Any heating device in the house that runs on liquid or solid fuel must be safe. The threat can come from an improperly installed chimney, so it is very important to accurately calculate all its parameters. Even a seemingly insignificant detail - the height of the chimney relative to the roof ridge - is very important.

Ideal chimney height relative to the roof ridge

What it is

During normal operation of the smoke exhaust system, gas generated as a result of fuel combustion is discharged outside. If the operating mode is incorrect, you may observe the opposite situation. The smoke does not go straight up through the pipeline, as it should, but down, it does not go out into the street, instead it pours into the house - that’s what reverse draft is. And it is not just an unpleasant, but a truly dangerous phenomenon, which, if neglected, leads to a fire hazard in the house, or even to severe carbon monoxide poisoning.

Supply and exhaust ventilation system

Technical documentation regulates the height of ventilation pipes above the roof of the building. SNiP and SP states: if the hood height is not regulated by the project, then the ventilation communication ducts are arranged in the same way as chimneys.

The height of the exhaust pipe above the roof located near the chimney is set at the same level with it Source dimari.stroimdom.com.ua

It is prohibited in houses with stove heating:

- use of forced

exhaust ventilation, without inflow compensation in the same way; - gas removal of combustion products into communication

ducts and the use of smoke removal systems for ventilation;

Rules for choosing a chimney cross-section

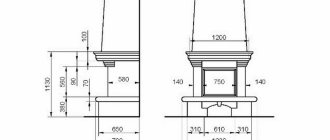

The cross-section for a cylindrical fireplace chimney is calculated in relation to the size of the firebox in proportions of 1:10, and the cross-section for a square brick section is 1:1.5.

The diameter of the chimney cannot be less than the size of the blower hole. Remember, compliance with these dimensions directly affects the operation of the heating system. With a heat transfer of 300 Kcal per hour, the cross-section cannot be less than 140*140 millimeters.

Chimney device

Ideally, the pipe should be installed without protrusions, in compliance with strict verticality.

The permissible vertical deviation can be no more than 30 degrees per meter. However, it should not change the internal section and be sharp. If the chimney is made of brick, the masonry must be made dense, and the inner surface must be as even and smooth as possible, without protrusions of hardened mortar.

The optimal solution is a vertical chimney arrangement

The chimney in its lower part must have a pocket with a door that will allow it to be cleared of soot. Its depth cannot be less than 20-30 cm.

In the interfloor ceilings, fire insulation is installed around the pipe - with a wooden floor system, it is at least 20-30 cm; for concrete - no less than 5-7 cm.

Calculation of the height of the chimney above the roof ridge

When calculating the correct chimney height, internal and external factors are taken into account. This is necessary so that the necessary draft is created in it, and the heating efficiency will depend on it.

The part of the chimney protruding above the roof is called the cap.

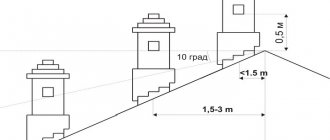

Layout of the chimney relative to the roof ridge

- If it is located at a distance of up to one and a half meters (horizontally) from the highest point of the roof, then it should rise above the ridge by a minimum of 50 cm.

- If the pipe goes out onto the roof at a distance of one and a half to three meters (horizontally) from the ridge, then its height should be equal to its height.

- Provided the pipe is located at a distance of 4.5 meters from the ridge, its upper edge is placed below it at a slope of 10 degrees.

- It must be taken into account that the head should always rise above the roof covering no lower than half a meter.

- If the chimney is made in a house with a flat roof, its height above it should be at least two meters.

Brief summary - the main requirements for a chimney pipe

So, in order for the chimney to function normally and be safe, the following requirements must be observed during its design, construction and during operation:

- its height above the roof and in relation to the ridge is in accordance with established standards;

- the brickwork of chimneys is laid with the highest possible density;

- the size of the channel cross-section throughout the entire chimney must be maintained in accordance with the calculation relative to the dimensions of the firebox;

- strict adherence to the vertical and permissible slope during construction;

- the use of exclusively safe materials approved for such conditions for its construction;

- ensuring constant good traction and careful control over it;

- a device above the head of the umbrella to prevent the ingress of precipitation and debris, and the colonization of birds;

- timely cleaning of the chimney channel from accumulated soot and debris.

You can get some practical advice by watching the video attached to the article:

The best option when installing a chimney would be to contact specialists to make qualified calculations. If possible, it is better to entrust the work of installing the chimney to an experienced craftsman. How this most important element of the heating system works will determine not only the correct operation of the stove or heating device, but also, first of all, the life and health of the inhabitants of the house.

Disadvantages of a chimney made outside the house

If the heat generator and chimney are installed close to one of the external walls, then the chimney must be inside the thermal circuit.

Another frequently asked question is whether it is possible to install a brick chimney outside the house.

Projects of houses with an external location of a beautiful stone chimney are often found abroad.

Regi-naFORUMHOUSE participant

I want to install a cast-iron fireplace stove in the house, and make a brick chimney with a liner on the outside, instead of an expensive metal sandwich, and then cover it with stone. How will such a chimney behave in a harsh winter?

The short answer is that such a chimney can be made, but is it necessary in relation to Russian winters?

Yuri KozakSchiedel specialist

Even if a well-insulated chimney is located in a cold zone on the street, then, in our harsh climate and long heating period, in winter favorable conditions are created for the chimney to cool and freeze. This can lead to:

1. to increased condensation formation; 2. to accelerated soot accumulation; 3. to difficulties with lighting the heat generator; 4. to deterioration of traction, up to its capsizing.

Do not forget about the complication of construction and installation of a long chimney located close to the edge of the roof slope. A rising structure, for example, a regular sandwich chimney, needs to be given additional static stability by making braces.

