Thanks to this innovation, the technical parameters of the building are improved, noise in the premises and heating costs are reduced.

Read on to learn about the design of the structure, technical characteristics of materials and the nuances of self-installation of formwork.

Options and characteristics

The density of the material is the determining factor by which products are divided into brands. The thermal conductivity and strength of the product directly depend on this indicator. Let's consider the technical characteristics of various types of foam:

- PSB-S 15. These are slabs with low density (15 kg/m³). They are extremely lightweight and suitable for insulating structures in which people stay temporarily.

- PSB-S 25. Material density 25 kg/m³. It is used to insulate facades, floors, and roofs.

- PSB-S 35. Excellent technical characteristics make the product in demand in the manufacture of sandwich panels and reinforced concrete structures.

- PSB-S 50. Extremely dense material. The slabs are used for arranging floors inside refrigerated warehouses and in road construction.

- Extruded polystyrene foam. The thermal conductivity of the product is ideal. The material also has different densities (25–47 kg/m³).

In production, foam formwork is made in different ways:

- Hollow blocks with removable or non-removable stiffeners. The products are similar to LEGO construction blocks.

- Facing option.

- Reinforced panels reinforced with mesh.

In addition to these basic options, they also produce polystyrene foam blocks that have a curved configuration. They allow you to pour non-standard types of foundations.

Reviews

This year my husband and I got married and decided to buy a home. There wasn't enough money to buy a new one. We settled on building a house, but the option is also not a cheap one. To reduce costs, we used polystyrene foam formwork. We managed to spend less money and were able to build a house faster.

Olya. Krasnodar.

Our company is engaged in the construction of houses. Pouring a concrete base using foam blocks significantly reduces the time for building construction.

Alexander. Chrysostom

Advantages and disadvantages

Expanded polystyrene formwork consists of several blocks that are connected together. The advantages of this design are as follows:

- the material simultaneously performs two functions: sound-proofing and heat-insulating;

- the elements are easy to assemble, so installation of the formwork is quick;

- due to the characteristics of the material, it is convenient to lay utility lines in the foundation;

- the low weight of the products allows you to move them without renting special equipment;

- foundation construction is allowed even in slight frost;

- concrete protected with polystyrene foam is not susceptible to fungal attack;

- there are no “cold bridges”;

- The material is environmentally friendly, it has a smooth surface.

However, polystyrene foam formwork cannot be considered a panacea that saves the developer from all troubles. Although the material has many positive parameters, it is not without some disadvantages:

- poor air permeability makes the room excessively humid;

- polystyrene foam is a flammable material;

- installation of permanent formwork when hiring specialists is too expensive.

Having studied the pros and cons of polystyrene foam products, everyone chooses the possibility of using it for the manufacture of formwork. All you need is to purchase the material and also have a little skill in installing it.

Video about the advantages and disadvantages of polystyrene foam (expanded polystyrene, EPS, EPS):

Recommendations

On our website you will find a lot of useful materials:

- How to waterproof a cellar? It is worth considering that waterproofing cellars is an important element in the arrangement of buried rooms. The main task is to prevent water from entering the basement and ensure it is dry. Carefully examine the depth of the water and select the necessary insulating material. The right approach to the matter will help to avoid problems with storing food.

- Before making a screed with expanded clay, study all the intricacies of the expanded clay material itself and the technology for making such a screed. It is advisable to listen to the advice of professionals and pour a 3 cm thick layer of concrete. Then the floor will not crack and all unevenness will be eliminated.

- How to strengthen the foundation of a private house? This is a very labor-intensive process that depends on many factors: what type of house (wooden or stone), what kind of soil, etc. Thanks to the correct selection of tools and materials, you can ensure a reliable foundation for your house.

- To answer the question whether it is possible to build a bathhouse from aerated concrete, compare all the pros and cons. Do not forget to take into account the properties of aerated concrete blocks: it is economical and fast, but staying in the bathhouse will be uncomfortable due to non-breathing walls.

- An important role in the durability of any building is played by a do-it-yourself foundation cushion, the main purpose of which is to create a stable and level platform for the foundation and ensure less settlement. With proper installation of the pillow, the structure will last for hundreds of years.

- The construction of houses on screw piles is a fashionable trend and an indicator of the quality of the practicality of the work and its speed. The main thing is to develop the correct project before starting such activities and be sure to take into account the analysis of the soil on the site.

- People often ask the question: “How to cover the outside walls of a house?” There is a wide variety of materials and technologies used, but be sure to remember that the exterior must conduct steam well. Then the moisture will be removed from the house naturally.

Prices for materials and installation

The products are sold by many construction stores. There are many companies that provide professional services related to the installation of such formwork and pouring concrete mixture into it.

Advice. If you want to save money, it is better to purchase material from those who perform the full production cycle - from the manufacture of parts to their installation.

