Owners of country houses are trying to get a cozy, warm bathhouse. In order for the building to fulfill the functions assigned to it, and for a trip to the bathhouse to become a pleasure, it is necessary to think through the heating system in advance. The stove in the bathhouse serves not only to heat the room - it provides visitors with warm water and heats the stones. The choice is based on the type of fuel that the owners plan to use.

Advantages and disadvantages of wood or coal stoves

Solid fuel sauna stoves are the most authentic. They create a special atmosphere in the steam room, turning a visit to the bathhouse into a ritual - with lighting the fire, adding fuel, maintaining the flame.

Traditionally, solid fuel stoves are installed so that firewood or coal is supplied from the dressing room. This is also where raw materials are stored and the ash pan is cleaned of soot.

A classic sauna stove consists of brick and is designed for long-term heating. This design gradually increases the temperature in the room and retains residual heat for up to 3-5 hours.

Advantages of bath products

- Performance. Stoves provide a large amount of heat at relatively low fuel costs.

- Autonomy. They do not depend on the power supply source and are suitable for areas where there is no electricity yet or where there are frequent interruptions.

- Environmental friendliness. The statement is relevant for firewood, which is considered a safe and even useful type of fuel.

- Choosing a suitable place for laying firewood, taking into account the layout of the bathhouse.

- There is no need to wait until the room heats up - you can start steaming as soon as the stones have warmed up.

- Long-burning stoves help retain heat in a steam room for a long time, protecting it from dampness and mold.

Among the disadvantages

- long heating of the oven;

- requirements for raw materials - it must be dry;

- availability of space for storing firewood and coal;

- bulkiness, the need to arrange a separate foundation;

- complex chimney device;

- The stove requires regular maintenance, cleaning of soot and ash.

Conclusions and useful video on the topic

Having collected information on how to properly supply gas to a bathhouse, we found out that the law imposes strict requirements on the design, equipment parameters and installation conditions of the gas pipeline. Independent design and connection is prohibited. Therefore, from the moment the idea is conceived, it is worth getting advice from professionals.

In the video, a representative of one of the gas companies explains how to obtain permission to gasify residential and non-residential premises, lists the main stages and necessary documents:

If your bathhouse is already gasified and you have something to share with other owners of country estates, we invite you to participate in the discussion. In the form below you can ask questions, talk about your experience, and comment on key points. Take the chance to get useful information!

Pros and cons of gas sauna stoves

Gas models are equipped with a burner with non-volatile automatic control and safety. During installation, a chimney system is provided to remove combustion products.

Product advantages

- Economical. Gas is considered one of the cheapest types of fuel, and given the small area of the bathhouse, the costs will be low.

- Useful functionality. A gas furnace can heat a room and heat water at the same time. For this purpose, the designs include a tank that is heated by fuel combustion products discharged through the chimney.

- Fast heating. Using natural gas, you can quickly increase the temperature in the bath to a comfortable level. The heat is soft, enveloping, and easily transferred to stones and the surrounding atmosphere.

- Versatility. There are combined gas-wood stoves with a separate firebox for wood.

Flaws

- Low level of security. Natural gas is highly flammable and explosive.

- Requirements for installing the furnace. Before installing a gas boiler, it will be necessary to obtain approval from the appropriate authority.

- Dependence on a central gas supply.

Requirements

To talk about the pros and cons of a heating system, you must first determine what requirements it must satisfy.

And this:

- Safety.

- Economical.

- Ease of use.

- Warm-up speed.

Knowing the requirements listed above, you can see how gas sauna stoves meet these points.

Advantages and disadvantages of electric ovens

Nowadays, electric baths are becoming very popular. They are equipped with a compact stove operating from the electrical network. It differs from a traditional electric boiler not only in its operating principle, but also in its design. The design includes a heater where the stones are heated in the same way as in a regular stone stove.

Electrical products have many advantages

- Light weight and dimensions. The stove can be placed on the floor of the bathhouse or hung on one of the walls using brackets. It can be easily moved or moved to another location.

