In terms of quality, practicality, and aesthetic characteristics, a bathhouse made from wood beams is practically no different from one built from rounded logs, but the construction process is much simpler and does not require special skill.

A wooden bathhouse is considered truly Russian, since once upon a time in Rus' every building was erected without the use of nails, but as efficiently as possible.

So, let's talk about building a bathhouse from natural timber.

Advantages of a timber bath

It is worth knowing what qualities distinguish this model from other known options:

- Natural materials.

- Good environmental performance.

- Ease of operation.

- With high-quality pre-treatment, the construction is safe.

- Relatively low cost.

- Save time. The construction of this model will take much less time, thanks to the use of shaped blanks and the absence of frame structures.

- Sufficient thermal insulation. The timber has a good thickness, which allows you to retain heat indoors.

Due to the presence of so many advantages of practical application, bathhouses made of timber have gained particular popularity among owners of summer cottages.

Why wood

The environmentally friendly natural material will release beneficial resin during use - the heated bathhouse is filled with evaporations of soothing essential oils. Pine wood also helps disinfect the room - it prevents the proliferation of microorganisms and viruses.

Wood is optimal from the point of view of natural ventilation; such walls establish natural air and moisture exchange. As a result, a microclimate that has a beneficial effect on health and an ideal ratio of oxygen and steam is formed. Baths made from the material in question are able to retain heat for a long time; their thermal conductivity is much lower than that of concrete and brick structures.

Another significant advantage of timber is the complete pre-processing of the material, so that builders do not need to waste time bringing surfaces to the required state for assembly.

The walls look neat, do not warp during use, and exhibit high sound insulation rates.

High-quality finishing gives the bathhouse a simply chic look Source mebel-go.ru

Features of material selection

When purchasing material, you should consider the following characteristics:

- Timber harvesting season. Ideally, the material should be prepared in winter. This indicator may affect the quality of construction.

- Storage period before use. This characteristic has the same basis as the harvesting season. You can check this information with the seller of the materials.

- Appearance. You should definitely evaluate the condition of the workpieces: stains, dampness, and traces of pests may alert you. The quality of trimming and the degree of alignment of the cuts are also assessed.

- Type of raw material.

- Wood species. The best options for building a bathhouse are hardwoods. It is better not to use raw materials from pine needles due to the presence of various resins in the structure.

Assessing these parameters is mandatory, as it will help avoid possible problems during the construction process.

Treatment with antiseptics

It is very important that only high-quality consumables are used in construction. It is imperative that the timber be pre-treated with specialized compounds that increase the fire protection and moisture resistance of the building. Special, safe antiseptics protect it from insects and rodents, natural elements, and allow you to preserve and improve the properties of wood.

It is also extremely necessary to treat materials adjacent to heating objects with fire-fighting components. Materials such as wood, without being treated with antiseptics, quickly deteriorate and become a fire hazard. The material processed with special means has a good level of fire safety and is reliably protected from fire. The use of high-quality antiseptics does not in any way reduce the environmental purity of wood.

Choosing a timber model

The material for the construction of baths differs not only in its species and quality characteristics, but also in its manufacturing technology. Today, manufacturers offer their customers the following types of timber:

- Profiled option.

- One-piece models.

Each of the presented models differs in the method of formation, finishing features, and methods of practical work with the material.

What are the criteria for selecting timber for a steam room?

One of the significant stages in the construction of a bathhouse is, of course, the choice of massif. After all, the characteristics of the bath directly depend on this.

First of all, pay special attention to the absence of any cracks in the logs, which, when expanded in the future, will become the cause of defects and rotting of the massif during shrinkage.

In addition, the wood should not have blue highlights, indicating internal rotting, which is associated with the presence of fungi.

It is not recommended to build a building from such material. In addition, the timber is defective if there is a wormhole on it.

At the same time, a good timber is absolutely smooth. If there are defects, as well as various distortions, this will not have the best effect on the arrangement of the crowns; accordingly, the construction of the steam room may take a long period of time.

There are several types of timber: solid and profiled. The second option is equipped with tenons and grooves that can be ground. Such parts are easier to connect to each other.

The most important advantage is that such walls are not susceptible to the adverse effects of moisture. As for the disadvantages, the material has a low degree of fire resistance, which means it must be subjected to additional processing with propylene.

