How to build a 3x4 frame bathhouse with your own hands. I present to you a detailed working photo project for the construction of an inexpensive and easy-to-make wooden frame bathhouse with a gable roof.

This frame bathhouse will be built on a strip foundation with a poured concrete floor.

Our foundation principle will be the same as shown in the photo.

Our foundation slab will be 440*340 cm and with a total diagonal of 556 cm.

We design ourselves: modern types of baths

Ready-made design documentation for a bathhouse made of timber with an attic or any other can be purchased at special bureaus or completed independently. In the second case, any standard project for the selected size of the building will come to the rescue.

Before starting to design a bathhouse based on a frame, key issues are resolved:

- find the most rational location of the building, taking into account convenience and simplicity for the provision of water, sewerage and lighting communications;

- plan the size of the future building;

- at the selected location, study the composition of the soil and differences in the ground surface. These factors will be decisive in choosing the type of foundation;

- solve the need to build 2 floors, an attic and the construction of external elements such as a veranda, terrace;

- determine the type of roof. Options for single-slope, double-slope and multi-slope structures are being considered.

When choosing the number of roof slopes, the size of the bathhouse, the climatic features of the area, the distance to other buildings, and the type of coating are taken into account.

The finished project will become an assistant in the rational distribution of spaces and the choice of building materials. Photos of bathhouses will also help you decide on your preferences.

Preliminarily think through the internal layout of the bathhouse in terms of functionality. Determine the installation location of the stove. It determines how the chimneys and ventilation will be located.

At the design stage, the issue of choosing the materials from which the structure will be built is decided and the approximate cost of construction is calculated. The more detailed the design of a frame bathhouse is developed with your own hands, the easier it is to make adjustments to it if unforeseen circumstances arise.

Option 4*5 m

The building, measuring 20 m2, is compact and suitable for a bathhouse consisting of three rooms:

- rest rooms;

- steam rooms;

- sanitary room with toilet and shower.

When determining the dimensions of interior spaces, the calculation is made not for the “pure” size, but taking into account the thickness of the partitions and walls.

The most suitable area for a relaxation room is 7-8.5 m2, for a steam room - up to 5 m2, for a bathroom - at least 2.2 m2. The small size of the building does not require a dressing room. The steam room houses the heater and the entire main surface of the stove. A firebox is brought into the rest room, which also plays the role of a heating device. To prevent cold air from entering the bathhouse from the street, it is necessary to provide a closed porch.

Consumables and elements of a 4*5 m bath:

- The foundation is a strip foundation buried 70 cm and a plinth height of 40 cm. Its arrangement requires a gravel cushion up to 20 cm thick.

- The frame consists of posts and trim along the upper and lower edges of the structure. It is optimal to use boards 100*50 mm.

- The roof is gable with a rafter system made of 150*50 mm boards. Laying pitch 580 mm.

The cladding is selected depending on the required level of thermal insulation.

Option 6*6 m with veranda, balcony

The size of 6*6 m gives space for imagination. The design of such a bathhouse can include the following premises:

- terrace or vestibule;

- rest room and bedroom;

- steam room;

- full bathroom;

- washing room

Linear dimensions require the use of standard length lumber, which reduces the cost of construction due to the small amount of waste.

The washing room can be made extremely large with direct access from the steam room and place sun loungers in it. In another version of the project, it is planned to separate the washing room and the steam room with a small corridor connected to the rest room. In this case, the washing room will be somewhat smaller.

Option 6*3 m: design with terrace

The design of a 6*3 m bathhouse with a terrace comes in two versions:

- The terrace is not included in the area of the building and its size is planned separately. In this case, the overall size of the building will increase by the area of the veranda.

- The terrace is part of the common building. Then all interior spaces will be smaller.

The small size of the bathhouse will not allow you to equip a full-fledged bathroom. The stove will be heated from the rest room.

Choose a compact stove, perhaps the model will be narrow and elongated upward.

