Criteria for choosing a stove for a bath

The basic indicator is power. It is impossible to indicate universal numbers, but for a good model the coefficient should be optimal (8-10 kW) in order to heat the steam room and adjacent rooms.

At low power, the stove operates under wear and tear; it takes a long time to heat, wasting energy. A high rate will lead to imbalance and overheated air.

Other factors to consider:

- type, shape of structure;

- material;

- type of fuel used;

- steam source;

- principle of operation;

- type of heater.

Power is the main criterion for choosing a stove for a bath.

If a factory model is selected, it is desirable that the package includes a water container and a convector.

It is recommended to read consumer reviews, instructions, and check the product for compliance with GOST.

Schemes and dimensions of vertical and horizontal furnaces

After choosing a model, before making a sauna stove with your own hands, a drawing is drawn; it must reflect all the parameters and configuration of the stove. A correctly drawn up drawing will not only facilitate the installation process, but also eliminate operational problems.

The diagram should show the main parts of the furnace. If this is your first time making a stove for a bathhouse, then it is better to use a ready-made diagram.

Horizontal model diagrams

It is the model in which the horizontal pipe is most often installed in bathhouses, if space allows.

Vertical furnace diagrams

As with a horizontal stove, a pipe with a diameter of 530 is also ideal for a vertical model.

An example of a drawing of a stove for a vertical bathhouse, which is easy to install yourself.

Calculation of stove power for a bath

Average value: 1 kW = 1 cubic meter. The technique is as follows:

- Calculate the volume of the steam room. If the room is 3x2 m, the ceiling height is 2.3 m, then the figure is 13.8 cubic meters.

- Calculate the area of window and door openings, multiply the resulting figure by 1.2 to calculate heat loss. Sum up the areas. If the window is 0.4 sq.m. and the door is 1.8 sq.m., then the total area is 2.2 sq.m.

- Find out the volume. Taking into account the indicated values - 2.2x1.2 = 2.64 cubic meters.

- Add up the indicators. Result - 16.44 cubic meters.

If the bathhouse is unfinished and the thermal insulation is low, then the resulting figure should be multiplied by 1.6 (16.44x1.6 = 26.3). The desired value is 26-30 kW (if taken with a small margin).

As standard for factory units, the power is specified in the accompanying documentation. If it is missing, then the area of the space is taken into account for the calculation. The volume of the firebox is calculated and multiplied by 0.5.

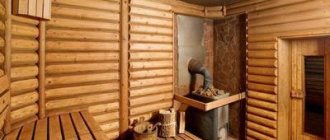

The hot heart of the bathhouse

The performance of a modern sauna stove is calculated based on the size of the steam room and the building parameters. To do this, they operate with the cubic capacity of the heated room, taking into account a number of additional factors that have a direct impact on the heat-saving capabilities of the steam room. By multiplying the height, width and length of the room, you can only get a certain starting point for further calculations, which is the minimum performance of the heating unit. In fact, there are a number of other parameters that change power requirements. It is necessary to add into the calculation heat loss from conditionally cold surfaces, such as a glass door, window, brickwork, stone or tile cladding, and so on).

If the steam room has a window, you need to add 3 m 3 for each square meter of window area in the case of single glazing and 1.5 m 3 in the case of double glazing. Using the same scheme, add 1.2 m3 for every m2 of glass door. The coefficient here is smaller, since behind the door there is a warm room, and not the street.

A brick partition is equivalent to an increase of 1.2 m 3 of steam room volume for each square of its area. The high heat capacity of brick requires additional heating. The same is done with the stone-lined surface inside the steam room.

Sauna stove material

The service life of the product depends entirely on the thickness of the heater and the material. If previously they were made only of brick, now they also use chrome steel (to produce clean indoor air, without burning oxygen) or cast iron.

Steel furnaces

Factory heaters have advantages. Products:

- lightweight, durable;

- compact;

- do not require foundation construction;

- quickly warm up the room;

- easy to install.

Steel stoves are lightweight and durable.

The disadvantage is that the fire safety level is low. The fire in the firebox must be maintained constantly, otherwise the room will quickly cool down due to the small heat capacity of the metal. The power may not be enough to heat large areas.

The best models are offered by Finnish ]Helo[/anchor], Harvia.

Cast iron stoves

Previously, users installed primitive potbelly stoves, although they are inferior to modern analogues in terms of safety and functionality. Manufacturers are now delivering safer, more durable units with increased heat transfer and heat capacity.

However, the devices have disadvantages, which include high price, fragility (cast iron can crack under loads and transportation) and dimensions, weight (a reliable foundation must be built before laying the stove).

Brick oven

They are fireproof and heat retaining. This is an option if you want to arrange a steam room like in a Russian bath. Although such heavy heaters are becoming a thing of the past, since the weight reaches 1200 kg, it is difficult to build and find a skilled stove maker.

The brick oven is fireproof.

In Rus', high-quality stone masonry for a sauna stove was considered art. These fireplaces retain heat for a long time, but are cumbersome when lighting and are oversized. They occupy most of the steam room and need to create a solid foundation.

