Frame house construction technology is widely used for bathhouses, garages, sheds and other outbuildings. Frame bathhouse projects (6x6, 3x4) are warm and durable buildings, and the speed of their construction is such that you can take a steam bath within 2-3 weeks after the start of construction. And, of course, the low cost of materials and work process leaves no one indifferent when planning real estate on the site.

Typical drawings of a 6x4 bath

Frame bath projects

The features of frame baths are visible both during the construction of the building and during its further operation.

For such buildings there is no need to prepare the foundation in a special way, because the frame itself and the wood facing materials are light enough not to sag even when installed on fairly loose ground. Frame baths are very popular due to their economy, compactness and practicality. A small room in a frame bath is usually divided into a compact steam room that can accommodate about four people, a shower room and a relaxation room. It is also necessary to have a small terrace or porch in the project.

Large baths are usually built in a more fundamental way using materials such as brick or timber, but, nevertheless, sometimes even two-story frame structures are found. Among the obvious advantages of this type of building are ease of installation, record speed of building assembly, and relatively low cost of building materials and work.

Thanks to all the above factors, Russians order frame bath projects much more often than the construction of brick bath structures.

Frame bathhouse with terrace

A small terrace gives a special charm to the bathhouse built according to the presented project, making it look like a pretty village house.

In fact, inside the building there is not only a traditional steam room and a relaxation room, but also a separate bathroom and a bedroom, which makes such a bathhouse quite suitable for living.

A small structure like this can be built in just a few days, but will serve you for many years.

This project contains all the necessary components for a comfortable stay.

Frame bathhouse 5.25×5.25 m

A small frame bathhouse with a large porch or small terrace can serve as a real decoration for your yard.

The room consists of a relaxation room, a washroom and a steam room.

The beautifully highlighted foundation and natural wood paint color make this project especially attractive from the outside. Inside the bathhouse there is additionally a small vestibule that protects the room from frost.

The next option is especially notable for its double gabled roof. This structure provides the opportunity to equip a second additional attic floor.

Thanks to the compact size of the sauna, the sauna stove can cope with heating the entire room in any weather.

The height of the attic ceilings is acceptable even for a tall person, thanks to the special shape of the roof.

DIY frame bath projects

Often construction is stalled due to the fact that you do not know how to properly plan a bathhouse to make it convenient and safe. Ready-made planning projects can help with this. Ideally, if one of them suits you completely: no need to rack your brains. Although you can make adjustments if necessary. And sometimes just an idea is enough for everything to “fall into place” for you and a plan for your frame bathhouse to emerge, which you will build with your own hands. To do this, we have selected several projects of frame baths of different sizes with different layouts of rooms.

Bathhouse layout 4*5 m

This is a bathhouse with a large relaxation room, a small bathroom and a steam room of 4.8 m2. The foundation is a shallow strip foundation - depth 70 cm, plinth height 40 cm (total height of the foundation with plinth 110 cm), gravel bed 20 cm. There is a small porch, which, if used year-round, can be sheathed and turned into a vestibule. Then cold air will not enter the premises every time the doors are opened.

Finished drawing of a frame bath 4*5 m

Total area 20 m2, rooms and their dimensions:

- Rest room 8.5 m2;

- Steam room 4.8 m2;

- Bathroom 2.2 m2

Necessary materials to create the frame:

- racks, lower and upper trims are made of 100*50 mm boards;

- floor beams - from boards 150*50 mm with a pitch of 0.58 m;

- rafter system - from 150*50 mm boards with a pitch of 0.58 m.

This bathhouse project has a fairly spacious relaxation room, and with such small dimensions of the building - 5 by 4 meters, there is a fairly spacious steam room - a “pure” size of 4.8 square meters. According to the project, the stove is heated from a steam room, which is problematic for such a small room: there will not be very much oxygen anyway. In this option, you can leave it in the same place and install a sauna stove with an extended firebox. In this case, the firewood will be supplied from the rest room, and the heater and the main “body of the stove” will be located in the steam room. With this arrangement of the stove, the problem of heating the rest room is also solved.

Project of a frame bath 6*6 m

The photo shows the layout of a fairly substantial bathhouse measuring 6 by 6 meters. There is a small veranda, a dressing room, and a full set of necessary premises.

6 by 6 bathhouse project using frame technology

This option is good because standard length lumber can be used in almost any room: 6 or 3 meters. This is convenient as there is little waste left. The foundation can be piled or columnar. A shallow tape or slab will do.

