A foundation is a structure that takes on the load of a constructed building and transfers it to the base. The foundation may be of several types, including strip foundation. This type is very popular in private construction, since its construction involves quite reasonable costs and simple construction technology.

Installing a strip foundation is a fairly simple process; the main thing is to study some technological features. It is advisable to lay the strip using a shallow laying method on dry, non-porous soils, and if the soil on the site freezes deeply, then the construction of a strip foundation is more expensive due to the large volume of excavation work associated with deepening the strip.

Types of strip foundations

The choice of foundation type is a decisive point, since it is an important structural element of the entire building. If a mistake is made at the beginning of construction, that is, the foundation is incorrectly planned or made, this can lead to serious consequences. It may have distortions, deformations, deposits and cracks in the supporting structure.

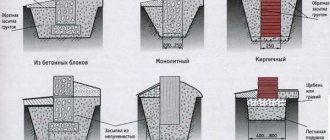

Strip foundations have several main types:

1. Shallow (shallow) – A shallow strip foundation is optimal for lightweight structures: wooden houses, foam concrete and frame houses, as well as small brick ones. It is located on slightly pubescent soils, its depth is about 50-70 cm.

Shallow tape device technology and its parameters:

| Options | Degree of soil heaving | ||

| Highly heaving | Medium heaving | Low heaving | |

| Thickness of the cushion protecting against heaving soils | 0.4m | 0.2m | 0.1m |

| Depth of the trench under the tape | 0.7m | 0.5m | 0.4m |

| Trench width for tape | 0.8-1.3m | 0.7-1.3m | 0.7-1.2m |

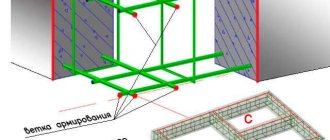

Scheme for laying a shallow strip foundation

Diagram of the device of a shallow-depth tape:

Scheme for laying a shallow strip foundation

2. Deep laying - Designed for massive houses and structures located on difficult or heaving soils. In addition, this type of strip structure is necessary when planning a basement or garage in a house. Its construction requires more significant labor and materials, and its depth is 20-30 cm below the freezing point of the soil, on average at a depth of 1.8-2 m. Under the walls inside a house or building, a shallower depth of 40-60 cm is possible for the tape.

Diagram of the deep-laying belt arrangement:

The choice of a strip structure, shallow or deep, depends on the degree of load, the geology of the soil and the problem that needs to be solved, for example, constructing a basement, plinth or garage.

Plastering

It is a type of coating-type waterproofing and is used to level surfaces. The material is a dry mixture to which components are added for water resistance. It must be applied with a spatula or brush.

Foundation for a garage - description of construction technology and selection of the optimal typeWhich foundation is better - how to make the right choice depending on the type of soil

Building a foundation - where to start building a foundation and a step-by-step description of the construction technology with your own hands

Do you need waterproofing for a strip foundation?

There is a clear answer to the question of whether waterproofing is needed, and it is YES, regardless of whether the house has a basement or not. Waterproofing is designed to protect the buried part of the tape from the effects of water, moisture, salts and minerals in the soil that can destroy concrete over time.

In the absence of waterproofing, the concrete strip base can face the following consequences:

- Cracks - concrete can crack or collapse as a result of constant temperature changes, since in the absence of waterproofing, water is absorbed into the concrete, freezes in winter, and thaws in spring, forming destruction, microcracks, pores, capillaries and voids in the concrete. If the tape is left without proper protection, the destruction intensifies every year as it overlaps each other.

- Destruction - Soil, surface and ground water are aggressive environments containing various impurities, minerals and salts, which, in the absence of waterproofing, can destroy the concrete base strip.

Important: Concrete tape is not intended to be constantly in water or to withstand exposure to moisture, various salts, minerals and aggressive environments. The reliability of the foundation is the key to the capitalism and durability of the structure.

Collapsible small panel formwork

An example of small-panel collapsible formwork

A design in the form of collapsible small-panel formwork is usually used for the development of summer cottages. Shields are made of plywood or wood. In this case, the boards should not be wet (less than 22%), their thickness is 40-50 mm and width 150 mm. First, stakes are driven into the ground, then shields are attached to them using braces. During installation, the bends and depressions of the concrete surface are monitored using a two-meter strip. Depending on the desired characteristics of the concrete surface, the distance between the panels and the size of the brace step are calculated.

Types of penetrating waterproofing

Waterproofing technology

If the tape was made from a monolith, then 7-10 days after pouring it, it is necessary to remove the formwork and begin work related to waterproofing. When constructing a strip of blocks, you can begin waterproofing as soon as everything is done. Regardless of what material was chosen for the construction of the tape, it must be protected both horizontally and vertically.