- Easy to care for. The device does not need to be cleaned of soot and fuel residues.

- Easy to install. An electric heater does not require a chimney or special requirements for installation; it is enough to ensure the presence of an outlet and ensure reliable insulation of the wires.

- Quick ignition. The oven heats up in a few minutes, the temperature is easy to control, and flame control is not needed at all.

- Different voltage supply modes. Depending on the wiring in the house, you can choose single-phase or three-phase power supply.

- Aesthetics. Manufacturers offer interesting modifications of electric heaters using modern facing materials.

- Minimal risks. Electric stoves do not create sparks or fire hazards, but only if the wiring is properly arranged.

Disadvantages include

- They do not have authenticity, do not provide “natural” warmth and a special spirit in the bathhouse.

- They do not emit those useful resins that are formed during the combustion of wood.

- The air in the room is too dry.

- They cool down quickly as the power supply stops.

- Furnaces cannot operate autonomously because they are powered from the mains.

- Requires large-section copper cables.

- They have a limited service life.

There is an opinion that electric heaters create unfavorable electromagnetic radiation, so it is recommended to periodically turn off the device while in the steam room.

How to choose the right gas stove?

The stove is the most important element of the steam room. It determines how comfortable and useful a visit to the bathhouse will be, and how much it will cost.

The design of a gas stove is not the last selection criterion. The volume of stones is also important; by splashing water on which you can adjust the steam hardness and other vaping characteristics.

When choosing a stove, take into account the requirements for gas baths, which relate primarily to operational safety. The manufacturer or seller must have official documents confirming that a particular model has been tested and meets government standards.

As for technical parameters, the main ones are:

- area of the steam room;

- rated power;

- firebox type;

- material of manufacture;

- control method;

- installation features;

- design.

If the power of the stove is too large for the volume of the steam room, the air will heat up quickly, and the stones will not have time to warm up. This means that getting decent steam will be problematic.

At low power, the oven will operate at the limit of its capabilities, which will lead to rapid wear and deformation. As a result, you will have to spend money on expensive repairs or even buy a new unit.

Therefore, it is necessary to determine the volume of the steam room and add to it the volume of adjacent rooms if they are also planned to be heated using the same stove. You can add 20-25% to the obtained value and, based on this data, select a model based on other criteria.

Facing a gas stove with bricks or slabs of natural stone significantly increases the heat transfer of the unit and protects bathhouse lovers from direct exposure to high and ultra-high temperatures

It is important to pay attention to the firebox, which must be made of steel grades that can withstand high temperatures and their significant differences.

It is desirable that the stove has thermal inertia, that is, it can retain heat after being turned off. This will not only save fuel during bathing, but also dry the bathhouse after completing all procedures.

If the stove will also heat water for the shower room, which is located outside the steam room, you should choose a model with a remote tank. Those who like wet steam need to buy a stove with an open heater. For connoisseurs of dry heat, you will need a unit with a closed heater, in which the heating of the stones reaches 500°C.

Multi-mode models will help you not to limit yourself to one thing and, depending on your mood, steam in either a Russian steam room or a Finnish sauna. Some stoves are capable of providing the conditions of an oriental hammam and an infrared sauna.

Additional equipment will allow you to control the unit from a distance and prepare the bathhouse for your arrival, being hundreds of kilometers away. All that remains is to wish you a successful purchase and easy steaming!

Which stove is better to choose for a bathhouse in the country?

When choosing a specific model, it is necessary to take into account the parameters that the device must meet:

- exclude fire, burns upon touching, short circuit;

- have sufficient power to heat the entire bathhouse room and provide visitors with steam and hot water;

- prevent gas and combustion products from entering the confined space of the bathhouse;

- does not require large fuel costs;

- please with appearance, fit into the interior.

Preparation of documents and obtaining permission

We have already mentioned that before starting construction it is worth checking the project and clarifying whether it is possible to supply gas to the bathhouse as intended by the owner. If everything is in order, construction can begin. A permit to build a bathhouse is not required. It is received only if the bathhouse is registered as a garden house.

