style of the building.

Laying pipes through ceilings

There are 2 main caveats: • When using flammable insulation, the space around the pipe must be treated with basalt fiber, which does not burn. • The minimum distance to wooden structures must be more than 13 cm. To create a unit, an opening is made in the ceiling, the lower part is strengthened and a pipe is passed through it. It is important that the joints of the components are not in the ceiling-passage assembly. A sleeve with a protrusion thickness is inserted (SNiP 2.04.01). • Cement mortar is used to treat the area 10 cm above the ceiling, the layer should be a couple of centimeters 2-3 cm. • Pipes should be wrapped in waterproofing material, excluding gaps, and only then plastered. • Thermal elongation of pipes must be taken into account. • When the pipe passes through the ceilings, its free movement is ensured, i.e. install the sleeves. Moreover, their internal caliber should be 5-10 mm larger than the size of the pipe. The space is sealed with soft material with non-flammable properties, which will allow the pipe to move freely. The protective case can be made of plastic or metal.

There are also additional requirements depending on the type of pipeline and purpose of the room, installation method. Sleeves are used for the following reasons: • Straight sections of a polymer pipeline are susceptible to temperature changes, which requires free movement during thermal deformation. • For the possibility of dismantling if a section of the pipeline is damaged. However, in some cases, the use of sleeves in building structures is not economically justified. In addition, sealing the space prevents the occurrence of unpleasant odors and insects. When using the sleeve in wet rooms, the seal must ensure tightness: water should not enter through the gap into the adjacent room.

Foundation passage kit 175-200 Price: 33646.00 RUB

Sewer bushing 110 mm PP Price: 3079.00 RUB

Sleeve for passage through the wall KGF 110×240 mm Price: 1587.61 RUB

Nuances of heating systems

When installing heating systems in houses, some of the pipes end up in the thickness of foundations, ceilings, walls, etc. Technical standards provide certain recommendations for organizing the combination of pipelines with building structures.

For example, the places where the risers pass through the ceilings must be sealed with cement to the full thickness of the ceiling being organized, and the perimeter 80-100 mm above the ceiling must be protected with a cement layer of 20-30 mm. Before sealing the riser with pipe mortar, you should wrap it with rolled construction waterproofing without a gap.

Another important point: when a polypropylene heating pipe passes through building structures, a specially designed pipe sleeve must be provided.

Diagram of a pipe in a sleeve.

The interpipe space is sealed with soft, non-flammable material so as not to interfere with changes in the physical parameters of the pipeline during its linear temperature deformations.

Equipping pipelines with sleeves: necessity or desire

The use of specially designed sleeves when crossing heating pipes of walls and ceilings of buildings is justified for a number of reasons:

Scheme of installing a pipe into a sleeve.

- Sections of polymer risers are extremely sensitive to temperature changes, which, accordingly, affects their ability to significantly move. Installing sleeves in such cases allows you to create conditions under which the pipeline in the event of temperature deformations (during installation and operational work, as a result of changing seasons or time of day) can move freely in the walls and ceilings.

- Ensuring the possibility of dismantling a faulty section of pipeline heating without destroying it. However, equipping each building pipeline structure with sleeves is not always advisable, since most often their need is determined by force majeure circumstances.

- Elimination of penetration of odors and insects from adjacent rooms.

The use of waterproof material when sealing the space between the pipe and the sleeve is not always necessary. This is only necessary if the sleeve is in the overlap. For example, if in the event of an accident on a heating riser from a metal-polymer pipeline, water should not penetrate through the interpipe gap to the lower floors.

Determination of sleeve sizes and materials

The inner diameter of a correctly selected sleeve should exceed the outer diameter of the heating pipe by 5-10 mm.

The length of the part must be 20 mm greater than the thickness of the building structure.

In addition, the following should be considered during the liner sizing process:

In a correctly selected sleeve, the inner diameter should exceed the outer diameter by 5-10 mm.

- A protrusion above the ceiling of 50 mm is justified for rooms where there may be cases where the water level rises above the level of the finished floor (in particular, showers). The seal of the product in this case must have waterproofing.