A tall chimney will have to withstand increased wind and snow loads.

Outdoor placement of the chimney, especially at the edge of the roof slope, will lead to additional costs during its design and installation:

- Under a heavy brick chimney you will have to make a reinforced foundation.

- The chimney, due to the increased consumption of materials, will cost more.

- The chimney will have to be well insulated along its entire length.

- An external chimney does not heat the house, for example, transferring part of the heat to the second floor, but the street.

Important: when smoke ducts are located outside buildings, the thickness of the walls made of brick must be at least 38 cm at an estimated outside air temperature of -20 °C. If the temperature in winter is lower, then the thickness of the chimney walls will have to be increased even more.

So, difficult decisions to avoid:

- Installing a chimney “in the valley” will most likely lead to leaks.

- Installation of the chimney close to the edge of the roof slope or on the “street”.

The best option is to place the chimney in the ridge, or next to the ridge, with the narrow side parallel to the axis of the roof.

If the width of the chimney exceeds 80 cm, then you will have to arrange a valley or slope so that rainwater and snow do not accumulate in this place.

Types of chimneys

- strength;

- high heat capacity;

- safety.

- construction requires a long time and money;

- the clay used, due to its porous structure, is capable of accumulating condensate during operation, which subsequently leads to the destruction of the chimney;

- with careless bricklaying (the clay inside is not smoothed), the accumulation of soot accelerates;

- rectangular cross-section makes it difficult for smoke to pass through;

- difficulty in maintenance and repair.

Asbestos-cement

Such chimneys can be used at gas temperatures not exceeding 300 degrees. Advantages:

- cheapness;

- ease of installation;

- round section;

- relatively light weight.

- material porosity;

- not heat resistant;

- no insulation;

- it is difficult to make turning elements;

- needs to be cleaned frequently to remove soot.

Steel single-circuit

The best material for such chimneys is acid-resistant and heat-resistant stainless steel with a thickness of 0.6-1 mm. In reality, ordinary stainless steel and even galvanization are often used. The last one is the worst solution. Advantages:

- relatively low cost;

- ease of installation;

- round cross-section and smooth surface;

- light weight;

- ease of repair.

- there is no thermal insulation, which leads to rapid cooling and condensation;

- when passing through flammable materials, such as wooden floors, a large diameter indentation and insulation with asbestos fiber or other non-combustible material are required;

- relatively short service life (10-15 years).

Steel double-circuit

Double-circuit chimneys differ from single-circuit chimneys in that they are made of two pipes, between which there is a non-combustible insulation. Advantages:

- maintain temperature, the rate of gas passage is higher;

- requirements for internal installation are underestimated;

- Little condensation is formed.

very high cost.

Ceramic

The product on the market is relatively young, but has already gained popularity. It consists of three components: fire-resistant ceramics, non-flammable thermal insulation and a lightweight concrete protective box. Advantages:

- very high temperature resistance (withstands up to 1200˚C);

- round cross-section and smooth inner surface;

- tightness and thermal insulation at a high level;

- installation is quite simple;

- durability (ceramic pipe will last about 30 years).

How does the cross-section of a chimney affect its height?

Round chimney

In addition to the fact that the height of the smoke exhaust ducts is regulated by the requirements of SNiP, its cross-section and internal shape must be taken into account. These parameters also affect the normal functioning of heating devices and their efficiency.

According to the laws of physics, warm air - in our case, flue gases - rises when heated. And the closer it is to the exit, the more it cools, resulting in the formation of draft. Accordingly, a large chimney cross-section, it would seem, should create better draft. But in reality this is not always the case. The larger the internal cross-section, the faster the heated air cools, releasing more condensate. And it negatively affects the quality of this very traction.

What is the expected way out? You can increase the height of the pipe and reduce its cross-section. In this case, the draft will be so great that it can lead to a loss of efficiency of the heating boiler or stove. After all, the supply of cold air from below will be increased, due to which the heating of the heating device itself will be insufficient. This means more fuel consumption and warm-up time will be required.

If the chimney is high and the internal diameter is insufficient, the draft will also be insufficient for normal operation of the device. In addition, smoke and carbon monoxide may be released into the room. To prevent this from happening, and to ensure that the heating devices operate at full efficiency and productivity, it is necessary to calculate all parameters using a calculator or inviting specialists.

What is traction and what does it depend on?

The removal of combustion gases is carried out using the draft created in the pipe. Due to the constant movement of air, gases hazardous to human health are drawn out.

The draft force is directly dependent on the height of the chimney and the temperature difference in the pipe channel and in the open air. In the chimney, when the stove burns, a temperature of 200-250 degrees is formed. Due to the cooling of gases due to contact with the metal surfaces of the connecting pipe, the temperature in the draft stabilizer becomes slightly lower, and therefore a constant stabilized draft appears.

It must be remembered that vapor condensation should not collect in the chimney against the background of high flue gas temperatures. Moisture entering the pipe leads to destruction of its surface. This happens especially often in winter, when there is a significant drop in temperature. As a result of these processes, cravings decrease. The air leakage that occurs in the draft stabilizer helps reduce humidity.

With high humidity in the environment, as well as as a result of precipitation getting inside the chimney channel, the draft also decreases. An umbrella installed on top will help protect the chimney from them.

The chimney on the roof must be covered with an umbrella

You can determine the traction force using an ordinary match, brought to an open firebox, with the vent open and half-open. A flame drawn inward indicates good draft. When the flame deviates towards the room, there is a reverse draft. In such conditions, lighting the stove is strictly prohibited, as smoke and carbon monoxide will escape into the room.

This situation often occurs when the chimney is dirty or damaged, so regular cleaning, inspection and repair are required.