Solid timber is also used in construction. However, it does not look attractive in appearance, so it is covered with siding.

Profiled version

Structures made from profiled timber are durable and resistant to moisture. During manufacturing, additional surface grinding is used due to the presence of tenons and grooves.

But in terms of safety, the material is inferior to the second model, so before construction, the workpieces are treated with an antipyretic.

Additional materials for construction

Any construction process requires auxiliary materials and a certain set of tools. Before starting work you should prepare:

- Foundation materials: cement, sand, gravel.

- Brick for the stove.

- Lining for interior decoration.

- Roofing material.

- Tool sets: nails, hammers, screws.

- Insulation materials.

- Lighting fixtures and cable.

Construction of a bathhouse

For a novice master, the main question is: how to make a sauna with your own hands correctly and for a long time. The construction process itself consists of several stages:

- Drawing up a bathhouse project.

- Foundation construction.

- Laying a waterproofing layer.

- Walling.

- Hiding cracks.

- Formation of the roof.

- Finishing.

Each stage requires certain efforts and skills from the master. If you wish, you can familiarize yourself with photos and video tutorials on building a bathhouse from timber.

Features of building a bathhouse from wooden beams: video

To achieve the optimal result from drawing up a steam room project to its implementation, it is necessary to take into account several features. It is also important to take things step by step. The entire process is described in more detail in the video below.

Dear readers of our online magazine. We invite you to rate the publication and offer your ideas for building home steam rooms. Also ask questions if some points are not clear to you. We will definitely contact you as soon as possible to respond to all your messages.

Save time: selected articles delivered to your inbox every week

Drawing up a bathhouse project

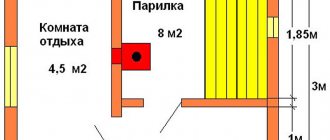

Any construction process requires a clear drawing or diagram. Preparation of the project includes sketching the following details on paper:

- Bath box dimensions.

- Indication of the location of doors, windows, stove, rooms (steam room, dressing room, shower).

- Electrical wiring indicating the location of sockets and lamps.

After drawing up the diagram, you should definitely calculate the required amount of material in order to avoid unnecessary financial costs.

Calculation of the required quantity

Now you can try to calculate the required amount of timber. For example, we will take a beam with a cross-section of 140x140 and a standard length of 6 m. 1 beam is approximately 0.1177 kb.m (8.5 pieces in one cube). Those. from one cube you can build a wall of 7.14 sq.m.

This is the basis that will be necessary to solve a practical problem during construction. Let’s say you are planning a standard bathhouse with an area of 6x6 m. From this it follows:

- The perimeter is 36 meters.

- The area of the walls, with a height of 2.5 m, is equal to: 36 x 2.5 = 90 sq.m.

- The area of the walls must be divided by the layout of one cube: 90/7.14 = 12.61 sq.m.

- Now you need to divide the area by the number of pieces in the cube: 12.61 x 8.5.

It turns out that to build a 6x6 bathhouse you will need about 108 pieces. It is also recommended to include about a dozen beams here for damage, non-compliance and manufacturing errors.

Foundation structure

The choice of foundation models is quite extensive and depends on the weight of the structure and soil characteristics. The most famous options for filling the base:

- Tape type.

- Pile type.

- Slab option.

- Columnar model.

For a structure such as a timber bathhouse, a columnar foundation is perfect. To lay the support, you should use the instructions:

- First of all, you need to mark the site. To do this, install pegs and pull the string.

- Additional marks are placed in the places of future support pillars.

- Niches are dug in the ground for filling.

- At the bottom of the pits, make a sand cushion of at least 20 cm, then fill it with water.

- The next layer is crushed stone and formwork is formed.

- A bunch of metal reinforcement acts as supporting structures.

- After installing the support column, the empty spaces in the pits are filled with cement mortar.

Experts advise making additional concrete inserts to increase the strength of the supporting structure.

Step-by-step construction instructions

A bathhouse with your own hands can be built on four foundations:

- tiled;

- columnar (light walls);

- pile;

- strip concrete.

The last type of foundation has the greatest reliability, which is recommended in all cases.

After pouring it, they proceed to the construction of walls. For them, it is most optimal to use bars 15 by 15 and 5 by 10 centimeters. Boards in section 2 by 15 centimeters.