- Excessive protrusion is not always advisable in terms of installation costs - the shorter the structure, the cheaper it is.

- The dimensions of the products should be determined depending on the method of installation of the heating pipeline: with hidden installation, it is possible to neglect the protrusion; for open installation, it is necessary to use parts with dimensions determined by the interior of the room.

In any case, the gap formed between the sleeve and the polymer pipeline fittings should not prevent its high-quality sealing. The inner diameter of the pipe sleeve must allow for the free passage of failed pipeline parts.

Installation of sleeves in walls and ceilings for utility networks

The sleeve should protrude beyond the wall. However, some features should be taken into account: • The standard requirement is a 50 mm output, but this is not always justified. • In rooms where the possible water level is higher than the clean floor (bathtub), a hermetically sealed sleeve near the pipeline is required. • Sometimes the case can protrude only 5-7 mm, since it is not economically feasible to make it large. • The sleeve should not be an obstacle to the finishing of the walls - protrude beyond the plaster or wallpaper. The size of the gap should ensure high-quality sealing with material. The inner diameter must allow free movement of the pipe. Practice has shown that sleeves are made from sections of polymer or metal pipes. In some cases, it is possible to use a rolled waterproofing material - roofing felt. But it is worth remembering that they contain petroleum components. This is undesirable for wooden building structures. Non-metallic sleeves have an advantage. No burrs or sharp ends that often scratch polymer pipeline components. To solve the problem, the edges of the steel sleeves are processed and flared outward. Plastic, in turn, does not have good adhesion to cement mortar. The thickness of the walls is determined by the type and objectives of the structure.

Connection methods

The assembly of cast iron pipelines is a complex and responsible task. There are several types of connections:

- into the bell This is the most popular type, which is called “caulking of sewer pipes.” The process requires accuracy and experience, strict adherence to technology requirements. Proper caulking can withstand several decades of leakage use;

- coupling connection. This option is used for socketless pipes. Special couplings are used that tightly grip the edges of the elements being connected. The build quality is high; no special experience or skills are required to complete the work. However, the necessary conditions for installing the coupling are not always available.

There are couplings that are not equipped with threaded clamps. They consist of two sockets into which the ends of the elements to be connected are inserted. Assembly of such lines also requires stamping of sewer pipes, performed using standard technology.

The procedure consists of filling the socket gap with a sealant and sealing it using hardening compounds. The sealant most often used is tarred hemp strand, which is stuffed into 2/3 of the socket and thoroughly compacted. The remaining third is then filled with a durable protective compound. For this purpose, cement and plumbing sulfur are used. Lead caulking is sometimes used in pressure lines, a complex but very effective procedure.

Gas duct passage through a wall, passage unit

A sleeve is also used to lay the gas duct. It is made from pipe according to GOST 10704-91. In external walls, the protective casing must protrude 20-25 mm onto the street. Moreover, on this side, the gap between the pipe and the sleeve should be sealed with grade 4 bitumen. The remaining gap is sealed with tarred tow. The internal size of the case should be 20-30 cm smaller. It must be sealed with cement mortar in the wall. Further installation is possible only after the sleeve has completely dried and secured. Considering the level of responsibility during the construction of gas mains, as well as the fact that all gas systems are subject to mandatory acceptance by service organizations, it is necessary to adhere to the requirements for the passage of gas mains through walls and ceilings with 100% accuracy.

When the pipe passes through the roof, a sleeve is also installed. It should protrude 30 cm above the outer surface of the roof, and 2 cm above the inner surface. The space between the pipe and the sleeve is also clogged with tarred tow; it is not necessary to use bitumen. The sleeve itself must be cemented only in the concrete part of the floor. The outer part of the sleeve from the street and the outgoing gas pipeline are protected from moisture by metal linings. Any seal must provide for the possibility of replacing or additionally installing new components. Additionally: you need to understand that sleeves for ventilation pipes differ from special roofing transitions used to remove the chimney.