Horizontal waterproofing

Horizontal insulation serves as a cut-off between the tape and the subsequent structure of the slab or walls of the house, which is why horizontal waterproofing is also called cut-off waterproofing. This protection prevents water and moisture absorbed into the concrete from below and rising by capillary action, forming wet spots and leaks on cold joints inside the constructed basement or basement.

Installation technology:

- Surface cleaning;

- Applying primer or primer;

- Cut-off waterproofing device.

You can read more about horizontal insulation in the article - “Horizontal waterproofing of the foundation: Device technology and materials needed for this.”

Installation diagram:

Installation diagram of horizontal strip base insulation

Horizontal waterproofing

Vertical waterproofing

Vertical insulation protects the vertical surface of the tape, located below ground level, from exposure to water and aggressive environments. If there is vertical protection, water and aggressive environments will not be able to exert their negative pressure on the concrete from which the tape is made, which will give it the opportunity to last a long time.

Installation technology:

- Cleaning vertical surfaces;

- Applying primer or primer;

- Vertical cut-off waterproofing device.

You can read more about vertical insulation in the article - “Vertical waterproofing: materials and methods of its installation.”

Vertical protection installation diagram:

Vertical insulation installation diagram

Installation of drainage system

If there is groundwater or marshy soil, it is recommended to make drainage around the strip structure. This system will allow water to be removed from the base of the tape, which will ease its pressure on the completed waterproofing, which in turn will extend its service life by 3-4 times. In the presence of groundwater, drainage will protect the structure from erosion and movement, which can cause destruction and cracks.

Important: When installing drainage, it is recommended to install the system at a level of 30-50 cm below the level of the tape, so that it takes in both the water that approaches it and the water that will be located under it.

You can read more about the drainage system in the article - “Turnkey installation of drainage around a house: Proper drainage, its types, installation technologies, diagrams and prices”

Installation diagram of a drainage system for draining water from the foundation:

View diagram

Diagram of the drainage system

How to determine the waterproofing layer

Experienced experts recommend adhering to several rules and technical requirements. They include:

- Level of groundwater and surface water;

- When choosing waterproofing, it is necessary to take into account the type and design of the building;

- Particular attention must be paid to possible floods. A similar requirement applies to buildings located near water resources;

- It is important to consider the composition of the soil during frost periods.

Types of waterproofing

To waterproof a strip structure, different materials are used, from the simplest bitumen mastic to high-tech systems such as liquid rubber. These materials are used to process the tape horizontally, as well as vertically from the outside and inside.

Next, we will study the main waterproofing systems designed for waterproofing strip foundations.

Bitumen mastics

Bitumen mastics are one of the cheapest and simplest methods of waterproofing.

This type of insulation is applied using a construction roller or brush in 2-3 layers, allowing the previous one to dry. Mastics are usually supplied in plastic or metal buckets of varying weights.

The disadvantage of this method will be its fragility, since bitumen mastics can quickly become unusable under the influence of aggressive soil and water environments, as well as under the influence of seasonal temperature changes.

Roll welded and self-adhesive materials

Fused and self-adhesive waterproofing comes in rolls made from fiberglass, fiberglass, polyester and bitumen-based binders.

Application method:

Rolls are applied to the surface using a torch using the fusing method. The rolls are fused overlapping and in at least 2 layers, overlapping the seams of the previous one.

The main disadvantages of roll waterproofing are:

- The presence of seams between the rolls, which diverge over time and allow water to pass under them, thereby breaking the tightness over the entire surface;

- Lack of adhesion (adhesion) to the surface, due to which water can walk under the waterproofing carpet moving from one place to another.

You can read more about roll waterproofing in the article – “Design of roll waterproofing”.

Plaster compositions

Plaster compositions are made on the basis of cement, polymer and acrylic additives. It is various additives and additives that give plaster and cement insulation its hydrophobic properties.

Method of application: To apply plaster compositions, spatulas and construction brushes are used. These mixtures are applied by coating on the surface in 1-2 layers.

Disadvantages of the method: Most cement mixtures do not have a high coefficient of elasticity and can crack when the building shrinks, which will compromise waterproofing.

You can read more about cement insulation in the article - “Cement-based waterproofing: Features, types and methods of its application.”

Penetrating compounds

Penetrating products have the ability to penetrate concrete pores and small capillaries, helping to clog them and prevent moisture penetration. These products are mainly used indoors and in situations where access from outside is not possible.

Method of application: Use a brush or roller for application. Before and after coating with a penetrating composition, the concrete must be moistened abundantly. If there is insufficient moisture before the device and for 5-6 days after the device, penetrating systems will not work.

Disadvantages: Where the porous structure of concrete has large voids or cracks, penetrating systems will not work, which will lead to leaks in problem areas of concrete or FBS blocks despite the waterproofing done.