Moving the terrace beyond the foundation of the main building will allow you to allocate a small space from the rest room for a vestibule . Then it is possible to take a steam bath in winter. Approximate dimensions of interior spaces:

- steam room – 3.5 m2;

- shower/washing room – 1.8 m2;

- relaxation room – 8.5 m2;

- vestibule – 2.6 m2;

- outdoor terrace – 11 m2.

To form the frame you will need a beam of 100*150 mm. They are strapped and floor joists are installed. For the roof, use 150*40 mm timber for the ceiling. The rafter system is laid from edged boards. A board with a size of 100*50 mm is suitable for this. The material for cladding and roofing is selected depending on personal preferences and climatic conditions.

Option 4*4 m with terrace

This size of the building assumes only an external, attached terrace, but under a common roof and on a common foundation.

An area of 4*4 m is larger for dry saunas. For Russian baths, this is not the most comfortable option.

The project involves dividing the common space into two parts of 8 m2 each and adding a terrace up to 6 m2 in size:

- A relaxation room after the steam room, also known as a dressing room.

- Steam room and sink.

The steam room should be made larger than a washing room. Then it will be possible to accommodate two people.

Option 5.4*6.3 m

A bathhouse with a total area of 34 m2 may have a built-in terrace. In this case, up to 2/3 of the total area is allocated to the interior. A typical project suggests the following room sizes:

- for relaxation in 11-12 m2;

- for the steam room – 5 m2;

- for sanitary needs - up to 6 m2.

The rest of the space will be occupied by the terrace. It is convenient to make part of the terrace closed so that warm air does not immediately escape into the street.

If a veranda is not planned, then a dressing room with an area of 5.4 m2 is made and the presence of a bathroom can be planned.

Interior work

Communications and electrical wiring in a frame building

In a bathhouse, the wiring is made internal, hidden in plastic gutters; power cables are not allowed to be placed in metal boxes or steel-braided hoses. Lamps are used with moisture-proof housings; sockets and switches are not installed in the steam room, only in the dressing room.

The water pipeline is laid in the ground if the bathhouse is used all year round. Pipes are placed taking into account freezing and insulated with insulation. During summer use only, an air method of supplying water in a hose is allowed, but with the onset of cold weather, the liquid is drained from the pipes, tank and toilet siphon.

What's the best way to set up a stove?

The remote firebox, which is connected to the steam room by a channel for supplying heated air, works rationally. The stove requires a separate base made of brick or reinforced concrete. A channel is cut out in the wall of the dressing room adjacent to the steam room, which is lined with thermally insulated brick.

A chimney is installed vertically with an outlet to the roof.

The location for the combustion channel is chosen so as not to reduce the space for shelves in the steam room.

The foundation of the furnace is insulated with a heat-resistant insulator, for example, fiberglass, asbestos. A metal sheet is stuffed in front of the oven door.

Insulation scheme for a frame bath

You can insulate the walls using mineral wool.

Types of insulation are used that do not release toxic components in conditions of humidity and heat. Mineral wool mats become saturated with moisture and lose quality, so they require a ventilated gap between the insulation and the waterproofing.

The foil look works well. It is placed with the shiny side into the room so that the thermal infrared rays are reflected back into the room. The foil is selected according to the thickness of the walls, the screen is installed separately or together with standard insulation. Reflecting heat significantly reduces fuel volume.

Drain device

The volume of wastewater depends on the area of the bathhouse and the intensity of use.

Drainage is organized in the following ways:

- liquid intake into the ground under the floor;

- discharge through a system with drainage wells;

- use of a cesspool;

- use of a septic tank system;

- connection to the city sewer.

Pipes in the ground are insulated from freezing and placed at a slope towards the receiving sump. Timely drainage of water helps to avoid mold, mildew and destruction of floor structures. A separate sewer system is made for the bathhouse or a pipe is connected to the general drainage system to the septic tank.