The use of sleeves when installing pipelines through building elements is rational and justified. In most cases, this is a requirement of construction SNiPs. The sleeve will allow timely replacement of pipeline components, provide insulation from the wall surface and compensate for the thermal expansion of the material.

Sleeves for pipeline passage: structure, types, equipment

If you have a private house or cottage, then this issue will become one of the decisive ones, because any building needs a water supply system, a gas pipeline and a sewerage system. In the twenty-first century, there are a huge number of opportunities to protect housing from environmental and atmospheric influences. The safest and lowest-cost method is to install sleeves.

In most cases, pipeline sleeves must be used

Several theses follow from this.

- Do I need to use sleeves or other materials to pass pipes through walls?

- Which cases are better?

- Which material is the most resistant?

- What is the internal volume of penetration in the floors?

- How to seal?

- At what distance from the partitions should it be located?

- What installation difficulties can you encounter?

- Is it possible to lay heating through walls using a sleeve?

Read the article and you will find the answers you are interested in.

Installing sleeves is the most cost-effective and safest way

Structure of sleeves in walls and ceilings

The first requirement when integrating pipelines, gas pipelines and sewerage into building structures is the continuity of the insulating layer. This requirement is due to the fact that in the presence of cracks, holes and other defects, air and dust begin to enter the pipes, as a result of which they are deformed and destroyed.

Naturally, after building a residential building, you do not want to encounter a similar problem, the solution of which will not only take a huge amount of time, but also waste of materials, up to partial or complete re-filling of the foundation (floors).

To prevent such moments, there are sleeves for pipelines, sewers, and cables.

The issue with sleeves needs to be resolved during construction, then it will be problematic

Types of pipeline sleeves (material)

- Metal sleeve

- Fireproof (clay, ceramic) sleeve

- Polymer sleeve

Steel sleeve is the most reliable option

- Steel is the most durable and expensive material that is suitable for almost any floor.

They are used on large-scale construction sites, as they can withstand pressures of up to 120 tons per 1 square meter. They are also very popular in the construction of reinforced concrete structures - they can be concreted not only at the construction site, but also in the production workshop. The edges of such a part must be sanded so as not to damage the polypropylene pipes inside. - Fireproof - distinguish between clay and ceramic. Used as an insulating material for chimneys. The main disadvantage is fragility, which means be careful when installing (you can not only break your purchase, but also get a cut injury).

- Polymer - used in interior floors for pipelines and cables. The main distinguishing feature of the material remains wear resistance and cold resistance.

Each material has its own characteristics and disadvantages

Equipment

Before choosing a material for construction, carefully check the pros and cons, taking into account the surface surrounding the sleeve, the size of the pipe itself, safety and previously integrated systems. The most important advantage is the acceleration of repair work. In addition, thanks to the arrangement of protection, you increase the wear resistance of the line and simplify their possible future replacement.

Pipeline diagram with sleeve

The most vulnerable parts are their gaps. When assembling, it is recommended to place the joints so that they do not lie in the same plane, and the longitudinal seams are shifted relative to each other by 1-1.5 centimeters.

Where pipes pass through building structures, it is necessary to insert sleeves from pipes of larger diameter with a soft gasket. The cartridges are inserted before placing the material and covered with concrete mortar. In addition, the specifics of the passage of pipes through the wall are directly related to the type of communications being laid.

Each method is determined by individual nuances, therefore, in order to provide individual protection to the internal life, we will consider the designs “in cross-section”.

When installing sleeves, many nuances are taken into account

- Plumbing In the case where the installation is made of steel parts, a protective coating is applied to them at the junctions with building elements to prevent the ingress of debris. If the pipeline is intended for cold water supply, a cover will be required.

It will help avoid moisture condensation on the surface, thereby making the channel last decades longer. If plastic profiles are used for laying, then you should first look at the instructions for it.If there are seals in the parts of the pipeline entrance to the room with the possibility of groundwater runoff, then waterproofing couplings are used in them and covered with concrete mortar so that liquid does not leak into the lower tiers of the building.