But there are some notes on the layout. The washing room for this frame bath project is spacious. This is an option for those who prefer to relax after the steam room not in a cool (relative to the steam room, of course) relaxation room, but continue to relax in the humid and warm atmosphere of the washing room. Then it maintains a temperature of about 30-35°C and fairly high humidity (due to the increased power of the oven and the open door to the steam room). They also install sun loungers,

Where to start building a bathhouse

Before starting the construction of a frame bath, it is worth planning the placement of the building. Pay attention to the following features:

- It is important to determine where the bathhouse will be located - separately or near the selected building on the site.

- Choose a place to install a bathhouse, taking into account the location of utility networks, and also mark the routes for laying communications.

- Find out the soil characteristics on the site in order to choose a foundation.

- Develop a new or choose an existing bathhouse project, taking into account your own requirements.

Many organizations offer ready-made projects. You can also order an individual project from them. The minimum size is 3x4 m. The optimal aspect ratio of the bath is 5x5 m.

Roof

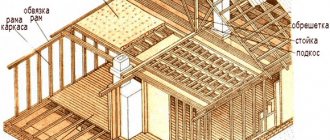

Construction of the roof

The frame of the bathhouse is ready, all that remains is to cover it with a roof. The roof structure is chosen taking into account the amount of precipitation; if there is a large snow cover, it is better to install a gable roof. The roofing material should not weigh down the structure of the bathhouse, because it has a light foundation. It is better not to use natural tiles, but to choose rolled roofing. To construct the roof, hanging rafters are installed, to which horizontal sheathing is attached. Its pitch depends on the choice of roofing material. A waterproofing membrane must be installed under the roof.

The interior of the bathhouse ceiling is finished with clapboard. For insulation, mineral wool is laid between the beams, a layer of vapor barrier is lined underneath, and waterproofing is placed on top. When sewing up the ceiling, the outlet of the chimney is arranged.

Own bathhouse project

In order not to waste time creating drawings, you can choose an already created project as a basis. In this case, the layout of the frame structure must correspond to the building area. Then it remains to make some amendments to it.

For a future frame building project, it is important to consider:

- layout - it is important for the rational distribution of space;

- costs for the construction and operation of a frame bath;

- terms of work;

- features of the foundation structure.

All interior spaces are arranged in accordance with the number of pieces of furniture and their sizes. For example, when creating a drawing of a frame structure, the length of the benches is taken into account. To make it comfortable to sit in the relaxation room after taking water procedures, a table, sofa and armchairs are installed in it.

It is important to correctly determine the location of the dressing room in the frame structure. It is designed in such a way that cold air does not enter the bathhouse when the doors are opened. In the washing compartment of the frame structure, a location for a water tank should be provided. The brooms are dried in a warm attic. Comfortable relaxation is possible by creating a veranda or terrace.

Flaws

Despite the large number of advantages of such structures, the negative aspects of such baths should also be taken into account.

These include the following:

- the maximum service life is 50 years, but only subject to high-quality assembly;

- It is imperative to ensure the integrity of the seams and joints; if the thermal insulation layer heats up above 125 degrees, it may catch fire or become deformed;

- externally, without additional cladding, panel baths are not very aesthetic and of the same type;

- if the installation technology is violated, the strength of the entire structure is greatly lost and thermal conductivity increases;

- during external and internal finishing it is recommended to use only non-combustible materials;

- If the seams are poorly sealed, the likelihood of large heat loss and rats and mice getting inside the panels also increases.

Attention! During repairs, care should be taken to ensure good insulation of the connection points of sockets and switches. Even a small spark can cause internal material to burn.

Advantages of frame structures

The construction of a frame bath requires compliance with certain rules. Such a structure consists of a supporting structure, which is covered with OSB panels. Insulation and vapor barrier are laid between the wall slabs.

A frame bath made of similar materials is light in weight and therefore does not require the creation of an impressive foundation. It is easy to build it yourself.

The obvious advantages of frame construction are:

- low costs for foundation construction;

- all work can be done independently, without using heavy equipment;

- short construction time.

Frame technology also has its disadvantages that require mention. The main disadvantage of such baths is their increased fire hazard. For this reason, it is better to carefully treat all structural elements with refractory compounds. For wiring in a frame structure, non-combustible casings should be selected.