Installing proper ventilation in the bath

After using the steam room, intensive ventilation is required to reduce the humidity in the room.

Three types of ventilation systems are used in the bath complex:

- natural hatching and feeding;

- forced method;

- system with air purification and recovery.

In the first case, the air leaves and is supplied through built-in or mounted channels. The forced method involves the use of fans. They are mounted at the input of the output channel and the output of the supply channel. A complex cleaning system is used in large establishments; it is not installed in private buildings due to its high cost.

The main advantages of frame technology

Advantages of frame buildings:

- the design is simple and it is possible to design and build it yourself;

- the building does not shrink and finishing work and installation of equipment begin immediately after the main construction;

- construction proceeds quickly, without restrictions on the time of year;

- the lightness of the design makes it possible to install any type of foundation;

- Any materials for cladding are suitable. Everything depends on material capabilities;

- environmental friendliness of the building;

- economic benefit in comparison with stone and brick buildings.

To perform the work, it is not necessary to involve heavy equipment and a whole team of workers. Simple construction tools and a maximum of one assistant will do.

Construction of a bathhouse: first stage - foundation with video

A panel bathhouse of any size begins with laying the foundation; we will tell you about the foundation for a one-story building. You will need:

1. Asbestos-cement pipes 4 m long, 100 mm in diameter.

2. Drilling wells according to pipe sizes. The diameter of the well is about 200 mm and the depth is 1.5 m.

3. The purchased pipes are inserted into the well; they can be secured with sand.

4. After laying, the pipes are cut to the mark, and then prepared cement mortar made according to the classic recipe is poured into them: water, crushed stone, concrete, sand.

After laying the foundation, piping is performed, which will require:

1. Board with a section of 50x100 mm.

2. Antiseptic, which is used to treat the boards 12 hours before the start of construction.

After preliminary preparation, the future walls must be marked, then the boards are laid along the outer contour.

Advice! Lay the boards with the outer edge, securing the joints with nails. Check the evenness of the filling with a level; if unevenness is detected, it is corrected by laying a layer of construction roofing felt.

Next, intermediate racks are installed, taking into account further cladding and installation of the heat-insulating layer. It is recommended to secure the logs and axles with metal plates, previously walled up.

The resulting piping is again treated with special solutions, which will further protect the bathhouse from rotting.

Video

What disadvantages do we take into account during construction?

Like all wooden buildings, a frame bathhouse will have an increased fire hazard. The design should take into account additional treatment with special compounds that will reduce flammability. Insulation materials are selected from the point of view of combustion resistance.

When building frame baths, you cannot skimp on the quality of electrical work. Electrical wiring is placed in non-flammable casings. When installing any electrical appliances, grounding is required.

High humidity in the bathhouse can lead to the destruction of mineral insulation if it is not covered with a vapor barrier. Therefore, it is recommended to use more functional materials as insulation.

All of the above disadvantages lead to higher construction costs.

Adviсe

When building a frame-type bathhouse, you should follow the advice of experienced builders. This will help build a durable building

It is important to follow these recommendations:

- It is worth very carefully securing the vapor barrier layer at the junction of the walls and floor of the bathhouse. This affects the durability of the building.

- Additionally, you can create reliable thermal insulation for a frame bath from the street side. To do this, additional layers of hydro- and thermal insulation are attached under the lining of the bathhouse.

- The inside of the bathhouse lining should not be painted or opened with varnish compounds. Such compounds can release toxic substances.

The ceiling and flooring in the bathhouse are insulated with special diligence. It is necessary to use the same materials that were used to insulate the walls. A frame bath is a profitable and forward-thinking solution. Its construction will not take much time. If you develop a bathhouse design in detail and prepare all the necessary materials, you will be able to build a bathhouse quickly and efficiently. Such an object will become a source of pride for the owners of the site.

Necessary materials.