Design requirements

A properly designed and constructed sauna stove from high-quality building material must meet a number of requirements:

- rapid production of high temperature conditions and, as a result, warming up the room in the shortest possible time;

- temperature resistance, long-term preservation of the required temperature conditions;

- uniform flow of heated air from all sides into the steam room;

- safe operation, absence of negative factors in the room in the form of soot, smoke and burning;

- the ability to fully heat the required amount of water.

In a traditional Russian bathhouse, the stove structure must provide a temperature regime during operation at the level of 60-70°C with humidity levels within 60-70%. Any heaters intended for installation in Finnish saunas must provide hotter air heating with minimal humidity.

Correctly calculate the power

The most common mistakes when independently calculating the power of stove equipment are choosing a sauna stove that is too powerful or low-power. In this case, hot air is supplemented by cold stones and a lack of steam, or there is no required temperature regime in the bathhouse.

An independent calculation consists of multiplying the length, width and height of the room, followed by calculating the area of non-insulated areas and multiplying by a factor of 1.2-1.5. The power of a standard stove is 1.0 kW per cubic meter of bath area.

Other oven selection options

When purchasing a design, take into account:

- Duration of operation of the unit. The device retains heat for a long time and operates for 3.5-4 hours without additional ignition.

- Heat storage capacity. The norm is 100 g of water per 1 cubic meter, so that the air from the steam room does not come out damp, heavy, and transparent. The temperature should not fall below 100˚C.

- The presence of a heat exchanger, thanks to which a high temperature is maintained in the bathhouse, saving on firewood.

- Price. Models with moderate power cost from 18,000 rubles.

What fuel does the stove use?

Firewood for igniting the firebox is an affordable material and even the only one if the region is not equipped with electricity or gas. The units are practical, durable and convenient. Disadvantages - the formation of ash after fuel combustion, the need to remove soot from the chimney and seal. It is characterized by a long, complex warm-up of the steam room (especially in wet weather) in contrast to other alternative options.

Firewood is an affordable material for lighting a stove.

Gas is used from mains or bottled gas. The installations are weighty, large, and difficult to install, so you can’t do it without a specialist. One of the advantages is that there is no need to constantly add firewood, keep the flame under control, or clean the ash pit. When operating gas appliances, it is enough to change the intensity of the fuel supply to keep the indoor temperature under control.

Disadvantages include a high fire hazard and replacement of containers when using bottled gas.

To connect the unit to the gas pipeline, you cannot do without the involvement of a professional.

Electric models do not have chimneys, and the appliances do not emit carbon monoxide. The user does not have to worry about poisoning from combustion products. However, the greater the power of the unit, the greater the energy consumption.

Electric models, despite their shortcomings, are in high demand. They are weightless, compact, fireproof, functional, and easy to operate. They heat rooms quickly and evenly and do not require a gas connection. Although the devices are not suitable for areas where electricity supply is intermittent. When connecting, it is important to ground the circuit.

Selecting a firebox type

This part is installed in 2 ways:

- Classic, without an external channel, with direct location in the steam room.

- With extension (located in the wall between the dressing room and the steam room).

The location of the firebox is possible directly in the steam room.

The first method is cheap, but has low fire safety ratings. The second option is more expensive, but more convenient. The stove is heated from the dressing room, and the firewood is laid without disturbing people steaming, and the microclimate in the steam room is not disturbed.

Steam source

The Russian stove emits light, dry steam when it reaches +85…+90°C. Although, when the air temperature is brought to high limits and the stones are heated to 500°C in order to produce finely dispersed steam, a person can get burned. To avoid this shortcoming, manufacturers began to produce alternative designs.

For example, with a steam generator, thanks to which the temperature in the steam room remains optimal even when there is oversaturation with the necessary steam.

Heater type

There are open and closed models. The first are safe models, but with high fuel consumption. They quickly warm up the air in the steam room due to the hot stones, but do not retain heat for long after the combustion of the fuel has finished. You can steam immediately after ignition, staying in the steam room as long as you like. It is advisable to install the devices when visiting the bathhouse frequently.

Closed models are also produced with a special damper to isolate the top row of stone backfill. Previously, units with increased efficiency were installed in public steam rooms. Now - to the Russian baths for uniform heating of the room. The design independently retains heat for up to 12 hours, although it takes a long time to heat to obtain the desired temperature. You won’t be able to steam until the stones are completely warmed up. Soot quickly accumulates on them.

By type there are open and closed models.

Technical equipment of the furnace

Modern functional models include:

- Convector (air passing through the casing and screen is evenly heated, creating optimal conditions in the steam room).

- Reservoir for heating liquid. The portable container is suitable for baths with high traffic. Built-in - for a family of no more than 3-4 people (to provide plenty of hot water).

- Heat exchanger to heat other rooms, incl. locker room

Combined products are popular. Heat is delivered to adjacent rooms by moving liquid through radiators. The steam room is heated by convection.