Before purchasing, you must definitely calculate the exact number of blocks required, taking into account that some of them may be damaged during installation. The estimated cost of the parts is as follows:

jumper - 10 rubles;- straight and corner element - 780 rubles;

- cap - 20 rubles;

- rotating block - 800 rub.;

- end part - 780 rubles;

- angle of 135° - 500 rubles;

- right angle - 500 rub.;

- standard unit - 495 rub.

The average cost of installation work is 225 rubles/sq.m. m.

Fixed foam formwork: types of structural parts

Formwork elements can have different designs, which are determined by their operational purpose. Today there are such options for these products made from polystyrene foam:

- panels;

There are several options for products made from polystyrene foam: panels, blocks and frame systems

- blocks (cast and prefabricated);

- frame systems.

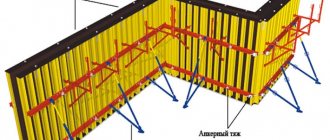

Frame systems are double-circuit structures with empty space between the walls. When installing such formwork, reinforcement is laid inside and the solution is poured. If you make a section of a finished wall made using this technology, you will be able to distinguish three layers: two outer layers, represented by formwork, and a middle one made of reinforced concrete.

Foam blocks are divided into two large groups: cast and prefabricated. During the assembly of the formwork, these elements are aligned so that they are located on top of each other. Moreover, no adhesive mixtures (for example, glue) are used for joining. The blocks are laid out in a checkerboard pattern.

Cast products are also called thermoblock. This is due to the fact that they have a fairly high density (up to 40 kg/m³). Features of the structure influence the thermal insulation characteristics. A block of this type consists of 2 sheets, which are joined together using special jumpers. The assembly of such parts and the connection of their individual elements are carried out at the manufacturing stage. It is worth noting that such structures have one drawback: they warm up rather poorly. This is due to the location of the insulation on the inside of the wall pie.

When installing, reinforcement is laid inside the formwork and mortar is poured

The sizes of blocks of cast foam formwork may vary. However, the standard option is considered to be products with dimensions of 1000x250x250 mm. The mass of such a block is usually about 1 kg. The thickness of the insulation located on both sides (outside) is 50 mm. Accordingly, the same indicator of the concrete layer will be 150 mm.

Related article:

Calculation of reinforcement for the foundation: how to do it correctly

How to do it for strip and slab types. A detailed example of calculating the need for reinforcing bars for a foundation.

The insulation in the forms used to pour concrete can be different. The future characteristics of the structure depend on the choice of insulator material. It is important to remember that such a layer traditionally performs two main functions. The first of them is shape-forming, and the second is thermal insulation. Depending on the type of blocks, the cost of polystyrene foam varies. How much do different types of molds cost? Pricing takes into account the design, as well as the thickness of the insulation layer.

Foam blocks are divided into two large groups: cast and prefabricated

Note! It is not recommended to carry out concreting in more than 3 rows. The ideal option would be to lay concrete in 2.5 rows, since in this case the seam will be located in the middle of the block.

Prefabricated polystyrene foam blocks for formwork

Formwork can be represented by prefabricated elements, which differ from cast ones in their structure and have some application features. Such blocks consist of two sheets, which are assembled into a single structure before installation work begins. It is important to note that such elements can be made not only from expanded polystyrene, but also from other materials. The distance between sheets 1 and 2 remains unchanged due to special components called spacers.

Building a house from permanent formwork of this type has several features that need to be emphasized. The main difference between prefabricated forms is that their use allows the use of more than 3 layers in the walls. Moreover, the combination of materials in this case does not play a role, while buildings made using cast blocks require strict adherence to the sequence of materials. Insulation in such a situation will always be located outside.

Formwork can be represented by prefabricated elements, which differ from cast ones in their structure

A common solution is a pie wall, which includes two facing layers of rigid sheet material. An insulating material (expanded polystyrene) is laid close to the outer sheet of this type. The second layer in this situation is reinforced concrete.

The design of a house made from permanent formwork is prepared in advance. It contains all the necessary data indicating design features, dimensions and individual solutions in accordance with the situation.

It is worth noting that such forms have one significant advantage over their cast counterparts. It lies in the fact that, if necessary, you can change the width of the internal cavity into which the reinforcement is laid and the solution is poured. This indicator is changed by using spacers. If such a need arises, longer retaining elements can be purchased.

All costs must be indicated in the formwork estimate. The device, prices, dimensions of individual elements - all this is recommended to be noted in the preliminary installation diagram.

The design of a house made from permanent formwork is prepared in advance

The design features of prefabricated forms affect the degree of wall heating. The absence of polystyrene allows this figure to be increased. If necessary, collapsible structures used for the construction of buildings can be made with your own hands.