Then documents are prepared to obtain consent for gasification:

- application for the provision of technical conditions;

- passport and title documents of the owner of the site;

- calculation of maximum consumption in one hour;

- site plan or diagram;

If the gas pipeline is private property, then the consent of the owner must be attached. After the gas distribution company issues the specifications, you need to make adjustments and invite a gas service inspector.

If the building complies, he will issue a permit for gas supply and an equipment layout diagram.

Since gas workers are much more willing to issue permits for gasification of residential buildings, many owners register the bathhouse in this very status. This simplifies obtaining technical specifications and speeds up the process

You can do the same with an old bathhouse already built on the site. It is possible that to bring it into proper condition it will only be necessary to organize additional window openings and an emergency exit.

True, practice shows that the percentage of obtaining permits in such cases is extremely low.

Why choose gas equipment?

It is necessary to decide on the model at the design stage. It is very important to do this correctly, since the performance characteristics of the bath depend on it. Today the market is equipped with a huge selection of stoves for baths.

In some, electricity plays the role of fuel, in others, wood. But recently, gas stoves in bathhouses have become increasingly popular, the prices for which are affordable, which allows them to be purchased by a wide segment of the population. The reason why they are preferred is widespread gasification.

Even in remote areas of the country, blue fuel is gradually replacing firewood and coal. In addition, it costs the consumer less than electricity. Moreover, nowadays it is not difficult to purchase a stove for a sauna running on gas, and many even make them themselves.

It is also possible to use combined devices capable of operating on several types of fuel. Of these devices, the most famous are gas-fired sauna stoves.

Compromise solutions

However, pure gas heating systems are not the only option for using blue fuel for heating baths.

Today, multifunctional and multi-fuel sauna stoves are widely available on the market, allowing the use of several types of fuel, or even all existing ones, if necessary:

- coal;

- peat;

- oil;

- fuel oil;

- diesel fuel;

- electricity;

- gas;

- firewood.

Naturally, such systems will cost significantly more when purchased than any of their monofuel counterparts. However, the difference in price will very quickly be compensated by efficiency and convenience. After all, the owner of such a stove gets the opportunity to use for heating the type of fuel that he gets at the lowest price or the one to which he has the most free access.

Of course, every bathhouse owner must proceed from the conditions in which he uses his property, from his material capabilities and access to the necessary resources. In some places, wood heating may turn out to be cheaper than gas heating. But for reasons of convenience, gas has no competitors as a fuel, except, perhaps, electricity. And given the constant lack of time for modern people, ease of use is a very important positive factor when choosing. Although, perhaps, to some, carrying and chopping wood seems like a pleasant activity and a form of useful physical exercise.

Features of application

Despite the rather stringent requirements regarding the use of gas in everyday life, equipment running on this type of fuel has found wide application. The same gas stoves for baths have differences not only in functionality, but also in low operating costs. They are environmentally cleaner, for example, wood-burning machines.

With the help of this equipment, the steam room warms up quickly, and the heating of the walls depends on the time of year. In summer, this takes less than three hours.

High-quality heating of the bath ensures comfortable conditions in all its rooms. Gas stoves in a bathhouse are not much different in design from similar units, but, of course, there are some features. They are primarily related to the type of fuel used.

In addition to the thermostat, they also have a fuse that trips if the flame in the burner goes out and stops the gas supply. The chamber where the fuel is burned is located immediately under the heater. This ensures rapid heating of the stones.

Gas devices, just like wood-burning ones, require chimney equipment. They can be used both for baths and for arranging a sauna.

A gas oven allows you to get the best steam. It heats up quickly and immediately transfers this heat to the heater and steam room. Stones that receive heat provide a stable temperature.

Features of work in winter

It is better to store floor-mounted or wall-mounted gas containers in insulated cabinets during the winter. At the same time, the cylinders themselves cannot be heated or insulated; they can be located inside separate structures with minimal heating. Empty cylinders cannot be stored; full cylinders may be placed at least 10 meters from the nearest residential premises. Before making calculations, you need to take into account that in winter, energy consumption costs increase greatly, and in summer they decrease.