In order for the design to be able to produce dry, light steam (not every device can), experts additionally advise buying an electric steam generator for comfort in the bathhouse.

Furnace shape

Models come in the form of a rectangle or cylinder.

The most common stoves are rectangular in shape.

Classic rectangular ovens are the best because they heat evenly.

For cylindrical analogues, the lower and upper walls can become very hot or remain cold.

Strengths and weaknesses of a coal sauna stove

As we undoubtedly remember, ideal things do not exist in nature, however, any object has a certain set of strengths and weaknesses. The stove we are considering is no exception. Let's start, as usual, with the good. In fairness, we note that the listed requirements are overwhelmingly relevant for metal structures:

- Low operating costs. Sufficiently high fuel efficiency, especially when using anthracite group coals, characterized by low parent ash content and extremely high calorie content, or otherwise, specific heat of combustion;

- Durability. A stove made from materials, especially its hot parts, can be used for 10-12 years;

- Good maintainability. Current repairs are not complicated and their implementation does not involve any special technological or instrumental difficulties;

- Resistance to temperature fluctuations. Tolerates long breaks from work well;

- A large selection of ready-made structures made taking into account the basic technological requirements;

- Relatively low cost of self-production or purchasing a finished copy;

- The construction of a separate foundation is not required;

- Flexibility in terms of placement or adaptation of the stove for use in various rooms, both in volume and configuration.

Now, about the main and critical shortcomings:

- When used in tandem with a closed-type heater and a large volume of inert stone backfill, a stove of this type can take a long time to accelerate and slowly reach the nominal temperature regime in a steam room;

- Due to the high surface temperature, it is necessary to take special measures to reduce the fire hazard of the room and erect a protective fence to avoid burns in the event of unexpected contact with the furnace;

- There are special requirements for the thickness and heat resistance of the metal used in the manufacture of critical elements of the furnace. Substandard raw materials can cause deformations and burnout of hot parts;

- The steam generated by a stove of this type is quite harsh and is more suitable for dry baths than for classic Russian ones.

A word from Experienced! It must be said that a coal-fired sauna stove, which is made of metal, should not have metal sheets less than 4 mm thick as the basis of its design. The only exception may be factory furnaces of famous foreign brands that use high-alloy heat-resistant special steels as raw materials.

We count the power

The thermal power of a furnace is one of the main and fundamental indicators that characterizes its efficiency and functionality.

The generally accepted practical volume norm for one person in a bathhouse is 9-11 cubic meters. m. For heating 1 cubic. m. bath room to a temperature of 60 degrees Celsius requires 55 kcal. at one o'clock. A metal sauna stove, when using ordinary coal of the DGr grade as fuel, can generate 320 kcal. from 1 sq. m of working surface. Thus, for heating to a nominal temperature of 10 cubic meters. The volume of a steam room requires 550 kcal. thermal energy, therefore, the working surface area of a coal-fired furnace to maintain the specified parameters cannot be less than 1.73 square meters. m. taking into account the minimum or close to it level of losses.

Attention! The main quality of a sauna stove is not so much the thermal conductivity of the material as its heat capacity. The heat capacity of steel is very low, so you need to be prepared for the fact that in order to maintain the temperature in the steam room for a long time, the oven will need to be heated. A good alternative to this feature of a steel stove is the use of cast iron. Cast iron casting is very close in heat capacity to masonry, so “long-lasting” sauna stoves are possible only on the basis of a cast iron “skeleton”.

Features of the furnace firebox

It is clear that using coal as the main fuel, it will not be possible to completely abandon firewood. The overwhelming majority of the main brands of coals require sufficient temperature for reliable ignition, which can be initiated by a wood stack.

A starting filling of finely chopped firewood or wood chips is used in a ratio to the main starting portion of coal, approximately 1 to 4. There are some brands of coal that ignite with a smaller amount of firewood, others require a ratio of 1 to 2 and are difficult to ignite.

Important! It should be said that grade T coals, the so-called lean coals or semi-anthracites and grade A-anthracites are used in the secondary stack, that is, when the starting stack of firewood and the primary stack of long-flame coals have created a thermal bed of sufficient volume and temperature. It is almost impossible to light such coals directly from firewood.

An important condition is the correct use of the furnace vent. At the moment the kindling starts, it is covered; as the stove flares up and reaches the nominal operating mode, it is opened, thereby regulating the air flow and the rate of combustion of the supplied portion of fuel.

Coal grades K and Sp, coking and caking require constant work with a poker in order to break the crust of the coal pie and provide the necessary air flow to the entire volume of the coal bed. In addition, coke group coals have a very high calorific value and, when placed in their pure form, can cause burnout of the grate.