Step-by-step construction with your own hands

The step-by-step assembly process looks like this:

The first step is to dig a trench or pit under the perimeter of the foundation (read about how the volume of excavation work is calculated when developing a pit, and from this article you will learn how much it costs to dig a trench under the foundation and how to do it correctly).- Then the bottom is leveled and the pillow is covered. It is better to make it from gravel, carefully leveling it with sand on top.

- Then the required base width is determined. This value is variable and depends on various factors. Traditionally, it is customary to make a foundation 30–60 cm wide.

- A foam sheet with a thickness of 5 cm is laid on top of the sand backfill. This lining guarantees excellent thermal insulation of the concrete mixture.

- After this, the corners of the structure are formed using special screws. EPS sheets are suitable for the internal as well as external walls of foam formwork.

- The layers are joined by performing a slight shift. This prevents concrete from leaking through the cracks.

- The installed walls are connected to each other, for which you will need universal ties. They allow you to accurately set the required width of the foundation, being at the same time guides and mortgages for the formation of the reinforcement frame. Everything in purchased products is clearly thought out, so assembling such a construction set is simply a pleasure.

- Having fastened the lower part with ties, install ventilation vents in several places, and then attach a horizontal reinforcing layer. Typically, sections of plastic pipes with a diameter of 110 mm are used for vents. They are easy to cut using a regular grinder.

- Metal rods are securely fastened with clamps located both on the inner and outer edges of the blocks. Fiberglass can also be used as reinforcement instead of steel. It is even more preferable, although in practice metal is traditionally used.

- When the creation of the lower reinforcing belt is completed, the next universal ties are attached at the top of the formwork, which hold the sheets together. The upper reinforcing belt is mounted on them.

- The final stage of the formwork installation is the fastening of the vertical elements of the metal frame. All intersections of the rods must be tied using soft wire.

After this, the permanent formwork, containing a reinforcement cage inside, is ready for use.

Attention! After pouring the concrete mixture into it, you only need to walk through the liquid mass with a vibrator to remove air pockets. When there is no such device, you will have to use the old-fashioned method - “pierce” the liquid solution with a stick.

From the video you will learn what permanent polystyrene foam foundation formwork is and how it is installed:

The main advantages of foundation formwork

So, what are the advantages of this technology over the classics? Let's try to list:

- Minimum labor costs. The formwork for the foundation can be assembled by 2 people in literally 1 day.

- The SVT universal screed is a convenient and practical fastening element: the reinforcement cage is securely attached directly to it, and due to the extensions, the width of the foundation can be easily adjusted.

- The ability to set exact dimensions and minimize concrete loss.

- Implementation of geometrically complex projects.

- No dismantling work (an exception may be the internal part of the formwork, which is suitable for insulating the floor, walls, blind area or roof, but this is at your request).

- The finished structure has no cold bridges and retains heat perfectly.

- There is no need to insulate the base: it is already there.

- The load-bearing base and thermal insulation are installed in one technological cycle.

General information about Penoplex insulation

This insulation is a domestic development. It is also produced for our conditions. This cannot but rejoice, since the material takes into account all the features of the domestic climate, which is far from mild.

The insulation is based on polystyrene foam, which at high temperatures is subjected to additional foaming - extruded. This operation allows you to significantly increase the already excellent performance characteristics.

The material is very popular not only among independent developers, but also among professional builders. Its main technical characteristics include:

- moisture resistance – no more than 0.5% of the total volume;

- guaranteed service life - more than 50 years;

- compression resistance – 27 tons per square meter;

- operating temperature range – from – 50 to + 75 C.

This information is not exhaustive, since the material also has many positive qualities. Full information can be obtained on the website of the material manufacturer.

Penoplex in packagingSource brus4you.ruThere are many varieties of this insulation on the market, but among them three main varieties can be distinguished:

- "Penoplex-45". This type of insulation has the highest density among all material lines. It is used for insulation of complex building structures that are subject to high loads. These could be airfields, various industrial structures or elements of highways.

- "Penoplex-35". This type of material is often called “Penoplex Foundation”. They are used for insulating monolithic and pile-type foundations. It is also used to insulate the pile base. The material can be laid in both vertical and horizontal directions.

- "Standard". The most widely used type of material, made in the form of flat slabs. It is used for insulating a wide variety of objects, from utility networks and stone walls to insulating wooden floors.

All of the listed insulation modifications are produced in the tongue-and-groove form factor. This allows the elements to be installed as closely as possible to each other and to avoid the formation of gaps between them.

Solid pad of insulation for pouring the base of the foundationSource ctkomplekt.ru

The method of cutting the material deserves a special mention. If a special tool is used for this, then professionals advise carrying out cutting work at medium speeds. This will prevent the material from melting and sticking to the cutting parts of the tool.