In the fall, it is recommended to pre-stock fuel and assemble a special rack for storing containers outside the house. The rack is insulated and the cylinders are placed in a horizontal position.

You can rearrange the cylinders vertically only after connecting to a single system. This requirement must be observed, because the gas from the inside presses on the walls and affects the upper part. In a horizontal position, the risk of leakage will be minimized.

Safety is the main rule

Like any gas-powered device, sauna devices must also be installed taking into account certain precautions. Their compliance must be mandatory.

Basic safety precautions include the following:

- The gap between the heater and the wall is at least 500 mm

- The base on which the stove is installed protrudes 100 mm from the device along the entire perimeter

- The burner hole has dimensions: width – 350-450 mm, and height – 470-550 mm

Gas procedure, practical advice

The preparatory stage is the purchase of pipes, consumables and gas equipment. To gasify a bath according to the rules, you need to check the project and the received technical conditions.

The documents contain a calculation of the length of the pipes, an indication of their diameter, as well as the name and brand of permitted equipment. Experienced users advise purchasing pipes and consumables with a 30 percent reserve.

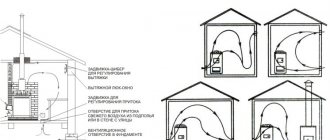

Stage No. 1 - installation of an external gas pipeline

Since it is recommended to install an external gas pipeline above ground, reliable supports will be required to secure the pipes. They must raise the gas pipeline above the ground by at least two meters.

The following requirements apply to supports:

- the distance between the supports is determined by the project;

- the strength of the structure should be calculated based on the gas pipeline’s own weight and the weight of possible ice with a coefficient of 1.2;

- the fastening part must correspond to the design dimensions of the pipe.

If the project specifies the installation of a gas pipeline with a slope, you can install metal spacers between the soles of the supports and embedded structures. The installation of such gaskets between the pipe and the support is prohibited.

The rules for placing supports also apply to the distance between them and the welds on gas pipes. This distance cannot be less than 5 cm

To protect against the effects of wet precipitation, the outer pipeline is painted with bright yellow oil paints. This is done by employees of the gas company that took over the installation.

But after they leave, many summer residents repaint the pipes in other colors that match the main palette of the site. This is prohibited.

Stage No. 2 - laying pipes inside

The internal gas pipeline must also consist of metal pipes. In places where they pass through the walls, it is necessary to drill holes and install embedded iron sleeves in them. Laying pipes through walls is permitted only through such sleeves.

When gasifying wooden buildings, this is extremely important, since any wood shrinks over time. And this is fraught with damage to the unprotected gas pipeline.

Holes for the gas pipeline are prohibited from being made between logs or beams, at their junction. They must be located inside solid wood

Fastening must be carried out using the products specified in the project. It is better to purchase fasteners in specialized stores, since regular retail outlets often offer analogues that do not meet the requirements.

To implement turning moments, it is important to use an induction pipe bender - a device that allows you to change the angle by 90 degrees. The manual bending method with heating is not suitable in this case, as it can damage the structure of the metal.

At the points where gas equipment is connected, the end of the pipe is threaded. Filters are attached to this thread and shut-off valves are installed. During the final pressure testing, a specialist must check the tightness of these connections and the integrity of the welds.

Before performing welding work, you should make sure that you have a fire extinguisher, cover the wooden walls of the bathhouse and nearby buildings with asbestos or metal sheets

It is important to ensure that the gas pipes inside the bathhouse do not intersect with the electrical wire. The minimum distance between them is 10 cm. If water supply or sewerage is installed in the bathhouse, then it is necessary to maintain a distance of 2 cm between them and the gas pipeline branch.

Stage No. 3 - installation of the chimney

We have already discussed the rules for installing a gas stove. Therefore, the next step is the organization of the chimney. Gas companies also have special requirements for it.