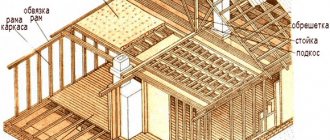

A building built on a frame consists of the following elements:

- timber frame;

- cladding from finishing materials on the inside and outside;

- laying insulation, vapor barriers between parts of the sheathing;

- foundation of any type. The most commonly used are shallow belt or pile ones. Depending on the project, other types may be used.

Each element can reduce the cost or, on the contrary, make the final product more expensive, due to the selected materials.

To assemble the frame and floor joist rafter system, timber from high-quality tree species with parameters of 100*150 mm is used. The stability of the structure can be increased by using 150*150 mm bars. Modern technologies offer laminated veneer lumber. For the remaining elements, smaller beams are selected. Any lumber or plywood is suitable for sheathing.

The following can be used as roofing material:

- roofing felt;

- corrugated sheeting;

- folded covering;

- metal tiles;

- Euro slate.

Ceramic tiles are very heavy and will create additional stress on the foundation.

Apart from the joists, the floor has a rough covering. It can be plywood, any type of board, special boards. Materials that imitate natural logs have worked well as external cladding. Various types of lining can be used inside.

All wooden elements must be treated with fire retardants and antibacterial mixtures.

Insulation materials are selected that are resistant to rotting and burning. These are mainly mineral wools. The insulation layer is determined by the climate of the region where construction is taking place. If other types are chosen, you must read the instructions so that they are resistant to high temperatures and do not support combustion.

Additionally, mounting materials and interior finishing are purchased. Principle of choice: lightweight, moisture-resistant, fireproof.

Benefits of a small project

For owners of garden and summer cottage plots who are making a difficult choice between a greenhouse and an extra bed, the 3 by 5 bathhouse project will be the optimal way to decorate their everyday life with bathing procedures. In addition to compactness, the advantages are the following features of such buildings:

- Sufficient capacity. The project is designed for the simultaneous presence of 2-3 people, which fits well into the Russian national traditions of collective visits to the steam room.

- Budgeting. The smaller the dimensions, the less materials required; The savings can't help but rejoice.

- Additional savings. If you choose a lighter material (for example, not brick, but wood or blocks), the need to build a reinforced foundation disappears; you can limit yourself to a budget base.

- Fast construction. The technology has long been known and proven, construction is carried out quickly.

- Savings in operation. A small steam room requires less fuel. You can warm it up by creating the desired microclimate much faster than a spacious steam room.

Classic layout of premises Source srubdomabani.ru

Construction of a bathhouse stage two: erection of walls with video

When constructing walls, the center gap plays a huge role. The future panel bath should have a gap of 0.6 m in the case where the opening and connection with other walls are not planned. If there is an opening or a docking, then the panel bath has an interaxal gap of 0.4 m more.

Advice! The distance between the posts directly depends on the size of the window and door openings. In those places where frames or slopes are connected to a lintel or wall, the construction of an additional rack is required. Then the elements are secured with nails and checked with a level for leaks.

The walls are built like this:

1. Assembly begins by forming a corner.

2. The wall of the bathhouse, which will be connected to the frame, is assembled first. After construction, it is checked for verticality; if the result is good, the walls are connected and strengthened with temporary struts.

3. Other frames are installed at right angles, after which they are secured with strapping and nails.

4. The panel bath must be covered after the frame has been completely secured.

Video

Stage three: floors and their installation

Floors in a panel bath are extremely easy to install:

• Take bars with a cross-section of 5x5 cm and attach them to the bottom of the joist. • A subfloor is laid on top of the timber. • The subfloor is insulated with roofing felt, a 10 cm layer of mineral wool or slabs of the same insulation. • A vapor barrier film or parchment is additionally installed on the insulation, after which a board is laid for the finished floor.

Advice! It is recommended to lay exhaust pipes under the floors of the bathhouse, which will remove excess moisture and prevent the formation of condensation.