If you are interested in the question of how to insulate a house with Penoplex, then slabs of medium and smaller thickness will most likely be used. They cut perfectly with an ordinary stationery knife and are neatly broken along the cut line.

How to calculate the cost of construction?

To become more familiar with the savings achieved by using foam formwork, we will calculate the approximate cost of constructing walls. Calculations are made based on the current cost of the material (more on this at the end of the article) and the size of the building itself. An approximate calculation of the required materials will look like this:

- concrete - about 125 liters per 1 sq. m. (price depends on the cost of the required materials);

- foam formwork - 3.3 pieces per 1 sq. m. (about 500 rubles);

- fittings - about 10 kilograms per 1 sq. m. (specific cost depends on current prices).

And if we proceed from prices in Moscow, then approximate calculations for the construction of one floor will look like this (the cost of the work itself is not included):

- total area (various types of openings are not included) - about 180 sq. m.;

- concrete solution for a given area - about 27 cubic meters, that is, 81 thousand rubles;

- the price of the formwork itself is about 88.2 thousand rubles;

- fittings - 1800 kilograms or 37.8 thousand rubles.

It turns out that the total cost of all consumables for one floor will average 207 thousand rubles.

Dimensions of permanent foam formwork

| Name | Dimensions | Thermal insulation thickness | |

| internal | external | ||

| Series 25 (one-piece) | |||

| Main wall block | 1250x250x250 | 50 | 50 |

| Wall end block | 1250?250?250 | 50 | 50 |

| Corner wall block (right/left) | 700?250?250 | 50 | 50 |

| 500?250?250 | |||

| Series 30 (one-piece) | |||

| Main wall block | 1250?300?250 | 50 | 100 |

| Wall end block | 1250?300?250 | 50 | 100 |

| Corner wall block (right/left) | 1250?300?250 | 50 | 100 |

| 500x300x250 | |||

| Series 35 (detachable) | |||

| Wall block | 1200?300?250 | 50 | 100 |

| Series 50 (one-piece) | |||

| Main wall block | 1250?300?500 | 50 | 100 |

| Wall end block | 1250?300?500 | 50 | 100 |

| Corner wall block (left/right) | 450?300?500 | 50 | 100 |

| 650?300?500 | |||

Monolithic slab insulation technology

The strip foundation can be insulated both during construction and after its arrangement. This trick will not work with a monolithic slab; the insulation of the slab is calculated at the design stage. Of course, after arrangement it can be insulated from the sides, but this will be ineffective and not rational, due to the small height of the base itself.

How to insulate a foundation with Penoplex:

- First, all preparatory work is done. Marking is carried out, soil is removed to the required depth, crushed stone and sand are poured, compacted, and formwork is installed.

- When all the preparatory work is completed, a base for the insulation is made from concrete. A thin slab 5-10 cm thick is poured, it is also called a concrete preparation or base. We wait until it dries.

- Next, we lay the Penoplex slabs in a “checkerboard pattern”, groove into groove, making sure that there are no gaps between the panels.

- We create a hydrolation layer, lay the film overlapping 15-20 cm, and seal the edge with tape. The film will prevent concrete from leaking along the seams of the insulation slabs.

- Next, according to the project, the slab foundation is poured, and after hardening, the formwork is removed.

- Insulation panels are attached to the side walls of the slab

Requirements for insulation

To obtain a high-quality result, it is not enough just to carry out all activities professionally.

It is quite difficult to choose insulation that is optimally suited for a specific purpose, both in quality and financially. After all, today you can find many options for insulation in different price categories and from different manufacturers.

Do-it-yourself installation of extruded polystyrene foam on a plinth

Therefore, when choosing, you should pay special attention to the following qualities of the material:

- Low hygroscopicity. This parameter is very important, as it determines the degree of moisture absorption. At a high rate, the material will absorb moisture and as a result will collapse, which will lead to the destruction of the base itself.

- High strength. The thermal insulator must withstand heavy loads of underground compressive forces. For example, the impact of soil, which increases in volume when frozen.

- Low thermal conductivity. The thermal insulator must have a reduced thermal conductivity coefficient to ensure good thermal insulation.

- Long service life. The thermal insulator should have approximately the same service life as the building, because replacing it is a rather labor-intensive process.

Coating waterproofing and penoplex

Economic benefits

In addition to the cost of purchasing wood, permanent formwork will save time and labor costs on the manufacture of a wooden structure and its dismantling. Note that when arranging a strip foundation, the construction of removable formwork is one of the most expensive processes.

If we compare two options for constructing a strip foundation (the first - with removable formwork and subsequent insulation with PENOPLEX® slabs, the second - with permanent formwork made from such slabs), then the first will cost 20% more.

In addition, by combining the operations of constructing formwork and insulating the foundation into one stage, the work is simplified and accelerated, and construction time is reduced.