To complete the information picture, we consider it correct to present the main characteristics of the calorie content and volumetric weight of the main grades of coal in the form of a table:

| Coal grade | Calorie content, kcal. | Volumetric weight, kg/cub.m. |

| Long-flame dry, grade D | 7950 | 1,23 |

| Long-flame fatty gas, grades DG, G | 8200 | 1,24 |

| Coke fat, KZh brand | 8400 | 1,24 |

| Coke, grade K | 8450 | 1,26 |

| Fat, grade J | 8750 | 1,27 |

| Leaned-sintered, OS grade | 8600 | 1,30 |

| Skinny, T brand | 8500 | 1,31 |

| Semi-anthracite, PA grade | 8400 | 1,32 |

| Anthracite, grade A | 8200 | 1,62 |

Brief recommendations for self-production

It is quite possible to make a coal stove with your own hands, the main thing is to follow the basic technological principles.

Let's consider the main types suitable for production in artisanal household conditions:

- Potbelly stove. In many ways it repeats the classic, well-known potbelly stove and differs from the latter in the presence of a tray for stone backfill. Overall dimensions, as a rule, do not exceed 420 mm in height and 470 mm in width. The foundation for such a furnace is not equipped; the function of a heat-resistant cutoff from the floor is performed by a piece of basalt slab, which, in addition, evenly distributes the load. The maximum volume that this stove can heat should be considered 22 cubic meters. m. and no more. A direct type chimney with a total height of about 4200-4500 mm. The draft is regulated not by a gate, but by a sliding damper, which blocks part of the passage holes in the stove door. It should be taken into account that the 2 passage holes should not overlap in any way. A stove of this type, due to the good draft of the direct chimney, allows flooding during cleaning. The maximum volume of liquid for a one-time supply of steam is no more than 0.25 l. and an interval of about 20-25 minutes.

- All-welded stove without the use of stone lining. The most primitive design, capable of effectively heating a steam room with a volume of up to 25 cubic meters with overall dimensions of height and width of 750×600 mm. m. The chimney diameter is at least 100 mm. organized through a sleeve with a diameter of 110-115 mm using a metal pipe with a wall thickness of at least 2 mm. A blower with an opening area of about 30-35% of the area of the fire door opening is formed in the face of the stove. The grate is installed along the firebox line from a set of reinforcing rods with a diameter of 15 mm cut to size and welded into a flat package. The thickness of the furnace body in cold parts is 4 mm, in hot areas 6 mm.

- Metal welded stove in a case. It is basically a brick stove, enclosed for higher heat transfer in a metal case made of cold-rolled steel with a thickness of at least 3 mm. The metal case heats up to a temperature of 100-120 degrees Celsius, so a prerequisite for such an oven should be the presence of an enclosing screen that blocks direct contact of body parts with the hot surface. Allows the use of a foundationless arrangement. Laying the hot part from refractory fireclay bricks using expansion joints. Suitable for use in both a dry sauna and a Russian steam bath. A coal stove for a bath of this type is capable of effectively heating a steam room of up to 40 cubic meters with overall dimensions in height and width of 1120×550 mm. m. A water heating circuit is easily integrated into the design, which provides hot water at a temperature of about 50 degrees Celsius. The cycle of heating a steam room to the nominal temperature does not exceed 120 minutes; flooding during washing is undesirable; the heat retention time at the nominal temperature is at least 60 minutes.

Important! When using a metal casing for a stone stove, you cannot use a stone casing for a metal one. Such a technique, due to the large difference in heat transfer between stone and metal, “locks in heat” and leads to the operation of a metal furnace and its firebox in critical temperature conditions. As a consequence, temperature deformation and rapid burnout of even a thick-walled cast iron stove.

In general, you should remember a simple rule: the higher the mass of the furnace frame and stone backfill, the more inertial the furnace is. That is, it takes a long time to accelerate and reach the nominal warm-up temperature, but it also maintains it longer, cooling more slowly.

When carrying out welding work, you should be guided by the rules and techniques for obtaining critical, highly loaded seams, followed by annealing and control testing at full speed of the furnace for 120 minutes. If defects are detected in the seam, it is cut and welded again, followed by control annealing 24 hours after the welding work.

Features of room heating

There are hot and cold ovens, taking into account the degree of heating of the walls. The room will quickly become warm if the surface of the heater heats up to +100°C. This is a good option when the bathhouse is not equipped with constant heating. Although it is difficult to monitor the temperature in the steam room. The air may overheat or remain cold.

A hot stove is suitable for a private steam room because it transfers heat well through the outer walls. But you can get burned and it is difficult to regulate the heating temperature.

The walls of a cold oven heat up to +40…+45°C (no more). Cold air enters through special channels and returns in a heated form. Such stoves are safe and convenient. They are distinguished by a stable thermal regime. Although the steam room takes a long time to warm up. This option is not suitable for quickly heating up the stove and visiting the bathhouse.

Wood stove selection options

When purchasing equipment, consider:

- Bath microclimate, temperature and humidity ratio. It all depends on the method and heating rate. The air will be dry, the temperature and speed will be increased if the metal furnace overheats. It is better if the surface area of the product is small.

- Steam quality. Water turns into the latter at +100°C. The optimal value for humans is +35...+40 °C, achieved with the help of stones in an open heater.

Do not overheat the stones above +400°C to obtain fine steam. Otherwise, the steam room overheats beyond its normal limits.