If steel parts are installed, they are treated with a protective layer at the end

- Drain pipes The specific design of cast iron caps lies in their difference from other materials that require reinforcement and sound insulation when crossing pipelines.

To do this, you need a steel cartridge with a gap of 20-25mm. must exceed the pipe. The specificity of the design of cast iron caps lies in their difference from other materials - Steam heating In a steam heating system for internal rooms, sleeves play a primary role.

If they are not installed, temperature changes will lead to deformation of the main line and the formation of cracks in the ceilings. Just like for installing hot water plumbing, you should rely on polypropylene caps. The fastening mechanism is distinctive; during production it is characterized by high heat resistance and maintains a high and constant temperature from the inside. Based on this, do not rush into purchasing, but properly study the offers of manufacturers who not only meet your criteria, but also meet the criteria of SNiP. This will save your strength and resources. Installation of sleeves for steam heating is a mandatory procedure - Size of the inner diameter of the sleeve This point becomes decisive when installing equipment in partitions, therefore it must be approached with the utmost care and pickiness.

If the outer and inner diameters of the sleeve for the hot heating pipeline do not match, the most unexpected surprises may appear. The structure must be chosen so that passage through the floors is free. The parts have similar technical gasket features, but at the same time have different endurance. When the pipe is laid through the ceilings, it is necessary to connect the sleeves, the outer diameter of which should be 10-15 mm wider than the pipe, with a gap of 2-3 cm. In this case, the case itself must be tightly secured in the passage hole. The gaps between them are sealed with glass wool. For metal-plastic pipes, when passing through building structures, try to install fasteners made of plastic pipes with a slightly larger outer diameter. As a result, in order not to make a mistake with the cost and reliability of the work done, we recommend that you turn to professionals - they will save both nerves and time. The issue of sleeve size must be approached with maximum care and pickiness. - Sealing

To protect the pump when crossing pipelines and partitions, it is recommended to seal them tightly so that even small gaps do not remain. The inner diameter of the sleeve should be 30mm wider than the thickness of the pipe. We insert washers with angular threads with a longitudinal section of 3-4 mm onto the connections.

Pipe sealing should be maximum

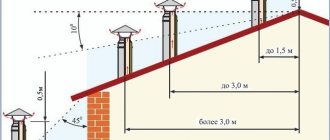

Passage of a flue through the wall of a building

The most successful way to exit the gas duct in the partition is from the pediment side. But if this cannot be done and the chimney comes out from the side of the slope, then we weld the stand and attach the structure to it with sliding fasteners. The result is an intelligent and long-lived system.

Diagram of the chimney exit through the wall and one of the implementation options

: Water pipe sleeve connection

Source: https://couo.ru/kvartira-i-zagorodnyj-dom/stroitelstvo-i-remont/vybiraem-gilzu-dlya-proxoda-truboprovoda-cherez-stenu.html

Types of lining

Sandwich pipe lining

The principle of behavior of lined liners and their placement in the channel is the same, but the liners differ in material, so there are certain nuances for each type.

Specialized stores offer inserts:

- made of polymers;

- of steel;

- from corrugated pipe;

- polymer sleeve;

- made of stainless steel.

Polymer sleeves

A plastic pipe is installed inside the operated chimney. PVC products are reinforced with fiberglass fabric and, when heated, acquire plasticity. As a result of this property, irregularities and spaces on the clinker surface are filled. After hardening, the internal area becomes smooth, and the wall has a thickness of 2 cm.

The downside of the application is the temperature limitation. Lining a chimney made of brick with plastic is done with exhaust flows up to +250°C, so they are installed to work with low-power units.

Application of steel elements

Corrugated pipe lining

A structure made of a rolled pipe is placed in the straight section of the chimney, or rectangular, square, oval and round shapes are made with your own hands. Sheets are taken with a thickness of 0.5 to 1.5 mm. In channels made of steel materials, it is possible to provide the required modules for cleaning, inspection, and containers for accumulating condensate in accordance with the standards.