During installation, it is recommended to ensure:

- lack of pipe joints in the ceilings - it is necessary to install the chimney so that the connections are located above or below the ceiling;

- the location of the pipes relative to the flammable elements of the building - the distance between them should not be less than 1 meter.

Above a flat roof, the chimney can protrude 1.2 meters or more. Above a roof with slopes, the minimum elevation value is 0.5 meters.

Main advantages

Gas sauna stoves have several advantages that set them apart and influence the growth of their popularity. Perhaps their main positive quality is efficiency. This is explained by the fact that gas today is not only an accessible type of fuel, but also the cheapest. You can save a lot on the maintenance of a gasified bathhouse, compared, for example, with those where electric or wood-burning models are installed.

Gas-powered equipment is quite simple to operate and does not require special attention. There is little ash and soot in such devices, the firebox and chimney practically do not become clogged, and they do not need to be cleaned very often.

Disadvantages of gas-type heating

- The relative complexity and high cost of the equipment in comparison with competing heating systems for baths.

- Difficulty in installing a gas heating system. Only sufficiently qualified specialists can carry it out; not everyone can do it on their own, and such a solution can result in security problems.

- The need to connect to the gas main. Not all areas of the country are gasified today. Using gas from cylinders for such purposes is not very convenient and quite expensive; they won’t last long.

- A relative disadvantage can also be considered what many consider an advantage - the lack of odor. After all, the indescribable aroma of burning wood in wood-heated bathhouses gives the bathing procedure additional chic.

The opinion that gas heating in a bathhouse is dangerous can today be considered erroneous - these systems are equipped with many safety devices and assemblies and, if the minimum operating requirements are met, are completely safe.

Therefore, we do not include the danger of gas used as fuel among the disadvantages.

Gas heating of a bathhouse fulfills to a large extent the requirements for heating systems for bathhouses, subject to a number of conditions. Namely:

- If possible, connect to a centralized gas supply.

- When installing equipment by specialists of the appropriate level of qualification.

Well-known domestic manufacturers of gas bath apparatus

On the Russian heating equipment market, the manufacturer from Novosibirsk especially stands out. The Teplodar stove has a special design that allows it to heat up very quickly.

This device is highly efficient. The stove heats the sauna room evenly and produces steam of excellent quality. The products are certified and meet high international standards. The company's high-quality products are in demand not only in Russia, but also abroad.

Termofor gas sauna stoves are also deservedly popular. The products of the Urengoy manufacturer are distinguished by their original and quite stylish design, thanks to which they fit into any interior.

The translucent glass door hides the entire internal contents of the device. According to numerous consumer reviews, this gas stove for a bath, the price of which ranges from 10-12 thousand rubles, has good technical characteristics and is easy to maintain.

Also of interest are such models of domestic gas stoves, “Urengoy”, “Uralochka”, “Rus”. Each of them has a number of specific advantages, but there are also small disadvantages, primarily related to the build quality of the devices, and which manifest themselves during operation.

The Kusatek gas sauna stove represents the most serious competition to traditional devices on the Russian market. It has many advantages. Compact dimensions make installation much easier.

One of its main advantages is fast heating; it does not take much time to reach the required temperature. Any level can be easily adjusted by turning the valve.

The Kusatek stove does not leave ash and, of course, does not require frequent cleaning. The device is safe to use and this allows it to be safely installed in a bathhouse. The control system responsible for combustion and gas pressure is at the highest level and virtually eliminates the risk of an unexpected accident.

Gas-wood options

Termofor Taimyr Inox TSB ZK

It has very compact overall dimensions and a decent power rating of 32 kW. This allows you to efficiently heat a steam room, the volume of which does not exceed 18 cubic meters. m. The heat transfer of this product is rather weak, so it will have to be kept on all the time while a person is steaming. Operation is cheap, since the firebox has everything necessary to work with gas or standard firewood.