When purchasing equipment, consider the quality of the steam.

When choosing, take into account the heating speed of the furnace. This happens most quickly in steel structures and cast iron models with greater heat capacity and wall thickness. Brick units heat up the slowest.

An important parameter when choosing is ease of maintenance, length and quality of firewood. The latter are placed from below, from above into the firebox. However, experience comes only after handling the unit. Consumers do not always realize what they might encounter after a purchase. Therefore, it is better to buy a familiar, proven model for ease of use.

Design Features

Structurally, furnaces are divided into:

- Classic ones, in which the firebox is equipped with a solid metal or glass door. The stones are placed on top of the heater.

- Mesh. The casing is assembled from metal rods.

- With a steam generator.

The classic stove is equipped with a solid metal or glass door.

Traditional designs are simple. They consist of an ash pan, a heater, a chimney, a flue, and a firebox. Additionally, a tank may be included for heating water and placing it on the chimney for convenience. This way the gases will heat the water in the container and not escape through the pipe.

Fuel loading is carried out:

- internal, through the steam room;

- external, from adjacent rooms (dressing room).

Stone capacity

Large boulders are placed down. The smaller ones go up. It is better to place them less often in relation to each other, leaving gaps. On average, 2-3 packs of 25 kg are used for 1 square meter of steam room.

The stones come in round shapes with processed edges. This is the best choice for air circulation. If oblong boulders are used, they are stacked vertically for uniform heating.

Principle of operation

Wood burning stoves are divided into the following types:

- Prolonged heating. Stones in small quantities are heated to +350°C. The outside of the heater is lined with metal sheets to prevent burns.

- Periodic, i.e. with loading the largest number of stones into the unit, heating them with the forces of an open flame. The option is well suited for a private steam room, since there is no partition. You can add water to the stones because it will not release soot particles into the surrounding air.

Wood-burning stoves come in long-term and intermittent heating types.

Warm-up time

The units are distinguished:

- Simple ones where you need to add fuel frequently. On 1 tab the device works for 8-10 hours.

- Long burning with 2 modes. First, the stove heats up, then the temperature is maintained in it.

Manufacturer

Various manufacturers supply stoves to the market. The leaders are:

- Harvia. Finnish suppliers offer floor-standing and traditional units in designer designs (corner, wall-mounted) and different in functionality. Branded wood-burning models from Harvia operate flawlessly, are characterized by long-term operation and high quality. The fireboxes are made of high-strength steel with a thickness of 1 cm or more. The outside is covered with fire-resistant paint. They will not lose their original characteristics even after prolonged use.

- Helo (Finland). It produces stylish, economical, smoothly heating electric options, budget and premium.

- "Hephaestus." Reliable ovens without seams.

- Bonfire. High-quality, inexpensive devices in stock.

- Tylo (Sweden). Units with convenient remote control modules.

Harvia offers a wide range of ovens.

Pros and cons of choosing a wood stove

When choosing, you should take into account the design features, technical characteristics of the device and pay attention to additional options and tank volume.

To wash the whole family, you need at least 100 liters of hot water in the bathhouse.

A visit to the bathhouse should be comfortable. Therefore, it is good if the package includes a steam generator and a panoramic door, and a beautiful soapstone lining is applied to the heater or coil.

Wood stoves are purchased where electricity and gas are not available. The heater can be heated to the desired temperature while maintaining the required conditions in the steam room for a long time.

The disadvantage is that you often have to throw logs into the firebox to prevent the flame from dying out. When burned, wood produces smoke and carbon monoxide. Therefore, it is imperative to take care of installing a good exhaust chimney.

Design and principle of operation

Firewood, in many regions of the country, has been steadily rising in price lately. Not everywhere there are conditions when the boundary of a personal plot abuts a forest, where the forester is a good friend and the chainsaw is not a wretched Chinese craft, but a branded Swedish or Canadian unit. In general, not everyone is lucky with firewood and, sometimes, the price tag for delivery of ready-made firewood makes you think about something sublime and unearthly. That’s when various thoughts about alternative fuels, for example, coal, come to mind.

At the moment, there are a great variety of different sauna stoves on the market that use coal as fuel. They are united by a single design basis, which is based on a number of general principles:

- Firebox. It is decorated with a massive combustion chamber with a grate in the base of the combustion space and a combustion door on the front side of the stove;

- Ash pit. Can be designed in the form of a classic ash pan and an ash pan;

- Kamenka. A box containing a stone backfill that accumulates and radiates heat into the space of the bathhouse;

- A chimney that has a vault in which the concentration and primary accumulation of flue and flue gases flows through the sleeve and then out into the pipe, which has a direct direct connection with the atmosphere.

The coal stove operates on the principle of convection of air masses, that is, it ensures effective circulation of internal air volumes heating the bathhouse with the simultaneous formation and high-quality removal of flue gases.

The main art of engineering is the simultaneous provision of good traction and high-quality and economical heating of the internal volume of the bathhouse.