Foundation

Columnar foundation from the inside

On the site chosen for the construction of a bathhouse, markings for the foundation are carried out using pegs and twine. For light frame construction, a pile base made of asbestos-cement pipes is most often used. These supports will last a long time, they are durable and do not collapse under the influence of moisture. The work does not require special skills or the use of special equipment.

The underground part of the pillars is buried below the depth to which the soil freezes in winter in your region. Their diameter is chosen taking into account the weight of the planned building; for a bathhouse, pillars of 20 cm will be required. Asbestos-cement piles are placed in each corner of the building and at the intersections of walls. All places for pillars are marked with pegs.

Ready-made baths

It is not always possible to start building a bathhouse with your own hands. In this situation, they buy a ready-made structure. The kit includes the following items:

- mounting beam - it is used to create a frame;

- fastening kit;

- flooring material;

- roofs;

- wall panels;

- documentation package.

The set of documents contains project drawings and a description of the assembly instructions.

Materials are prepared in advance so that there is no need to purchase them in addition. For any frame bath you need:

- Material for creating a frame. Often a beam with a cross section of 100x150 mm is chosen for it. Crossbars and slopes are created from 80x80 mm timber.

- The rafter system is erected from 150x150 mm timber. The finishing coating is made from soft tiles. It is important to choose a material that does not place a large load on the frame walls. For this reason, you should not pay attention to ceramic tiles.

- The sheathing of the roof and walls is created from 20 mm slats.

- OSB panels are used to cover the walls. They are also laid as a base under soft tiles.

- An edged board treated with antibacterial and fire-resistant compounds is suitable for the floor.

- Imitation of timber is often used for external cladding, and lining for internal cladding.

- The frame bath is insulated with mineral wool with fire-resistant properties. What the thickness of the layer will be depends on the climatic conditions of the region. It is best to choose basalt wool with a thickness of 15-25 cm.

You will also need to prepare nails and screws of various lengths. Given the high humidity inside the bathhouse, galvanized fasteners should be used.

Necessary materials

The basis of a frame house is frames assembled from wooden beams. Depending on the planned size of the bathhouse, timber 100*150 or 150*150 mm is used for their assembly. For jibs and crossbars that are nailed between vertical posts, thinner bars are suitable.

When installing a roof for the Mauerlat, you will need approximately the same timber - 150 * 150 mm or so. For rafter legs, the same bars 100*150 or 150*150 mm. Depends on the configuration of the selected roof and the weight of the roofing material. By the way, it is undesirable to use very heavy roofing material - such as ceramic tiles - for frames - the load on the walls is too great.

You will need a lot of different timber

You will also need slats to create lathing, counter laths, and all sorts of auxiliary work. Moreover, you will need a lot of them: lathing is needed both on the walls on both sides and on the roof. Although, in some versions, the outside of the boards is covered with plywood (as in the video above). There are a lot of construction options, as well as the materials used.

Read about how to make a rafter system for a gable roof with your own hands here.

You will also need subfloor material. What it will be - unedged or edged boards, plywood or other board material - is up to you to decide. But all the wood will need to be treated. And fire retardants - to reduce flammability, and protective antibacterial compounds. Read about how to treat wood inside a bathhouse here.

Frame cladding materials inside and outside are selected based on personal preferences or the purpose of the building. If we talk about frame baths, then usually everything inside is lined with clapboard (tiles are placed in the washing room), and outside with imitation timber or a blockhouse.

It is advisable to use mineral wool as insulation for a bath: they do not burn. The thickness of the insulation layer depends on the region. In central Russia, mainly basalt wool is used for baths, in a layer of 15-25 cm. If you are concerned about the possibility of formaldehyde release (a lot has been written about this), then you can use non-woven mats. The emission of harmful substances in them is minimal.

Frame baths are often insulated with mineral wool

It has proven itself well as insulation and polyurethane foam (not polystyrene foam). In addition to low thermal conductivity, it is also a sound insulator, which is important for frame construction. There are a few "buts":

- It cannot be used in a steam room - the temperature conditions do not allow it;

- it melts and supports combustion;

- This insulation costs a lot (we are talking about extruded polystyrene foam).

You will also need a lot of nails and screws. For the construction of bathhouses, it is advisable to use galvanized ones: so that they do not rust and do not leave unsightly streaks on the wood. They will be needed in different sizes and diameters - large frames for assembly, smaller frames for sheathing and cladding.