The design is equipped with a special funnel through which water is supplied to the lower layers of the heater. This helps to form a light haze of steam, the temperature of which does not exceed 60 degrees. This microclimate ideally corresponds to the parameters of a traditional Russian bath. The design has an original and very attractive appearance; the burner itself is hidden behind a decorative screen. It is made using high-quality thermal insulation materials, so it is unlikely that you will get burned on it if you accidentally touch it.

Advantages:

- Compact overall dimensions;

- Cheap model to operate;

- Produced in modern colors;

- The oven uses Italian-made automation.

Flaws:

- Heat transfer is rather weak, which increases fuel consumption.

Furnace Termofor Taimyr Inox BSE ZK

Koster-Potok 18

This stove has fairly thin walls - their thickness is only 4 mm, so the design is relatively light, its weight is about 70 kg with small dimensions of 609x354x798 mm. This model is perfect for small steam rooms that do not have a foundation. Using the stove you can heat up to 18 square meters. m of area, it allows you to create a stable, controlled climate in the steam room, which lasts for a long time.

The key difference from standard wood-burning stoves is that this model has a high smoke collector and a flame divider in the upper part of the firebox. By using these design features, it is possible to ensure stable heat transfer and uniform heating of the stones. The steam-generating surface, together with the heater, is located in close proximity to the flame.

Advantages:

- There are reliable design parts made of stainless steel with the addition of titanium and chromium;

- High efficiency;

- The stones get very hot.

Flaws:

- If you heat the stove with wood, it will take quite a lot of it.

Stove Koster-Potok 18

Ermak Uralochka-20

This model is designed for several types of fuel - low pressure gas or firewood. The compartment for stones is open here, thanks to which you can create either dense hot steam, as in a Russian bath, or get a dry steam room, which will be almost impossible to distinguish from a sauna. The model is more powerful compared to the previously considered options - it is capable of efficiently heating up to 20 cubic meters of steam room volume.

If you heat the sauna with gas, the air temperature in the steam room will be maintained at 70-120 degrees. The stove is easy to install; it is characterized by high build quality, reliability and a long service life.

Advantages:

- Designed for two types of fuel;

- Capable of producing quite high temperatures;

- The kit includes quite large, capacious and remote tanks;

- The duration of warranty service is 5 years.

Flaws:

- Burners and stones are not included in the kit - they will have to be purchased additionally.

Furnace Ermak Uralochka-20

Vesuvius Skif Forging 18

One of the cheapest models that can only be found on the Russian market today. The device is characterized by high power - 18 kW, it is capable of efficiently heating a steam room with a volume of up to 20 cubic meters. The kit also does not include a burner, but you can purchase one, especially since its cost is also quite reasonable. The structure is made of high-quality thick sheet steel, the door is made of cast iron. This solution allows you to prevent the stove from burning out, significantly extend its service life, and make it safe to use.

More: Top 10 best motorized winches [yearcode]

The entire heating surface is placed in a special casing, which also serves as a convector. The steam room heats up quickly, the convector itself will block infrared radiation, so the heat will be quite soft. The capacity of the heater is 130 kg, thanks to this the temperature in the steam room will be as uniform as possible.

Advantages:

- Interesting and attractive appearance;

- Reliability and durability of the model;

- High power levels;

- The walls are made of thick steel sheets;

- You can heat it from another room.

Flaws:

- A tray for stones and a gas burner are not included.

Furnace Vesuvius Skif Forging 18

EasySteam Sochi K

The products are made from stainless steel sheets, which are characterized by high strength. If the customer wishes, the furnace can be made of a similar material of a different brand with a higher concentration of nickel, which provides increased strength of this metal. The power of this heating equipment is 40 kW, so the device is capable of heating a room with a volume of up to 22 cubic meters. The model is equipped with a gas burner; you can additionally order a remote water tank.

In the most loaded areas, multi-layer welds are provided. In order to reduce extreme temperatures, the combustion chamber is lined with fireclay bricks. The design provides for the presence of two steam generators at once, so water will hit the heater in doses, thereby providing light steam at a comfortable temperature.