Attention! The principle of using a coal stove in a bathhouse is a categorical ban on using it as a heat source in black baths. There are many reasons: the formation of toxic combustion products that are difficult to remove, the release of coal tar and soot.

Electric oven selection parameters

The following aspects are taken into account:

- Power indicator.

- The area of the room where the device is planned to be used.

- Type of heating element (tubular, tape, combined heating element).

- Facing.

- Design.

When choosing an electric oven, power is taken into account.

Main selection criteria

The stoves operate on electricity, so the package must include a remote control, built-in. The first one is much more convenient to use.

The heater or heating element is an important element of electric heaters:

- The tube-shaped part heats up to high temperatures, but its service life is short. It is better if the heating element is made of stainless material.

- The tape element is characterized by fast heating, efficiency, and environmental friendliness. It lasts a long time, consumes little oxygen and does not dry out the air much.

- Combined (tape together with a ceramic part) is an expensive heating element device. However, it has the highest temperature characteristics and has a good rate of heating the room.

The material of the furnace is taken into account. The standard case is metal. The lining itself is made of soap magnesite and soap chlorite to improve the external properties of the unit and protect owners from ultraviolet radiation.

If you decide to choose an electric sauna stove, then you need to ask the seller for a quality certificate. The unit must comply with fire safety parameters. It’s good when the heater accumulates heat, creates a uniform background and has a beneficial effect on the human body.

Advantages of electric heaters

Advantages of the models:

- Compact, do not take up much usable space, unlike solid fuel and gas analogues.

- Easy to use (if fully automated), available for controlling temperature and moisture indicators.

- Environmentally friendly because they do not have a chimney. Dust, smoke, and ash will not fly around the room.

- They have a long service life.

- Easy to use. After installation, the user will only have to turn on the device and wait for it to heat up.

Electric heaters are compact and easy to use.

Electric heaters are equipped with sensitive automation and safety shutdown devices. There will be no problems during operation and combustion of fuel.

The models quickly warm up the steam room and create soft and uniform heat. Moreover, you can install the device in any convenient place: against the wall, in the center of the room.

Modern features

Technologies enable manufacturers to produce different types of stoves with functionality and optimal technical characteristics.

If there is a source of electricity nearby, you can install an electric heater with a timer and remote control to ensure comfortable use.

By choosing a wood-burning stove, you will retain heat even after heating once. The continuous combustion model is suitable for a sauna where many people steam during the day. Installation with gas heating is economical. The main thing is to organize a fireproof base.

Pros and cons of choosing an electric oven

If you choose an electric heater, its advantages are that:

- Can be installed anywhere in the steam room since no foundation is required. The main thing is that there is an outlet nearby.

- The air in the steam room warms up quickly.

- The level of security increases.

- The temperature and optimal mode are automatically adjusted, and it is possible to regulate the water/steam supply.

- There is no need to take care of the chimney to ensure normal draft.

The electric heater can be installed anywhere in the steam room.

For installation in a city apartment or sauna, electric portals are the most advantageous option.

Kinds

The main models of cast iron stoves from Russian manufacturers that appear on the modern market meet all modern requirements and have excellent technical characteristics.

Wood-burning cast iron sauna stoves are in high demand due to their simple design, high level of reliability and ease of operation. The shape of the oven can be rectangular, square or round.

The operating principle of such a furnace is quite simple:

- A wood-burning stove is equipped with a firebox into which solid fuel is placed;

- During the combustion process, heat is released, which is absorbed either by the stove body or by the heater.

There are models where the design provides for the presence of a hole, which allows the installation of firewood not only through the steam compartment, but also in the adjacent room. Models that can be classified as “advanced” are equipped with a water tank in which water is heated and used for washing. Heating occurs due to the heat given off by the case.

The next type is stoves with a closed heater. In terms of fuel consumption, this is the most economical option. The level of soot formation in them is significantly lower than that of other models. The volume of the heated room is up to 45 m3. One of the design features is the location of the stones inside the furnace itself. They are completely hidden from view, water is supplied through a hole located on top, as a result, the liquid turns into dry, clean steam.

Another popular type of heating device for a bath is a stationary stove with a non-removable firebox. The size of such stoves is small, and they perfectly complement the interior of the steam room. They are often used in buildings of limited size without a utility room. Sitting in the steam room, you can watch the wood burn. Of course, permanent storage of firewood near the stove is prohibited, as this is fraught with the possibility of a fire.

The next model is a stationary stove with an external firebox. For such models, the firebox is located in the utility room or rest room.

It is not always possible or desirable to heat the stove with wood. Therefore, an excellent option would be to purchase gas cast iron stoves. In addition, a wood-burning cast-iron stove can be converted into a gas appliance with the help of specialists.

You cannot carry out this procedure yourself, since it requires the installation of a certified gas burner. She is inspected by a gas service inspector. While an iron wood stove can cause a fire, gas creates an explosion hazard.

The next category of heating devices is a cast iron stove with a heat exchanger. A heat exchanger is a system of pipes through which water flows continuously. The exchanger heats water in direct contact with a heat source. It can be located both outside and inside the stove body, in other cases it is a coil that wraps around the chimney.