Steel products are used for fireplaces using various types of fuel. The material resists acids and is not subject to plaque deposits. The disadvantage is that only straight sections can be lined with this method; winding pipelines cannot be equipped.

Using corrugated pipe

Manufactured using various types of stainless steel, the pipe shells are made of two layers. The positive thing is that flexible liners are used for complex channels with turns. The products do not require connecting elements. Double-layer inserts significantly reduce the diameter of the air duct; this must be remembered when choosing.

Polymer sleeve

Polymer sleeve for chimney lining

The sleeve is made of copolymer resin and reinforced with fiberglass. The insert is used to combat condensate drops; it is used to treat low-temperature chimneys and those coming from powerful boilers.

Types of polymer products:

- Fitfire is a liner containing two layers, the maximum element has a length of 60 m. After installation, the chimney duct has a diameter of 80 - 500 mm. The manufacturer specifies a service life of 50 years; the hose is used to remove low-heat gases.

- Fitfire HT 1000 is used in pipelines of sauna and fireplace hearths with high smoke heating. The sleeve consists of three layers, the middle one is a reinforcing mesh.

When lining the chimney with a polymer sleeve, the internal protection is obtained without seams, with a smooth surface.

Stainless steel pipe

The material is one of the most popular types. The products work for many years and do not deform due to high temperatures or corrosion. Lining a brick chimney with a stainless pipe is often used because... There is a large assortment of ready-made inserts for sale, sometimes products are made by hand, taking into account the dimensions.

The inserts are made from stainless steel sheets with a thickness of 0.8 - 1.5 mm. To connect and turn the channel, standard tees and pipes are used, but to install them you need to know the exact layout of the chimneys. Sleeves with a rectangular cross-section are installed only on straight sections of chimneys.

Advantages of external installation of chimneys ↑

The external method of wiring the outlet pipe has the following obvious advantages:

- Removing the main part of the drainage channel from the house allows you to increase the usable living space of the room.

- The installation of a combustion product exhaust system can be carried out upon completion of the main construction activities.

- External installation of a chimney will not require you to spend a lot of time and effort.

Easily removable disadvantages of this approach include:

- The need for mandatory insulation of chimney pipes.

- Possibility of significant heat loss with low quality thermal insulation.

- The difficulty of combining the design of the chimney with the architectural style of the building.

Despite all these difficulties, when deciding how to make a chimney through a wall, preference is usually given to its external placement (full or partial).

Differences in introducing bottled gas

Gas cylinders are placed in a metal box outside the house, and the connection to the stove is made through a flexible rather than metal hose.

Installation diagram of gas equipment in a system with cylinders. The rubber hose is protected by a reliable metal sleeve installed in the wall of the house.

The house is made of timber, and the gas supply hose is of small diameter, so making a hole and installing the case is not difficult.

Image gallery

Photo from

Hole in the wall of a wooden house

Gas hose entry from the inside

Adapter from rubber to bellows hose

Metal sleeve on the outside of the house

You cannot install the sleeve between beams or logs; it is recommended to drill a hole in the middle.

Installation instructions for the case

The process of installing the case is simple and takes little time. It is necessary to prepare in advance a tool for punching the wall and material for sealing the cavities between the sleeve and the wall.

Step-by-step instruction:

- Make a hole in the wall with a diameter exceeding the estimated diameter of the gas pipeline in a location determined by the project.

- Place the sleeve inside the hole and check if it is the right size.

- Fill the gap between the sleeve and the wall tightly with concrete mortar.

- Wait until the solution dries and check the stability of the installation.

The remaining work is usually carried out by gas service employees - they lay the gas pipeline and insulate it.

To pierce a concrete or brick wall, use either a regular hammer drill or diamond drilling - an expensive pleasure, but the result is a smooth and beautiful hole

If the house is wooden, then a large hole in the beam can be made with a drill, drilling around the perimeter or using a large-diameter crown.