Chimney

When building a chimney, it is very important to correctly calculate all dimensions and select the right material. All these parameters directly depend on the fuel that will be used for heating.

A chimney made of brick is suitable for heating with solid fuel and gas. The height, its diameter and cross-section also need to be correctly calculated - this is the key to the normal and safe functioning of the heating system.

If the dimensions are chosen incorrectly, the efficiency of the heating device (appliance) will be reduced or the necessary draft will be absent, which can lead to undesirable or even tragic consequences for the residents of the house.

All these criteria are very important if smoke from not one, but two heating devices is installed into one chimney. In such a case, it is better to contact specialists to calculate the data, since you can make a mistake in one direction or the other.

According to the rules, one chimney can serve no more than two heating devices, provided that the size of the internal cross-section in total allows their simultaneous operation. The cutting channel should be about 70-80 cm high.

If the parameters are greater than required, the efficiency of the entire heating system will decrease. If they are not large enough, the draft will be small and carbon monoxide may begin to enter the premises, which can lead to irreversible consequences.

Which chimney is better

The best shape for a chimney is considered to be a cylinder. That is why even in brick structures, metal or asbestos-cement pipes are often built in, having the diameters required by calculations.

the ideal chimney shape is a cylinder (pipe)

Hot combustion products tend to move upward in a spiral path, and the cylinder is the optimal shape for this. Maximum thrust is generated precisely in such conditions.

Modern boilers operating on the “stop-start” principle cannot do without such a pipe. The main thing in them is to quickly warm up the system to the set temperature and switch it to standby mode, this is what saves the operation of the boilers.

In a pipe that has corners (rectangular or square), turbulence is created and draft activity is reduced. For fireplaces and wood-burning stoves - this form is acceptable and even gives certain “preferences” - it helps to slow down the heat output and increase the efficiency of the devices.

Parameters to consider when installing a chimney

From the outside, all chimneys look the same, in fact, they differ greatly from each other

The first thing you should pay attention to is that in different houses they have different heights above the roof level

Secondly, they differ in width. Indeed, the height and width of the chimney matter. These parameters must be taken into account first.

But it’s not only what’s on the outside that matters, but also what’s hidden inside.

Before planning a chimney installation, it is necessary to determine:

- The number of heating appliances that are connected to the chimney. In a private house there may be one combustion product outlet for several devices. The parameters of the chimney directly depend on their quantity.

- Fuel used for heating. The physicochemical properties of combustion products depend on it. First of all, you need to know the chemical composition.

- Combustion temperature. It depends on the type of fuel and how it is burned. During installation, it is necessary to take into account the temperature that will be created inside it.

The listed factors are important because they affect the parameters that must be taken into account when installing a chimney:

- Thermal stability of the material from which it is made. Chimneys are metal, more often steel, ceramic, asbestos-cement, brick and glass. Each of these materials has its own heat resistance. The last option is the most exotic and least stable. It is used for decorative fireplaces. Another material that is unstable to very high temperatures is asbestos cement; it is used in the installation of heating boilers. The material from which it is made must be selected depending on the type of fuel and its combustion temperature.

- The height of the chimney above the roof. In order for smoke to be removed from the room to the street, there must be sufficient draft in the chimney. Creating draft is a passive process, but its implementation requires certain air flows inside the pipe. If it has a lower height than required, it will not generate sufficient draft and the smoke will remain indoors.

- The diameter of the internal section of the chimney. The correct inside diameter is also necessary to ensure sufficient traction. In addition, if the diameter is less than required, some of the gas will remain in the room, which poses a threat to both the house itself and the lives of its inhabitants.

The correct selection of these three parameters when installing a chimney system guarantees long-term and safe operation of heating devices. In addition, external factors affecting the draft in the chimney are important. These include: roof height, roof slope, height of buildings and trees around, location of the chimney relative to the wind rose.

Summarizing the above

We understand how to calculate the height of the pipe above the ridge. All that remains is to comply with some requirements when calculating and constructing the system in order for it to work stably and reliably:

- the height of the chimney above the roof must meet the necessary rules;

- the chimney system should be cleaned and inspected for repairs;

- when laying a brick chimney, it is necessary to ensure its maximum density;

- It is advisable to install an umbrella over the chimney to prevent dust and moisture from entering it;

- it is necessary to regularly monitor traction for its good quality;

- when manufacturing a chimney exhaust system, make sure that it stands vertically to the ground and control the angle of inclination, which is considered acceptable;

- the system must be constructed of materials that are not flammable.

Perhaps these are all the criteria by which the chimney pipe is calculated. You can, of course, do it yourself. But it’s better for specialists to do this for you. Everyone must do their job. Peace and warmth to your home!

How to correctly calculate chimney parameters

The following rules should be followed:

- The height of the chimney is not the only parameter that affects the performance and safety of the heating system, with a gas or solid fuel boiler as a heating device. Chimney design begins with determining the operating parameters of the heating system. This means that the complex for calculating the boiler room must take into account these factors as well. At this point, the owner of the premises must decide on the type of fuel used (gas, pellets, firewood or peat), and, with the help of a specialist, determine the thermal power of the boiler. decide on the types of radiators or convectors. There are a lot of questions, however, missing a point can have a detrimental effect on the performance of the entire heating system. For example, many novice home builders are mistaken that all chimneys are the same. This is wrong. A brick chimney is suitable for heating with solid fuel, such as wood, but it is not intended for heating premises with a gas boiler.

- With regard to the operating parameters of boilers, the height of the chimney can also affect the final efficiency during heating. Do not forget about the cross-section of the pipe - the diameter affects the minimum and maximum volume of combustion products passing through, provided by natural draft.