Currently, there are several trusted manufacturers who produce all of the above types of stoves.

Gas oven selection options

The units are distinguished by their high rate of room heating and efficiency. There is no need to add fuel as it burns or monitor the remaining amount.

When buying a device, take into account the power of the equipment and:

- Device dimensions. It is better to choose a small model, and with an extended remote channel for fuel.

- Gas consumption (the lower it is, the better the device works).

Additionally, take into account that there are universal devices that can operate on both gas and wood.

Design features of a gas furnace

Classic gas burner devices consist of the following components:

- housings with a gas burner inside;

- water tank;

- a pallet placed at the top (to lay stones);

- removal of combustion products;

- cobblestones;

- a thermostat and a safety element so that users can monitor the temperature in the steam room and turn off the fuel supply in case of an emergency.

Features of the furnace design.

Key recommendations for selection

The equipment must be certified (you should ask the seller). This is the first and key recommendation when choosing. You should handle the gas burner carefully - strictly follow the selection rules and safety precautions during operation.

It is recommended to find out the power, efficiency of the unit when purchasing and what is the gas consumption of each burner.

It is necessary to check the design features of the equipment taking into account the characteristics and area of the room. The safest, most versatile, and inexpensive are gas-wood stoves.

It is worth refusing to buy if the seller is trying to sell the product by offering it for next to nothing at a discount.

Requirements for installing gas sauna stoves

You can’t take risks by installing gas equipment yourself.

Important installation requirements:

- there is a distance from the stove to the nearest wall of at least 50 cm;

- installation at a fire-resistant distance in compliance with all dimensions from the openings to the gas burner (see the instructions for the unit);

- use only stainless pipes when connecting the chimney to gas equipment, extending the pipe into the pipe by at least 50%, taking into account the diameter;

- opening the door outwards;

- installation of a smoke exhaust pipe at a height of 50 cm from the burner;

- sealing the junction of the chimney with the gas system.

The sauna stove must be installed at a fire-resistant distance.

Pros and cons of choosing a gas stove for a bath

The models differ from their wood-burning counterparts because:

- deprived of an ash pit and firebox;

- compact, the devices can be installed in the tightest steam room;

- Easy to use, just set the desired mode.

The disadvantages include:

- impossibility of installation where there is no gas supply;

- low fire and explosion safety;

- difficulties and dangers during self-installation.

It is better to entrust the installation of gas equipment to professionals.

What is the price?

Here are some examples of the average price for 2 types of coal, which may vary depending on the region and the seller’s company.

| Coal grade | Average price for 50 kg (bag) | Cost 1 t (up to 10 tons purchased) | Price (for purchases over 10 tons) |

| Anthracite grade "AKO" | 700-750 rub. | 13500 rub. | 10,000 rub. |

| Brand "DPK". | 450 rub. | From 6800 rub. | 6500 rub. |

The wholesale price per ton is significantly lower than the retail price.

Expert opinion Pavel Kruglov Stove maker with 25 years of experience

It is better to purchase coal from a time-tested seller. For each region you will need to find dealers for coal companies. In any region, such sellers distribute high-quality fuel at dealer prices.

The main thing is to check all the documentation for the coal and its quality and compliance with the type upon delivery. If they brought you coal dust under the guise of a nut, it is better to refuse the services of such a company.

Model ratings

The main purpose of heaters is to heat the bath room and create a comfortable microclimate in it. But the models may differ in shape, appearance, and characteristics. Therefore, it is worth considering the best units, selected based on ratings and customer reviews.

The best wood-burning stove for a sauna

The Vesuvius Skif 22 model is popular among consumers. From the main characteristics:

- power - 22 kW;

- unit dimensions (width, height) - 560x740 mm;

- built-in “clean glass” system, so virtually no soot settles on the heater.

Vesuvius Skif 22 is a popular stove model.

Price - from 17 thousand rubles.

A good model is “Kastor KARHU”. The outer body and door are made of steel alloy. From the characteristics:

- weight - from 30 kg;

- Sauna volume (cub.m.): 8 – 40

Kastor KARHU is a popular stove model.

The cost of equipment is from 43,000 rubles.

“Sauna stove GFS-ZK in mesh 18” is a cast iron unit. Key equipment indicators:

- The volume of the steam room is 18 m³;

- Efficiency - up to 87%;

- Recommended weight of stones: 140 kg

Hephaestus GFS-ZK in grid 18 - cast iron stove for a bath.

Price - 56 thousand rubles.

The best electric stove for a sauna

A good device is the Mini Cirrus Rock 2 CRR2-30NS-P. Among the main equipment indicators:

- weight of stones - 46 kg;

- sauna volume - 2-4 cubic meters;

- power - 3 kW;

The unit is equipped with a remote control, the price of the device is from 34 thousand rubles.

A good model, according to consumer reviews, is Harvia Vega Pro BC-165. Main characteristics:

- power - 17 kW;

- weight - 15 kg;

- dimensions - 435x640 mm.