The lower trim is made with waterproofing. Installation of vertical block racks is carried out with the definition of window and door openings. Then the upper trim is constructed. A level must be used in all work. Vertical posts and corner joints are attached. The sheathing for the flooring is being prepared. And finally, the walls are covered with boards. Polystyrene foam or mineral wool plays the role of insulation. The ceiling is insulated in layers. First a vapor barrier, then insulation.

The roof can be made single or gable. If necessary, you can make a complex structure of four or more slopes. Recommended material is metal tiles. The inclination of the surface determines the presence of power load in winter and insufficient water flow in the warm season.

The floors in the recreation room are usually laid out with simple wooden floors. For the steam room and washing room, two levels must be provided. Concrete with a slope towards the drain hole is the first. Board with gaps for drainage flows is the second. You can put tiles or porcelain tiles instead of wood.

When choosing a boiler model, you should proceed from financial considerations and fuel. For those who have the necessary cooking skills, it is not difficult to independently make a heating device from sheet iron of a certain thickness. There is no problem contacting a specialized company that will present you with a choice of the most suitable electric or gas fueled models.

The installation is carried out so that the combustion chamber is loaded with fuel from the street or dressing room. The distance from the walls should be at least 10 or 15 centimeters. The most convenient thing is to make the lining with brick. Then it will retain heat for a long time.

The smoke exhaust hole is insulated with a refractory special material at the junction with the ceiling. The place where the chimney goes to the roof is carefully sealed.

Laying a layer of waterproofing

This stage should not be ignored, since laying an additional protective layer will significantly increase the service life of the structure. The step-by-step scheme looks like this:

- After the concrete has hardened, a layer of bitumen is laid on top of the foundation.

- Next comes a layer in the form of roofing material.

This procedure is repeated several times.

Walling

The first step in construction is laying the strapping crown. The closest attention is paid to this layer, since the even laying of subsequent rows depends specifically on the first row. You can check the laying direction using a building level.

A layer of insulation can be laid on top of the first row. Next, proceed to assembly, depending on the type of fastening structures:

- Metal pins. The advantage is the strength of the connection.

- Wooden dowels.

There are features regarding the frequency of screeding: when building a bathhouse from laminated timber, the screeding is done after every 5th row.

6x4 bathhouse projects: photos, design features and advantages

A 6 by 4 bathhouse will not take up much space, so it can be installed even in a small area. Moreover, it can accommodate up to 4-6 people, i.e. one family or a small group of friends.

The 6 by 4 bathhouse design is optimal. The construction will not be too large, but not small either. In it, you, your family and friends will be able to relax in comfortable conditions, without jostling with elbows in the steam room or relaxation room.

It is extremely important to design a 4 by 6 bathhouse correctly. If mistakes are made, they will all come up during construction, which will lead to financial and time losses. You can create a project yourself, find a ready-made one on the Internet, or order it from specialists.

If you look at photos of 6 by 4 bathhouse projects, you can see that such buildings vary greatly. A building of such an area provides ample opportunities: someone makes a bathhouse with a gazebo, someone allocates a lot of space for a steam room, etc.

6 by 4 bathhouse designs are presented in a wide selection of freely available options. On the Internet you can easily find a variety of implementation options. If you want something special, a drawing made especially for you, then you can always contact a special company that will develop a drawing of a 6x4 bathhouse taking into account your site and personal preferences.

Of course, everyone makes a project taking into account their own wishes, but there are some general rules.

Typically, the layout of a 6x4 bath includes the following rooms:

- dressing room/dressing room;

- steam room;

- washing;

- restroom.

The dressing room can be small; it only needs space to leave shoes and hang outerwear; firewood is also often stored in this room. There are projects where there are only three rooms - without a dressing room. But it is preferable to choose 6x4 bathhouse layouts with a vestibule, since it prevents the appearance of drafts in the rest room, and is also used for storing various things that may be in the way in the rest room.

The steam room is the main and most important room. It should accommodate a sauna stove and shelves. The size of the steam room depends on how many people will visit it simultaneously in the future. But you don’t need to make the steam room too large; the more spacious it is, the longer it will take to warm up and the more fuel you will need.