- The process of calculating the chimney of a fireplace or solid fuel boiler may require additional calculations and measurements. This is due to the use of one smoke channel by several devices in the boiler room at the same time. Amateur action can lead either to unforeseen heating parameters or even to dire consequences.

- There is no chimney system that could be universal for any type of fuel, boiler equipment and used as a standard solution. In this regard, the most difficulties arise for developers and owners of private houses and cottages.

Optimal placement of the heat generator and chimney in the house

Many people are familiar with the expression: “Dance from the stove!” It means that the house should be built around the stove, and not vice versa - the heat generator and chimney are squeezed into an already built cottage by hook or by crook. In other words, it all starts with design. This is the choice of location for the foundation and chimney, for example, under a stone stove or fireplace lined with brick, the size of the indentations when passing through the ceilings and rafters and the chimney outlet through the roof.

If you neglect this rule, the installation of the entire system will become significantly more complicated, which will lead to an increase in construction costs.

Traditionally, the most rational place to place a stove and further install a vertical chimney is the conventional center of the house on the ground floor.

With this scheme, heat flows from the heated furnace are optimally distributed. Additionally, several adjacent rooms are heated, and the chimney ends up in an insulated area and as close as possible to the ridge of the house. We will explain why this is so important below.

Features of the chimney

Removal of gases through the channel will occur effectively only if the pipe is constructed according to standard dimensions and made of the correct material. These pipe characteristics are selected depending on the type of fuel; the material for the chimney is:

- refractory ceramic bricks;

- asbestos pipes;

- stainless steel;

- sandwich pipes with an inner layer of insulation.

Brick channels are made in the case of a stationary chimney. providing gas removal when heating with wood and coal

To determine the diameter and internal size, the boiler power and the dimensions of the firebox are taken into account. If the calculation is incorrect, reverse draft results or the useful effect of the furnace is significantly reduced.

For gas boilers, it is effective to use pipes with two walls. between which insulation is laid. The problem with a chimney for a gas fuel boiler is internal condensation, so insulation will help avoid significant temperature differences.

It is allowed to install one chimney for two operating heating units. if the internal size of the chimney, raised to the required height above the roof ridge, allows combustion products to be easily removed from both stoves. The cutting section pipe is about 0.8 m high.

A feature of the functioning of the chimney is that all overall, internal dimensions and height must be made with maximum accuracy. A wide and tall chimney, folded to a large height, with a low power of the heating unit, will reduce the efficiency. Insufficient dimensions will lead to smoke being sucked into the room, creating backdraft, and leaking dangerous carbon monoxide.

The warmth in the house depends on a well-designed heating system. But not a single stove or boiler will be able to cope with the task of supplying heat unless a technically competent chimney is made, raised to the required height above the roof ridge.

Dependence of draft on pipe height

The importance of the chimney in the heating system cannot be overestimated. Attempts to save on an extra meter of pipe will lead to cold walls during the heating season and excessive waste of fuel

The danger of carbon monoxide is that it is invisible and undetectable, but can be fatal.

Thrust occurs when heated smoke and gas with low density, in accordance with the laws of physics, rises upward. The result is a pressure difference at the beginning and end of the channel, that is, draft occurs. To ensure that the process is constantly repeated, cold oxygen is supplied through the blower. The greater the temperature difference, the stronger the thrust will be.

A narrow chimney of great height relative to the ridge will accelerate the smoke masses, thus reducing heat transfer. To maintain the desired temperature in the room, you will have to add fuel in excess of the norm. A wide channel of small height will allow smoke and gases to rotate arbitrarily in the pipe, their movement will slow down, and most likely a reverse flow of gases will result. Most often this happens in autumn or spring, when the temperature difference between outside and inside decreases and smoke, without overcoming resistance, is drawn into the room through the firebox.

Chimney location and height

To correctly select the height of the chimney relative to the roof ridge, you need to take into account the location of nearby structures. For an outdoor home, the draft indicators will be good, since there is constant blowing and pick-up of smoke masses. If we talk about a small building surrounded by high-rise buildings, then the length of the pipe should be increased. The height of the chimney depends on several factors:

- slope of the roof plane;

- location of the channel on the roof plan relative to the ridge;

- the location of surrounding buildings and trees;

- estimated thickness of snow cover in a specific area.

When installing a chimney, you should determine:

- elevation of the pipe relative to the roof ridge;

- the total length of the smoke channel from the stove;

- type and dimensions of the head;

- the height of the chimney relative to ventilation and windows of neighboring buildings.

The norms and rules for the construction of a chimney are prescribed in documents SNiP 41.01.03 and in building regulations under number 7.13130.09.

Traction force: how to achieve ideal fuel combustion

The traction force itself is influenced by several important factors:

- chimney material;

- foundation height above sea level;

- flue gas temperature at the furnace outlet;

- cross-sectional shape of the chimney pipe;

- smoothness or roughness of the inner surface;

- violation of the internal tightness of the chimney;

- temperature and humidity of outside air;

- ventilation of a room with a boiler or stove;

- completeness of fuel combustion;

- degree of contamination of the boiler (or stove) and chimney;

- type of burner used (modulating or discrete).

First of all, you need to determine the amount of static draft of the chimney, which is measured in ∆p value. Here is the formula for calculation:

h=(∆p·Tp·Tн)/(3459·(Tp-1.1·Тн))

Tp is the average temperature in the pipe, and Tn is the outside temperature. It is measured by default in degrees on the Kelvin scale, but you can also specify it in Celsius by adding +273.