Read about what fasteners to use when building a bathhouse in the article “Fasteners for baths and saunas”

From all that has been said above, we hope you have concluded that you can build a frame bathhouse with your own hands. To make sure of this, watch the video. The house was built using frame technology with the participation of only one person. It describes in more detail the technology for constructing some units.

If you have selected a frame bath project and decided to build it yourself, but have no idea how to proceed, we recommend watching the video. In it, experienced American carpenter Larry Hohn explains and shows the technology for constructing the walls of a frame house. The video is very detailed and takes more than an hour, but by the end of watching the frame construction technology will be clear to you.

Algorithm for building a bathhouse

A column-type base is best suited for a frame bath. It can be built using asbestos-cement pipes. You will need elements with a diameter of 20 cm and a length of 2 m. They should be buried in the wells to 1.5 m and filled with concrete-crushed stone mortar. The number of pillars varies depending on the size of the structure. For a 3x4 m frame bath you will need 12 pieces. When building a 5x5 m bathhouse, you need to prepare 18 pillars.

After installing the bathhouse supports, a timber frame is attached to them. The elements are fastened with nails. Roofing material must be placed under the strapping beams to ensure waterproofing.

Logs from boards are laid on the frame - they will be the basis of the bathhouse floor. The frame is treated with an antiseptic and fire-resistant agent. The installation of bath walls is carried out in the following order:

- Supports are installed in the corners, between which intermediate posts are placed.

- The sauna wall cladding sheets are secured to the racks with self-tapping screws.

- After finishing the sewing of the walls, openings for doors and windows are formed.

The rafter system for a frame bath is assembled on the ground and then raised to the roof. Only then the sheathing is attached and the roofing is laid. After installing the main frame, doors and windows are installed. To build a frame bath yourself you will need:

- three days to install the foundation;

- three days to install the frame with the walls;

- two days for the rafter system;

- two days for laying the roof, installing windows and doors, as well as finishing.

Knowledge of these features helps to design and build a durable and practical bathhouse for the whole family.

Important points before purchasing

After deciding to purchase and build a frame-panel bathhouse, several points need to be taken into account in order for the structure to be as strong and durable as possible:

- all panels must be smooth, without bumps or streaks;

- there should also be nothing superfluous or deformed in the internal section;

- it is desirable that the heat insulator be of an even shade without interspersing other materials;

- SIP boards should not emit a sharp or unpleasant odor;

- when purchasing a turnkey panel bathhouse or with a rough finish, all seams must be foamed, the places of sockets, switches and light bulbs must be well insulated;

- you should definitely pay attention to the window frames, the connecting joints should also be well foamed and hidden;

- the minimum width of the plinth beam cannot be less than 20 cm;

- all panels must be treated with antiseptic and anti-foam, these points can be checked in quality certificates;

- the minimum cross-section of timber for the construction of a vertical frame cannot be less than 10 cm;

- for the longevity of the bathhouse, it is better that the roof is gable, especially in areas with snowy winters, and does not weigh down the frame;

- you should not buy structures covered with metal tiles; it is better to buy buildings with sheet or roll roofs;

- There should be a vapor barrier material between the inner and outer skins, and ideally there should also be water and wind insulation.

If possible, during construction you should invite a third-party specialist who can evaluate all technological aspects and errors.

Internal and external decoration of the bath

For the exterior finishing of frame baths, imitation timber or siding panels are used. Interior decoration requires special attention. First you should choose a lining. For the rest room and vestibule, you can choose pine. It requires no maintenance and looks quite impressive.

The steam room is decorated with linden or larch. These breeds are not afraid of high temperatures and are able to retain color. Sometimes other wood is chosen:

- Abashi is a tree from tropical forests that has low thermal conductivity;

- cedar – when heated, it begins to release essential compounds that are beneficial to the body;

- Aspen – this tree is resistant to rot and mold.

Base trim

A layer of roofing material must be laid on the installed pillars as waterproofing. Next, the base piping is installed. To do this, take a 120x120 mm beam and soak it with an antiseptic. It is better to use softwood such as pine or cedar. The beam is laid around the entire perimeter and fastened using the “half-log” method - half of one beam is sawn off from the top, and from the second from the bottom. When connected, a flat plane is formed. The piping, checked using a level, is attached to the pipes with anchors.