Material

To make a sleeve for sewer pipes, a passage through the ceiling can be used:

- Metal. Steel products are characterized by strength, reliability and durability. They can be installed in any ceiling. Steel products can withstand loads of more than 100 kg per 1 m2. Pipeline protection can be installed directly at the construction site and at one of the stages of manufacturing a reinforced concrete structure. Before concreting, the edges are sanded to prevent damage to the polypropylene pipeline.

- Polymer materials. A polymer sleeve is used to arrange the sewerage passage through the ceiling between floors. The material is resistant to wear and low temperatures.

How can highways be laid?

The gas pipeline can be laid underground or above ground. The latest technology is the most economical. The method of laying underground is considered safer. This is how gas pipelines are usually pulled through populated areas. However, the implementation of such a technique is more expensive. Such a highway is also more expensive to maintain.

Some sections of the network in large populated areas can also be laid above ground. But they are almost never too long. Aboveground gas pipeline installation is also provided on the territory of industrial enterprises.

Before starting the installation of the network, it is mandatory to draw up its diagram. The highway project, according to the regulations, must be carried out in topographical terms.

Making or buying?

You can find a large number of ready-made solutions on sale - from inexpensive stamped 20-ruble sleeves of small diameter to products made of thick-walled structural steel. Almost all cases are universal, that is, they are used for making penetrations for any communications, including gas ones.

To protect against exposure to a humid environment, manufacturers apply a zinc coating or paint to the metal. The products are suitable for installation in any type of wall and have fire safety certificates

But if you don’t want to use a purchased part, and you have a lot of material left over from building a house, then you can make a sleeve with your own hands. A large diameter pipe is suitable, according to the standards - exceeding the gas pipe by about 20 mm.

A fragment is cut from the pipe, equal in length to the width of the wall - its edges should not protrude beyond the surface. The ends are cleaned so that they do not have burrs or sharp edges. Then the workpiece is coated with protective paint for metal, preferably in 2 layers - the sleeve is ready.

Intersection of the gas pipeline with other communications and roads:

We carry out design, construction and installation work on

· At places where gas pipelines intersect with underground communication manifolds and channels for various purposes, heating mains of ductless installation, as well as at places where gas pipelines pass through the walls of gas wells, the gas pipeline should be laid in a case. When crossing with heating networks, gas pipelines should be laid in steel casings.

· Covers for polyethylene gas pipelines of all pressures in the territory of settlements must additionally be installed at the intersection with underground utility networks located below the gas pipeline route.

· When crossing underground gas pipelines of all pressures at intersections with railway and tram tracks, highways of categories I-IV, as well as with main streets and roads, cases should be laid in cases. In other cases, the issue of the need to install cases is decided by the design organization.

· Design, construction and installation work on the removal of gas pipelines from the roadway during reconstruction, road expansion and installation of covers at road crossing areas.

· We carry out work on constructing cases using both open and closed methods (punching, puncture, directional drilling).

Announcements on NN.RU - Construction

We invite furniture showrooms, shops, online stores to cooperate. We are.

We have a tank (capacity) of BU 85 cubic meters available. Clean, steamed, without residual cargo. Suitable for storage of fuels and lubricants, technical equipment. Price: 220,000 rub.

I will deliver a new ash orchid set for free around the city of Nizhny Novgorod, Dzerzhinsk. There are other colors and models from RUB 5,000 on sale. Price: 7,500 rub.

Hanger in the hallway, pouf for the hanger with free delivery to the entrance of Nizhny Novgorod Dzerzhinsk, soft wall panel and pouf. Price: 3,400 rub.

Additional standards

All norms of distances from the gas pipeline to communications were taken care of by the adopted resolutions. There are reference tables in the PUE standards and the minimum distance provided for gas pipes in main pipelines, residential and industrial buildings.

Power supply cables

Everything about specific cases that may constitute an increased danger - from a huge overpass to an electrical outlet located dangerously close to a thin gas pipe connected to a cooking stove - depends on the type of cable and voltage, gas pressure and its type. If in doubt, it is always better to play it safe and check your calculations with a specialist than to endanger the world around you.