Calculating the average temperature is not difficult

This is usually reported in the technical data for the boiler, but it is also important to take cooling into account. This is 1 degree for every meter of brick pipe, 2 degrees per meter of insulated steel and 5 degrees for uninsulated

In this case, it is advisable to take the value of the outside temperature that is typical for summer as the most problematic time for traction:

Make an aerodynamic calculation and find out the exact required height and diameter of the chimney. The amount of draft itself means the difference in the densities of air and flue gas, multiplied by the height of the house. It is 5 meters of the chimney that provide vacuum and draft for smoke.

But what to do if the height of the pipe cannot be set higher, and the draft for certain reasons is still insufficient? This often happens when flue gases cool down too quickly, especially in the cold season. Then, to restore traction, the required section of the pipe is simply insulated.

Also remember that real thrust is always less than static due to the resistance to the movement of gases inside the pipe walls. The narrower the flow section of the chimney, and the more bends, horizontal sections, etc. there are in it, the worse the draft will be, because the draft is affected by the loss of pressure along the entire length of the pipe.

Another problem with chimney height is cold air from the fireplace. So, when it is not working, cold air from the street is released from it. This happens when the chimney head is below the end of the ventilation hood, or when the attic is too large and poorly insulated.

What should be the height

The height of the chimney above the roof requires special attention, since this is where combustion products pass from a closed and safe environment to the outside. If this height is not sufficient to safely cool the gases and mix them with air, a dangerous situation of combustion poisoning or even a fire may occur.

Design parameters for the location of the chimney on the roof

Another issue that deserves attention is the physics of the process of the emergence of natural draft. The fact is that, being in the chimney pipe, heavy air tends to rise upward, forming the physical phenomenon of draft

The more warm air, the more draft is created. The volume inside the pipe is affected by two indicators: internal volume and height.

Here it is worth achieving the “golden mean” indicator. Natural draft can lead to a significant increase in heat loss, since the exhaust will not have time to exchange heat with the internal volume. This is very critical for fireplaces and stoves that burn solid fuel.

Let's say you have a chimney about 4 meters high. Based on the above, the higher the chimney, the greater the draft, but it turns out that there is also a downside to this process - cooling. A tall pipe will cool faster and create an air lock with heavy cool gas, which will interfere with draft. The second negative phenomenon caused by abuse of the chimney height will be condensation.

Specialists calculate the height and cross-section of chimneys using special software products that are based on thermodynamic data.

Volume of incoming air

As a rule, residential buildings are equipped with natural air circulation. The flow of outside air can be through a window or a special valve. The outflow occurs through the ventilation duct. It can be located inside the wall or designed as an extension. A ventilation duct cannot be installed in an external wall, since in this case condensation may form on the surface, which will lead to damage to the structure. Also, due to cooling, the speed of air movement may decrease.

The values for ventilation pipes in residential buildings are determined by the established requirements, which are regulated by SNiP

The frequency of exchange, which reflects the quality of operation of the ventilation system, is also important. So, the volume of air flowing into the room should have the following values:

- in a residential building - 3 m³ per hour per square meter of area. Moreover, this indicator does not depend on how many people are in the room. Sanitary standards establish that for temporarily staying people in a building, 20 m³ per hour of supply air is sufficient, and permanent residents require 60 m³;

- in a utility building (for example, in a garage) - at least 180 m³ of air per hour.

To calculate the diameter of the ventilation pipe, use a system in which there is only natural air flow, without installed forced devices. The simplest method of calculation is the ratio of the area of the room to the cross-section of the ventilation duct opening.

Calculation of pipe diameter and height

In order to calculate the diameter and height of the pipe as correctly as possible, it is necessary to think in advance about what material it will be made of, what type of fuel the heating device will operate on, since the flue gases of different energy carriers have different temperatures, and this must be taken into account when constructing the structure.

The functionality of the heating equipment of any home depends on the diameter of the pipe, its internal cross-section, as well as the design features of the chimney itself. Incorrectly selected diameter and height of the pipe will immediately affect the performance of the boiler, fireplace or stove.

Sometimes such oversights can only be corrected by completely dismantling and reinstalling the channels.

All heating units that emit flue gases during operation require a ventilation system, and due to the fact that it is quite unprofitable to build separate ventilation ducts and a chimney, these two systems are usually combined into a single whole.

Correctly calculating the diameter and length of a pipe is not the easiest task, but you can handle it yourself if you set a goal.

Chimney height above roof

In order to correctly calculate this parameter, it is necessary to take into account:

- Where exactly will the chimney pipe be located on the roof relative to the ridge?

- The angle of inclination of roof slopes.

- The presence or absence of trees or buildings taller than the house itself near the roof.

- The intensity of wind loads and the height of snow cover, characteristic of a given area.

If the pipe on the roof is located at a distance of about 0.5 m from the ridge, then the minimum height of this element above the level of the run should not be lower than 0.5 m. This height is considered optimal, since in this case material for the construction of the chimney structure is significantly saved.

In addition, in such places there is no significant accumulation of snow in winter, which reduces the risk of roof leaks.

The calculation of the diameter and height of the structure is carried out taking into account the basic requirements of building codes and regulations, as well as the stated recommendations of heating equipment manufacturers.

After choosing the length and diameter of the chimney, you need to decide on the location of its installation. The length of the pipe, regardless of its diameter, from the grate to the passage through the roof should not be less than 5 m.

If we are dealing with a flat roof, then regardless of the diameter, the length of the pipe from the roof to the tip should not be less than 0.5 m.

When a chimney duct is installed on a building with a pitched roof at a distance from the roof ridge of 1.5 m, the height of the chimney should not be lower than 0.5 m relative to the purlin or enclosing roof structure. If the pipe is located from 1.5 to 3 m from the ridge, then it must be no lower than the purlin or enclosing parapet.

In the case when the chimney is installed from the ridge girder at a distance exceeding 3 m, its height can be determined by drawing an imaginary line relative to the horizon at an angle of 10 degrees.