You can read more about penetrating compounds in the article - “Penetrating waterproofing: A detailed description of its work on concrete, types of materials and application technologies”

Scheme of operation of penetrating mixtures:

Liquid rubber

Liquid rubber is a reliable and durable protection for strip foundations from moisture, water and aggressive environments. Liquid rubber consists of modified bitumen, latex and various polymers, which gives it such unique properties as:

- High coefficient of stretching and elasticity (more than 800%), allowing the rubber not to diverge or crack during shrinkage of the foundation or its dynamic movement;

- Complete absence of seams;

- 100% adhesion to the surface.

Application method: Liquid rubber can be applied by hand coating using a brush and a roller or by spraying using a special spray unit.

You can read more about liquid rubber in the article - “Waterproofing with liquid rubber”

Polyurethane insulation

Polyurethane mastics are based on polyurethane, the main components of which are polyols, diols and diisocyanates. Thanks to the combination of these components, the resulting coating is waterproof, elastic and resistant to mechanical pressure.

Method of application: Polyurethanes can be applied by spraying through special equipment or manually with a roller and brush, having previously prepared the composition for application and mixed all components in the correct proportion (if there are 2 or 3 component materials).

You can read more about polyurethane coatings in the article - “Polyurethane waterproofing”.

Advantages of self-adhesive insulation

As noted above, roll types of waterproofing are chosen for work. Cover the bottom layer with bitumen, which, when heated, allows the insulation to be firmly fixed on a vertical or horizontal plane.

For work, special adhesive compositions are used, which, under the influence of high temperature, allow achieving tight fixation. Care must be taken during work. Failure to comply with the technique increases the risk of injury.

The only drawback of this type of protection is the price of waterproofing the foundation. Experienced specialists can fix this material on the surface.

What can be done if the strip foundation is not waterproofed?

If the house has already been built, a blind area, storm drainage, and landscaping have been completed, and then it turns out that the strip structure does not have horizontal or vertical waterproofing, then several actions can be taken that differ in their approach to solving the problem.

In the absence of vertical waterproofing of the tape: The house must be dug up, thereby disturbing the created blind area and the landscape around the house. After excavating the house, waterproofing is applied to the tape. Since the house has already been dug up, it is recommended to install a drainage system in the dug trench , which will drain water from the foundation, preventing it from constantly being in water.

In the absence of horizontal waterproofing of the tape: If your strip foundation does not have horizontal protection from water, then it is quite possible that through voids, capillaries and microcracks in the concrete, water and moisture will rise through the tape up the slab or walls and appear in the form of a wet spot or damp wall in the area of the cold seam where the floor and wall meet. Having dug up the house, you will not get to the place where it was necessary to perform horizontal or cut-off waterproofing, since it is located between the tape and the wall or between the tape and the slab. In this case, the only way to restore is to use injection waterproofing.

Restoring waterproofing by injection

The injection system can be used from inside the premises, when the house has already been built and put into operation. When restoring the horizontal insulation of the tape, work must be carried out in the area of the cold seam where the slab and the wall meet; this is what will help the injection composition penetrate deep into the cold seam and serve not only as its protection, but also as protection against the capillary rise of moisture from the bottom of the tape up the wall (which it was supposed to serve horizontal waterproof system).

When performing restoration work using injection, to achieve the most effective and durable result, you must perform the following steps:

- It is necessary to reach the base of the cold seam (slab and wall) - For this purpose, the edge zone of the finishing elements of the slab (tiles, screed) and walls (plaster, drywall, etc.) are dismantled;

- Reinforcing a cold seam - so that when injecting, the injection resin goes deep into the room, and not into the room (through a weak joint), the seam is opened by making a small groove, and then sealed layer by layer with a special expanding sealant;

- Injection - injectors are installed into the wall structure at an angle of 45 degrees, so that when injecting, the resin gets exactly at the contact between the wall/slab and the tape (where there should be a horizontal cut-off) and fills this space.

You can read more about the injection method in the article – “Injection waterproofing”.

Diagram of horizontal waterproofing using the injection method:

GOST requirements for moisture protection of buildings and structures

There are approved rules and recommendations for foundation waterproofing. They are enshrined in the following regulatory documents:

- GOST 27751-2014;

- SP 250.1325800.2016;

- SP 72.13330.2016.

The standards provide for different waterproofing schemes depending on the type of foundation, as well as general requirements:

The insulation thickness should vary from 3 to 6 mm.- The material is applied to concrete with a moisture content of up to 4%.

- Waterproofing work can be carried out at temperatures from -30 to +30, but the recommended temperature for bitumen is from +19 to +29.

- Waterproofing can only be applied to a clean, dry surface after the primer has completely dried.