We recommend reading:

Bathhouse designs with a relaxation room: design features, types

The washing room can be small or spacious, depending on the layout. A 6x4 bathhouse can include a washing room the size of a steam room or a small room that can only accommodate a shower stall. In the first case, a bench with buckets or buckets is usually placed in the bathhouse, and in the second - a shower stall, a tray with a shower tube. Each option is convenient in its own way, so the choice depends on personal preferences. The advantage of a small washing room is the ability to add an additional room to the project or make another one more spacious.

The relaxation room is a place where you will cool down between visits to the steam room. There must be seating (benches, chairs) and a table. The layout of a 4x6 bathhouse can be different, but it is important that the room be spacious. People go to the steam room in groups, 1-2 people go to the washing room, but the relaxation room is the place where the whole company gathers. It is important that you can not only sit, but also move around the entire room calmly.

Bathhouse 4 by 6 (layout inside, photo):

The advantage of 6 by 4 bathhouse projects is the ability to vary the size of each room depending on your desires, increasing the area of one of them by reducing the other.

Bathhouse 4x6: projects:

A 4x6 bathhouse design may include a bathroom: although it is not a necessity, it significantly increases the comfort of visiting the bathhouse. The presence of a toilet is especially important if the bathhouse is a separate building that has access to the house only across the street. In winter, running to the toilet in the cold is quite problematic, and you can also catch a cold.

Many people build a bathhouse in their country house and visit it only in the warm season. In this case, instead of a rest room, you can make a small veranda. The design of a 4x6 bathhouse with a veranda is convenient because in this case you will relax in nature, and not indoors, you will be able to enjoy the landscapes around you and breathe fresh air. A 6 by 4 bathhouse with a veranda can have a spacious terrace that can accommodate a company of up to 6-8 people.

The veranda must have a roof, usually common with the bathhouse, which is supported on supports. You can decorate the walls of the veranda in different ways. It can be open, semi-closed or closed, it all depends on your preferences. A semi-enclosed veranda is considered the best option, since in this case you do not block your view of the surrounding areas, while it protects you from the wind and other external influences.

We recommend reading:

Veranda to the bathhouse: photos, projects. How to build a veranda for a bathhouse with your own hands?

Below you can see projects and photos of a 6x4 bathhouse with a terrace:

In the process of drawing up the project, do not forget to provide for ventilation in the bathhouse, sewerage system, water supply system, as well as electrical wires.

Roof assembly

The assembly process depends on the covering model, material and shape (single or gable roof). Regardless of the type chosen, the entire process will consist of a number of steps:

- Preparation and fastening of rafters.

- Laying the covering.

Very often, tiles are used as a material, but the final choice is made by the owner of the bathhouse, based on personal wishes and financial capabilities.

Bath decoration

The whole process is divided into two options: interior and exterior finishing. The external design of the building plays only an aesthetic role, and therefore is not a mandatory stage. But the same cannot be said about the interior design, which includes:

- Wall covering with decorative materials.

- Conducting electricity, installing sockets and lamps.

- Construction of the stove and installation of a shower cabin or washing room.

There are a lot of options and ideas for interior decoration, and the choice is individual for each style.

Original author's ideas

For those who have not yet decided on a timber bathhouse model, here is a selection of the most original options:

- Bathhouse with terrace.

- Unusual shaped baths. One of the most famous and original models is a steam room in the shape of a horizontal barrel.

Non-standard sizes and shapes, as well as interesting approaches to design, are great for construction when there is a shortage of free space.

Photos of finished baths can be found on landscape design websites, where it is easy to choose a unique option for every taste.

Types of modern baths

Today there are a variety of types of modern baths, namely:

With attic

This is one of the common options for a steam room with an attic roof and a veranda. At the top of the structure there is a bedroom where you can relax comfortably after taking a bath.

And the veranda is a great place where you can drink a cup of aromatic tea.

With terrace

Are you planning to build a barbecue in your country house? Then build a steam room with a terrace where you can install a stove directly. After time, you can create a pond in front of the steam room.

With veranda

A bathhouse with a spacious veranda is considered one of the simplest structures.

How to obtain permits for construction: list of documentsModern Bluetooth headphones

- Construction services for business

In this case, it is preferable to glaze the veranda and use it as a summer recreation area or kitchen space.

With porch

Are you a fan of the true Russian bathhouse? Then build it with a spacious porch, which is not just beautiful, but also as practical as possible.

A small table, a traditional samovar and the splendor of the surrounding nature.

Photo of a bathhouse made of timber

Total

Category: Gazebos and baths