When there are taller structures near the house, and firewood is used as an energy source, the pipe should be higher than the buildings. Ventilation ducts installed very close to the chimney may have the same height as it.

How to make it yourself

The purlin is made of steel or wood. When building private houses, the second option is mainly used, since steel ones are quite heavy.

We recommend that the timber be impregnated with a fire-retardant agent before installation to ensure the durability of the structural element.

- Installation is carried out after completing the main stages of roofing. The basic principle of laying the ridge trim elements is to lay the outer fragments on the side of the gables, through which the mounting cord is pulled. The lace is leveled and temporarily fixed to the opposite gables. It will serve as a guide for the remaining fragments.

- It is recommended that two people work together. After installing and fastening the first structural element, move on to the next. The fragments are laid with a spacing of about 20 cm, which allows for better waterproofing of the structure. In the same way, all elements are laid and secured along the slope.

Attention! Particular attention should be paid to fastening the outer elements, since they are exposed to maximum wind loads.

- However, adjustment alone, even if the shelf width is more than 20 cm, is not enough to ensure sufficient waterproofing. In any case, there will be gaps through which drops of rain or snow blown by the wind can get under the roof. You can put a layer of glass wool in the groove, but try not to compact it too much, as this may interfere with ventilation.

- There is another way: instead of glass wool, use self-adhesive foam tape (filler), which is laid along the edge of the shelf from the bottom. But this material is quite expensive, and the result obtained is similar to the option using glass wool.

- A ventilation compartment must be provided. Otherwise, condensation cannot be avoided, even if the roof has been reliably protected from moisture.

Note: If, due to the peculiarities of the roofing structure, it is not possible to equip it or at least provide the required gap, then to combat attic dampness, windows are installed in the end parts.

How to attach a ridge to a roof: from corrugated sheets, on slate

The method of fastening depends entirely on the material of the protective strip. Figured elements are often made from the same material.

A mandatory procedure is waterproofing wooden roof elements. Before installing the finishing elements, the purlin is covered with roofing felt tape.

Corrugated roofing. Let's look in more detail at how to install a ridge on a roof made of corrugated sheets.

konek-5 konek-6

- Strips of sealant or special ventilation tapes that match the pattern of the sheets are attached to the edge of the profiled sheet.

- Fastening is carried out in increments of 20–30 cm based on the parameters of the corrugated sheet pattern. Elements laid overlapping are fixed to already installed bars, screwed with self-tapping screws through the upper corrugation.

Attention! Note that the screws must be equipped with rubber or neoprene seals.

To get the most durable and high-quality connection, it is recommended not to screw in all the hardware at once. It is advisable to make fragments of two to four pieces of hardware each. The rest are tightened only after checking the lace and level. Agree that every extra hole in the roof poses a potential threat to its reliability.

Ventilation device

To create ventilation, you must perform the following operations.

- After installing the rafter system, a waterproofing film is fixed across them. The connecting seams are taped with mounting tape. In this case, an overlap of 150 mm is required;

- Lathing is installed along the rafters. The movement of air flows occurs precisely due to a certain gap formed by the sheathing. If the waterproofing does not allow moisture to seep into the thermal insulation layer and the wood of the supporting structure, then the gap provided by the sheathing makes it possible for any moisture that gets in to dry out quickly enough.

- An additional ventilation hole is created in the ridge part. Excess steam and condensate are removed through it.

- It is necessary to provide gaps along the bottom of the eaves through which outside air will flow under the roof.

How to install a roof ridge made of metal tiles can be seen in the video.

https://youtube.com/watch?v=LDszZ7EqCyY%3F

2019stylekrov.ru

Main types of chimneys

Common types of chimneys:

- Brick. As a rule, an asbestos pipe is installed in a brick shaft. The key disadvantage of a brick chimney is the need to install a foundation for it. In addition, this design impairs traction and also promotes the formation of debris and condensation products. This destroys the system and makes the room damp. The advantages are high heat capacity and fire safety.

- Ceramic. The most expensive and high-quality option. Made from fire-resistant ceramics. A layer of thermal insulation of non-combustible material is required. Pros: they do not require frequent cleaning, have smooth walls and a round cross-section (provides good traction), have high sealing and thermal insulation rates, are heat-resistant, durable, and easy to install. Disadvantages: the foundation is required and the high price.

- Modular made of steel. They are assembled from tees, adapters, elbows, etc. Stainless steel structures are often installed with brick channels (the aforementioned sleeve). However, you can install such a chimney separately. Stainless steel must be resistant to acids and be heat-resistant so that corrosion does not appear in the chimney (wall thickness is from 0.6 to 1 mm). Galvanized steel is not suitable because zinc quickly burns out at high temperatures. Disadvantages of steel structures - increased thermal conductivity leads to rapid cooling of gases, a large volume of condensate is formed, the service life does not exceed 15 years. The advantages are good traction due to the rounded shape, no separate foundation is needed, and no soot accumulation occurs.

- Corrugated steel. They are a flexible pipe made of metal tape. Used for lining brick structures with curves. Easy to install, but do not last long.

- Sandwich structures made of steel. They are two pipes inserted into each other. The area between them is filled with special non-flammable insulation. Cons: high cost. Pros: reduced thermal conductivity and slow cooling of gases, rapid smoke passage, minimum condensation, ease of installation.

- Asbestos-cement. Suitable if the resulting heating gases are not hotter than 300 degrees. Not suitable for standard ovens due to poor heat resistance. Disadvantages - fragility, lack of thermal insulation and unsatisfactory heat resistance, porosity, the need for frequent cleaning, weak rubber connection. Pros: lightweight, round cross-section, low cost and easy installation.