The cost of the unit is about 50 thousand rubles.

Harvia Vega Pro BC165 is a stylish and efficient electric oven.

A reliable model is the Harvia Cilindro PC70F electric oven with a built-in remote control. The characteristics include:

- dimensions - 360x930 mm;

- power - 7 kW.

You can purchase the design from 37 thousand rubles.

Harvia Delta D36E is popular. From the characteristics:

- power 3.6 kW;

- dimensions - 340x635 mm;

- weight - 8 kg.

Harvia Delta D36 is a compact electric heater.

Price - 19 thousand rubles.

Best steel stove

The Kalita Druzhina model has positive reviews. The volume of the combustion chamber is about 40 liters. The unit is designed for bath rooms up to 16-18 cubic meters.

Advantages:

- laconic style;

- ease of use;

- light weight (can be easily moved around the territory).

However, the working surface does not allow the device to be used in a large room. The model hums when wood is actively burning.

From a pro's point of view

Cast iron wood burning units are chosen from the following: Harvia, Kastor, Hephaestus, IKI, Feringer

From a hobbyist's point of view

Users like the following cast iron bath models - “Hephaestus”, Harvia, Koster.

From the point of view of undemanding vapers

Undemanding or inexperienced steamers prefer cast iron wood-burning structures Hephaestus, Feringer, IKI From steel units - Harvia, Helo

Electric oven Harvia Vega Compact BC35 Steel, built-in remote control included

The best sauna stove with a water tank

There is no universal model. According to user surveys and calculations using a separate method, the Harvia 20 RS PRO was recognized as the best stove with a water tank. This is a compact, simple, easy-to-use model. It is no worse in build quality and features than other premium analogues.

The loading of stones inside reaches 40 kg. The unit has a built-in heat exchanger. The chimney is made as a labyrinth, which increases efficiency.

The best stove for a bath with a heat exchanger

The unit from the economy class line is “TERMOFOR VITRIVIA”. The package includes a heat exchanger.

The model is distinguished by its complete set and low price. Creates a moderate indoor climate. The water does not boil, but remains hot for a long time.

The disadvantage is that the stones heat up slowly.

How to calculate the volume of the firebox

Calculating a stove for a sauna, which you plan to make yourself with power from the mains, is quite simple. It is necessary to obtain the final power requirements and then calculate the required number of heating elements based on their characteristics and wiring capabilities.

However, bathhouse owners often have difficulty determining the parameters of wood-burning stoves. There is nothing complicated here either. It is enough to calculate the volume of the firebox, the compartment where the fuel will burn. The calculation formula is simple:

- the volume is calculated by dividing the required power by 0.6 for a stove installed directly in the steam room;

- The combustion volume of the firebox is equal to twice the calculated power if the stove is located in an adjacent room.

The resulting figure is measured in liters. To roughly estimate the dimensions of the firebox, you need to take the cube root from it and divide the result by 1000. This way you can get the value in linear meters. However, this is a rough estimate. It will show the side of the cube without taking into account how the geometry of the firebox fits into the existing room.

Answers on questions

Owners often ask different questions, which only specialists can answer.

How to choose a stove for a bath

You should definitely study information about the product before purchasing, compare prices and choose the best brand based on owner reviews and ratings.

The main criteria when choosing a design:

- power and efficiency;

- the presence of a steam generator, convection;

- shape, location of the pipe;

- equipped with a water tank;

- materials, type of heating.

The model must comply with operating conditions and technical documentation, be reliable and durable. You need to start purchasing only after studying all the details and nuances, ratings and consumer reviews, and consulting with a specialist.

Which one is better to put in the bathhouse?

Having studied the models, it is worth concluding that it is better to install in a bathhouse a structure that will heat a large volume of the room and will be safe.

The following models with heated air volume of 25 cubic meters or more are suitable for large and small steam rooms - “Vesuvius Scythian”, “Hephaestus PB”. The units retain heat for a long time and heat the room in 0.5 hours. They are easy to operate and can withstand high thermal loads (450ºC).

Which sauna stove is better - steel or cast iron?

Everyone chooses based on preferences and situation.

Steel structures, unlike cast iron ones, do not require a high-quality foundation because they are lighter in weight. They heat up the room quickly. However, cast iron retains heat longer.

Key characteristics when choosing

Having chosen cast iron, you need to compare the parameters of the product with the bathhouse in which it will be installed.

Working properties:

Productivity, characterized by the area of the room heated by the unit. Fuel type. Most often, buyers prefer wood stoves. Type of firebox (standard or extended). The extended one is mounted in the wall. You can heat the sauna directly from the steam room or from the dressing room, which is very convenient. Material. There are several variations of cast iron. The service life of the unit and the thickness of the furnace walls depend on the correct choice. Wall thickness. Best option: gray cast iron. Availability of a water tank and its type. There are two types: built-in and suspended. In use, preference is given to hanging tanks: it is easier to fill in water and control the level of the remaining

The mounting location of the tank is also important: at the back or on the side. Depends on where you will install the unit.