- The recommended drying time for liquid insulation is 28 days.

- Rolled waterproofing is laid overlapping to strengthen the protection of the seams.

- The implementation of insulation by the contractor must be supported by a certificate of completion of work.

The regulatory documents do not indicate that insulation is a type of work that requires special skills or training. Although work with bitumen must be carried out in compliance with fire safety rules. This means that you can waterproof a private house yourself.

What is the best way to waterproof a strip foundation with your own hands?

In order to do the work yourself, you need to know the principles of waterproofing, namely:

- Waterproofing is applied to horizontal and vertical surfaces;

- Waterproofing must be applied to a rigid base, and not to soil or loose concrete;

- Before applying most materials, the surface must be cleaned and primed;

- When installing a waterproofing coating, it must be solid without weak seams or open areas between the membrane or mastic. If there are open spaces or weak seams, water will pass into the concrete and under the waterproofing carpet, violating its integrity and tightness;

- If you do not follow the instructions for installing a particular material 100%, you risk that the work performed will become unusable at least with the first serious rain or temperature change, and at most within the first 3 years of operation.

Stages of independent work:

- Choice of material – If you decide to do waterproofing yourself, then it is recommended to choose a high-quality material, for the installation of which you will not have to purchase special equipment or gain a lot of experience to facilitate its correct application. Such a product can be high-quality bitumen mastic or one-component liquid rubber;

- Surface preparation - the surface is cleaned of dirt, and sharp corners and stones are knocked down;

- Applying a primer if necessary – A primer is a primer that improves adhesion (adhesion) between the base and the waterproofing coating. The primer is applied using a roller or brush;

- Application of waterproofing - Apply strictly following the manufacturer's instructions.

Diagram of waterproofing of the strip foundation structure:

Scheme of waterproofing strip foundation

Where can you buy high-quality waterproofing yourself?

When purchasing waterproofing or any other building material on the market or from an unknown supplier, you risk the following consequences:

- Fake;

- Low quality;

- Products that were stored incorrectly in terms of temperature conditions and other storage nuances, as a result of which they lost their properties;

- Expired building materials;

- Fraud during delivery or its absence in principle (the supplier received the money and disappeared).

If you do the work yourself and order construction products yourself, then we, as experts, recommend that you turn to trusted construction hypermarkets, such as the Petrovich Construction Trading House. These stores are located in many cities of Russia and have serious advantages, such as:

- Low prices

- Quality products

- Convenient online purchase, without visiting the store

- Delivery within 2 hours after placing an online order.

What materials should be used

When the question arises about whether it is necessary to waterproof a strip foundation and how best to protect it, it is necessary to proceed from such factors as the structural features of the foundation itself and the entire building, the type of soil, operating conditions, etc. There are many materials on the market today and choosing the most relevant option is not difficult.

Materials for foundation waterproofing:

- Rolled (also known as adhesive) - produced in the format of films, membranes, bitumen sheets, mounted on a layer of mastic or by heating, placing on glue (already applied to the sheets).

- Coating materials - bitumen, cold mastics, various compositions for application in liquid form with subsequent hardening.

- Penetrating - sprayed or applied with a brush, absorbed into the concrete monolith, followed by crystallization and filling of its pores, which makes the concrete resistant to moisture.

- Injection - similar in action to penetrating ones, they are applied by drilling holes in concrete and subsequent distribution of the composition under pressure, due to which the monolith is impregnated and strengthened from the inside.

- Painting – liquid polyurethane foam and liquid rubber can be used, which completely harden after application and create a water-repellent elastic film. They don't last long, but are easy to apply.

Price for waterproofing strip foundation

| Name of works | Unit _ | Price in Rubles |

| Installation of welded rolled sheets | m2 | 390 |

| Installation of self-adhesive membrane | m2 | 390 |

| Application of mastic insulation in 2 layers | m2 | 400 |

| Application of liquid rubber in 2 layers | m2 | 400 |

| Application of cement-mineral 2-component mastic | m2 | 300 |

| Polyurethane mastic device | m2 | 600 |

| Application of cement compositions | m2 | 550 |

| Primer application | m2 | 50 |

Calculator for independently calculating the cost of waterproofing

Open calculator

Waterproofing cost calculation

Coating

This is the most economical, but not durable option. The surface is covered with bitumen in several layers. Use a brush, roller or spatula.

The surface must first be cleaned and primed with a bitumen primer. Mastic can be purchased prepared or diluted directly at the construction site.

To prepare the mixture, you need to split the bitumen material into tiny fragments, pour it into a metal tank and melt it over a fire. Then turn off the heat and add diesel fuel in a volume equal to a quarter of the mastic. The composition is mixed with a wooden beam.