- Polymer. Manufactured from composite polymers. Used for lining channels made of brick or concrete. Due to poor heat resistance, it is not suitable for hot gases with temperatures above 250 degrees (furnaces). Only for geysers or boilers with increased efficiency. Disadvantages: instability to high temperatures, fragility, lack of thermal insulation. Pros: flexibility and light weight, low cost, long service life.

We hope the material was useful to you. As you understand, calculating the height of the chimney is quite simple. Apply these solutions and your home will always be warm.

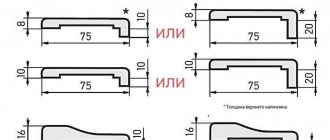

Passage of a round chimney pipe through a wooden ceiling using polyurethane foam of various designs

To pass the chimney through wooden structures, you can use a ready-made ceiling-passage assembly (see photo). It is selected based on the outer diameter of the pipe. Before installation, this ceiling passage unit must be prepared: all surfaces that will come into contact with the wood of the ceiling sheathing, and all internal surfaces of the passage box, are lined with thermal insulation.

Factory-made ceiling passage unit. Before use, it must be covered on all sides except the front with heat-insulating material.

Usually basalt wool serves as thermal insulation, but it must be special: it can withstand high temperatures. When purchasing a material, make sure that it is designed for use at temperatures of 800-1000 o C. These materials have a higher cost, but it is unreasonable to skimp on safety. Cheaper options contain binders that sinter at high temperatures, causing the thermal insulation to lose all its properties, and this can lead to a fire. In addition, it is advisable to use foil heat insulator - this will make the structure even safer.

Having insulated the passage unit, prepare a place for its installation. Mark on the ceiling where the chimney will be located. Draw a hole of a suitable size: slightly smaller than the size of the front panel of the pass-through unit in such a way that it is convenient to attach it to the ceiling trim with self-tapping screws. Having cut a hole, cover its edges with the same heat insulator as the pass-through unit, or any other with similar properties. To increase the level of fire safety, metal strips can be strengthened on top of the heat insulator. Insert the prepared passage unit into the finished hole. It can be put on the pipe and installed with it. Having installed this structure in place, secure the panel of the passage unit with self-tapping screws (the holes can be pre-drilled).

Preparation and installation of ceiling penetrations

After checking the vertical installation of the chimney pipe, proceed to complete this stage. The voids remaining in the passage unit are filled with thermal insulation. You can use pieces of the same basalt wool or fill the voids with expanded clay. In theory, you can use sand, but you shouldn’t. It is inferior in terms of thermal insulation properties to both expanded clay and basalt wool, in addition, sooner or later it will end up at the bottom, since there are cracks, and through them grains of sand will fall onto the stove.

Further actions depend on where you led the chimney: to the second floor or to the attic. But the main difference is in aesthetics and the availability of finishing. If you led the chimney pipe into the attic, the passage through the ceiling can be considered complete. If you brought the chimney to the second floor or into the attic, you put a protective metal screen on the pipe, which is now attached to the floor with the same self-tapping screws. After this, you proceed to the next stage - output through the next ceiling (this is if you are on the second floor) or through the roof, if in the attic or attic.

This is what the finished ceiling penetration looks like

The chimney passage through the ceiling may also look like this. This is a ready-to-use option that consists of two boxes. The inner box is made of metal, the outer one is made of heat-resistant material (in this case, mineralite).

Minerite roof passage assembly. It is completely ready to use

There is an air gap between them, ensuring fire safety. According to the manufacturers, the remaining free space between the sandwich pipe and the cutting box does not require filling with a heat insulator. You can leave everything as is, or you can, for greater reliability, still add heat-resistant thermal insulation. In such a case, such as a chimney passing through a wooden ceiling, it is better to be on the safe side than to put out a fire later.

This is how a mineralite assembly for passing through the roof is installed. Just put it on the pipe and inserted it into the prepared method

The passage through the ceiling can be like this (see photo). In this case, sealing the edges of the hole in the ceiling is mandatory (remember, there is thermal insulation around the edge first, metal on top).

The factory aisle assembly may look different. Depending on the shape, the installation method varies slightly

Thrust calculation

Any ventilation system will not be able to function normally without good draft, which is created by the difference in pressure inside and outside the room.

To calculate the draft of a chimney, you need to multiply the height of the channel by the difference in the density of the internal and external air.

The calculation is carried out using the following formula:

F= A(pв - pд)h,

- F – thrust;

- A – coefficient;

- pв – density of outside air;

- pd – density of flue gases;

- h – pipe height.

Example

When fuel burns in the firebox, heated gases are removed. Natural draft occurs due to the difference in temperatures inside and outside the room.

Air density and temperature are directly related

When calculating, dynamic pressure is not taken into account, since the process speeds are very low

All data is substituted into the famous Bernoulli equation. Next, the pressure loss values are found, then they are compared with the thrust parameter.

If the same indicators are obtained, further calculation does not make sense. The system will work normally, combustion products will begin to be completely removed.

If equality is not maintained, you need to increase the level of traction or reduce the number of losses. To implement the first method, you can:

- lengthen the chimney pipe;

- increase the temperature difference.

To reduce pressure loss, it is recommended to use the following methods:

- make the canal walls smoother;

- reduce the path of removed gases;

- reduce the number of turns;

- increase the cross section.

Using the same method, natural ventilation indoors is calculated.

Calculation of the parameter taking into account the wind support zone

This is the name given to an area where the air pressure is increased compared to the rest. The air masses here encounter an obstacle, which reduces the traction force of the chimney. In the worst case scenario, the treated gases begin to flow back into the room.

If such a situation arises, calculations must be carried out according to a different scheme. To begin with, a sketch is drawn that takes into account the height of both buildings. Next, the angle between them is determined.