Advantages:

- Multilayer welded joints are used;

- Two-stage steam generators;

- Provides high-quality protection against infrared radiation;

- Reinforced key structural parts.

Flaws:

- Expensive;

- The heating volume could have been larger.

Oven EasySteam Sochi K

Do-it-yourself installation

Of course, you can install the stove or even create it yourself, with your own hands. This will save you some money. But there is a danger of making some kind of mistake, which could lead to equipment breakdown or even a gas explosion.

Installation of the device must be carried out strictly in compliance with all safety rules, and this requires certain knowledge and skills. Therefore, the best option in this case would be to carry out all work on installing a gas furnace by specialists.

Building a bathhouse is the dream of many people nowadays. However, recently, foreign technologies have been increasingly used in construction: compared to original Russian buildings, baths have now changed in appearance and have completely different characteristics. The classic sauna heater, which requires a foundation and occupies a considerable area, remains a thing of the past. Modern people prefer innovative equipment that allows them not to think about the operation of certain devices. Currently, the leading position in the market is occupied by metal gas stoves, used as equipment for Finnish saunas, Russian steam rooms and even Turkish hammams.

How to obtain permission to install equipment

Before starting the construction of a gas-heated bathhouse, it is necessary to check with the relevant services about the possibility of connecting the facility to the gas network. It is made on the basis of an application. Gas services, based on the power of the equipment planned for installation in the baths, calculate the maximum gas consumption m.cub./hour.

Based on this calculation and safety requirements, they develop technical conditions for connecting gas to the facility and issue its passport. After obtaining permission to connect gas, work is carried out by specialized organizations. At the same time, the bathhouse room to which gas is supplied must comply with the requirements of SNiP 2.04.08-87.

Design features of gas furnaces

In their design, gas stoves differ little from classic wood-burning or modern electric sauna stoves.

A gas-fired stove is a universal stove for a bathhouse, with the ability to use various types of fuel: low-pressure natural gas or firewood to produce steam, heat water and heat the steam room and adjacent rooms with a volume of 6 to 24 cubic meters. Original design solutions in combination with carefully selected materials ensure high reliability of the furnace. The Uralochka models use 4mm thick steel, and the elements experiencing maximum thermal load are made of 6mm thick steel. From us you can buy a stove for your bathhouse at the most attractive prices.

Design features of gas models of sauna stoves: powerful burner with non-volatile automatic control and safety; operation in automatic mode at a given temperature in the steam room (+70 .. +120 °C); A unique heat exchange system of the firebox design evenly distributes heat loads. A design feature of gas furnaces also includes a system of chimneys with an increased length of passage of the flame and combustion products - gases.

The materials used in the manufacture of gas wood stoves ensure reliability, environmental friendliness and safety. In the manufacture of gas sauna stoves, modern technologies for cutting, bending, welding and metal shaping are used. The design of the stove is made in a strict and modern style - it has ergonomic shapes and classic colors: a black matte casing coated with silicon-organic paint, decorated inserts and frames made of mirror stainless steel. The products fit organically into any interior of a bathhouse or sauna, complementing it. The model range is designed for steam room volumes from 6 to 24 cubic meters.

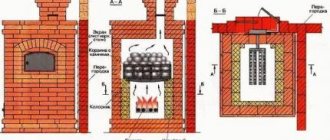

Construction of a gas stove for a bath

The design of a gas stove for a bath consists of the following elements:

The main tasks of the GGU installed on the stove boil down to heating, automatically maintaining the set temperature of the coolant (air in the steam room) and turning off the gas supply in emergency situations. The safe operation of sauna stoves with GGU is guaranteed by the SABK-T automatic control and safety system, which allows you to automatically turn off the gas supply in emergency situations when the coolant (air in the steam room) overheats, the flame goes out on the ignition burner and the draft is disrupted.

2. Firebox with an original heat exchange system and a built-in stepped chimney system.

3. The chimney system is designed so that the fuel burns with maximum heat transfer and ensures high-quality removal of combustion gases into the atmosphere.