Chimney size for gas boiler

Gas boilers come with open and closed combustion chambers. Units with a closed combustion chamber are equipped with coaxial chimneys. The rules for placing them are quite simple:

- The chimney rotates 90 degrees and ideally should immediately exit horizontally behind the wall

- The outlet should be made at a slight slope towards the street so that condensate does not enter the boiler.

- If the pipe is mounted vertically, then a condensate drain must be provided.

- The height of the chimney for a gas boiler with a closed chamber is regulated by each manufacturer in its own way, because the power of the smoke exhauster into the boiler may vary. Therefore, please read the instructions before installation.

- There is no need to install a chimney above the roof and ridge.

For boilers with an open combustion chamber, the height of the chimney is calculated similarly to the method described above.

Prevention and testing methods

We told you why there is backdraft in the stove and what to do to eliminate it, and now we want to share the secret of how to prevent its occurrence. There is no secret in this, you just need:

- clean the chimney in a timely manner;

- regularly heat the system so that it does not stand idle;

- eliminate sources of drafts in residential premises;

- monitor the condition of devices installed on the pipe.

We have already described the testing methods in the section on identifying the problem, so here we will mention cases in which it is worth carrying out tests with a candle, paper or an anemometer. This should be done when the house has not been heated for a long time, when there is (or has recently been) bad weather outside - heavy rain, blizzard, gusty wind, thick fog - and you want, for example, to light a fireplace. This is also true when the rooms are cold, despite the kindling, and when you suspect a malfunction.

And as a conclusion to the review of backdraft in the chimney and what to do when it appears, we offer a video - watch a useful video on this topic:

A couple of tips

When the house has alternative heating, it also requires a chimney. But it is unprofitable to produce different smoke exhaust systems. It is easier to combine them into one, which will connect all the channels made taking into account such parameters as equipment power, amount of smoke and type of fuel. Such structures have a number of advantageous qualities:

- they save living space;

- all systems work stably;

- time, money and labor are saved.

But only specialists can calculate such structures.

Types of chimneys

The chimney is another functional element of the building, the location and height of which is regulated by building codes.

There are several ways to classify chimneys.

Chimneys are distinguished by location:

- wall (located inside the main walls);

- indigenous (not connected to the wall and located at a distance from it in the interior of the building);

- external (pass through the facade of the building).

The main method of classification is to distinguish types of chimneys according to the material of manufacture:

- Brick. They are fireproof and have high heat capacity, but their maintenance requires a lot of time and effort, and the draft of a brick chimney is relatively low.

- Steel single-circuit. Inexpensive and easy to maintain, but wear out quickly and require additional fire safety.

- Sandwiches. A more advanced and expensive version of single-circuit chimneys, where there is a layer of non-combustible material between the layers of steel.

- Ceramic. Fire-resistant, durable, easy to install and maintain, but very expensive.

- Asbestos-cement. The cheapest variation, but its performance indicators are low: asbestos-cement chimneys quickly become clogged with soot and burn out. To avoid a house fire due to soot ignition, you need to constantly clean your pipes.

- Polymer. Inexpensive, but not fire-resistant chimneys.

Types of chimneys

The height of the chimney above the ridge

When calculating the height of the chimney above the roof, it is necessary to take into account the distance at which the pipe will be located, the type of roof and buildings or trees that impede the passage of wind. If the roof is flat or the pipe is located at a distance of no more than one and a half meters from the ridge, then the minimum height of the chimney is 500 mm. When the distance from the ridge to the center of the smoke exhaust duct is from 1500 to 3000 mm, the height of the chimney pipe should be either level with the ridge or slightly higher. If the pipe is expected to be located at a distance of more than 3 meters from the ridge, you will have to calculate the height of the chimney pipe. Its minimum height should be 10˚ from the imaginary horizon line. Graphically this is done in the following way. You need to draw a house to scale. From the highest point, draw a horizontal line in the direction of the chimney. A perpendicular is drawn in place of the pipe. Using a protractor, an angle of 10 degrees is drawn from the ridge and a line is drawn until it intersects with the pipe. This will be the height of the chimney. Based on the specified scale, the result is converted to real size. When calculating mathematically, you will have to remember the school curriculum or use an online calculator. To do this, you need to know the exact height of the house at the level of the ridge and the distance at which the chimney will be located. Measurements are carried out using a tape measure (not every summer resident has laser measuring instruments at hand). For example. The height is 8 meters. The distance to the center of the pipe is 5 meters. And there is an angle of 10˚. Adjacent to it – 80˚. Based on it, calculations are carried out using the formula: x = y ÷ tg80˚, where x is the distance from the ridge to the top of the pipe, y is from the estimated center of the chimney to the ridge. tan80˚ is equal to 5.67. x = 5 ÷ 5.67 = 0.88. Rounded to the nearest 0.9. It turns out that the top of the chimney should be 0.9 meters lower from the top of the building. That is, with a building height of 8 meters, the pipe rises from the ground level by 7.1 m.

(no votes yet)

Requirements for pipe dimensions

Ideally, the chimney should be strictly vertical, without any protrusions. The maximum deviation allowed in this case is only 30 degrees per meter of length. However, the deviation should not be sharp or affect the channel cross-section. If the structure is brick, then the masonry should be extremely dense, while the internal surfaces should be smooth and even (no protrusions from the hardened mortar should remain).

Note! At the bottom of the pipe there should be a special pocket with a door, through which soot will be removed. The minimum depth of this pocket is 20 centimeters

Fire insulation is installed in the ceilings between floors around the chimney. If the ceiling is made of concrete, then its thickness should be from 5 to 7 centimeters, and if it is made of wood, then from 20 to 30.