Furnace equipment

Gas sauna stoves have a fairly simple structure:

- a burner is installed in the housing, to which a gas pipe is hermetically connected;

- above the burner there is a water tank, which is an integral part of the heat exchange and heating system;

- A tray for the heater is installed on top of the body. It is worth understanding that the performance indicators of gas and wood stoves differ significantly, so for the heater you need to use cobblestones from the river or seabed. Thanks to the combustion of gas, the heater can heat up to 200 degrees. This, coupled with water getting on it, can lead to rapid failure of the heater. River and sea stones, unlike others, are able to withstand such impacts;

- In addition to the tray for the heater, there is an outlet on top of the body of the gas stove; a chimney is connected to it;

- Gas sauna stoves with a water tank and models that do not have this element of the heat exchange system have a fuse in the design, which is responsible for automatically turning off the gas supply when the fire goes out.

Having studied the design of the device, you can understand that a gas stove for a bath with your own hands is a reality. You can assemble it yourself. The exception is burners, which must be purchased from a trusted manufacturer.

Gasification methods

There are several ways to provide a sauna with gas:

- Lay a pipe from the house to the bathhouse in the ground, while the gas line can be either metal or polypropylene;

- Perform air installation of the main; this is the most common and most expensive gasification option. Laying a pipe usually takes ¼ of the entire estimate for laying gas;

- Install a ramp with three cylinders in a separate room of the bathhouse or even outdoors in an equipped box;

- Equip a gas holder gas supply for your home and bathhouse.

The latter case can be considered the most convenient, but the cost of such gasification will exceed the cost of laying gas from a centralized supply pipe. If the house already has gas, no one will interfere with gasifying the bathhouse using a gas holder. A huge advantage of a gas holder is the quick completion of work. That is, the contractor company will complete the project, approve the gas tank, install the tank underground and connect the gas equipment of the bathhouse in literally three to four days. She will also fill the gas into a 3-5 thousand liter tank. This is enough for several years of using the bathhouse.

Rules for gasification of a bath

According to the existing rules, gasification of a bathhouse is allowed, this is also evidenced by the Russian Government Decree of 2008 No. 509, however, with a slightly strange condition - the non-use of a separate premises for commercial purposes. In practice, obtaining permission is almost impossible.

Alternatively, gas services can only give approval if the steam room is installed inside a residential building. And even in this case, the gasification project for the bathhouse should include:

- A separate emergency exit from the premises, with the doors made of heat-resistant materials with the possibility of opening from either side of the entrance;

- Availability of special fire alarm and fire extinguishing systems;

- According to the conditions of gasification of the bathhouse, stove and boiler equipment must be industrially manufactured, with certificates of conformity and quality.

In order to persuade the fire safety inspection to sign the project, you will probably need to install a special ventilation system, carbon monoxide and semi-automatic fire extinguishing sensors.

Nuances to consider before installing a gas stove

We have not touched upon the topic of making a gas oven yourself for one simple reason:

IMPORTANT! Homemade gas stoves and gas burners are not certified ; they are prohibited for use by law . In case of violation, you will have to pay fines.

The only thing in your power is to buy a ready-made burner and prepare the stove for gasification. Compliance with the following standards should be checked:

- the firebox must (!) go into the dressing room, and the firebox opening is finished with iron;

- dimensions of the firebox opening: 47-55 cm in height, 35-45 cm in width, and if together with a metal frame, then 61-68 and 51-66 cm, respectively;

- The minimum room volume for installing a gas stove is 8 cubic meters. (Remember, yes, that atmospheric ones are installed with a volume of at least 12 cubic meters);

- the height of the room cannot be less than 2.2 m;

- It is necessary to have a window with an area of 0.6 sq. meter, a gap under the door to the steam room from 4 cm or a ventilation grille;

- the refractory material under the stove must be at least 10 cm wider than the dimensions of the stove on each side;

- combustible walls should not be closer than half a meter to the heating device.

IMPORTANT! All work related to gasification is carried out by professionals .